What is an Industrial Grade Plywood Production System?

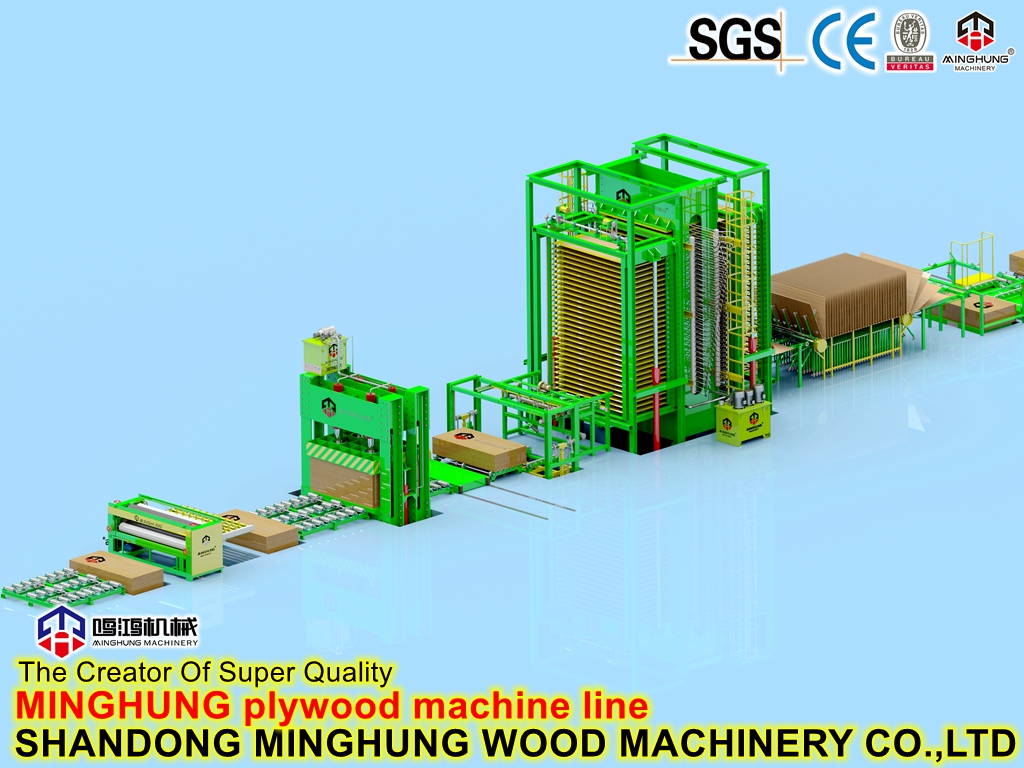

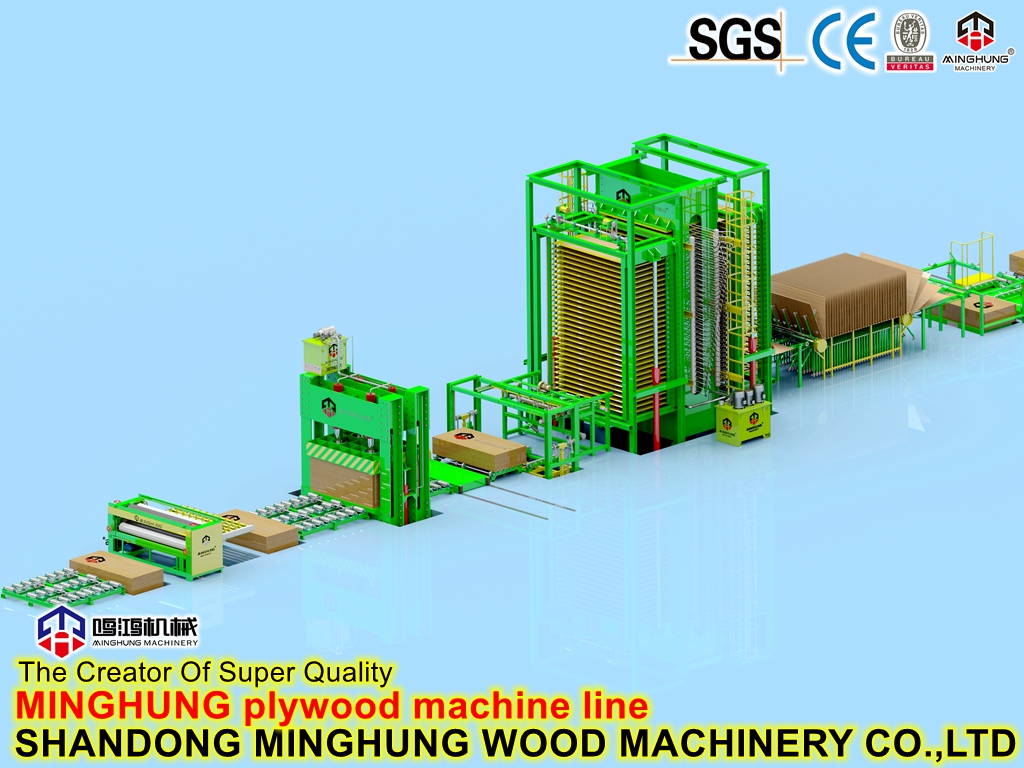

An Industrial Grade Plywood Production System is a comprehensive manufacturing line that integrates mechanical, electrical, hydraulic, and automation control technologies. It is designed to efficiently and consistently transform raw logs into finished plywood of various specifications and grades. Unlike small-scale or semi-automated equipment, this system emphasizes continuity, automation, high output, and stability, representing a "Turnkey Project" solution designed for large-scale industrial production.

This system is capable of meeting the mass production demands for various types of plywood, including construction formwork, furniture panels, and decorative sheets, serving as the core equipment for modern wood processing enterprises seeking industrial upgrading.

| Core System Components & Workflow |

A complete Industrial Grade Plywood Production System typically consists of the following core units, which work in synergy to form a seamless production process:

1. Raw Material Processing Unit

Equipment: Log Debarker, Log Bucking Saw, Log Steaming/Vat.

Function: Pre-processes incoming logs, including removing bark, cutting them into specific lengths as required, and softening the wood through steaming to facilitate subsequent peeling.

debarker

sawmill

2. Veneer Preparation Unit

Equipment: CNC Veneer Peeling Lathe or Slicing Machine.

Function: This is the core of the system. The peeling lathe continuously rotates the log segment and peels it into a continuous sheet of veneer with uniform thickness. Industrial-grade peeling lathes feature high-precision control, ensuring minimal veneer thickness tolerance and maximizing yield.

3. Veneer Drying & Processing Unit

Equipment: Roller Dryer or Mesh Belt Dryer, Veneer Splicer, Veneer Patcher.

Function: Feeds the wet veneer into the dryer to rapidly and uniformly reduce its moisture content to the required standard. Subsequently, through splicing and patching, small or defective veneer sheets are repaired into full sheets, increasing raw material utilization.

4. Gluing & Layup Unit

Equipment: Automatic Roller Glue Spreader, Automatic Layup Line.

Function: The glue spreader uniformly applies urea-formaldehyde, phenol-formaldehyde, or eco-friendly adhesives to the veneer sheets. The automated layup system then precisely stacks the glued veneers and face sheets according to preset layers and grain directions (cross-banding) to form a mat. Automation in this stage is key to ensuring consistent product quality and reducing labor costs.

