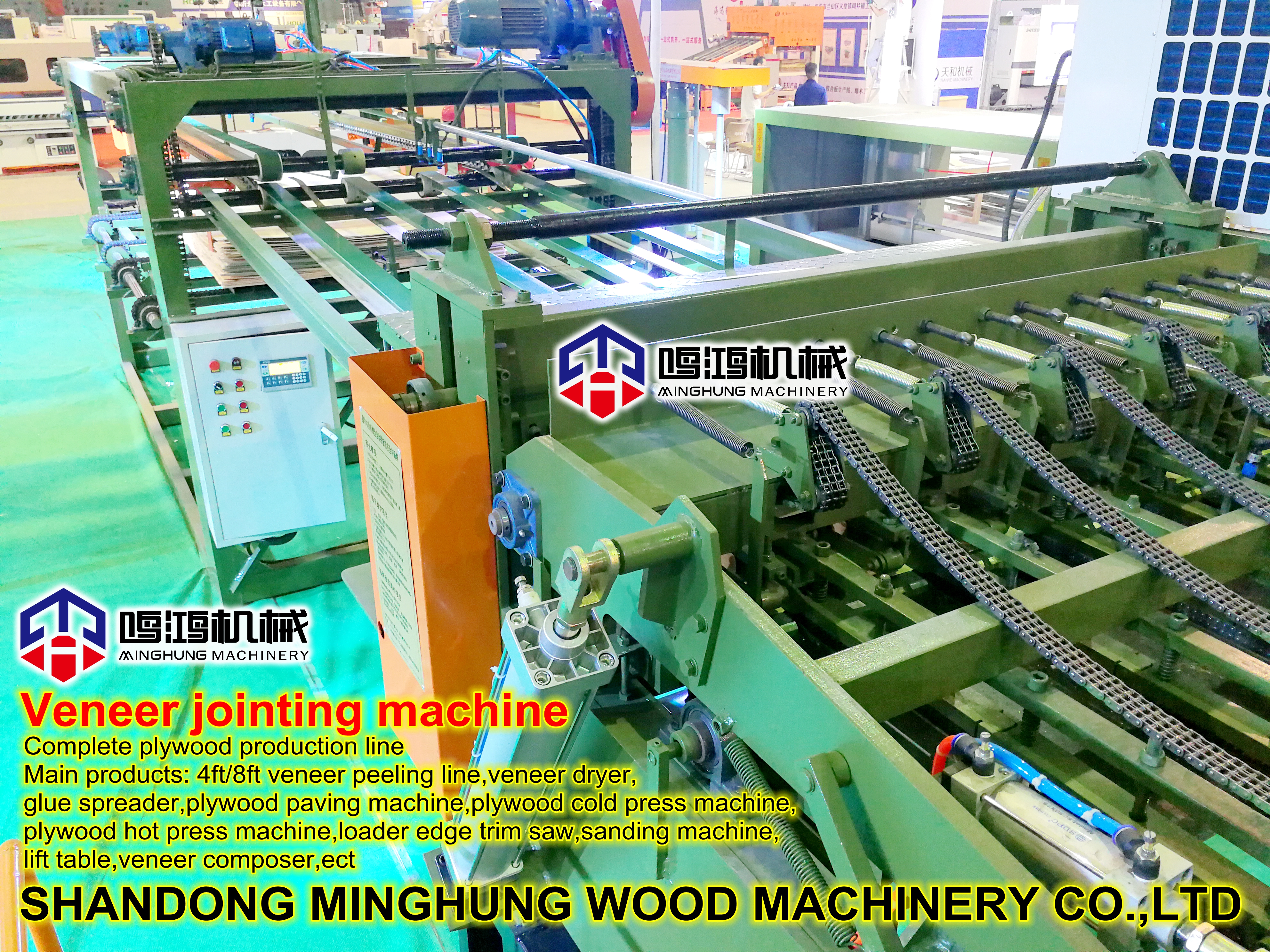

01 PRODUCT DESCRIPTION

>>Introduction: Pavement forming is to pave the glued dry fibers into slabs with uniform thickness and density according to process requirements, and then pre-press and saw them into specified sizes.

>>Requirements for particleboard forming from shavings to panel baord: Only when paved into qualified slabs can high-quality medium-density fiberboards be obtained. First of all, when the fibers are formed, they are required to be non-clumping, non-aggregated, evenly distributed, and naturally well interwoven. Secondly, the formed slab is required to have a certain strength and not fall apart during transportation. Third, the density of each point of the entire slab is required to be uniform, and the weight error per unit area is ±3%. Fourth, it is required that the slab should be as dense as possible to reduce the opening of the hot press. Fifth, the thickness of the forming slab is controlled between 15 and 28 times the thickness of the finished product to reduce the consumption of raw materials and adhesives.

02 WORKING PRINCIPLE

Step1: The surface core shavings after mixing with glue are sent to the surface core layer measurement silo of the paving station respectively, and then are paved separately through each paving head. |  |

Step2: The perianth is laid directly on the surface; the core layer is laid horizontally with fine sub-small shavings. When it comes to the surface core layer shavings paving effect is as shown in the figure. Oriented strand board designed by our company |  |

03 DETAILS DISPLAY

04 PRODUCT PARAMETERS

| Oriented Strand Board Thickness (mm) | Proportion of surface shavings (%) | Proportion of core layer shavings (%) |

8

| 50 | 50 |

| 10 | 45 | 55 |

| 13 | 40 | 60 |

| 16 | 36 | 64 |

| 19 | 33 | 67 |

05 COMPANY PROFILE

We China manufacturer and supplier of Particle board making machine+ MDF board making machine +OSB board making machine. if you want to produce these board, we can offer you the full necessary production line.

With many years production experience, and adhere to continuous innovation and improvement, with specialized R&D center, obtained a number of research and development patents, with experienced technians and engineers, and professional sales team and after-sales team, We have beome one China's high-end Wood based panel machinery manufacturing enterprise.

According to your own conditions like the budget, factory room and other factors, we can offer you the suitable, good and high quality machine for help you produce good quality panel.

For us, we know clearly that only keep machine good quality, can let us develop longer and better. Therefore, we always keep to choose good material and parts to make our machine, and during the whole machine production process, be made by experienced workers, and through many times test and monitor, to make sure each production step is good, to make sure the whole machine is good.

06 WHY CHOOSE US?

07 WHAT WE OFFER?