Production Line Overview

This line is a technologically advanced, highly automated, large-scale specialized system for Medium Density Fiberboard (MDF) production, engineered with the core objectives of "Super High Efficiency" and "Superior Machinability". Boasting a remarkable capacity of 1000 cubic meters per day, it specializes in producing high-quality 6mm thick MDF boards. By integrating state-of-the-art hot pressing, fiber treatment, and precision control technologies, the boards produced are renowned for their excellent internal bond (IB) strength, exceptional density uniformity, and smooth surface quality. They are specifically designed for downstream high-speed sawing, CNC routing, and precision cutting, making this line the ultimate solution for large-scale furniture manufacturing and decorative molding industries.

| Advantages & Features |

1. Remarkable Productivity & Output:

1,000 m³/Day Output: The high daily capacity meets the demands of global large-scale projects and stable bulk orders, providing clients with unparalleled economies of scale and market responsiveness.

Continuous Stable Operation: The use of a continuous press as the core enables seamless production from forming to pressing and unloading, minimizing efficiency losses associated with batch processing and ensuring stable output.

2. Exceptional "Fast-Cutting" Board Properties:

Optimized Fiber Quality: A high-precision defibrator delivers long and elastic high-quality fibers. Combined with precise resin and wax application, it ensures strong inter-fiber bonding, which is the foundation for resistance to chipping and tearing during rapid machining.

High IB & Density Uniformity: An advanced pendulum feeder and precise pre-pressing form a uniform and consistent mat. Coupled with the gradient pressure and temperature control of the continuous press, this results in optimal density distribution throughout the board's thickness. This guarantees smooth and clean edges on both the top and bottom surfaces during high-speed cutting, effectively minimizing "bottom-side chipping" and "top-edge tear-out".

Superior Surface Quality & Sanding: The multi-head heavy-duty calibrating sander at the line's end precisely controls the final board thickness (e.g., 6mm±0.1mm) and provides a flawless, double-side smooth surface, ideal not only for fast cutting but also for subsequent laminating, direct printing, or painting.

3. High Automation & Intelligent Control:

Full-Line Central Control: Based on industrial computers, PLCs, and SCADA systems, it enables centralized monitoring and intelligent adjustment of the entire process from chipping to sanding, ensuring optimal process parameters are maintained.

Online Quality Monitoring & Feedback: Integrated online density gauges, moisture meters, and thickness scanners monitor the mat quality in real-time, providing immediate feedback to adjust forming speed, pressure, and temperature, guaranteeing consistent quality from the source.

4. Energy Saving & Environmental Production:

Efficient Energy Utilization: The drying system is equipped with high-efficiency heat recovery units that reuse flue gas waste heat. The thermal oil system of the continuous press is also optimized for lower energy consumption.

Environmental Compliance: Efficient cyclone and bag-house dust collectors handle process dust. Optional exhaust gas treatment systems can be equipped to ensure emissions meet international environmental standards.

