Chipboard Paving Machine

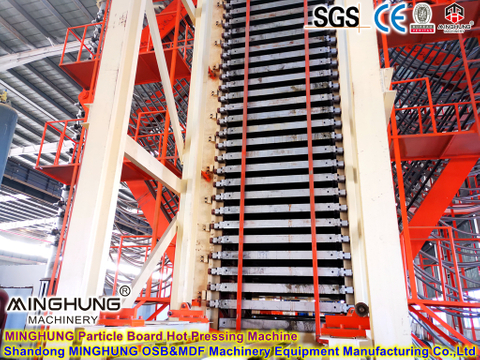

Mechanical graded paving is a commonly used paving method at present, using the principle of grading screens for graded paving. The shavings scattered by the dialing roller fall on the moving paving roller (diamond roller) and move forward in a jumping manner. By adjusting the gap of the paving roller, the fine shavings fall from the smaller gap at the starting end, while the coarse shavings fall from the smaller gap at the starting end. It falls into the larger gap at the back, thereby paving the slab with a gradual structure on the moving paving belt. Depending on the production scale, small and medium-sized production lines use two-head or three-head mechanical paving machines, while large-scale production lines can use four-head mechanical paving machines. There are usually three types of paving rollers: fine-toothed rollers, medium-toothed rollers and coarse-toothed rollers. In actual use, the three types of paving rollers with toothed shapes can be combined to adapt to the paving of different raw materials. Another notable feature of graded paving is that airflow assistance during paving can improve the paving effect. Especially when paving on the surface, the auxiliary effect of airflow makes the gradient structure of the surface layer more obvious and the surface of the finished board more delicate. Improve board quality.