The Differences And Comparisons between PB OSB And MDF

Particleboard, oriented strand board (OSB), and medium-density fiberboard (MDF) are three commonly used man-made board materials, each with its own unique characteristics and application scenarios. Below is a detailed comparison from multiple perspectives:

1. Raw Materials and Structure

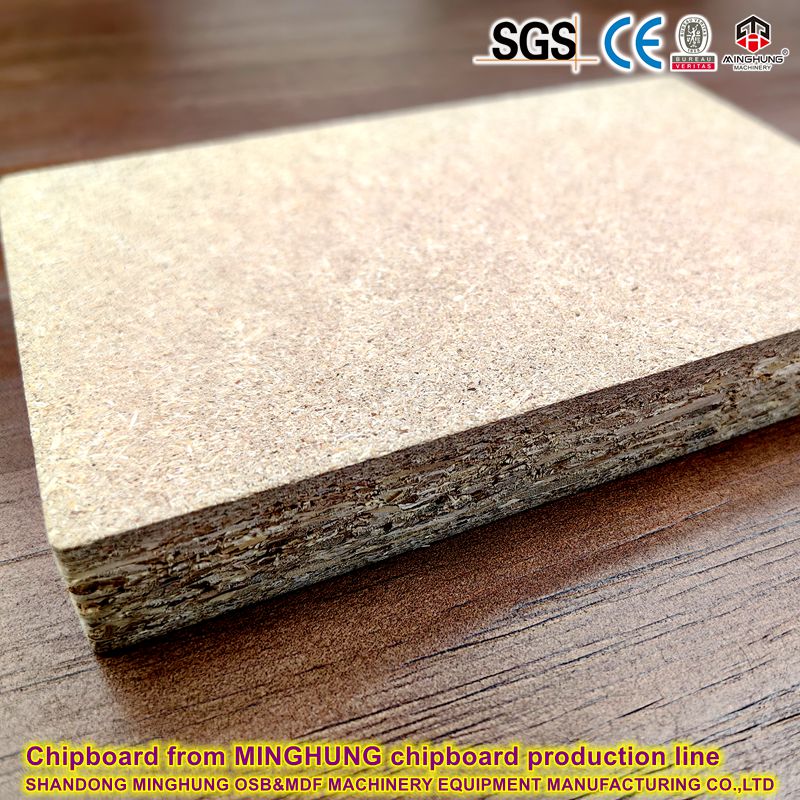

Raw Materials: Small, irregularly sized wood processing residues (such as wood chips, shavings, and sawdust).

Structure: Made by mixing wood chips (particles) of various shapes and sizes with an adhesive and pressing them together under heat and pressure. The internal structure is relatively disordered.

Oriented Strand Board:

Raw Material: Wood from specific tree species (such as fast-growing poplar and pine), cut into larger, thinner, and longer wood chips (shavings).

Structure: Its core characteristic is orientation. The surface chips are laid in a directional pattern along the length of the board, while the core chips are typically laid perpendicular to the surface (or randomly, but most often in a directional cross-layer pattern). These chips are then bonded together under high temperature and pressure, creating a cross-layer structure similar to plywood.

Medium-density fiberboard:

Raw materials: Wood processing residues (such as sawdust, shavings, small-diameter lumber, and branches) or plant fibers.

Structure: The wood raw material is completely separated into wood fibers or fiber bundles (through processes such as hot grinding and blasting), glued, and then pressed under heat and pressure. The internal structure is very uniform and fine, similar to felt.

2. Physical and Mechanical Properties

Particleboard:

Strength: Average. Bending and tensile strengths are relatively low, especially nail holding power (screws tend to loosen and fall out). Impact resistance is average.

Density: Density range is wide, but generally lower than MDF and OSB. Structure is relatively loose.

Dimensional Stability: Poor. Hygroscopic expansion is high, making it prone to expansion and deformation when exposed to moisture, resulting in a significant decrease in strength.

Oriented Strand Board:

Strength: High. Due to its oriented structure and large strands, it offers exceptionally high bending and tensile strength (especially along its length), strong nail holding power (screw retention), and excellent impact resistance. Its overall strength approaches or even exceeds that of plywood.

Density: High, with a dense structure.

Dimensional Stability: Good. Its hygroscopic expansion is relatively low, resulting in superior moisture resistance compared to standard particleboard. Its cross-linked structure effectively resists anisotropic deformation.

Medium-density fiberboard:

Strength: High internal bond strength (due to dense fiber interweaving). Flexural and tensile strengths are moderate, but generally higher than those of standard particleboard. Nail holding power is poor (especially at the edges, where screws can easily tear and pull out fibers). Impact resistance is average, and the surface is prone to denting.

Density: High and very uniform (typically 600-800 kg/m³).

