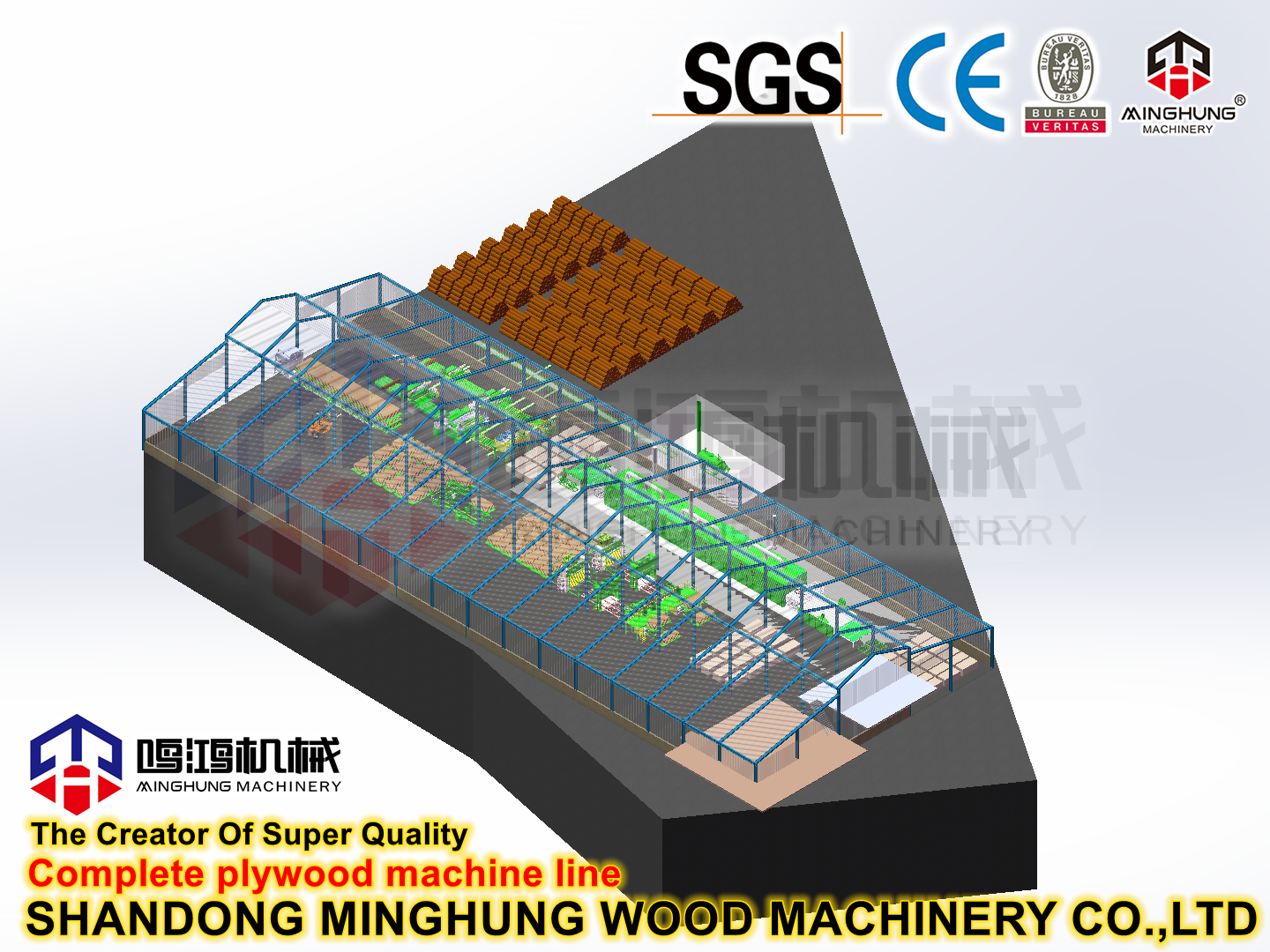

