II. Core Components of Ultra-Thick Board Press

1. Reinforced Frame Structure

Box-welded frame: Bending stiffness ≥5×10⁶ N·m/rad (vs. 3×10⁶ for standard presses)

Column preloading: Hydraulic synchronous tensioning system (preload error <±1%)

2. High-Pressure Heating Platens

Parameter | Specialized Design | Standard Press |

Number of zones | 60–80 zones (lengthwise) | 30–50 zones |

Max. working pressure | 70 MPa (inlet zone) | ≤50 MPa (inlet) |

Temperature uniformity | ±1.5°C (micro-channel oil + PID control) | ±3°C |

3. Anti-Deflection Steel Belts

Reinforced alloy belts: Thickness 12–15 mm (vs. 8–10 mm standard), pre-tension 8 kN/cm

Surface treatment: Laser texturing + tungsten carbide coating (HV1200 hardness)

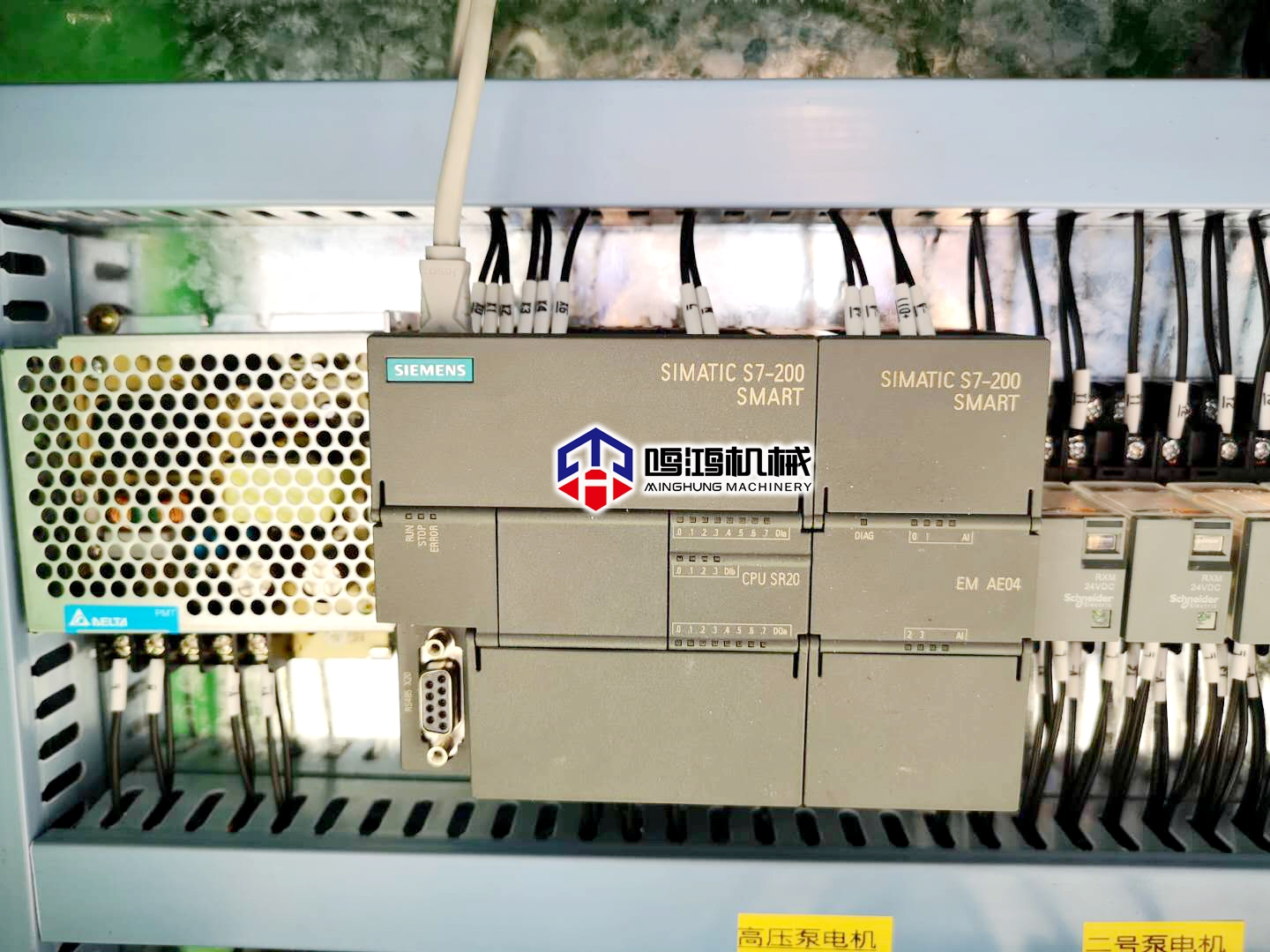

4. Intelligent Thickness Control

Gamma-ray density profiler: Scans cross-sectional density every 2 seconds

Hydraulic servo closed-loop: Dynamically adjusts zonal pressure based on density data