Ultra-Thin 1mm Plywood Production Line

| Core Advantages of 1mm Plywood |

Feature | Technology Highlights |

Ultra-Thin Stability | 3–5 cross-grain layers, thickness tolerance ±0.05mm, 50% less warping vs traditional plywood |

Eco-Safety | WBP phenolic resin (72h boil-proof), formaldehyde ≤0.3mg/L (Super E0) |

Surface Quality | Double-sided sanding Ra≤3.2μm, laser-cut without burrs, CNC compatible |

Material Yield | 9-foot width (5% higher utilization than 8-foot), supports custom shapes |

| Production Process |

1. Precision Veneer Processing:

Rotary cutting (0.3–0.8mm) → IR pre-drying (8% moisture) → Anti-curl leveling.

2. Smart Gluing & Layup:

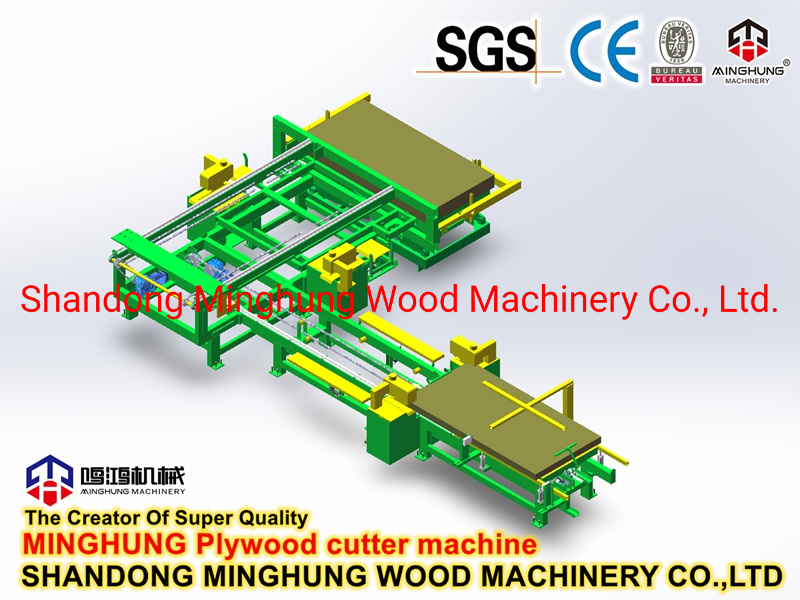

Curtain coating (30g/m²±2g) → Auto-layup with cross-grain alignment (±0.5mm photoelectric positioning).

