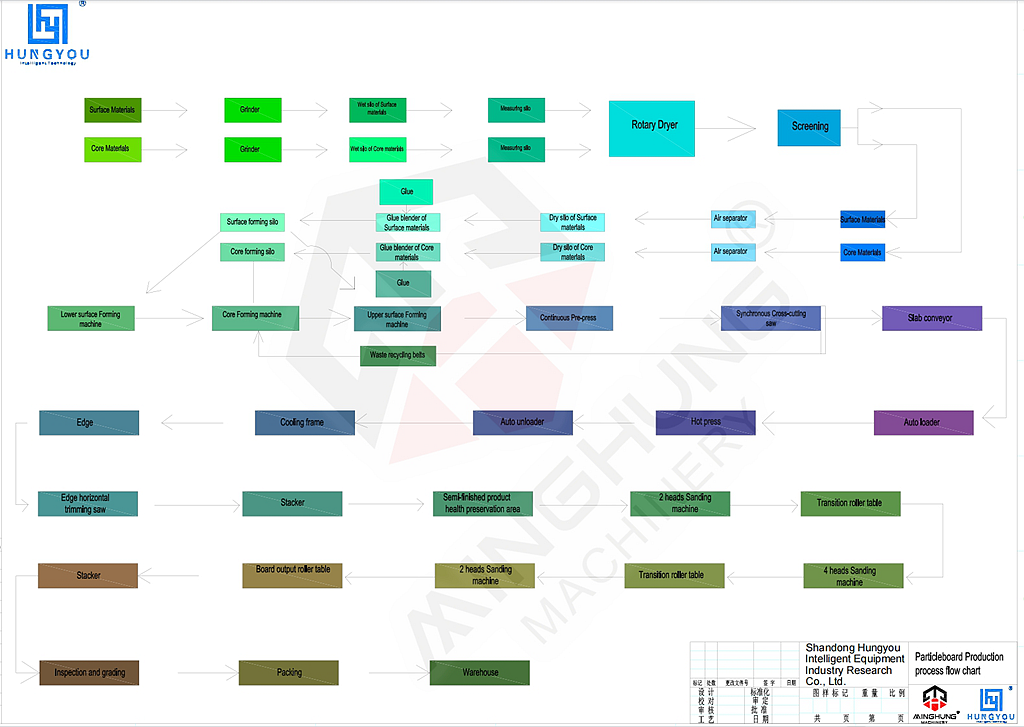

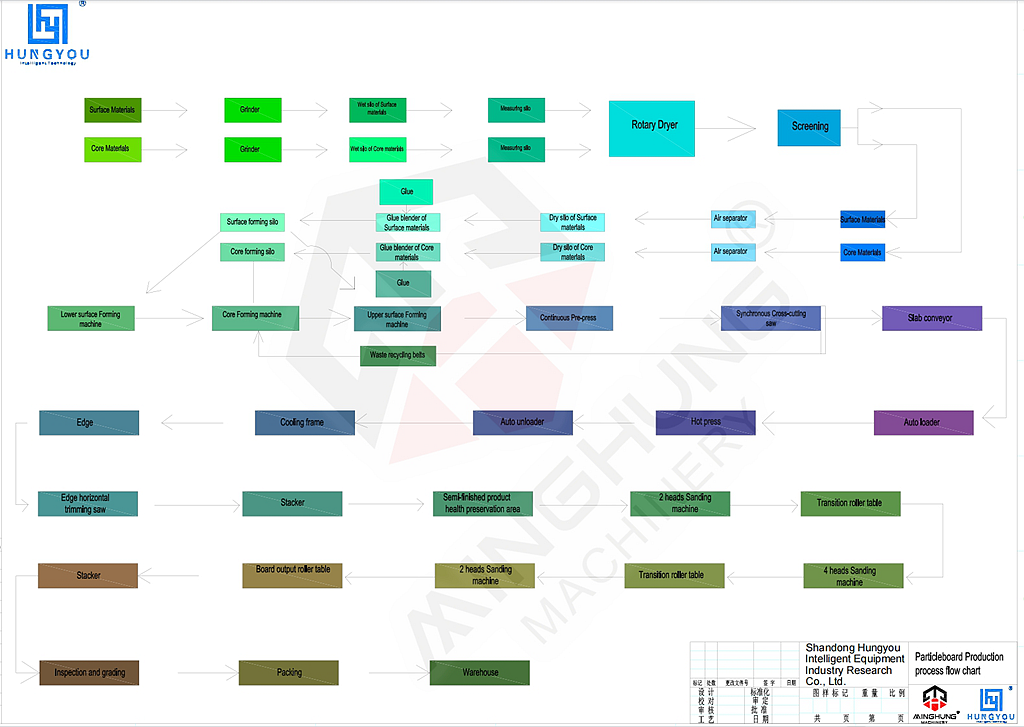

1. Raw Material Pre-Treatment

Wood Chipping: Logs/branches → Drum chipper → 15~30mm flakes

Screening: Rotary sieve separates coarse/fine flakes. Fine flakes (≥65%) for surface layer, coarse flakes re-chipped.

Drying Control: Rotary dryer (inlet temp. 180~240°C), moisture reduced from 45%→8~10% (surface layer requires lower moisture).

2. Resin Application & Forming

Resin Preparation:

Urea-formaldehyde resin (50~55% solids) + hardener/waterproofing agent (paraffin emulsion).

Resin Loading: Surface layer 10~12%, core layer 8~9% (no-added-aldehyde resin requires +20% dosage).

Air Forming:

Layered forming: Surface fine flakes (0.2~0.5mm) → Core coarse flakes (0.5~2mm) → Surface fine flakes.

Forming Accuracy: Density deviation ≤±5% (requires regular laser calibration).

3. Hot Pressing

Pre-Pressing: Cold press compacts mat (0.5~1 MPa pressure), reduces thickness by 50%.

Parameter | Standard Value | Function |

Temperature | 180-200°C | Activates resin curing |

Pressure | 2.5-3.5 MPa | Removes air, compacts mat |

Time | 25-40 sec/mm thickness | 18mm board: 7-12 min |

Stage Control | Pressing→Holding→Decompression | Prevents delamination |

4. Post-Processing & QC

Stacking & Curing: 24 hours in constant-temperature room (25±3°C) to release internal stress.

Sanding: 4-head sander (coarse→fine grit), removes 0.3~0.5mm, thickness tolerance ±0.2mm.

Trimming & Grading:

Qualified boards: Cut to 1220×2440mm standard size.

Defective boards: Crushed for reuse (≤5%).

Eco-Testing:

Perforator method for formaldehyde (ENF grade: ≤0.025mg/m³).

24-hour boil test for internal bond strength (≥0.35MPa).

5. Critical Equipment & Bottlenecks

