|

Product equipment

1. Raw Material Preparation Section

Disc Chipper: Used instead of the more expensive longwood flaker. It processes low-cost raw materials like small-diameter wood, branches, and slabwood into standard chips. It offers low investment cost and simple maintenance.

Flaker: Planes the wood chips into flakes that meet OSB requirements.

Crusher: Used to process oversized flakes, reducing them to meet core layer specifications.

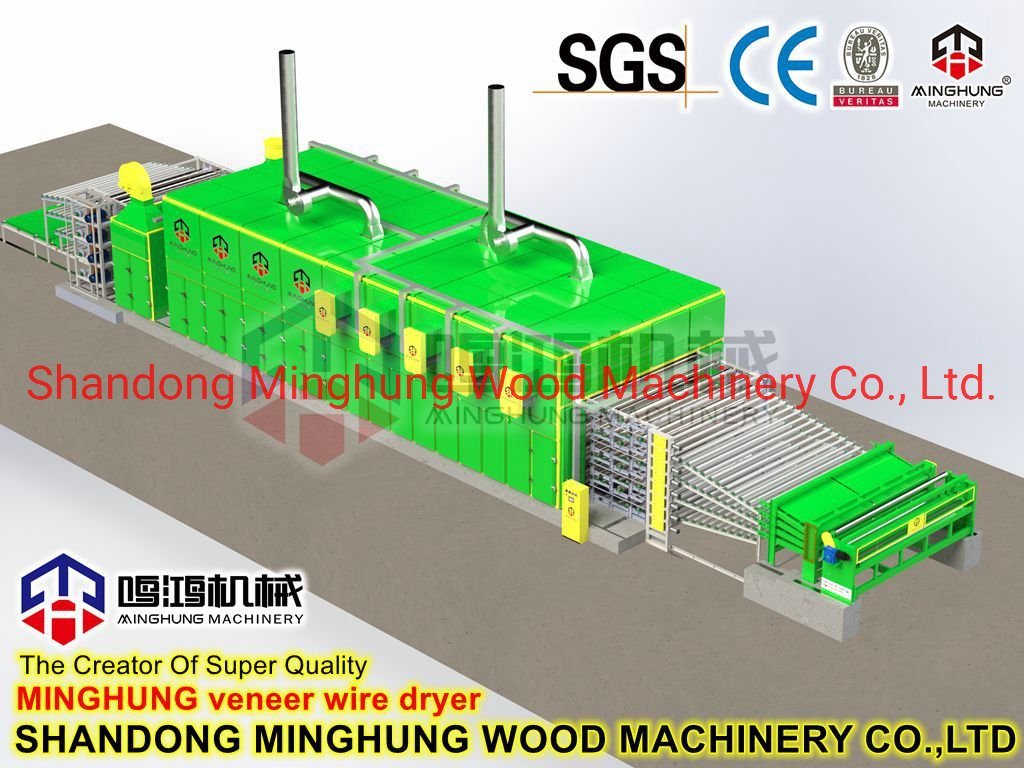

Rotary Drum Dryer: Designed as single-pass or triple-pass, using biomass (e.g., sawdust, flakes, bark) as fuel, significantly reducing energy costs for the drying process.

chipper

disc chipper

OSB drum dryer

2. Blending and Forming Section

Ring Blender: Core equipment. Ensures uniform mixing of flakes with adhesive (typically cost-effective PMDI/MDI) and waterproofing agents.

Mechanical Oriented Forming Station: The key choice for a low-cost line. Employs mechanical oscillating forming heads instead of high-cost pneumatic forming systems. While the orientation accuracy is slightly lower, it fully meets the requirements for producing OSB for pallets, packaging, and other applications where extreme strength is not critical. Investment and maintenance costs are significantly reduced.

glue sizing system

forming machine

3. Pressing and Finishing Section

Batch Hot Press or Small Continuous Press:

Primary Low-Cost Choice: Batch Hot Press. This is the core choice for minimizing investment cost. It uses a multi-opening hot press with a no-pallet loading/unloading system. Although production efficiency is lower than a continuous press, the equipment cost can be a fraction of the latter, making it highly suitable for a 60,000 m³ annual capacity scale.

