This production line is used for manufacturing midium density fiberboard (MDF)/ HDF with capacity of 100cbm-400cbm per day. Output size: thickness 10mm-30mm, common size 4x8ft (1220x2440 mm) and 6x9ft (1830x2745 mm). MINGHUNG is one of the best MDF/HDF plant supplier and has its own strength in key technology of chipping/refiner/ drying and sifting/ mat forming and sanding.

MINGHUNG MDF plant is good in its stable running quality and over production capacity. Sufoma gets strong aftersales service team for either plant optimization or capacity upgrade modifications.

|

Product Packaging

|

Company Profile

1)We China manufacturer and supplier of Particle board making machine+ MDF board making machine +OSB board making machine. if you want to produce these board, we can offer you the full necessary production line. With many years production experience, and adhere to continuous innovation and improvement, with specialized R&D center, obtained a number of research and development patents, with experienced technians and engineers, and professional sales team and after-sales team, We have beome one China's high-end Wood based panel machinery manufacturing enterprise.

2)For us, we know clearly that only keep machine good quality, can let us develop longer and better. Therefore, we always keep to choose good material and parts to make our machine, and during the whole machine production process, be made by experienced workers, and through many times test and monitor, to make sure each production step is good, to make sure the whole machine is good.

|

Production Process

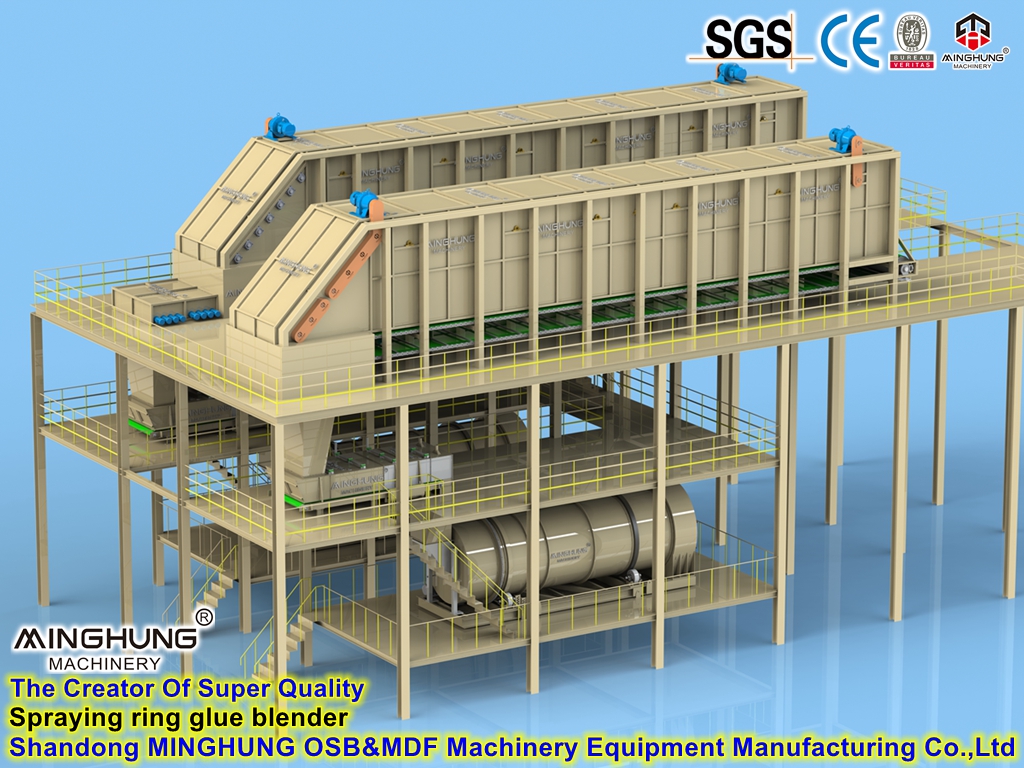

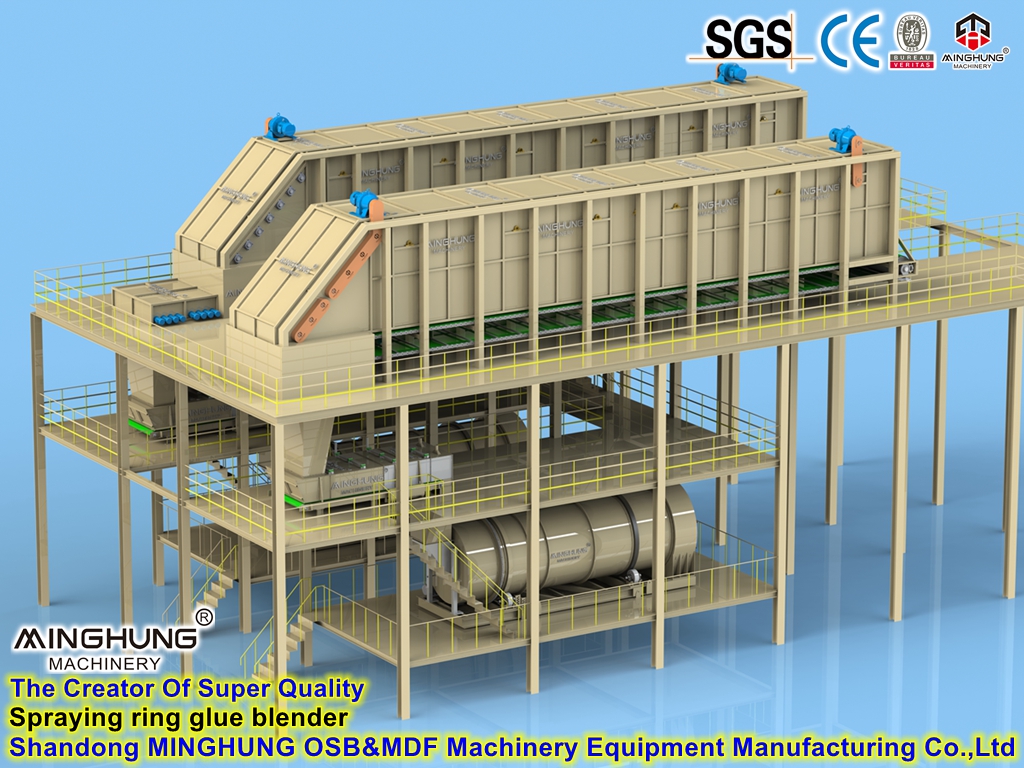

GLUE BLENDING MACHIEN

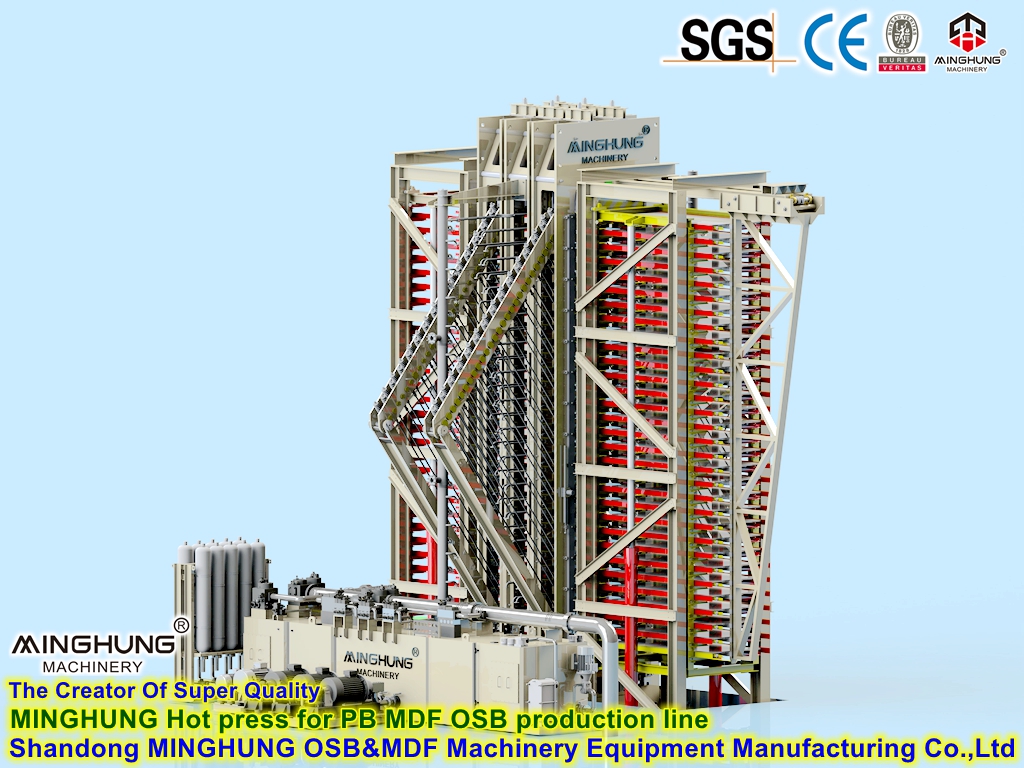

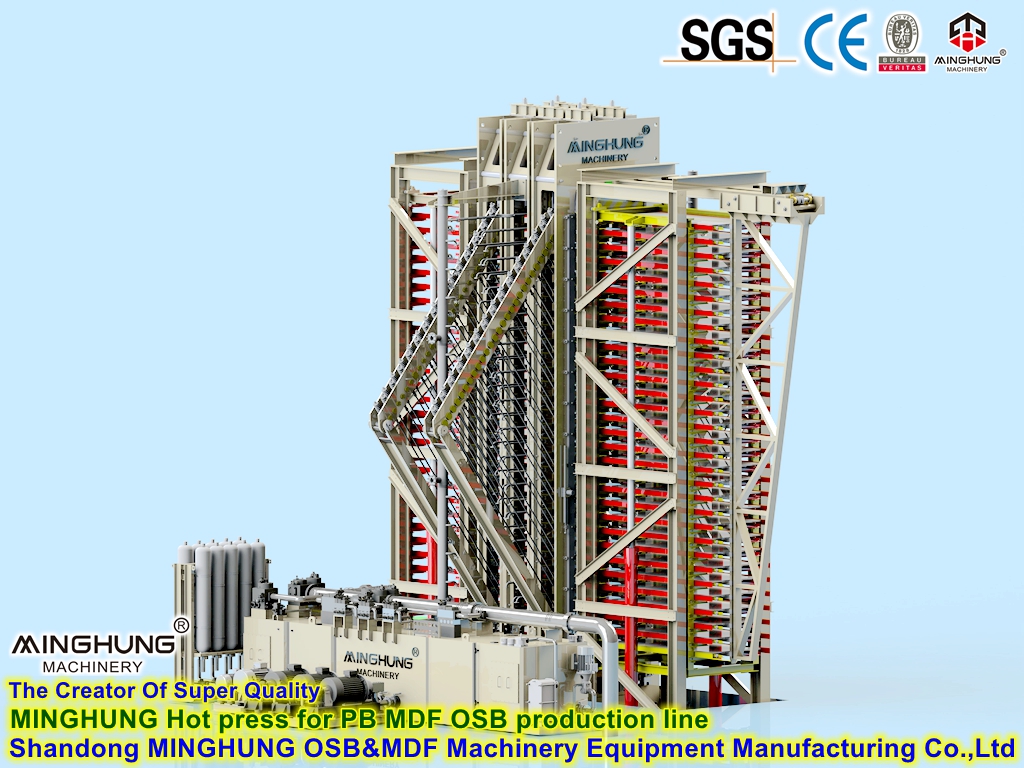

HOT PRESS MACHINE

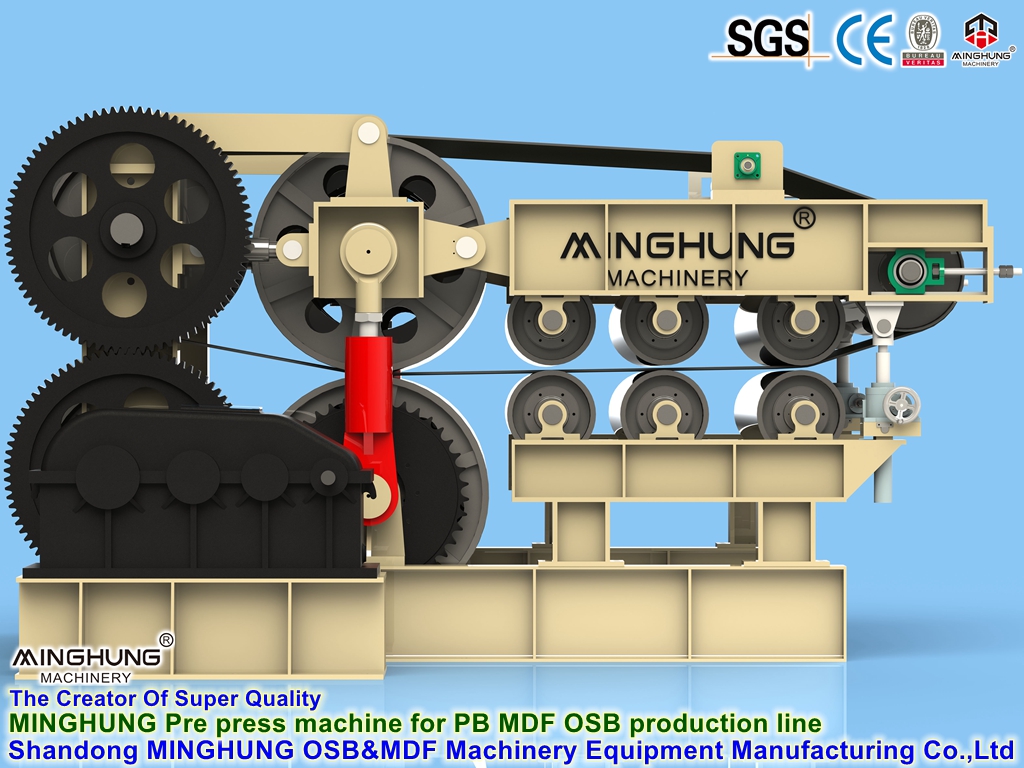

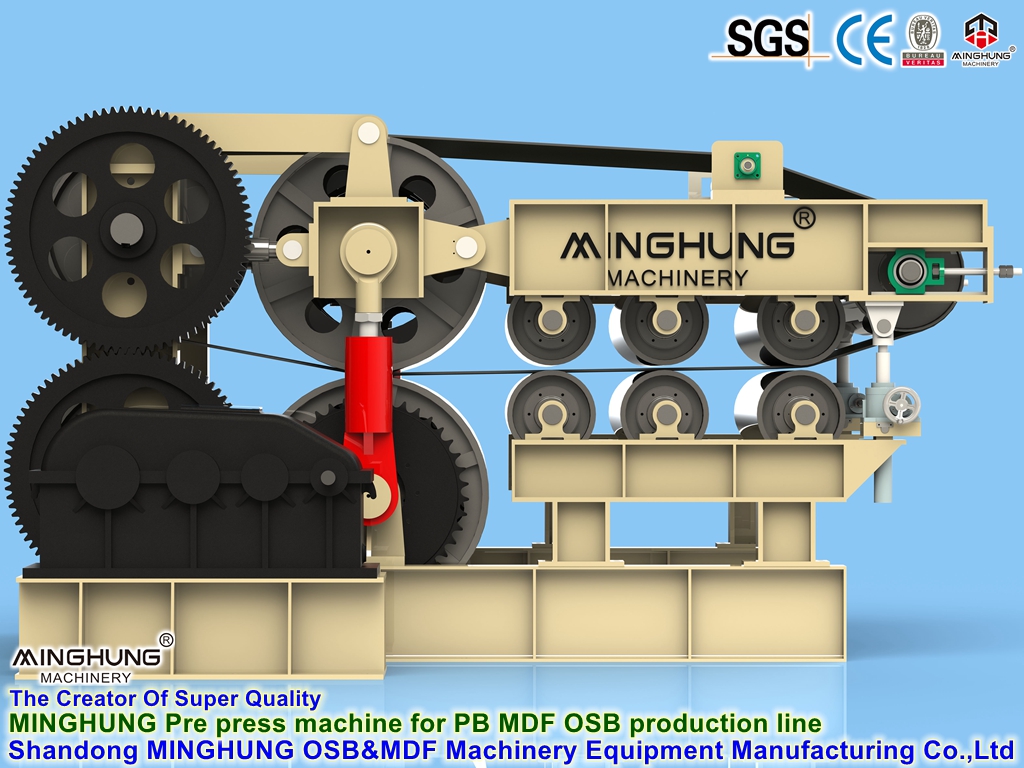

PRE PRESS MACHINE