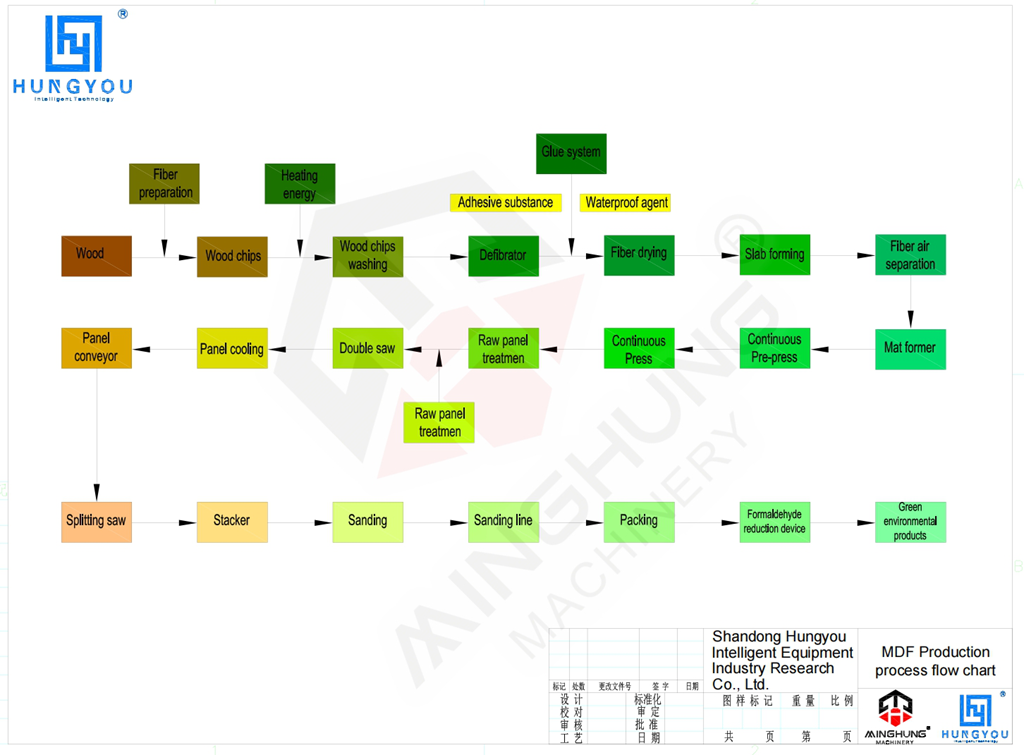

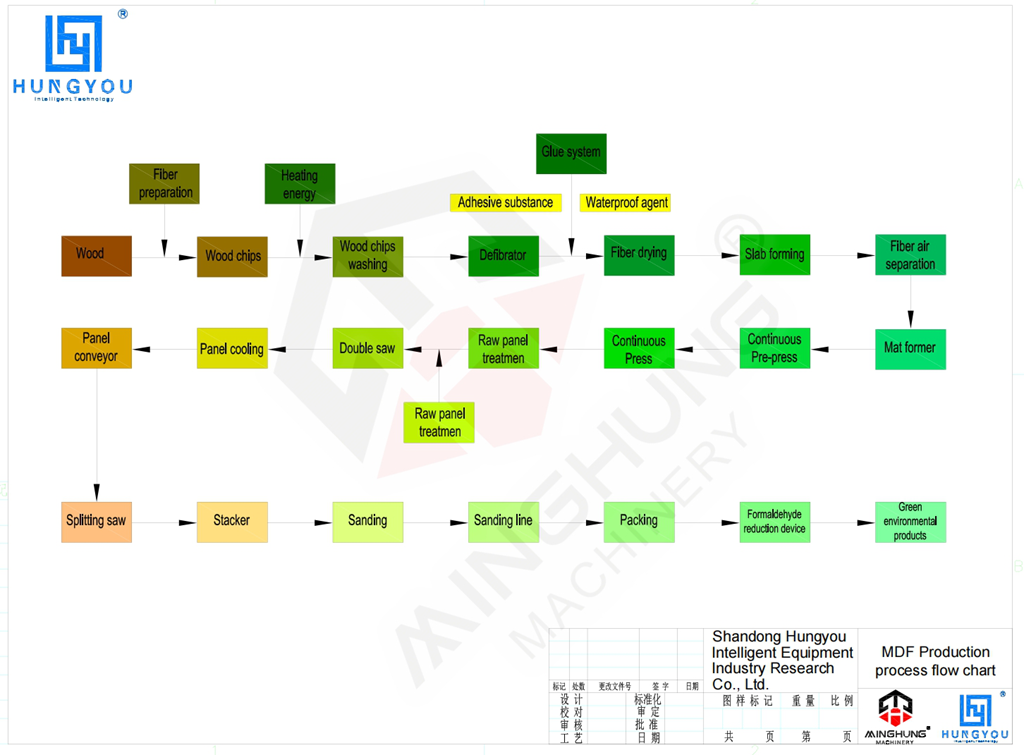

| Process Flow |

The process flow of this production line is a highly continuous and automated operation, designed to efficiently transform raw wood materials into high-quality 6mm fast-cutting MDF. The entire process can be divided into the following four core stages:

Stage 1: Raw Material Preparation and Fiber Treatment

1. Chipping and Screening

Purpose: To convert irregular logs or wood waste into uniform, clean processible chips.

