Oil boiler

Three main processes are going on in the boiler: (1) The fuel is burned in the furnace, and its chemical storage can be released in the form of heat energy, which makes the flame and combustion products (flue gas and ash) have high temperature. (2) The high-temperature flame and flue gas transfer heat to the working fluid (heating medium) through the "heating surface". (3) The working medium (heat medium) is heated, and its temperature rises or evaporates into saturated steam, or is further heated to become superheated steam. The above three processes are interrelated and carried out simultaneously, realizing the conversion and transfer of energy. Along with the conversion and transfer of energy, there is also the flow and change of matter. Water-steam system, coal-ash system and wind-smoke system are the three main systems of the boiler, and the work of these three systems is carried out simultaneously. Generally, the processes on the fuel and flue gas side (including combustion, heat release, slagging, gas flow, etc.) are collectively referred to as "furnace processes"; the processes on the water and steam side (water and steam flow, heat absorption, vaporization, steam-water separation, thermochemical process, etc.) collectively referred to as "pot process

General concept 1. Calorie: Calorie is a process quantity. In daily life, some intuitive concepts such as hot water and hot weather are more common, but how is calorie measured? Rule: At atmospheric pressure, one kilocalorie is the amount of heat required to raise the temperature of one kilogram of water by one degree Celsius. 1cal= 2. Temperature: Temperature is the degree to which an object is hot or cold. In engineering, the Celsius temperature scale and the thermodynamic temperature scale (absolute temperature scale) are generally used to measure the atmosphere. The temperature on the Celsius scale is represented by "t", and the unit is degrees Celsius (°C). Under standard atmospheric pressure, the freezing point of pure water is 0°C and the boiling point is 100°C. The thermodynamic temperature scale is also known as the Kelvin scale, represented by "T", and the unit is Kelvin (K). Under standard atmospheric pressure, the freezing point of pure water is , and the boiling point is . The temperature 1°C of the Celsius temperature scale is numerically equal to the temperature 1K of the thermodynamic temperature scale, and the relationship is T=t+ 3. Pressure: Pressure refers to the vertical force exerted on a unit area. The units often used in engineering are: Pa (Pa), MP (MPa).4. Some concepts about water vapor a. Saturated water: When water is heated to a certain temperature, it starts to boil. The temperature at this time is called saturated temperature, and water is called saturated water; Saturated steam is called dry saturated steam; c. wet saturated steam: saturated steam containing moisture is called wet saturated steam; d. steam dryness: refers to the percentage (%) of dry saturated steam in wet saturated steam; e. vaporization Latent heat (r): the heat required to heat one kilogram of saturated water under constant pressure to completely vaporize into dry saturated steam at the same temperature, or the heat released by condensing the dry saturated steam into saturated water at the same temperature, called is the latent heat of vaporization; f. Superheated steam: When the dry saturated steam is heated at a constant pressure, the steam temperature starts to rise from the saturation temperature to the specified superheated temperature. Such steam is called superheated steam.Flash point is an important indicator to avoid oil fire. When the oil is stored in an open container, the oil temperature is at least 10°C lower than its flash point to be safe. In pressure vessels and piping, since there is no free liquid surface, it is not restricted. e. Freezing point: The temperature at which oil loses its fluidity is called the freezing point. The freezing point is related to the amount of wax in the oil. The higher the wax content, the higher the freezing point; the more jelly-like substances in the oil, the higher the freezing point. Freezing point is the main indicator of oil storage and transportation. 2. The gas fuels commonly used by gas boilers refer to three categories: natural gas, liquefied petroleum gas and artificial gas. Gas fuels generally contain combustible gases such as hydrocarbons, hydrogen, and carbon monoxide with low molecular weight, and are often accompanied by non-flammable gases such as carbon dioxide and nitrogen. The output of gas-fired boilers is calculated based on natural gas calorific value 8500kcal/Nm3, liquefied petroleum gas calorific value 24000kcal/Nm3, and city gas 4000kcal/Nm3

more about boiler contact us:

whatsapp: +8618769900191 +8615589105786 +8615805493072

website: www.plywoodmachineline.com

email: minghungmachinery@gmail.com

Heat transfer oil boiler operation rules

Heat transfer oil boiler operation rules

1. Automatic control of the burner (collecting the oil temperature sensor at the outlet)

When the boiler outlet oil temperature is lower than the set lower limit of outlet oil temperature and the oil pressure difference between inlet and outlet is normal, the first stage fire and the second stage fire of the burner are automatically started;

