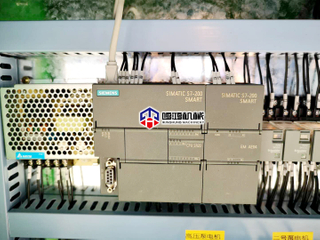

PLC control system design

The general steps of PLC control system design can be divided into the following steps: Familiar with the control object and calculate the input/output equipment, PLC selection and hardware configuration, design electrical schematic diagram, design console (cabinet), compile control program, program debugging and prepare technical documentation.

1. Clarify the control requirements and understand the production process of the controlled object

Familiarity with the control object design process layout diagram is the basis of system design. First, you should understand the process of the controlled object and its requirements for the control system in detail, and the relationship between various mechanical, hydraulic, pneumatic, instrumentation, and electrical systems. The working mode of the system (such as automatic, semi-automatic, manual, etc.), the relationship between PLC and other intelligent devices in the system, the type of man-machine interface, the way of communication network, the type and scope of alarm, power failure and emergency treatment, etc. Wait.

At this stage, user input devices (buttons, operation switches, limit switches, sensors, etc.), output devices (relays, contactors, signal indicators, etc.) and control objects driven by output devices (motors, solenoid valve, etc.).

At the same time, it should also determine which signals need to be input to the PLC, which loads are driven by the PLC, and classify and count the nature and quantity of each input and output, whether it is digital or analog, DC or AC, and voltage. Size grades provide a basis for PLC selection and hardware configuration.

Finally, classify the control objects and control functions, which can be divided according to the signal use or control area, determine the physical location of the detection equipment and control equipment, and analyze the form, function, scale, and relationship between each detection signal and control signal Relationship. After the signal point is determined, the process layout or signal diagram is designed.