Process: Raw material is fed via conveyor into a Drum or Disc Chipper, where it is cut into small wood chips. These chips then enter a Multi-deck Vibrating Screen. Acceptable chips are screened out and conveyed to the next stage, while oversized chips are sent to a Re-crusher for re-processing. Bark, sand, and other impurities are removed.

2. Fiber Preparation and Resin Application

Purpose: To separate the wood chips into individual fibers and mix them uniformly with adhesives and other additives, forming the foundation for the board's internal bond strength.

Process:

Pre-heating and Steaming: Acceptable chips are softened with low-pressure steam in a pre-heating bin.

Defibration: The softened chips are fed into a High-Precision Defibrator, where they are separated into graded fibers under high temperature and pressure. This is a critical step determining fiber quality and yield.

Resin Application and Drying: The separated fibers are blown into a High-Speed Ring Blender, where they are thoroughly and uniformly mixed with precisely metered urea-formaldehyde resin (or melamine-modified resin), wax (waterproofing agent), and hardener. Subsequently, the fibers are sent into a Pneumatic Tube Dryer, where their moisture content is rapidly and evenly reduced to the optimal range for the process (typically 8%-12%) using a high-temperature air stream.

Stage 2: Mat Forming and Pre-pressing

3. Forming and Pre-pressing

Purpose: To form the dried, resinated fibers into a mat of uniform thickness and dense structure, and to give it initial strength for transport.

Process:

Precision Forming: Dried fibers are spread evenly via an Air or Mechanical Former onto a moving steel belt, forming a fluffy mat of specific thickness and width. Advanced forming technology ensures absolute density uniformity across the width and length of the mat, which is a prerequisite for consistent internal bond strength and excellent cutting performance in the finished board.

Continuous Pre-pressing: The fluffy mat then enters a Continuous Pre-press, where it is initially compacted by large roller pressure to remove internal air, forming a "fiber blanket" with sufficient initial strength for stable, damage-free transport into the hot press.

Stage 3: Hot Pressing and Curing

4. Continuous Hot Pressing

Purpose: To rapidly cure the resin between the fibers under high temperature and pressure, solidifying the loose mat into an MDF board of predetermined thickness and high strength.

Process: This is the core of the entire production line. The pre-pressed mat enters the Continuous Press. Inside the press, the mat undergoes a dynamic curing process under precisely controlled temperature, pressure, and conveyor speed. For 6mm thin boards, the continuous press provides excellent heat transfer and pressure distribution, ensuring the mat cures synchronously from the surface to the core. This results in very high internal bond strength and exceptional density uniformity, which is the decisive factor in achieving "fast-cutting with minimal chipping".

Stage 4: Finishing and Post-processing

5. Cooling, Conditioning, and Trimming

Purpose: To stabilize the board's properties, release internal stresses, and cut it to standard sizes.

Process: The hot pressed boards enter a Star Cooler for uniform, gradual cooling to stabilize their internal structure. The cooled boards are then precisely sawn to standard market sizes (e.g., 1220x2440mm, 1830x2750mm) by Cross-Cut and Trim Saws.

6. Sanding and Inspection

Purpose: To precisely control the final thickness, achieve a perfectly smooth surface, and conduct quality grading.

Process: The trimmed boards enter a Multi-Head Heavy-Duty Calibrating Sander (typically with 4 or 6 sanding heads). Through progressive sanding from coarse to fine grit, the final 6mm thickness tolerance (e.g., ±0.15mm) is precisely guaranteed. The pre-cured surface layer is removed, revealing the dense, uniform internal structure and creating a mirror-smooth surface on both sides, providing the perfect substrate for fast cutting and high-end applications. Finally, finished boards are graded via manual or automated inspection lines.

7. Automatic Stacking and Packaging

Purpose: To enable intelligent warehousing of finished products.

Process: Qualified boards are stacked by grade and specification using a Fully Automatic Stacker. An Automatic Packaging Line then completes the wrapping and strapping, forming neat packages ready for storage and shipment.

| Core Components |

The exceptional performance of this production line relies on a series of its high-tech core components. The core equipment for each section and their functions are as follows:

1. Core Equipment of the Raw Material Handling Section

Drum/Disc Chipper: Responsible for efficiently and uniformly chipping the raw material into wood chips.

