The Ultimate Guide to Plywood Hot Press Machines: Crafting High-Quality Plywood

The Ultimate Guide to Plywood Hot Press Machines: Crafting High-Quality Plywood

Introduction:

Plywood is a versatile and widely used material in various industries, from construction to furniture manufacturing. Behind the scenes, plywood hot press machines play a crucial role in the production process. In this comprehensive guide, we will delve into the intricacies of plywood hot press machines and explore how they contribute to the creation of high-quality plywood.

Understanding Plywood Hot Press Machines:

Plywood hot press machines are specialized equipment used to manufacture plywood sheets. These machines apply heat and pressure to layers of wood veneers, bonding them together to form a strong and durable plywood panel. The process involves multiple stages, including preheating, pressing, and cooling, each essential for achieving the desired quality.

Preheating Stage:

Before the pressing stage, the plywood hot press machine preheats the wood veneers. This step ensures that the moisture content is reduced, allowing for better adhesion during the pressing process. By controlling the temperature and humidity, manufacturers can optimize the bonding strength and prevent issues like delamination.

Pressing Stage:

The pressing stage is the heart of the plywood hot press machine. Here, the preheated wood veneers are stacked together with adhesive in between. The machine applies both heat and pressure, activating the adhesive and bonding the veneers tightly. This process typically takes a few minutes, during which the machine maintains consistent pressure and temperature to ensure uniform bonding.

Cooling Stage:

After the pressing stage, the plywood panels undergo a cooling process. This stage is crucial to stabilize the adhesive and solidify the bond between the veneers. The cooling process is carefully controlled to prevent warping or deformation of the plywood sheets. Once cooled, the plywood panels are ready for further processing or distribution.

Factors Influencing Plywood Quality:

The quality of plywood produced by hot press machines depends on several factors. First and foremost is the choice of adhesive. Different adhesives offer varying levels of bonding strength and resistance to moisture and heat. Manufacturers select adhesives based on the intended use of the plywood.

Hydraulic station is one important part for plywood hot press machine, it will offer the oil to cylinder, driving it lift hot press machine.

The hydraulic station is also called the hydraulic pump station. The motor drives the oil pump to rotate. The pump sucks oil from the oil tank and pumps the oil. The mechanical energy is converted into the pressure energy of the hydraulic oil. The hydraulic oil is realized by the hydraulic valve through the integrated block (or valve combination). After the flow adjustment, it is transmitted to the oil cylinder or oil motor of the hydraulic machinery through the external pipeline, thereby controlling the direction change of the hydraulic motor, the size and speed of the power, and promoting various hydraulic machinery to do work.

>>>Main Parts:

Cylinder:

The oil cylinder is treated with anti-rust, alloy casting, high hardness, scratch resistance, suitable for high-strength operations, and uses a good oil seal to prevent leakage, ensure the pressure in the oil cylinder, and good performance

Hot platen:

Usually hot platen use 42mm or 52mm, The hot platen be processed by large lathe, make the surface is smooth, with sufficient strength and stiffness. It does not deform at high temperatures, and the temperature and heat are uniform. This makes the plywood heated evenly, the surface is flat, and the thermal efficiency is high, which improves the production efficiency.

Hydraulic Station:

Hydraulic station is one important part for press machine, Our hydraulic station be designed by our engineer, reasonable design of hydraulic system, save energy, all hydraulic components are arranged reasonably, neatly and beautifully placed, and the components like electromagnetic valve, hydraulic pump all use good one.

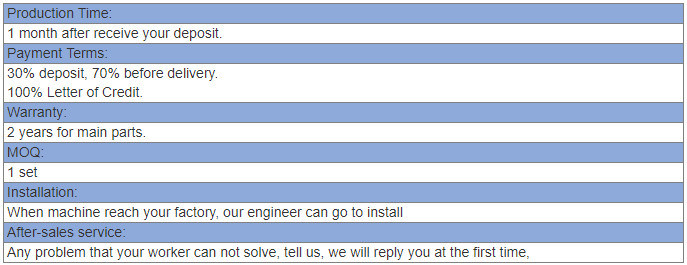

>>>Hot press in client factory:

> For convenient loading, hot press machine's frame is combined, and use international standard steel plate, make sure hot press weight is very heavy, stable and good quality.

> When plywood press machine and other plywood machine reach your factory, our engineer will go to install and teach your worker how to operate and maintain machine.

> And in the future, when your worker meet any problem, or your factory need purchase some spare parts of plywood machine, we will help you solve and help you buy.

>>>Us

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

>>>Delivery:

1> When loading, we will share the loading pictures of plywood press machine with you.

2> When ship leave, we will offer the container and ship information for you.

3> Offer all documents which for your custom clearance.

>>>Related Plywood Machine:

we produce the full line of plywood machine.

wood debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine include veneer press dryer and roller dryer, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

>>>RFQ

>>>Contact us:

Whatsapp: +8618769900191

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com