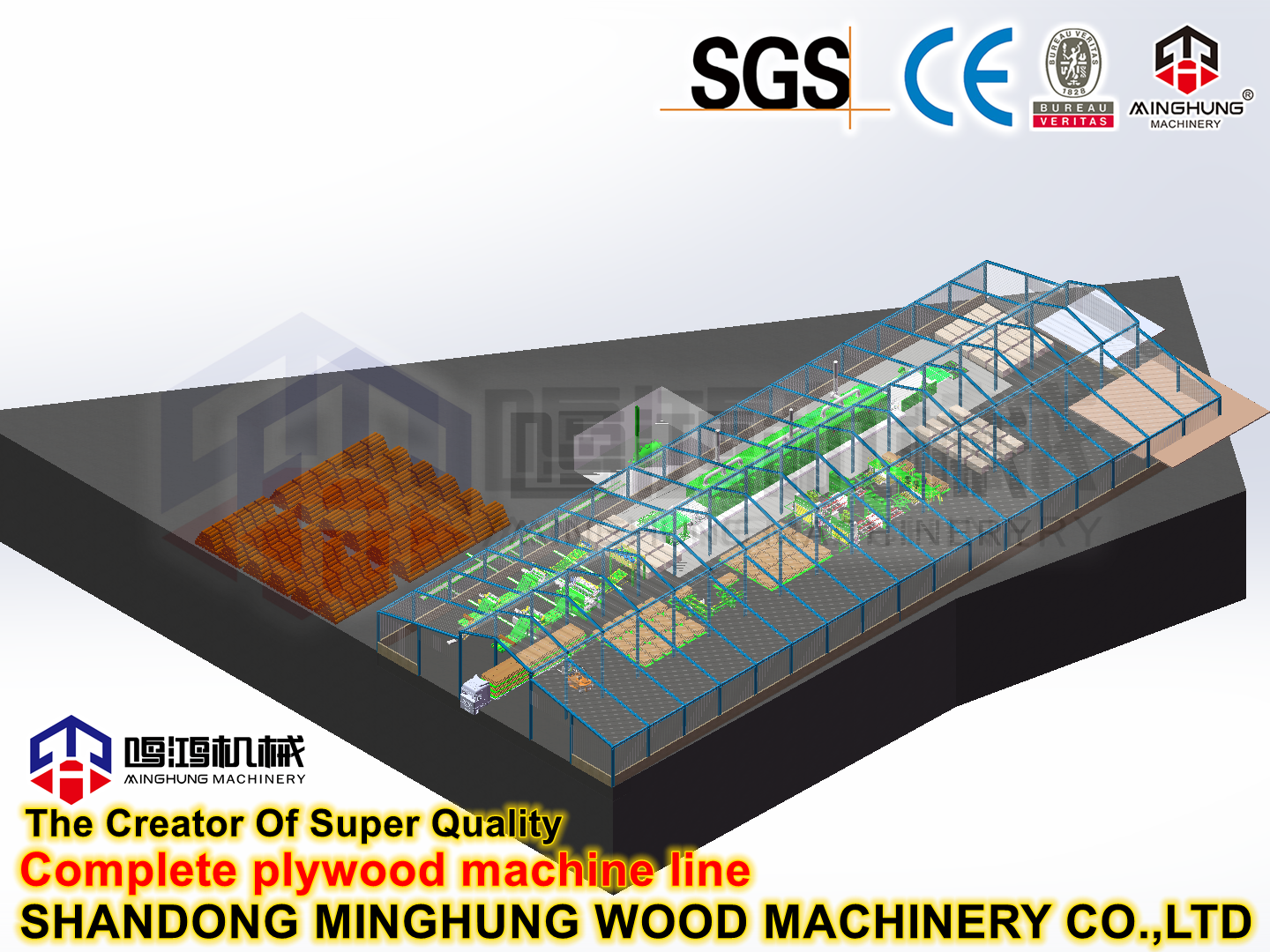