When the boiler outlet oil temperature is higher than the set outlet oil temperature upper limit of -5°C, the second stage fire of the burner is turned off, and the first stage fire remains in the state;

When the boiler outlet oil temperature is higher than the set outlet oil temperature upper limit, turn off the first stage and second stage of the burner;

2. Automatic control of oil injection pump (collecting oil tank oil level float ball normally open point)

When the oil level in the high oil tank is low, the oil injection pump is automatically started;

When the oil level in the high oil tank is high, the oil injection pump is automatically turned off.

3. Automatic control of circulating pump

When the system goes to work, the circulating pump is turned on until the system is turned off after get off work;

When the system is off work, when the outlet oil temperature is lower than 100°C and the temperature difference between the inlet and outlet oil is less than 20°C, the circulating pump is turned off.

4. Automatic control of the oil pump (collecting the oil level floating ball normally open point of the daily fuel tank)

When the oil level of the daily fuel tank is low, the fuel pump will be started automatically;

When the oil level of the daily fuel tank is high, the fuel transfer pump is automatically turned off.

Fault automatic processing 1. The outlet oil temperature over-temperature fault

When the outlet oil temperature exceeds the set outlet oil temperature upper limit of 20°C or exceeds 350°C, the computer will flash to display the over-temperature temperature, and the controlled equipment will be forced to shut down.

2. Flue temperature over temperature fault

When the flue temperature exceeds the set limit temperature of 300 ℃, the flue over-temperature indication will be displayed, and the controlled equipment will be turned off.

3. Low differential pressure fault (collect external differential pressure gauge)

When the oil pressure between the inlet and outlet of the boiler is lower than the set pressure difference, the computer will indicate a fault and the controlled equipment will be forcibly shut down.

4. Overpressure fault (collect external pressure gauge)

When the boiler oil pressure is higher than the set high pressure point, the computer fault indication will force the controlled equipment to be shut down.

5. Power failure prompt

When the system grid voltage exceeds the normal operating range (180V-260V), the screen will prompt for fault, and the equipment will not be interlocked.