Upgrade Option: Small Continuous Press. If the budget allows, a smaller continuous press can be chosen, offering advantages in energy efficiency, productivity, and surface flatness, representing a balance between cost and performance.

multilayer press

hot press machine

Cooling & Turning Star: Cools the hot boards from the press, stabilizing their properties.

Cross-Cut & Trim Saws: Cuts the large panels into standard sizes (e.g., 1220x2440mm).

Sanding Machine: Sands the boards to a precise thickness, ensuring dimensional tolerance and surface flatness.

Cooling & Turning Star

Cross-Cut & Trim Saws

OSB sanding machine

4. Auxiliary Systems

Thermal Energy Center: Core energy-saving equipment. Equipped with a biomass burner that utilizes production waste (bark, sander dust, sawdust) as free fuel to provide thermal energy for the dryer and press, drastically reducing operating costs.

Simplified Control System: Uses a PLC-based control system to automate key process parameters (temperature, pressure, time), ensuring consistent quality. Advanced functions of larger DCS systems are omitted for cost savings.

Localized Components: Fans, motors, cylinders, conveying systems, etc., largely use quality local brands, significantly reducing procurement and maintenance costs while ensuring reliability.

Energy Center

Control System

|

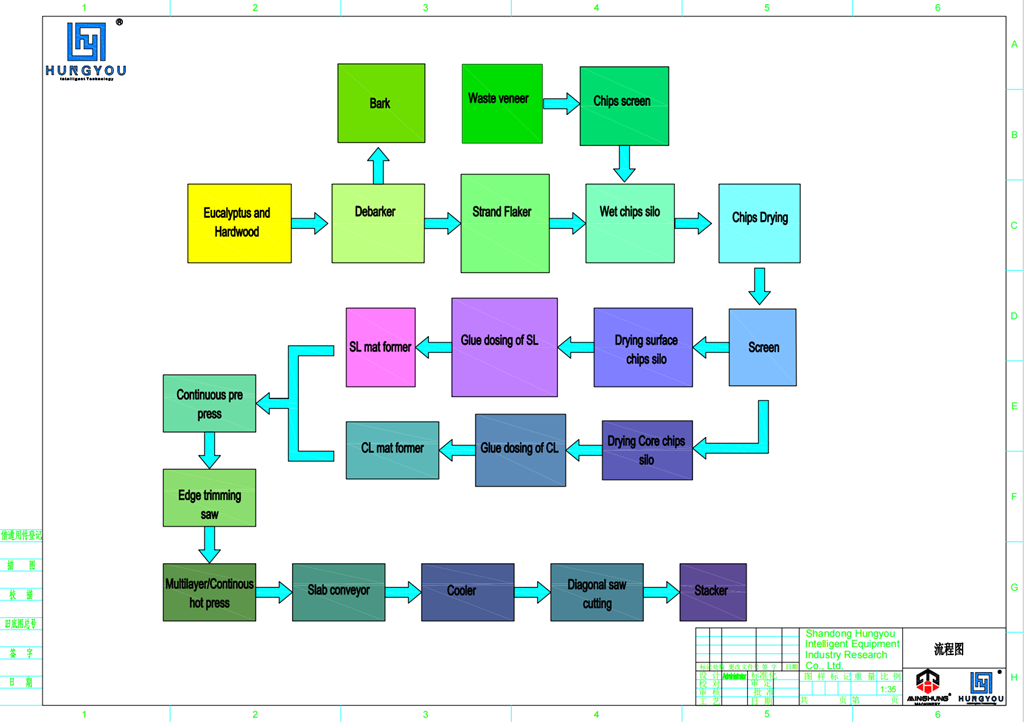

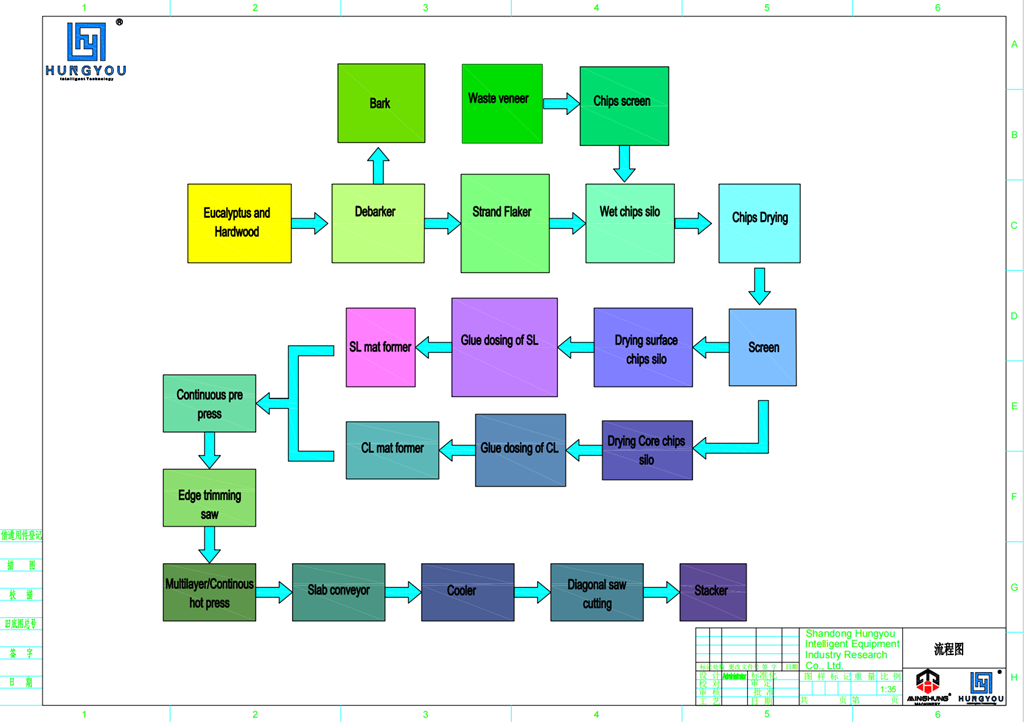

Product process

The core of the low-cost OSB production process lies in: significantly reducing investment and operational costs by optimizing processes, selecting economical equipment and raw materials, while ensuring the product meets basic usage requirements . Its process is similar to high-end production lines but has key differences in critical steps.