3. Continuous Hot Pressing:

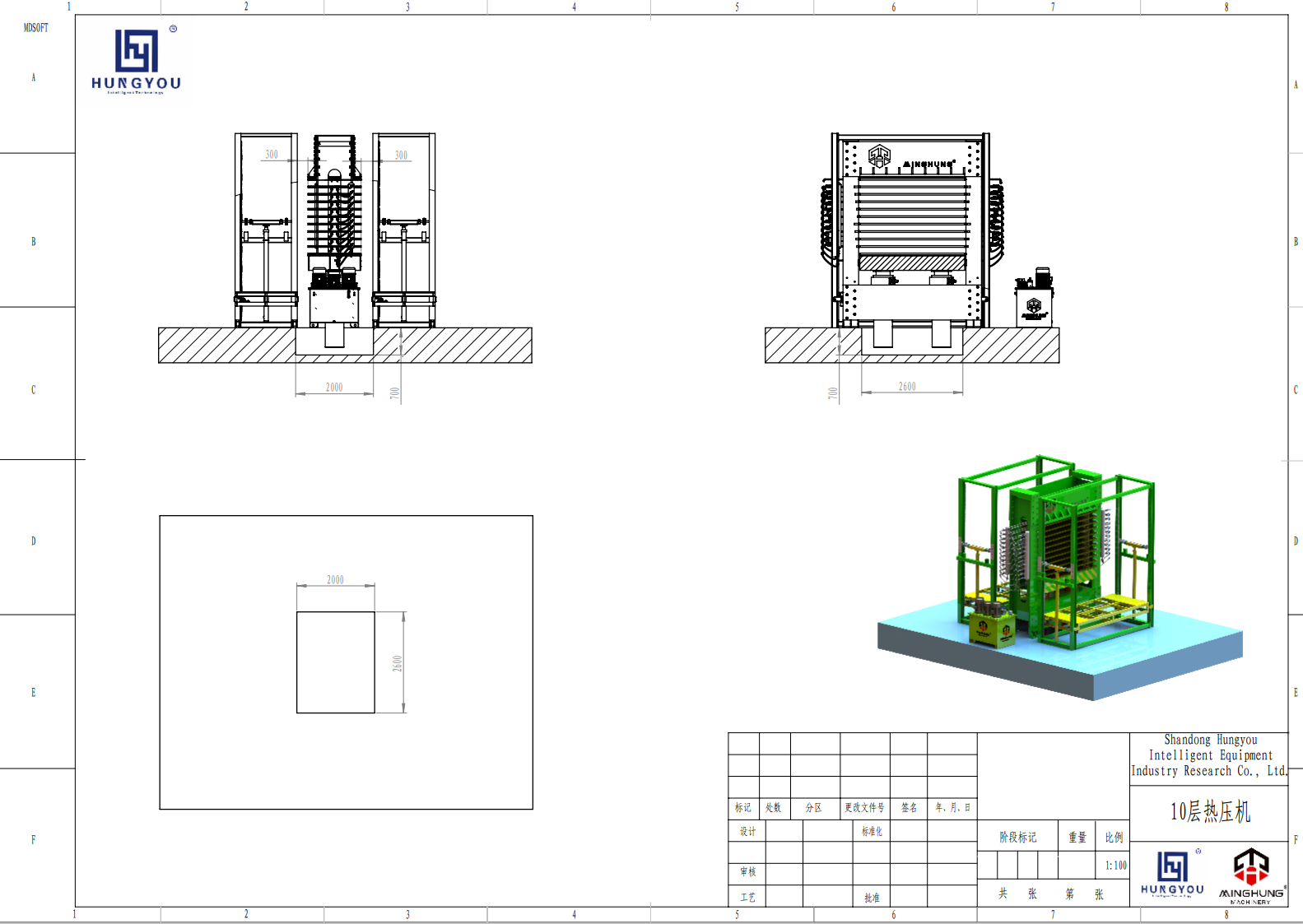

Flat press (135–160℃, 1.5MPa) → Speed 20–50m/min adjustable.