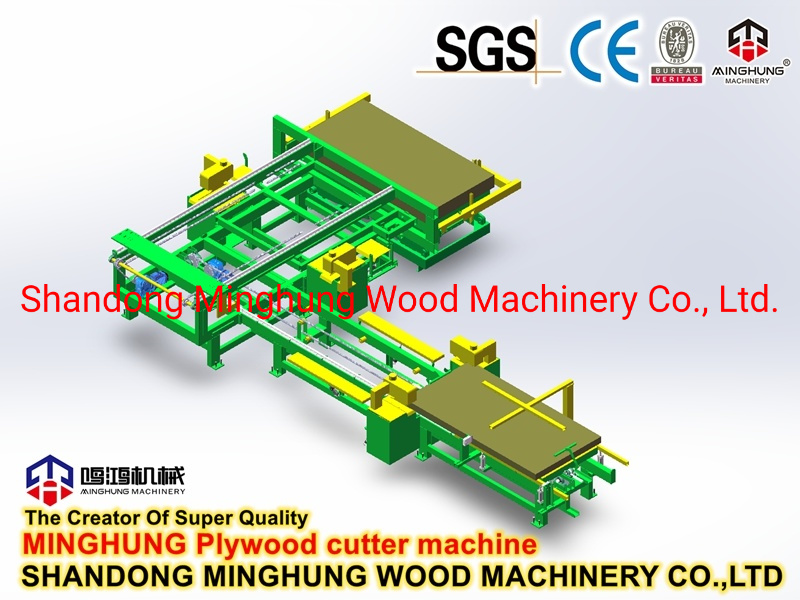

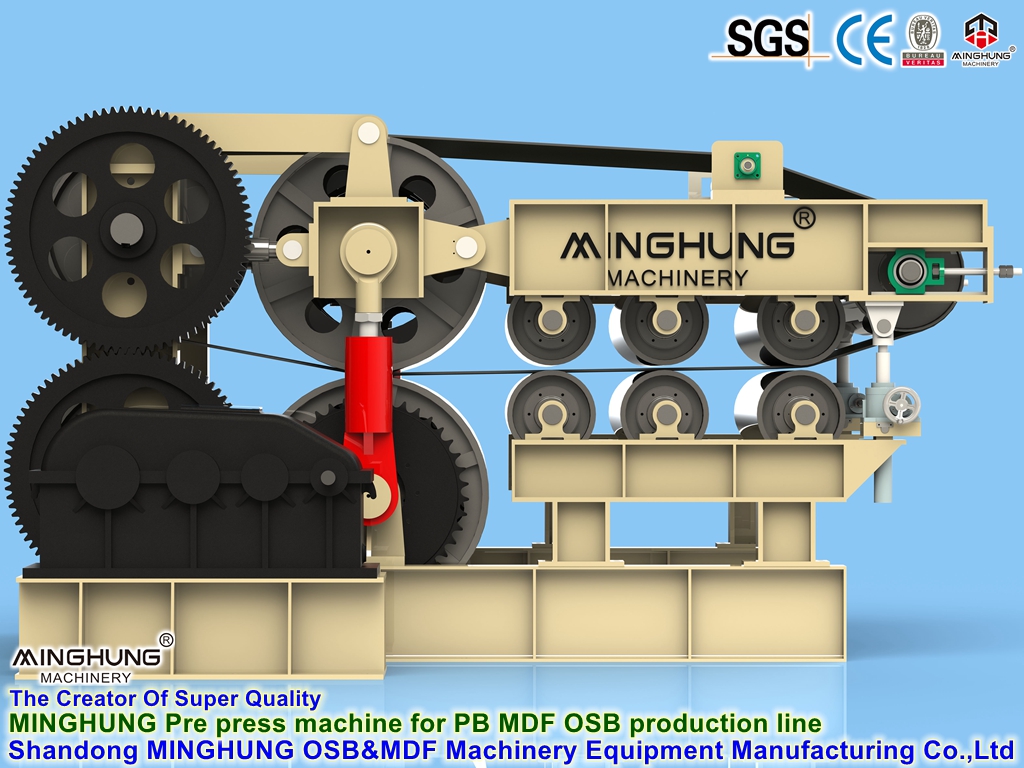

5. Pre-pressing & Hot Pressing Unit

Equipment: Cold Press, Hot Press.

Function: The mat is first pre-pressed in a cold press for initial shaping, allowing the veneer layers to preliminarily bond. It then enters the core hot press, where high temperature and pressure permanently cure the adhesive, firmly pressing the multiple veneer layers into a solid board – the plywood.

