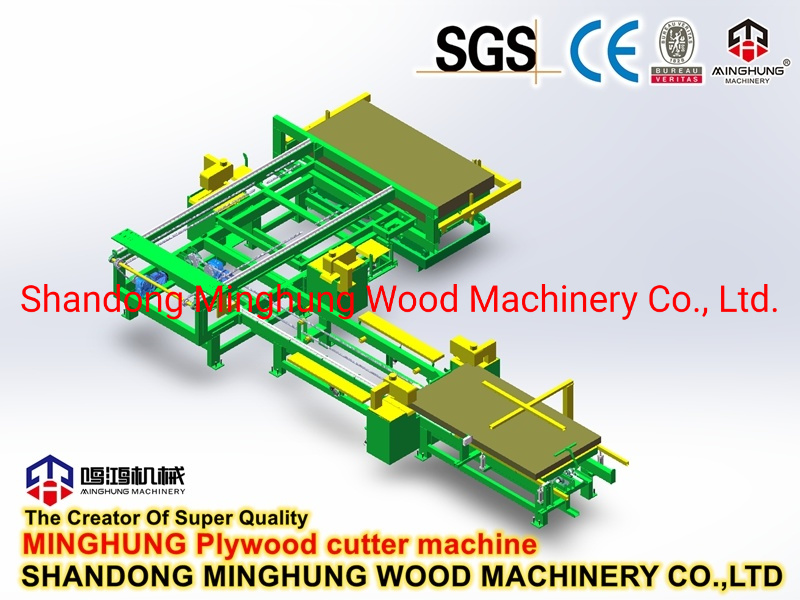

China High Quality Automatic Veneer Peeling Machine for Plywood Making

Dear Friends,

The structure of veneer peeling machine:

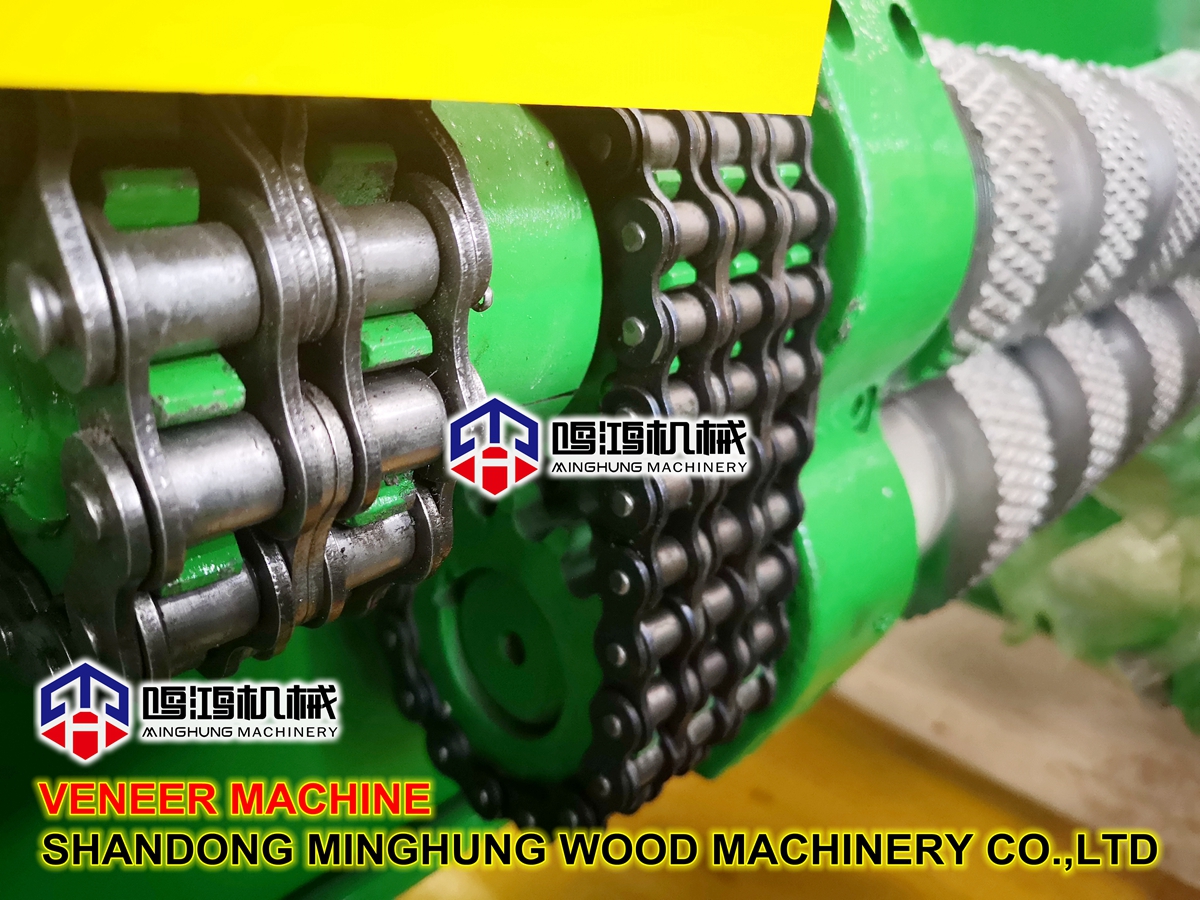

Wood veneer peeling machine mainly consist by: the machine frame, the knife frame, rotary roller, motors, conveyor.