4. Damage-Free Finishing:

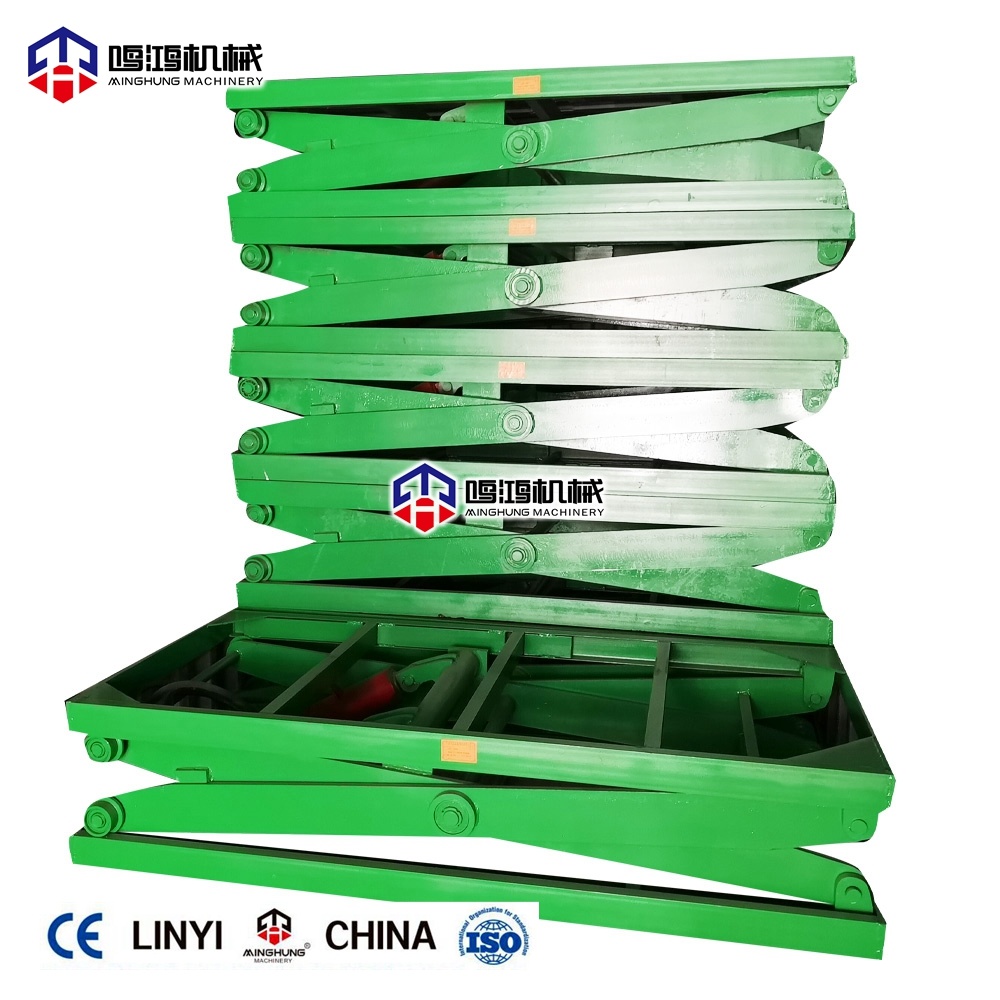

Soft-conveyor trimming (±0.5mm) → 3-head calibrated sanding (removes 0.1–0.3mm) → EVA film lamination.

| Key Equipment Configuration |

Equipment | Technical Specs | Innovation |

Continuous Flat Press | Width 1650mm, max temp 180℃, pressure 0–3000psi | German servo hydraulics (30% energy saving) |

Anti-Breakage Glue Spreader | Stainless steel roller coating, glue spread ±2g accuracy, heated tank | Elastic rollers prevent veneer cracking |

Auto Layup Line | Robotic handling + vision system, 5 sec/layer | Compatible with 1mm veneer |

Wide Sander | 3 heads + end trimmer, accuracy ±0.1mm, feed speed 30m/min | Air-cushion conveyor (scratch-proof) |

Central Control | IoT remote monitoring (real-time T/P/S adjustment), fault self-diagnosis | 50% less labor input |

veneer peeling

hot press machine

glue spreading machine

sander

| Application Scenarios |

1. Premium Packaging & Luxury Goods

Products: Jewelry/watch boxes, wine crate liners, cosmetic trays.

Advantages: Burr-free laser cutting (±0.1mm), sanded surface (Ra≤3.2μm) ready for foil/leather lamination. Lightweight (≤700kg/m³), reduces shipping cost by 30%.

2. Furniture Veneer & Composite Substrate

Products: Curved furniture surfacing, lightweight base for stone/metal composites (1mm ply + 0.5mm veneer).

Advantages: Bendable (radius ≥30mm), phenolic resin withstands 100℃ hot pressing.

3. Creative Design & Laser Processing

Products: Architectural models, artistic inlays, lampshades, bookmarks/puzzles.

Advantages: Laser edge carbonization <0.05mm (vs. >0.2mm for traditional plywood), UV print compatible (4B adhesion per ASTM D3359).

4. Lightweight Transportation

Products: Aircraft cabin panels, yacht partitions.

Advantages: Flame-retardant (FAR 25.853), smoke density ≤50 (NBS), 40% lighter than aluminum.

5. Electronic Components

Products: Drone frames, instrument mounting boards, PCB test fixtures.

Advantages: Low dielectric constant (ε≤2.8 @1MHz), EMI shielding.

| Why Choose 1mm Plywood? |

Advantages vs. Alternatives

Factor | 1mm Plywood | Acrylic/Metal Sheets |

Processing Cost | Laser cutting: $0.5/m | Acrylic cutting: $3/m |

Sustainability | Carbon footprint ≤8kg CO₂/m³ | Acrylic ≥35kg CO₂/m³ |

Design Flexibility | Bendable & laser-cuttable | Metal requires welding |

1mm ultra-thin plywood is the core material of the "wood replacing plastic" strategy. It has clear technical barriers and significant premium capacity in high-growth tracks (such as luxury packaging with an annual growth of 12% and laser engraving with an annual growth of 18%), and is suitable for entering the trillion-yuan market to replace acrylic and thin metal plates.