cold press

hot press

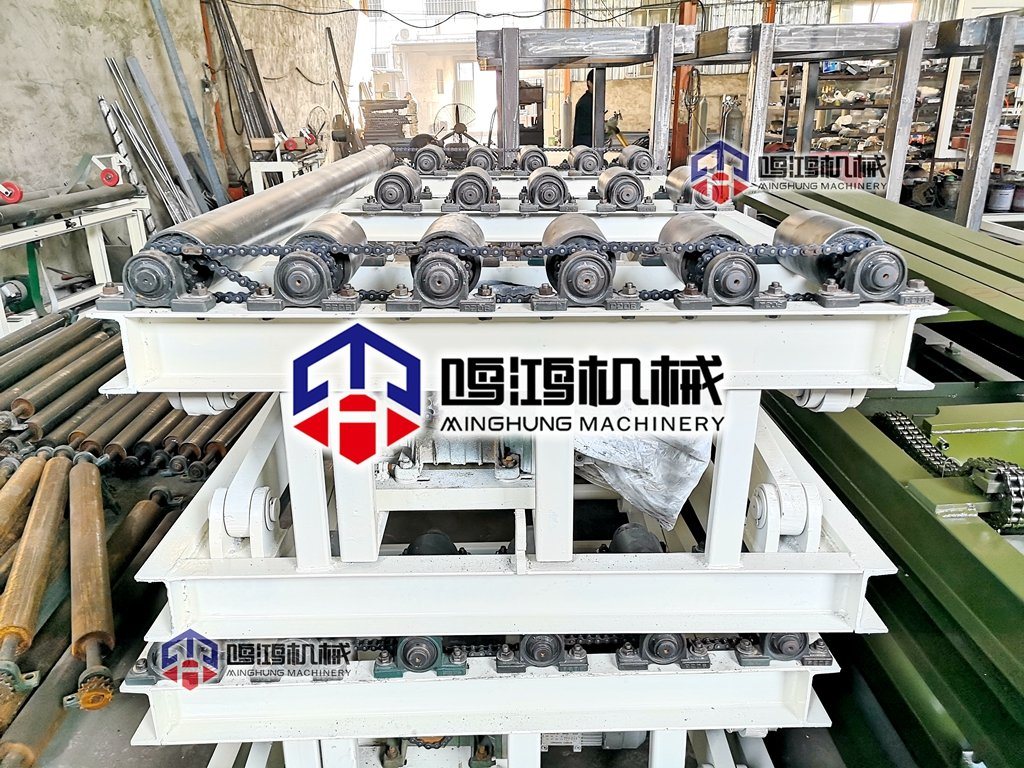

6. Finishing & Handling Unit

Equipment: Double-sided Calibrating Sander, Cross-Cut and Edge Trim Saws, Cooling and Turning Machine, Automatic Stacker.

Function: Sands the pressed rough board to ensure uniform thickness and a smooth surface; precisely cuts it to standard dimensions; finally cools and automatically stacks the finished panels for storage and shipping.

trimming saw machine

sanding machine

7. Intelligent Control System

Function: Acting as the "brain" of the entire system, it uses PLCs (Programmable Logic Controllers) and an HMI (Human-Machine Interface) for centralized control of the entire line. It enables real-time monitoring of equipment status, setting and adjustment of process parameters (e.g., temperature, pressure, speed), and provides fault diagnosis and alarms, ensuring stable and efficient production.

| Key Technical Features & Advantages |

High Degree of Automation & Intelligence:

Minimizes manual intervention from log feeding to finished product stacking.

Centralized control for one-touch operation and digital parameter management ensures product consistency.

Reduces dependence on skilled labor and significantly cuts labor costs and human error.

Exceptional Production Efficiency & Output:

Continuous flow-line operation with fast cycle times and minimal downtime.

Designed for 24/7 continuous operation, achieving massive annual capacity from tens of thousands to hundreds of thousands of cubic meters.

Superior Product Quality & Stability:

High-precision equipment (peeling, sanding) ensures dimensional accuracy and surface quality of veneer and finished boards.

Stable hot-pressing process guarantees bond strength, flatness, and compliance with international standards for metrics like formaldehyde emissions (e.g., CE, CARB, E1/E0).

High Raw Material Utilization Rate:

Precise peeling control reduces veneer breakage.

Automatic patching and splicing technology converts off-cuts and waste into usable material, directly improving economic effectiveness.

Robust Reliability & Durability:

Key components utilize renowned brands (e.g., Siemens, ABB, Schneider for electrics; Rexroth for hydraulics).

Sturdy construction and long design life withstand the harsh demands of industrial environments, ensuring long-term stable operation.

Energy Saving & Environmental Protection:

Incorporates energy-efficient dryers and hot presses with effective insulation.

Dust collection and exhaust gas treatment systems are available as options to meet environmental emission standards.

| Market Applications |

Construction Industry: Producing overlaid formwork, concrete shuttering panels.

Furniture Manufacturing: Producing substrate for office furniture, cabinets, wardrobes.

Interior Decoration: Producing substrate for decorative panels, flooring underlayment.

Packaging & Transport: Producing packing case boards, container flooring.

Other Industrial Uses: Interior panels for vehicles and vessels.

| Why Choose Our System? |

We provide not just equipment, but a comprehensive productivity solution:

1. Customized Design: We tailor the optimal production line solution based on your raw materials (poplar, pine, eucalyptus, etc.) and target products.

2. Turnkey Project: We offer a one-stop service from plant layout and equipment installation to commissioning and personnel training, ensuring a smooth project launch.

3. Continuous Technical Upgrades: We consistently focus on industry-leading technologies, offering clients ongoing process optimization and equipment upgrade advice.

Investing in our Industrial Grade Plywood Production System is an investment in your company's core competitiveness for the next decade—delivering higher efficiency, superior quality, and lower total operating costs.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com