Hot Press: Single-daylight press = primary bottleneck (1 board/cycle, daily output ≤100 m³).

Emission System: RCO catalytic oxidizer treats 1,200~1,500 m³/h exhaust gas (VOCs removal ≥90%).

III. Market Positioning & Product Strategy

Survival Key: Target Niche Markets

trategy | Product Examples | Price Premium |

Custom Sizing | Shaped substrates (curved/extra-thick) | +15–20% |

Functional Boards | Moisture-resistant board (bathroom) | +10–15% |

Eco-Upgrade | No-added-aldehyde board (nursery) | +25–30% |

Waste Utilization | Boards from fruit/tea tree branches | +5–10% |

> Target Clients:

> - Regional furniture factories (≤100 km radius)

> - Custom furniture studios (small-batch orders)

V. Upgrade Recommendations – Transition to "Small but Specialized"

1. Equipment Optimization:

Install online monitoring (X-ray density scanner), reducing sanding allowance (saves 5% material).

Upgrade thermal system: Replace 30% coal with sander dust .

2. Policy Incentives:

Apply for crop waste subsidies (if using agri-residues): 150–200 RMB/ton

Green Factory Certification : Grants for upgrades.

3. Cluster Collaboration:

Join regional alliances , cutting resin costs by 8–12% via bulk purchasing.

Shandong MingHung OSB&MDF Machinery Equipment is a China professional factory who specilize in manufacturering and offering Wood based panel machine, including OSB making machine, MDF making machine, and Chipboard /PB making machine.

Our factory with the advanced processing lathes, Mature production technology, and Professional engineers and technicians, and independent ability of reasearch and development, and quickly service, ensure that we have the ability to offer you the suitable and good woodworking machinery as different conditions and requires.