How to produce Particle board? What is the production step of Making Particle board?

Introduction:

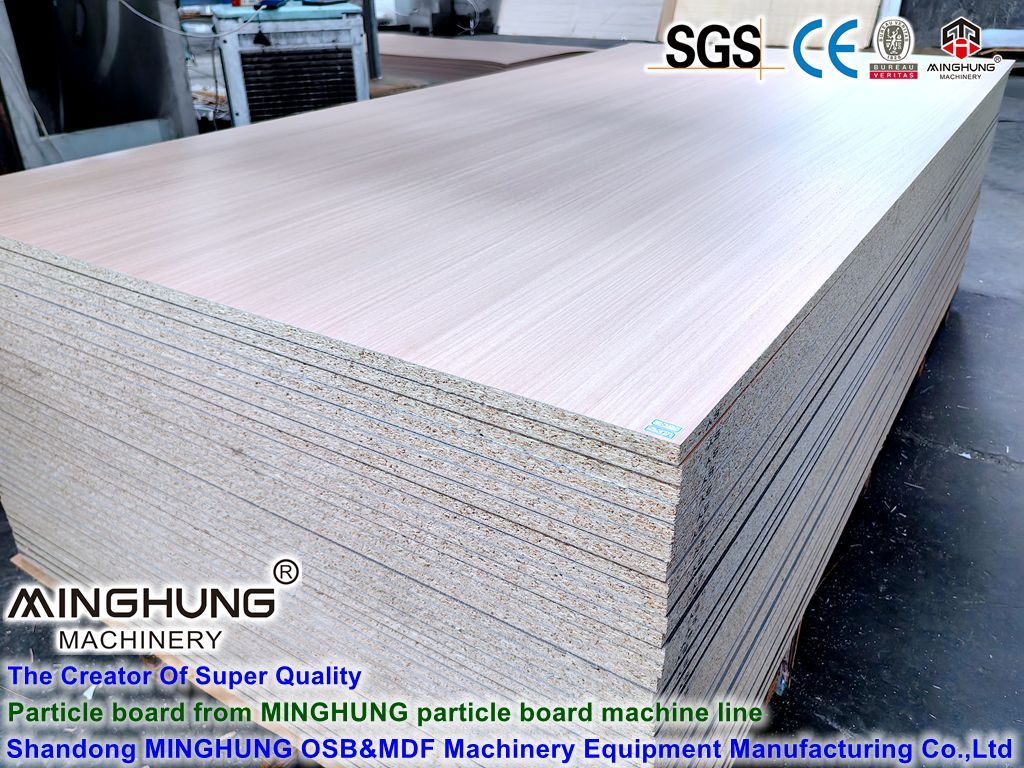

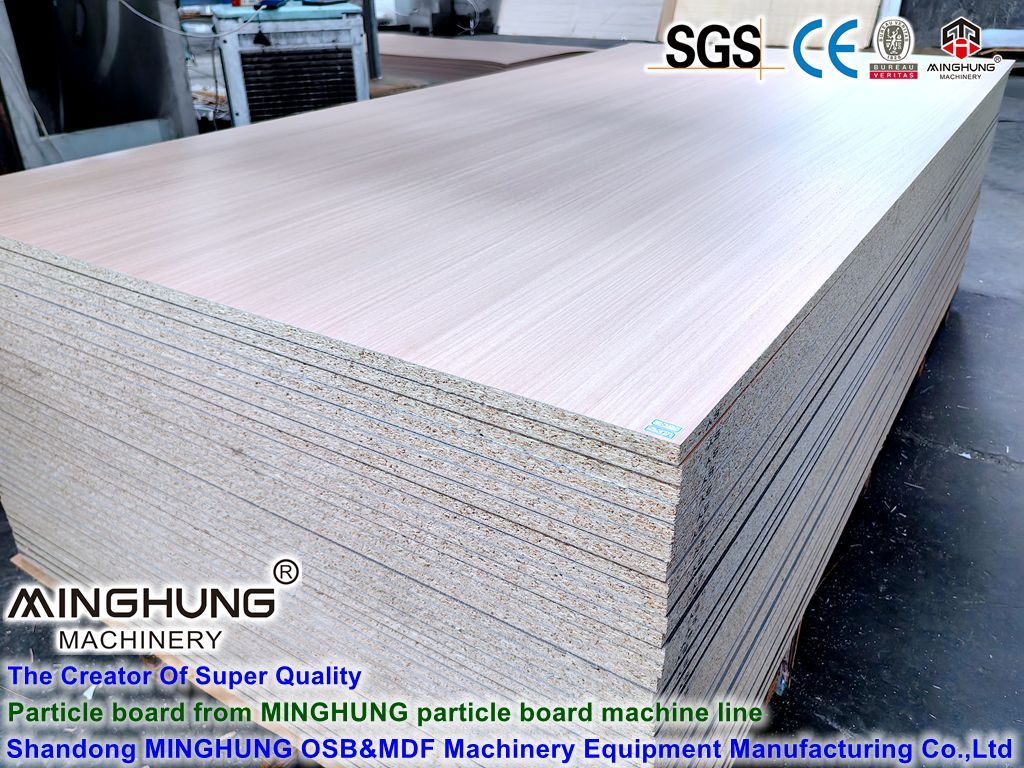

Particle board, also known as chipboard, is a versatile and cost-effective material widely used in the construction and furniture industries. It is made by compressing wood particles and adhesive together under high pressure and temperature. we will explain each production step of producing particle board, thus you will know clearly how its made

1. Raw Material Preparation:

wood shredder

wood chips

The first step for particle board production, is the preparation of raw materials. Wood chips or shavings be produced by wood chipper, to peeling and crushing wood bark into small chips.

2. Rotary drum dryer

drum dryer

rotary drum dryer

Drum dryer is one of the traditional drying equipment, equipment reliable operation, flexibility, adaptability, large processing capacity, widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar and other fields, diameter :Φ1000-Φ4000, length depending on drying requirements to determine.

In the center of the tumble dryer can avoid increasing the dispersion mechanism, the wet material entering the drying cylinder body is picked up and thrown repeatedly by the sheet on the wall of the rotating cylinder, in the falling process is broken into fine particles by the dispersion device, the specific area is greatly increased, and the hot air is fully in contact with dry.

3. Particle Sizing and Blending:

glue sizing system

glue system