We choose good material, and use thick steel and solid bottom frame, make sure veneer peeling machine is very stable when working; and all main parts through accurate processing by professional worker, durable and long lift span. The roller using cross-roller, make the left core diameter only 26mm, improve your wood utilization. Total power of veneer machine is very big, make sure offer powerful energy to driving rollers working, and will be easy for processing kinds of hardwood like birch beech acacia wood and others. And there has pneumatic device for knock the left core, convenient.

Operation:

Although when producing machine, the whole production step is complex, need our workers to be careful and make sure accurate of every step.

But when your worker operate machine, please don’t worry, it is not complex. Connect power supply, start the button, adjust the veneer width and thickness you want through the cnc screen in english version, put log into it, veneer machine will automatic peeling log and producing veneer, if you have veneer stacker connect with veneer peeling machine, then it will be fast and high efficiency, if not have, two workers required to receive the wood veneer.

When not use machine, cut the power supply for keep safety.

Installation:

Usually when veneer machine soon reach your factory, after you finish custom clearance, our engineer will prepare go to install your peeling machine, and teach your worker how to operate and maintain.

And you need not worry what if machine has problem and our workers are not there, first, we know clearly that we in different countries, so it is far between us, so when we produce veneer peeling machine, we focus on each production step, make sure veneer peeling machine in good quality and in good conditions. One good quality peeling machine will help you save cost and create much benefits from long term to see, and that’s our factory insist do.

Second, when using machine, if your worker meet some problem that they don’t know how to solve, please contact me, i will reply you at the first time, help you find where is the problem and solve it.

Because we know that we are so far, and you choose to believe our factory, so we cherish this relationship, therefore, we not just business partners, we are friends too. We will try our best to help your business become better and better.

Our factory:

With many years improvement and development, our factory plywood machine and veneer machine has been very mature, advanced and stable.

We mainly produce machine includes like #wooddebarker, #veneerpeelingmachine, #veneerstacker, #knifegrinder, #veneerdryermachine, #veneerollerdryer, #faceveneermeshdryer, #gluespreader, #plywoodveneerpavingline, #plywoodveneerlayout, #corecomposer, #hydrauliccoldpressmachine, #hotpressmachine, #plywoodsawmachine, #plywoodsanding machine, #lift table.

All plywood machines have CE.

Principle:

Offer good and suitable machine to every our client, help your business going better, help you created much benefits.

If you now have demands of plywood machine, welcome contact me, i can offer you details for your reference, get one more choice is good for you.

And i believe our plywood machine will satisfy you.

The Purpose Buying Veneer Peeling Machine:

The Purpose Buying Veneer Peeling Machine:

produce good quality wood veneer, accurate and balance thickness, surface smooth. be helpful for your business, whatever you use by yourself for making plywood or wooden furniture, or you sell to your clients.

This is what our factory focus on, make sure offer the good and suitable veneer peeling machine for you.

In general, veneer peeling machine has 4feet/5feet and 8feet/9feet, their configuration will be very different according to different requires. One type is not suitable for all people, so we always produce machinie according to our clients own conditions, make sure offer the most suitable machine to them.

Parameter:

| name | veneer peeling machine |

| model | MH-VPM8A |

| max log length | 2700mm |

| max log diameter | 550mm |

| thickness | 0.5-4.0mm |

| max speed | 80m/min |

| total power | 50.2kw |

| total weight | 13t |

| size | 5200*2300*1500mm |

Parts of Veneer Peeling Machine:

Wood Veneer Test:

If veneer peeling machine can not produce good quality wood veneer, then that is not a good machine.

If veneer peeling machine can not produce good quality wood veneer, then that is not a good machine.

When finish production of veneer machine, our engineer will test many times of different thickness, to test and check machine quality, ensure veneer thickness accurate and balance.

Many our clients came to visit our factory and measure thickness, then they usually will give a thumps-up geature.

Workshop:

No 1. Matrial

Our experienced purchase manager choose the good machine material and spare parts after compare different suppliers,

No 2. Engineer

Our engineer service domestic and abroad clients more than ten years, from clients start build factory, plant layout, machine maintain, etc, offer all-sided support, this is a real engineer. The most important thing is: their serious and responsibility attitude is the main source for improving and optimizing our machine.

No 3. Processing Lathe

Our processing lathe make sure machine accurate, we have invested $3000000 for cnc lathe, precise cutter, welding machine, PLC test system, Machine test system and other machines, It reduces the intensity of workers' work, improve machine parts accuracy. this is the big weapon for us to competitive with other suppliers.

No 4. Multiple inspection procedures

The whole production step, will through more than 5 times detection to make sure machine production is good. And after finish production, our engineer will test machine to ensure it is in good conditions.

No 5. Factory Management

Our company and workshop use 5S (Seiri and Seiton, Clean-up and Removal, Attainment), the application of 5S make us become one international company, keep up with the world's top 500 companies.

No 6. Our Company Value

Continuous create much more value for clients.

Delivery:

Contact us:

whatsapp/telegram: +8618769900191 +8615589105786 +8615805493072

Website: www.plywoodmachineline.com

Email: minghungmachinery@gmail.com