1. Raw Material Preparation

Low-Cost Strategy: Does not use expensive, high-quality large-diameter logs, but instead utilizes large quantities of low-cost materials such as small-diameter wood, branches, and wood processing residues (slabs, off-cuts). Fast-growing species like poplar are also used extensively due to their low cost.

2. Flake Production

Process: Raw materials are converted into chips by a disc chipper. These chips are then processed by a flaker into flakes of specified dimensions. Oversized flakes are treated in a crusher.

Low-Cost Strategy: Uses a disc chipper instead of an expensive longwood flaker, sacrificing some uniformity in flake length for a significant reduction in equipment investment.

3. Drying

Process: Wet flakes pass through a rotary drum dryer, where thermal energy (often provided by biomass fuel) reduces their moisture content from ~50% to 3-6%.

Low-Cost Strategy: A biomass thermal energy center is installed to burn waste generated during production (bark, sawdust, sander dust), providing almost free energy for drying. This is the most effective way to reduce operating costs.

4. Blending

Process: Dried flakes are uniformly mixed with adhesive (typically PMDI or MDI), waterproofing agent (wax), etc., in a ring blender.

Low-Cost Strategy: Although PMDI adhesive is relatively expensive, its excellent bonding properties allow for the use of slightly lower-grade raw materials and can reduce the total amount of adhesive needed, making it economical overall. The key is to ensure even blending to avoid waste.

5. Forming

Process: The blended flakes are formed into an oriented mat by a forming station.