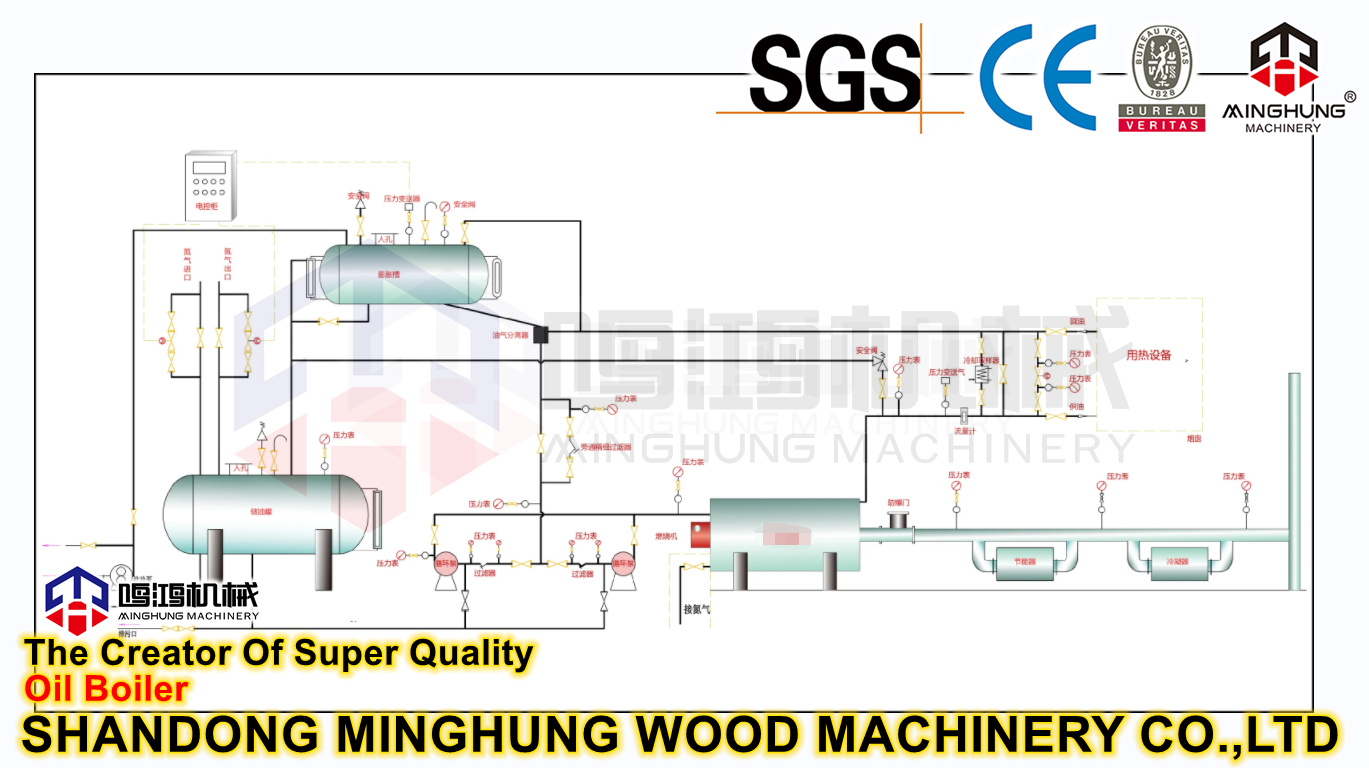

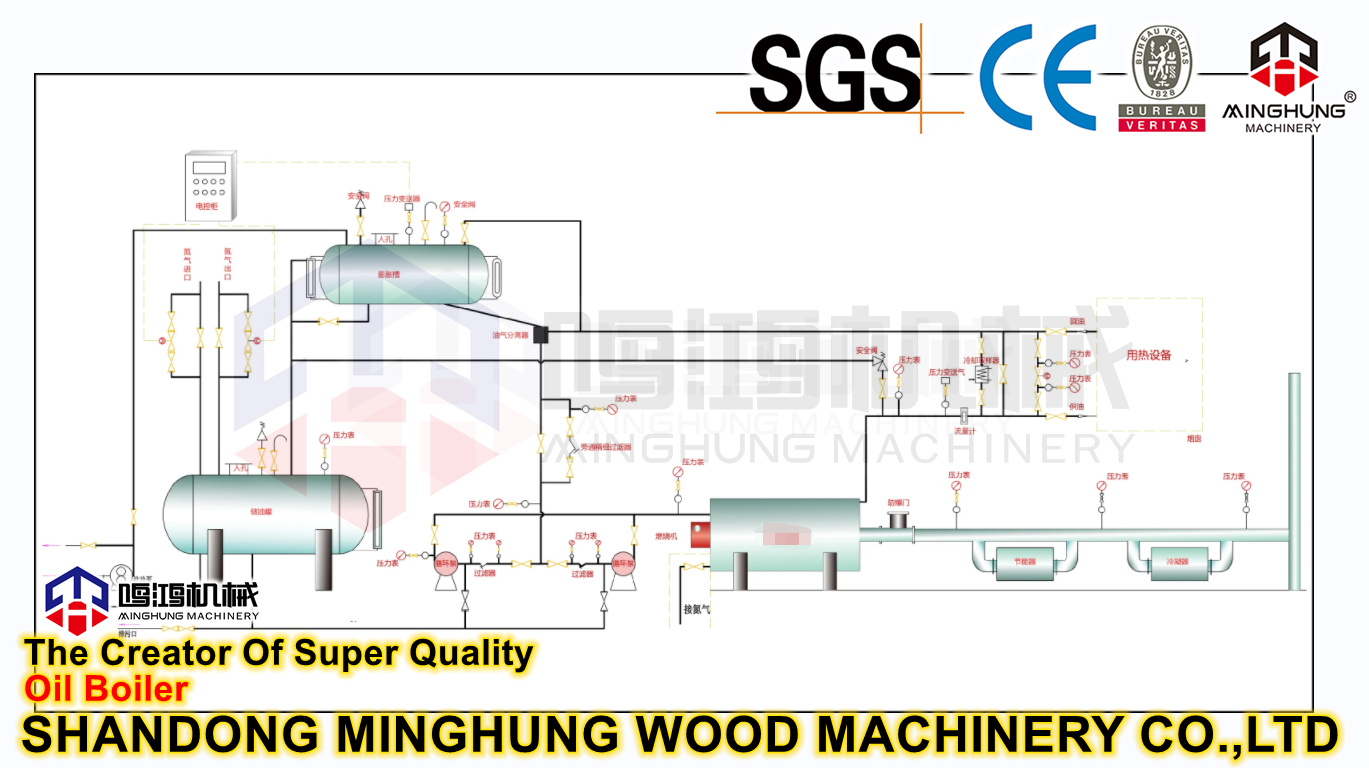

Heat transfer oil boiler installation diagram Heat transfer oil boiler operating procedures:

1. Inspection before starting 1. Whether the heating furnace and its surroundings are clean and free of debris, check whether the furnace body, burner, controller, fire hole, chimney (chimney), etc. are normal; 2. Reverse process equipment and process , Check whether the oil level of the expansion tank is above 1/4-1/2 liquid level, and whether the thermometer and pressure gauge are normal; 3. Turn on the power supply of the heating furnace control cabinet, check whether the voltage is normal, check the indicator lights and various display instruments 4. Adjust the main gas pressure reducing valve and secondary pressure reducing valve so that the pressure is controlled to 0.005 MPa.

2. Start 1. Start the heat transfer oil circulating pump (run one and prepare one, refer to the operation rules of the water pump). After starting the pump, it will circulate normally for about 0.5 hours to make the pressure stable; 2. Press the burner start button to observe whether the furnace flame is burning normally. If there is no ignition, the burner should be started again after troubleshooting.

3. Shutdown operation 1. Shutdown normally ①Reduce the temperature gradually, turn off the burner, and stop the combustion; ②When the temperature of the hot oil drops below 70℃, stop the operation of the hot oil circulating pump (refer to the operation rules of the water pump); ③Turn off The total power supply, make a shift record. 2. Emergency shutdown If the furnace is urgently shut down due to an emergency, the burner should be turned off quickly, and the burner should be moved along the hinge axis of the burner to form a natural ventilation state between the furnace and the chimney, and dissipate the heat stored in the furnace. , so that the heat transfer oil cools naturally and prevents overheating.

Fourth, matters needing attention 1. During the patrol inspection, attention should be paid to check whether there is leakage around the heat transfer oil furnace. There should be enough oil and electrical fire-fighting equipment nearby, and water is not allowed as a fire extinguishing agent.

Safety countermeasures for heat-conducting oil boilers (1) Ensure equipment safety

The heat transfer oil heating system should be managed as pressure equipment, and it is necessary to ensure that the heating equipment is in good condition, otherwise the consequences will be very serious. During use, the wall thickness and compressive strength of the equipment should be checked regularly, and pressure gauges, safety valves and venting pipes should be installed on the equipment and pipelines.