Once the raw materials are dried, they are subjected to a sizing process. The wood strands are sorted into different sizes, ranging from fine to coarse. These particles are then blended together in specific proportions, depending on the desired density and strength of the final particle board.

4. Resin Application:

The blended wood particles /wood strands are transferred to a mixing chamber, where a resin binder is added. The resin, typically a urea-formaldehyde or melamine-urea-formaldehyde mixture, acts as an adhesive that binds the wood particles together. The resin is carefully applied to ensure even distribution, enhancing the overall strength and durability of the particle board.

5. Mat Formation:

Auto forming machine

Mat former

The resin-coated wood strands are spread onto a continuously moving conveyor belt, forming a thick mat. This mat is carefully monitored to ensure uniformity in thickness and distribution of particles. Special attention is given to achieving the desired density and surface smoothness of the particle board.

6. Continuous Pre-pressing:

3D of continuous pre press

Continuous pre-press for particle board

After forming section, the formed panel will enter into continuous cold press machine, through press it, the mat will become solid and forming. Thus it will be easy to enter into the next step Hot press machine

7. Hot Pressing:

Multi layers hot press

Hot press for particle board

The mat of resin-coated wood particles is then transferred to a hydraulic multiple hot press. The press applies high pressure and temperature to the mat, activating the resin adhesive and facilitating the bonding process. The duration of pressing varies depending on the desired thickness and density of the particle board.