Key Low-Cost Strategy Differentiator! Uses a mechanical oscillating forming station. Mechanical forming achieves longitudinal orientation of the flakes through the mechanical movement of oscillating arms. Although the orientation accuracy and uniformity are slightly inferior to pneumatic systems, it is sufficient for applications like pallets and packaging where mechanical performance demands are not extreme. Equipment and maintenance costs are significantly lower.

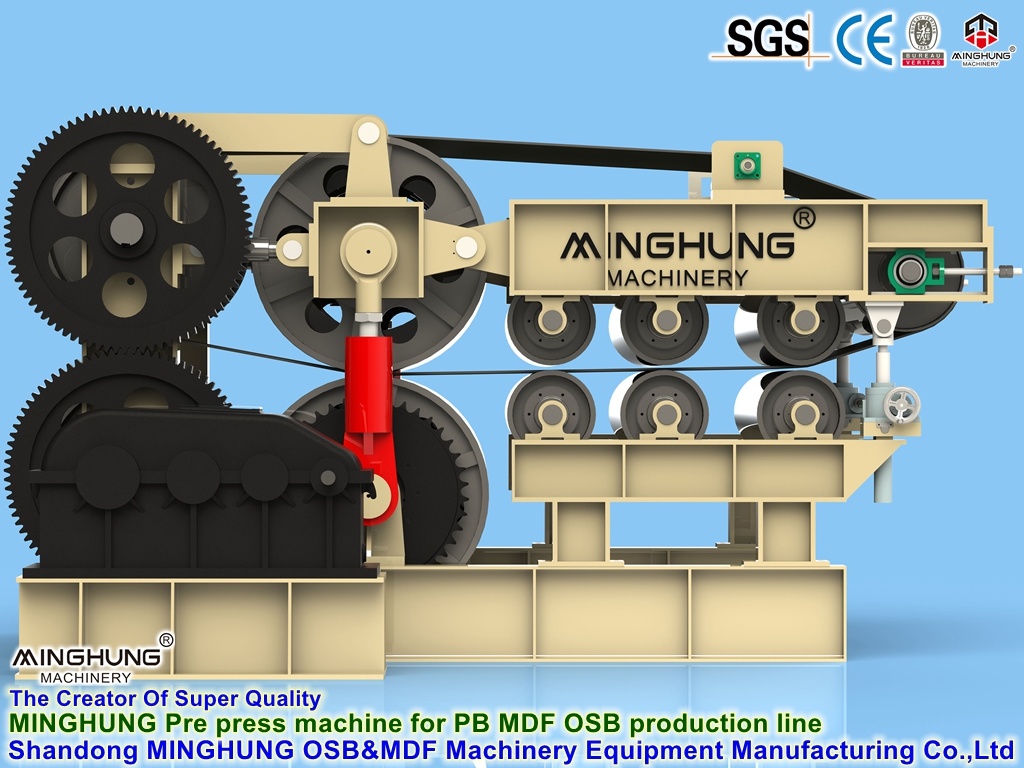

6. Pre-Pressing & Pressing

Process: The mat is initially compacted by a pre-press and then sent to a hot press where the adhesive cures under high temperature and pressure.

Core Low-Cost Strategy Differentiator! Uses a batch-type multi-opening hot press .

Batch presses have very low investment costs but also lower production efficiency, making them well-suited for small to medium capacity scales like "60,000 m³ annual output".

Combined with a no-pallet loading/unloading system, it eliminates the need for expensive pallet return systems, further reducing costs and failure rates.

7. Cooling, Sawing & Sanding

Process: Pressed boards are cooled, cut to standard sizes (e.g., 1220x2440mm) by cross-cut and trim saws, and finally sanded to a precise thickness.

Low-Cost Strategy: This section differs little from standard lines, but equipment configuration focuses more on practicality and reliability than high automation. For example, semi-automatic or manual packaging lines might be used.

|

Application scenarios

The core advantage of low-cost OSB particle board lies in its exceptional cost-performance ratio. Its mechanical properties far exceed those of standard particle board, approaching or even reaching the level of standard OSB, while its price is significantly lower than high-end OSB or plywood. This makes it highly competitive in numerous cost-sensitive applications that require certain structural strength.

