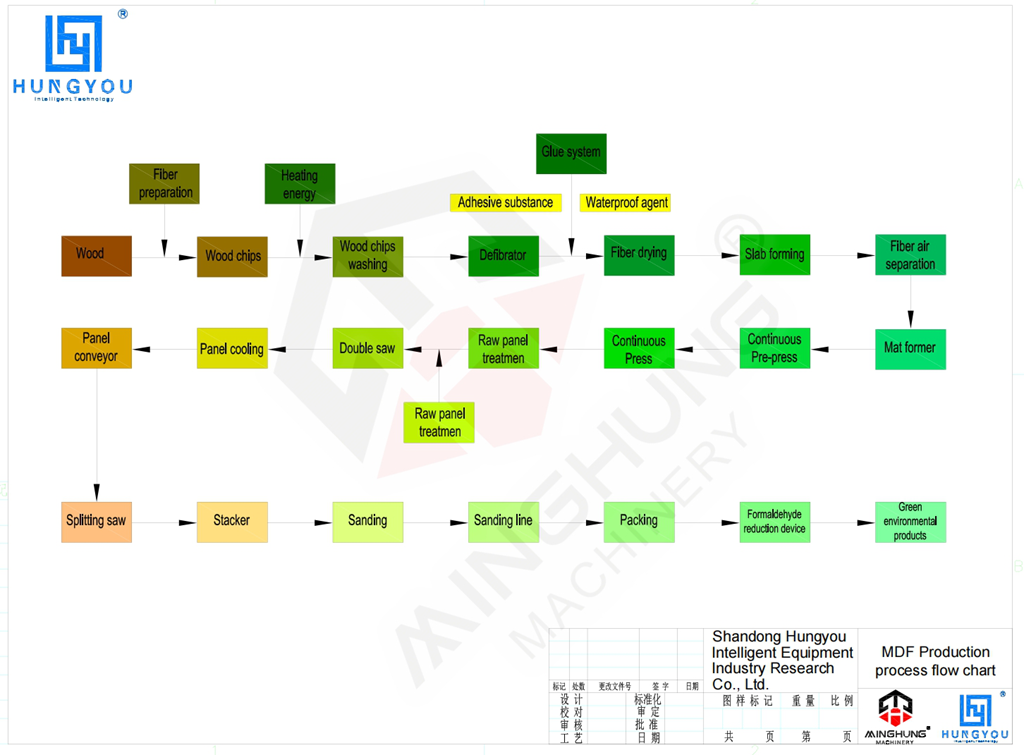

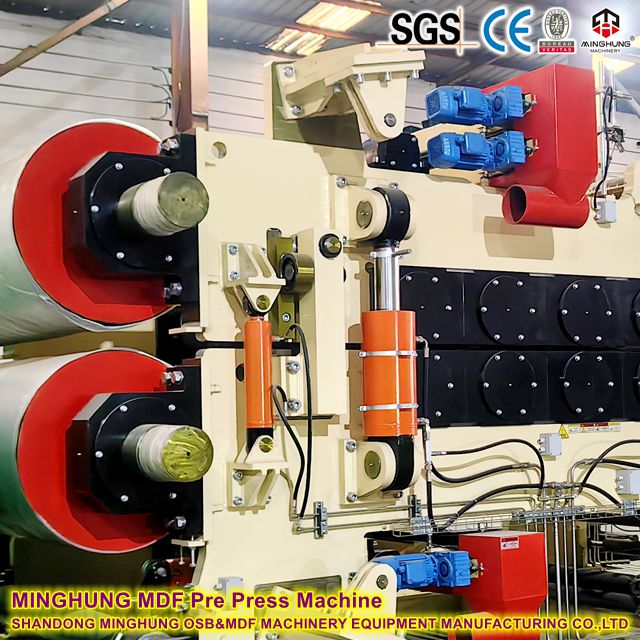

Ultra-Thin Board Technology: The core of the line features an advanced Continuous Press combined with high-precision forming and control systems, ensuring the stable formation and uniform curing of ultra-thin mats, overcoming the technical challenges of thin MDF production.

High Precision & Superior Surface Quality: Equipped with a multi-head heavy-duty calibrating sander, it ensures minimal thickness tolerance and a mirror-smooth surface on the ultra-thin boards, providing a perfect substrate for subsequent fine processing.

High Efficiency & Stable Output: The line is scientifically designed with a high degree of automation, enabling continuous and stable production to guarantee the 50,000 m³ annual capacity. An integrated thermal energy center utilizes process waste as fuel, significantly reducing operating costs.

Advanced Automation & Control: Utilizes advanced PLC and SCADA central control systems for precise monitoring and adjustment of production parameters (temperature, pressure, speed, moisture content), ensuring consistent product quality and traceability.

Flexibility & Reliability: The production line offers good flexibility to produce MDF boards in various thicknesses from 3mm to 12mm. The equipment is robustly built, reliably designed, and easy to maintain, ensuring long-term stable operation.