| Who We Are |

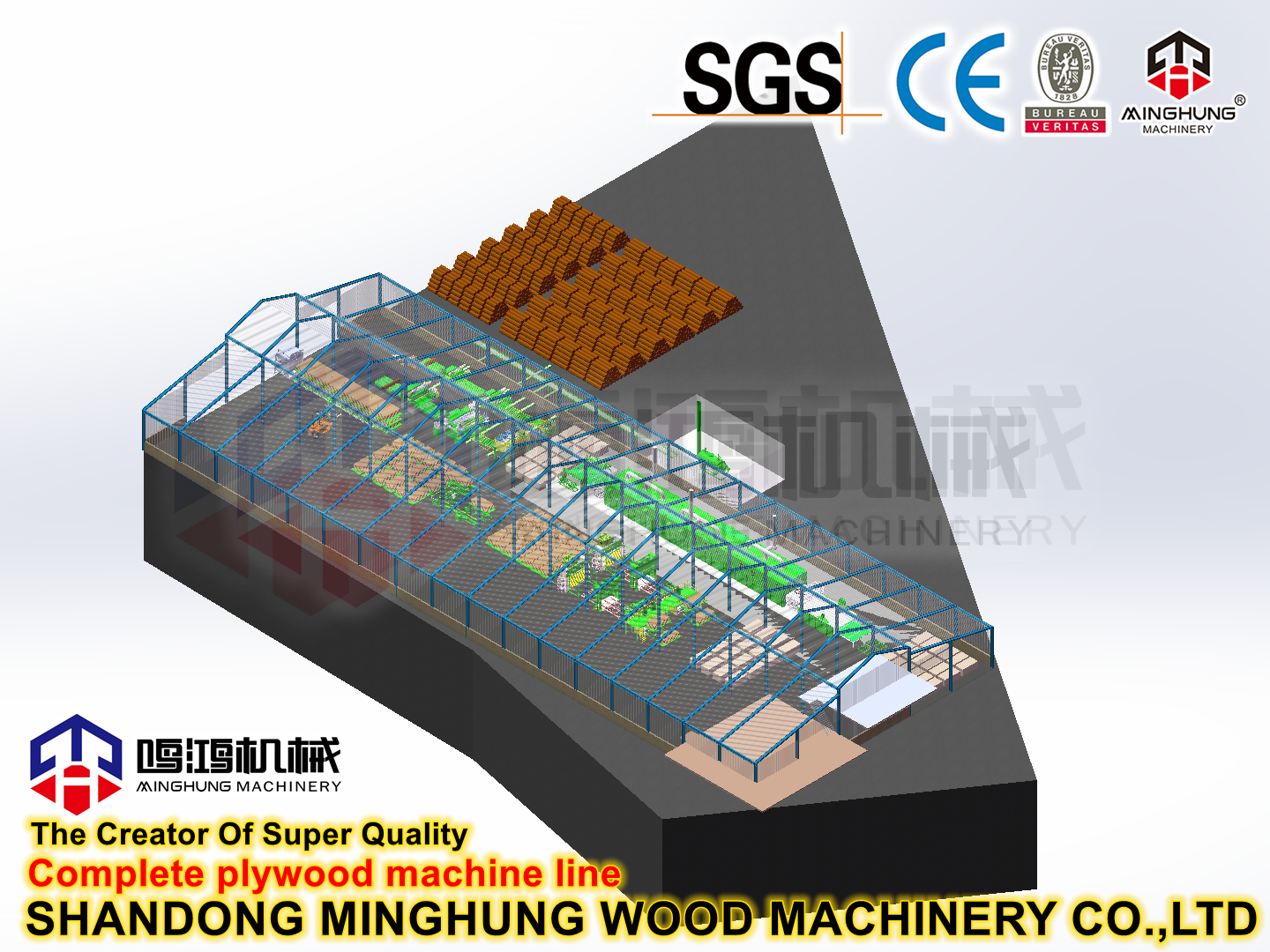

Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd Located in Xiaogezhuang Industrial Zone, Yitang Town, Lanshan District, Linyi City.

MINGHUNG Company provides a complete set of process design, electrical design and manufacturing, We can provide one-stop complete factory solutions for wood-based panel customers. MINGHUNG product series include medium density fiberboard (MDF), high density fiberboard (HDF), particle board (PB), oriented strand board (OSB), veneerable super strong particle board (LSB) multi-layer heat press production line, double-sided fixed thickness broadband Sanding machine, gauge saw, mechanical paving machine, air flow paving machine, channel dryer, super screen, post-processing system artificial panel cooling system, turning machine, stacker, storage and transportation trolley. etc. For artificial panel equipment mainly involved in particleboard, medium density fiberboard, oriented strand board, multilayer plywood machinery.

In addition to providing a complete new brand production line, MINGHUNG is a leading manufacturer of regulating glue and glue mixing systems.,created many glue blending technologies and promoted them worldwide, and is also a supplier of innovative online and laboratory quality control equipment.

MINGHUNG supplies equipment including branch material loading devices, drum chippers, long wood chippers, ring chippers, milling machines, hammer crushers and other complete artificial panel preparation section suppliers. The high-capacity particle super chip machine has unique advantages in the global particle board field. The development of the MINGHUNG system proves that Industry 4.0 has come to the field of artificial boards.

| photos of shipping |

Request Your Thin Plywood Solution Now! 3D plant layout, on-site commissioning & global spare parts – Dominate the premium board market today!

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com