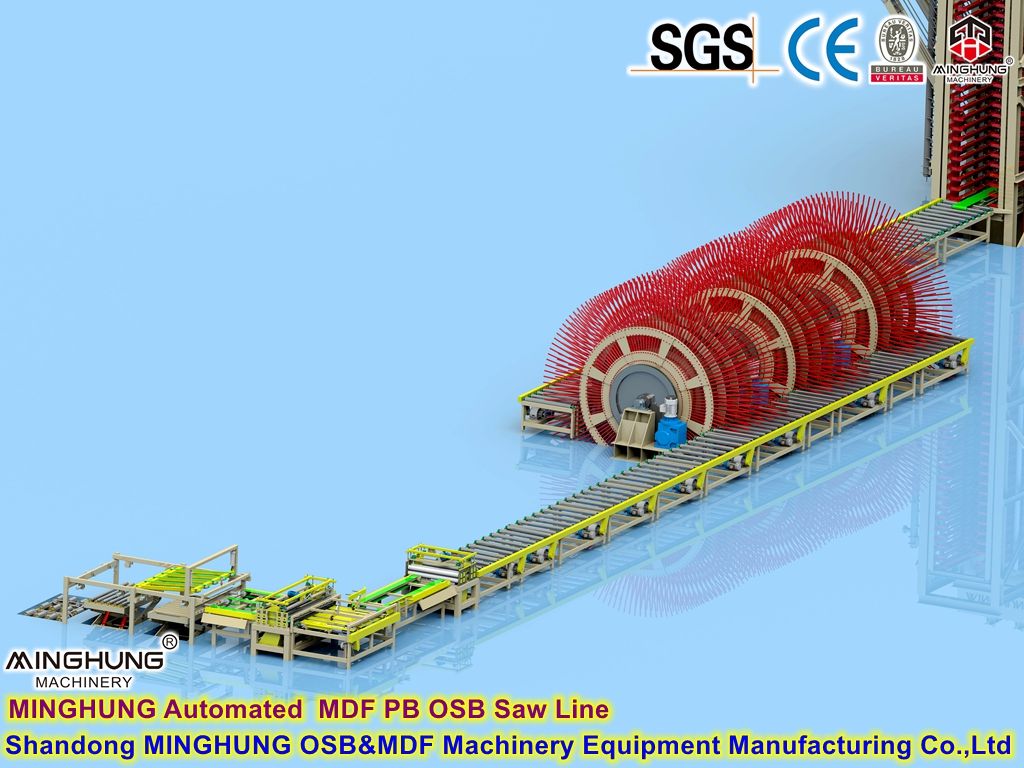

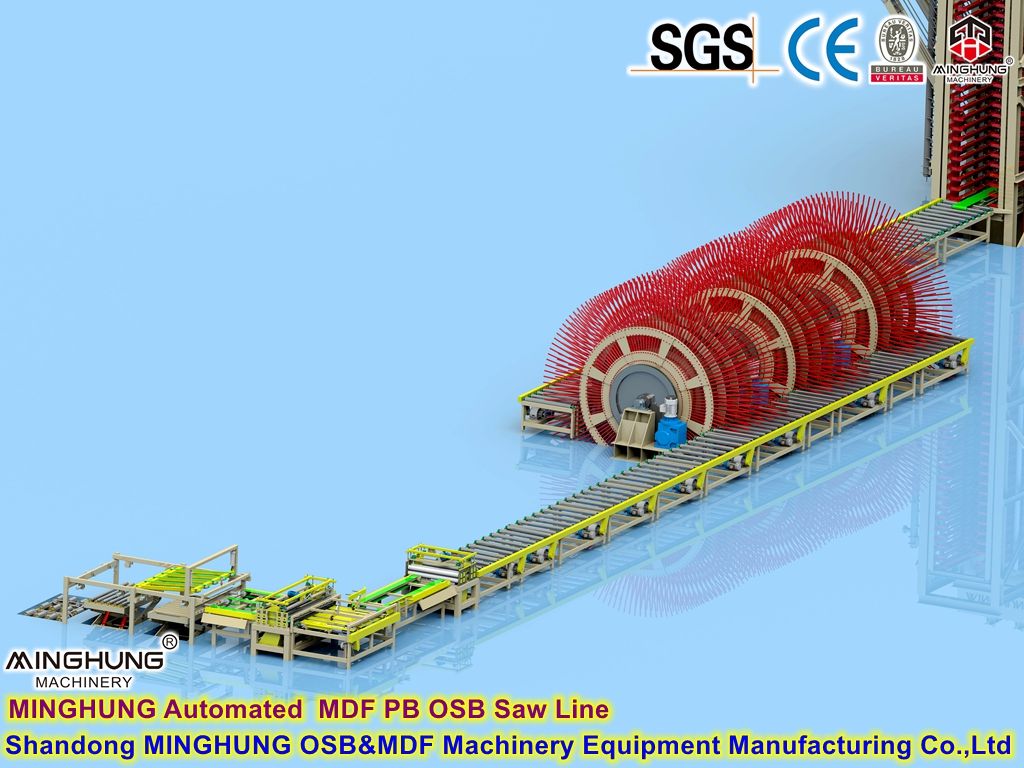

8. Cooling and Trimming:

Cooling & Cutting section for particle board production

Auto cutting machine

After the hot pressing stage, the particle board undergoes a cooling process to stabilize its structure and enhance its dimensional stability. Once cooled, the board is trimmed to achieve precise dimensions and smooth edges. Any surface imperfections or irregularities are carefully removed during this stage.

9. Finishing and Quality Control:

sanding machine line

Sanding machine for chipboard

The final step in particle board production involves finishing and quality control. The particle board is sanded to achieve a smooth and uniform surface. It may also undergo additional treatments, such as the application of a protective coating or decorative veneer. Quality control measures are implemented to ensure that the finished particle board meets industry standards and customer requirements.

10. Heating Center

Heating center for particle board factory

Heating center for OSB factory

Heating center system offer the heating energy to the whole production line

Each production step, will need different machine. If you want to produce high quality particle board, then the high quality particle board machine is required. And according to different production capacity, we can offer different specification machine.

If you want to produce particle board, welcome contact us

We are China manufacturer and supplier of particle board making machine, mdf board making machine, and OSB board making machine

Contacts:

Mark: +8619953900191

Ali: +8615589105786

Lucinda: +8615805493072

Lucy: +8618954906501

Email: minghungmachinery@gmail.com