1. Logistics & Packaging Industry

Pallets & Dunnage: This is the most core and high-volume application. Pallets, forklift pallets, and packaging liners made from low-cost OSB offer excellent bending strength and nail-holding power, sufficient for multiple reuse cycles. Their durability far surpasses paper or ordinary wooden packaging, while the cost is much lower than plastic or hardwood pallets.

Heavy-Duty Crating: Used for export crates for heavy goods like machinery, electronics, and automotive parts, providing robust protection.

2. Construction & Interior Decoration

Non-Load-Bearing Structures: Used for roof sheathing, wall sheathing, and floor underlayment (subflooring). As a substrate, it provides a flat, sturdy base for external coverings (e.g., metal tiles, asphalt shingles, siding, flooring).

Temporary Facilities & Movable Buildings: Widely used for temporary site fencing, guard booths, and walls/roofs of movable buildings on construction sites. Its low cost, ease of installation, and disassembly make it ideal for these scenarios.

Concrete Formwork: Can be used to make disposable concrete pouring forms. Although the number of reuses is lower than dedicated phenolic-overlaid forms, its extremely low cost is very economical for one-time or low-reuse projects.

3. Industrial & DIY Applications

Shelving & Storage Systems: Used for shelf dividers, storage cabinets, and workbenches in factories and warehouses. Its load-bearing capacity is sufficient for daily storage needs.

Furniture Back Panels, Drawer Bottoms, Cabinet Sides: In furniture manufacturing, used for parts with low visibility and strength requirements, effectively reducing the overall production cost of furniture.

DIY Projects & Creative Works: Popular among DIY enthusiasts for making storage boxes, dog kennels, display racks, stage scenery, and exhibition booths. Its ease of cutting and processing makes it ideal for personalized creations.