(2) Strict and safe operation

When using a heat-conducting oil furnace, the temperature should be strictly controlled not to exceed 350 °C to prevent the temperature from rising and overpressure, which may cause danger. In order to avoid overheating of the pipe wall of the heating surface of the heat transfer oil, the flow of the heat transfer oil should be in a turbulent state, that is, the Reynolds number Rc>10000, and have a certain flow rate to reduce the thickness of the boundary layer when it flows through the heating surface. The circulation pump of the heating medium is not allowed to stop during the heating operation. When the heat load is reduced or temporarily disabled, the bypass return regulating valve should be opened to adjust the system flow, so that the heat transfer oil in the pipe has sufficient flow and flow rate.

When the heating furnace is started, the heating surface tube and the empty tube of the system pipeline should be preheated. When starting to ignite and heat up, due to the low temperature of the heat transfer oil, high viscosity, low flow rate and thick film layer, the heating rate must be strictly controlled, generally below 40~50℃/h to avoid local overheating. When the temperature of the circulating heat-conducting oil is high but the temperature of the heat-using equipment does not rise, the outlet temperature of the heat-conducting oil cannot be raised blindly, but the reasons should be found from the heat-using equipment, such as fouling, blockage, etc. When using heat transfer oil for heating, attention should be paid to the relationship between temperature and pressure at the beginning of driving. If the pressure is too high and the temperature is too low, it means there is water, and it should be exhausted in time; if the pressure is too low and the temperature is too high, it means that the amount of heat transfer oil is insufficient, and heat transfer oil should be added. When the system stops running, the circulating pump of the heat transfer oil should continue to run for a period of time. After the heat carrier is cooled, put all the heat transfer oil in the system back into the storage tank, especially the heating surface must not be left behind.

(3) Prevent the heat transfer oil from mixing with water or other impurities

It is strictly forbidden to mix water or other low-boiling impurities and flammable and explosive substances into the heat-conducting oil. When driving, the water in the system should be drained first, then the intake valve and the check valve should be opened, and the temperature should be raised to remove the water in the heat carrier; the newly replaced or added heat transfer oil must be preheated and dehydrated before it can be added; In case of moisture, the air valve should be opened first, and then the temperature of the heat transfer oil should be raised to 150℃ with a heating rate of 5℃/h on a small fire, so that the moisture can evaporate and escape. Then close the vent valve, and heat it up to 250°C at a heating rate of 10°C/h. During the heating process, if you hear the sound of water hammer or see that the pressure is too high, you should immediately open the large vent valve to expel the water vapor, and then close the vent valve to drive. When the furnace is shut down, the heated material should be released and then the steam valve of the heat transfer oil furnace should be closed to prevent the material from leaking into the system.

(4) Remove coking and scaling

In production practice, it is safe for the coking thickness to be less than 2 mm, and the coking layer in the furnace tube is between 0 and 1.5 mm. At this time, the continuous accumulation of the coke layer is roughly balanced with the melted amount washed by the heat carrier. The thickness of the coke layer in the furnace tube can be measured with an ultrasonic thickness gauge.

A filter should be installed at the inlet of the circulating pump to filter out the suspended polymer and carbon particles precipitated by local overheating caused by chemical changes. The filter should be easy to disassemble and replace, so as to regularly clean up the slag and impurities to ensure the filtering effect.

(5) Strengthen safety management

It is necessary to pay attention to the formulation and implementation of technical specifications for the operation of heat transfer oil heating equipment and management regulations, and strictly abide by relevant laws and regulations and safety operation rules. There should be a complete emergency response plan for the heating operation of the heat transfer oil, especially to prevent the occurrence of material overflow, spray material, material leakage, and overloaded operation.

(6) Set up safety devices and fire-fighting facilities

Set the temperature, pressure, flow, liquid level automatic adjustment system, alarm system and safety relief device to ensure that the instruments and meters are sensitive and easy to use. During the heating operation, if the pressure suddenly rises, the vent valve should be opened immediately to relieve the pressure, and the valve of the heating medium pipeline leading to the heating equipment should be closed.