Multi-deck Vibrating Screen and Re-crusher: Form the chip screening system, ensuring only properly sized chips proceed further; this is the first checkpoint for guaranteeing fiber quality.

2. Core Equipment of the Fiber Preparation Section

High-Precision Defibration System: One of the "hearts" of the production line. It includes the pre-steaming digester and the main defibrator. Its performance directly determines fiber morphology, yield, and quality, thereby affecting the board's mechanical properties.

Resin Application and Drying System:

High-Speed Ring Blender: Ensures each fiber is uniformly coated with resin and additives, which is key to achieving high-strength bonding.

Pneumatic Tube Dryer: Responsible for rapidly and uniformly reducing fiber moisture content. The stability of its air temperature and velocity critically affects resin application and subsequent forming.

3. Core Equipment of the Forming and Pressing Section

Air/Mechanical Former: One of the "brains" of the production line. Through precise scanning and spreading actions, it forms a mat with highly uniform density, which is core to ensuring consistent board thickness and excellent cutting performance.

Continuous Pre-press: Prepares the mat for entry into the main press, giving it initial strength to prevent deformation or breakage during transport.

Continuous Hot Press: The most expensive and technologically intensive component of the entire line. Using computer-controlled hydraulic systems and heating platens, it achieves precise curing of the mat. It is the absolute core for achieving high output and high-quality thin board production.

4. Core Equipment of the Finishing Section

Star Cooler: Allows the boards to cool slowly and uniformly, preventing warping and internal stress concentration.

Cross-Cut and Trim Saws: Cut the continuous board strip into standard-sized panels.

Multi-Head Heavy-Duty Calibrating Sander: The "beautician" of the production line. Through powerful sanding capability, it precisely controls the final thickness and provides a smooth surface, directly impacting the product's added value and the customer's processing experience.

Fully Automatic Stacking and Packaging System: Enables unmanned operation at the end of the line, enhancing overall automation level and ensuring the finished product's appearance quality.

5. The Nerve Center and Lifeblood

Central Control System (PLC + SCADA): The "nerve center" of the production line. Through sensors and computer systems distributed across the entire line, it performs real-time collection, monitoring, and automatic adjustment of thousands of process parameters, ensuring stable production and consistent quality.

Thermal Energy Plant and Environmental Protection System: The "lifeblood" of the production line. Includes thermal oil heaters, heat recovery units, cyclone separators, bag-house dust collectors, etc. It provides stable heat for production and handles dust and exhaust gases generated during the process, ensuring efficiency and environmental protection go hand in hand.

| Applications of the Finished Board |

Furniture Manufacturing: Used for cabinet doors, backs, and drawer bottoms in panel furniture, suitable for high-speed CNC cutting, drilling, and edging.

Decorative Moldings & Skirting Boards: The ideal substrate for producing various routed and carved decorative moldings and skirting boards, requiring no additional edge filling.

Door Skins & Cores: Used as reinforcing layers for composite door skins and cores, easy to process with high flatness.

Electronics & Display Props: Used for TV back covers, speaker boxes, and shop display cabinets, requiring high machining precision.

Packaging Industry: Used for high-end gift boxes and display inserts.

| Technical Parameters |

Item | Parameter / Description |

Design Capacity | 1000 cubic meters per day (based on 24 hours) |

Primary Board Thickness | 6mm (Adjustable range typically 3mm - 30mm) |

Raw Material | Wood Raw Material (Pine, Poplar, Mixed species chips), Recycled Wood |

Finished Board Density | 720-780 kg/m³ (Adjustable) |

Internal Bond Strength | ≥ 0.75 MPa (Ensuring excellent fast-cutting performance) |

Thickness Tolerance | ±0.15mm or better (After sanding) |

Formaldehyde Emission | Can meet E0, CARB P2, ENF, and other international standards |

Control System | Fully Automatic Centralized PLC Control, supports IIoT & Remote Monitoring |

If interested please contact us for a quote.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com