|

Company Profile

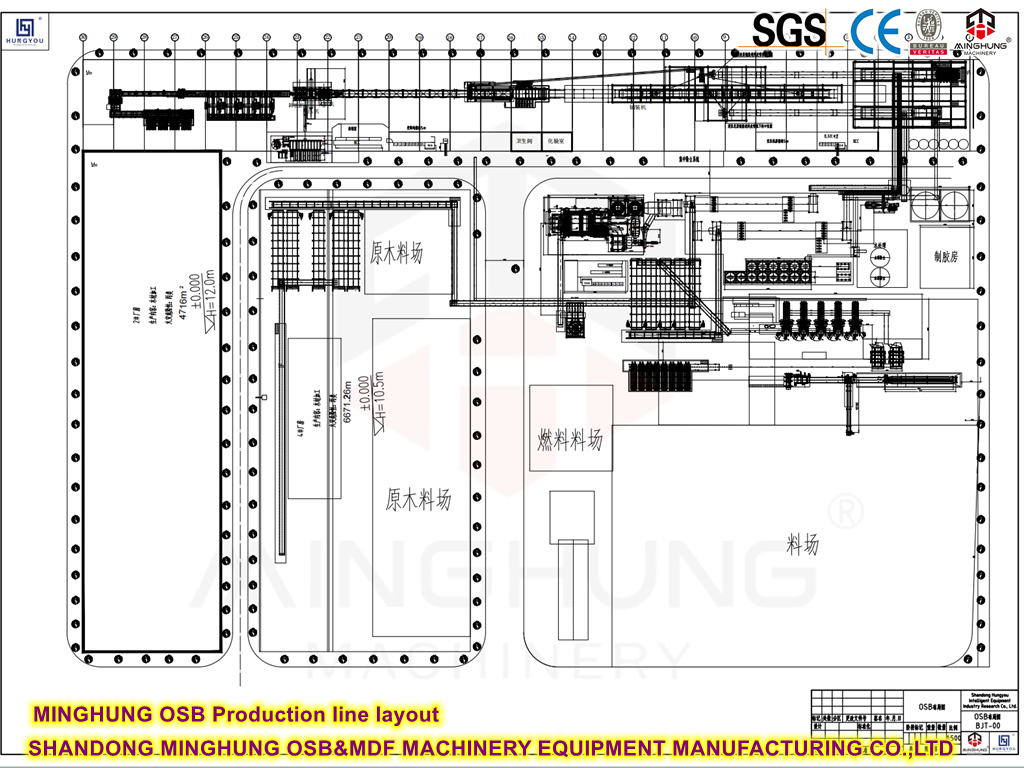

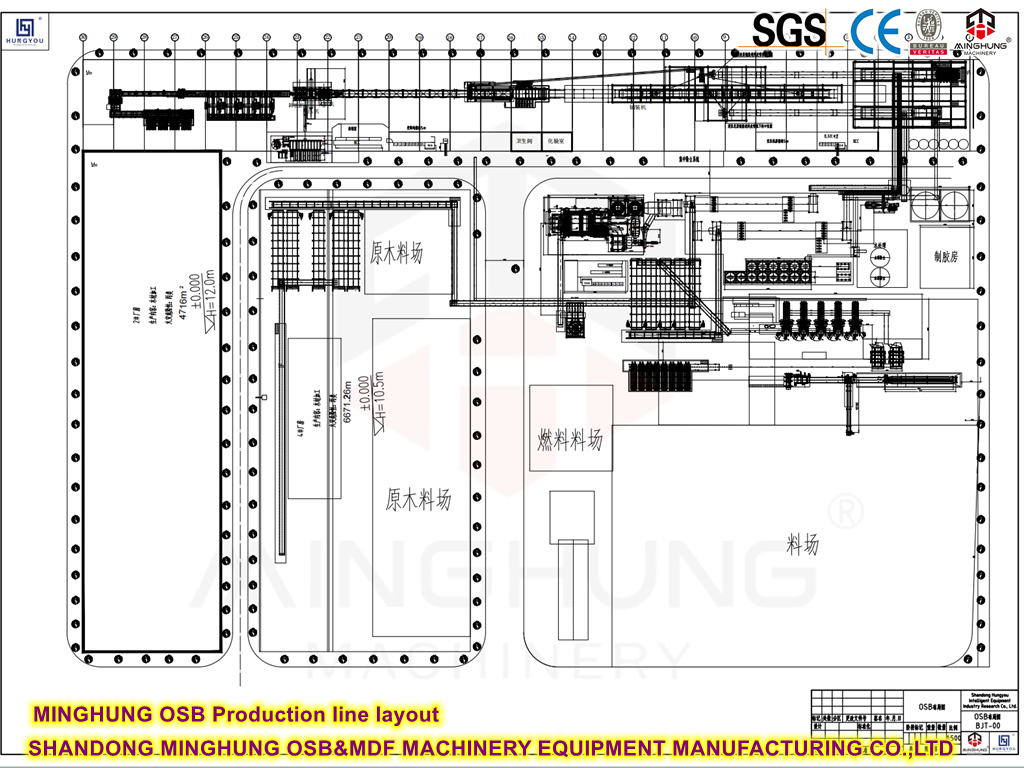

MINGHUNG OSB&MDF Machinery Equipment Manufacture Co., Ltd. Located in Xiaogezhuang Industrial Zone, Yitang Town, Lanshan District, Linyi City.

MINGHUNG Company provides a complete set of process design, electrical design and manufacturing, We can provide one-stop complete factory solutions for wood-based panel customers. MINGHUNG product series include medium density fiberboard (MDF), high density fiberboard (HDF), particle board (PB), oriented strand board (OSB), veneerable super strong particle board (LSB) multi-layer heat press production line, double-sided fixed thickness broadband Sanding machine, gauge saw, mechanical paving machine, air flow paving machine, channel dryer, super screen, post-processing system artificial panel cooling system, turning machine, stacker, storage and transportation trolley. etc. For artificial panel equipment mainly involved in particleboard, medium density fiberboard, oriented strand board, multilayer plywood machinery.

|

Photos of shipping

|

Exhibition

We provide global installation support and technical training, 2-year machine warranty, and 24-hour online response - let your OSB production enter a new era of intelligence and low carbonization.