Dimensional stability: Good (better than standard particleboard, but not as good as OSB). It will swell and deform after absorbing moisture, but more uniformly than particleboard.

3. Surface Quality and Processing Performance

Surface: Rough, with a noticeable grain texture and porosity. Direct finishing results are poor.

Processing: Edges are prone to chipping during machining, such as sawing and drilling. Edge banding is crucial but relatively difficult. Carving and milling are difficult.

Oriented Strand Board:

Surface: The surface has a distinctive, large-scale, "popcorn" or "scale" texture and is relatively rough. Direct veneerability is inferior to that of MDF.

Processing: Sawing and drilling performance is good, but edges may show slight chipping (better than particleboard). Carving and milling are very difficult (the large flake structure is prone to tearing).

Medium Density Fiberboard:

Surface: Extremely smooth, flat, and fine-grained, with no grain and minimal pores. It offers the highest surface quality of the three types of board materials, making it ideal for direct application to various finishes (veneer, stickers, PVC, varnish, spray paint, etc.).

Processing: Excellent processability. Sawed and drilled edges are smooth and dense, with minimal chipping. Ideal for fine engraving, milling, and routing, capable of creating complex curves and edge shapes. Edge banding is easy and effective.

4. Environmental Performance

The environmental performance of all three adhesives depends primarily on the type and content of the adhesive used (primarily formaldehyde emissions).

They all have varying environmental ratings, ranging from E2 (restricted use), E1 (market mainstream, compliant with most national standards), E0 (more environmentally friendly), to formaldehyde-free (e.g., when using MDI adhesive).

It's difficult to generalize which is more environmentally friendly; the key is to look at the environmental rating labeling of the specific product you purchase (e.g., Chinese standard E1, European standard E1, CARB P2, F★★★★, etc.).

5. Moisture/Water Resistance

Particleboard: Poor. Ordinary particleboard is not moisture-resistant and easily swells, deforms, molds, and loses strength when exposed to water or high humidity. Moisture-resistant particleboard with added moisture-proofing agents has improved its performance, but it is still limited.

Oriented Strand Board: Good. It has a dense structure and is often used with adhesives that offer improved water resistance (such as phenolic resin). Available types include OSB/1 (for indoor, dry environments), OSB/2 (load-bearing, dry environments), OSB/3 (load-bearing, humid environments), and OSB/4 (heavy-duty, humid environments). OSB/3 is the most common and widely used type on the market, offering excellent moisture and water resistance and suitable for use in humid environments such as bathrooms and kitchens (although surface waterproofing is still required).

Medium-density fiberboard: Poor. Ordinary MDF is not moisture-resistant and has a high rate of expansion when it absorbs water. Moisture-resistant MDF (HDF) with added moisture-proofing agents improves performance. Water-resistant MDF also uses special resins (such as melamine-modified urea-formaldehyde glue or MDI glue), but these are more expensive.

Mainly used for non-load-bearing structural components or concealed areas where strength, moisture resistance, and surface finish are not critical.

For example: back panels, side panels, and drawer bottoms of low-end furniture; cabinet bodies (economical); interior partitions (dry environments); packing box padding; and the core layer of laminate flooring.

Oriented Strand Board (OSB):

Primarily used for structural applications, replacing plywood.

For example: walls, floors, and roof panels in timber-framed buildings; container floors and train decking; I-beam webs; packaging boxes; furniture structural frames, load-bearing shelves, and bed panels; baseboards for interior and exterior decoration (such as exterior wall lining and roof lining); and exhibition stand construction.

Medium-density fiberboard (MDF):

Mainly used for non-structural components requiring fine processing and a high-quality finish.

For example: furniture door panels, front panels, and drawer fronts; cabinet door panels; laminate flooring substrates; interior door leaves and door frames; skirting boards; decorative moldings; mirror and photo frames; speaker cabinets; toys; and handicrafts. MDF is often used as the substrate for varnished boards, blister boards (molded boards), veneer boards, and melamine veneer boards (double-sided veneer boards).

General ranking (low to high): Particleboard < OSB < MDF

Specific prices are significantly affected by factors such as brand, environmental rating, thickness, origin, and market supply and demand. High-quality particleboard may be more expensive than low-quality MDF. The price of OSB/3 is generally between regular particleboard and MDF.

Simple Selection Recommendations

Need load-bearing, structural support, and use in a humid environment? → Choose OSB (especially OSB/3).

Need a smooth, even finish (paint, blister, laminate), intricate carving, or complex shapes? → Choose MDF.

Strictly limited budget, using in a dry environment, non-load-bearing, and non-exposed areas (such as cabinet backs and drawer bottoms)? → Consider particleboard, but pay attention to nail holding and edge banding.

If you want to produce chipboard, or OSB, or MDF/HDF, welcome contact us. We are the manufacturer and supplier of these wood based panel machinery.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com