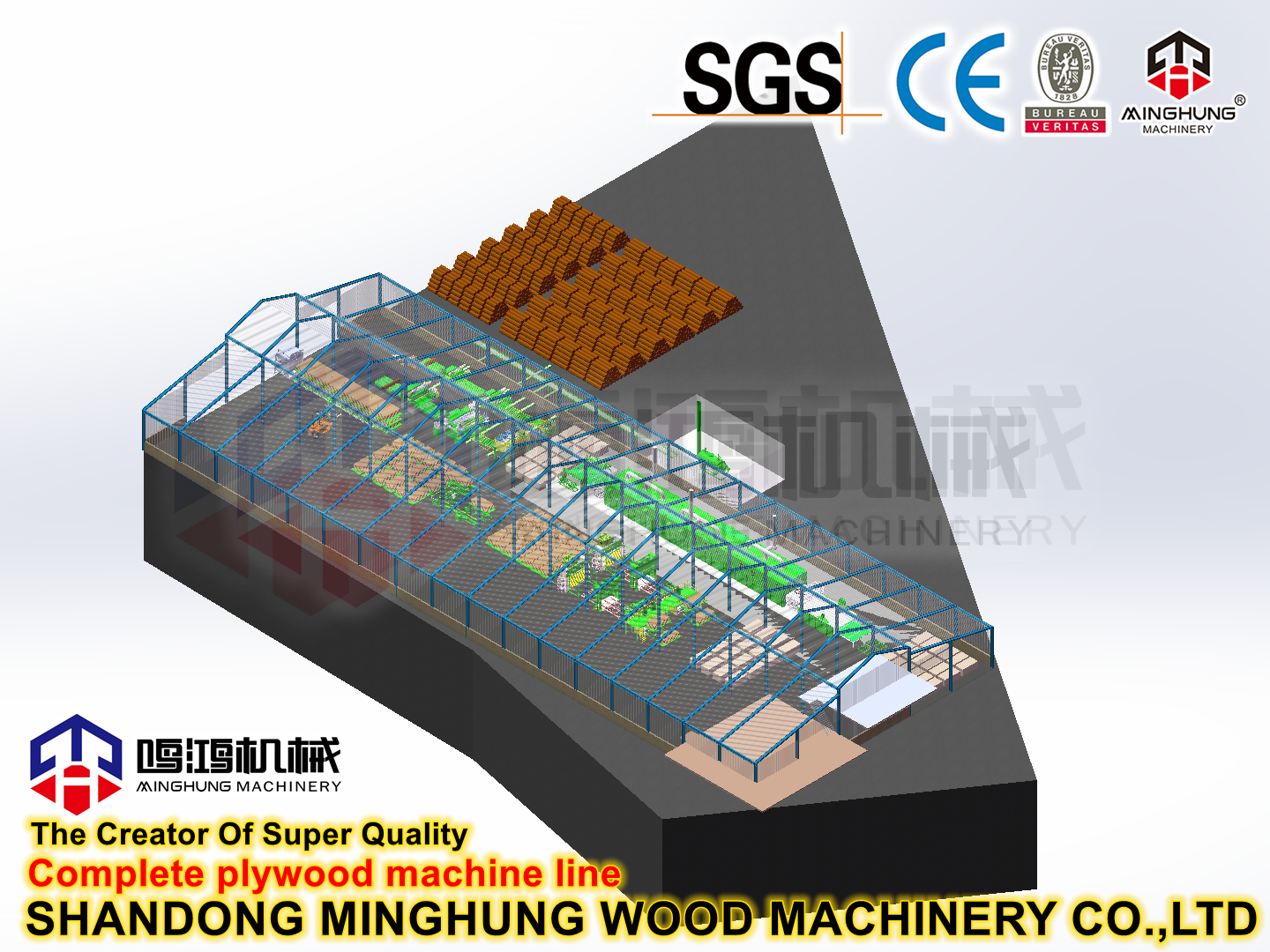

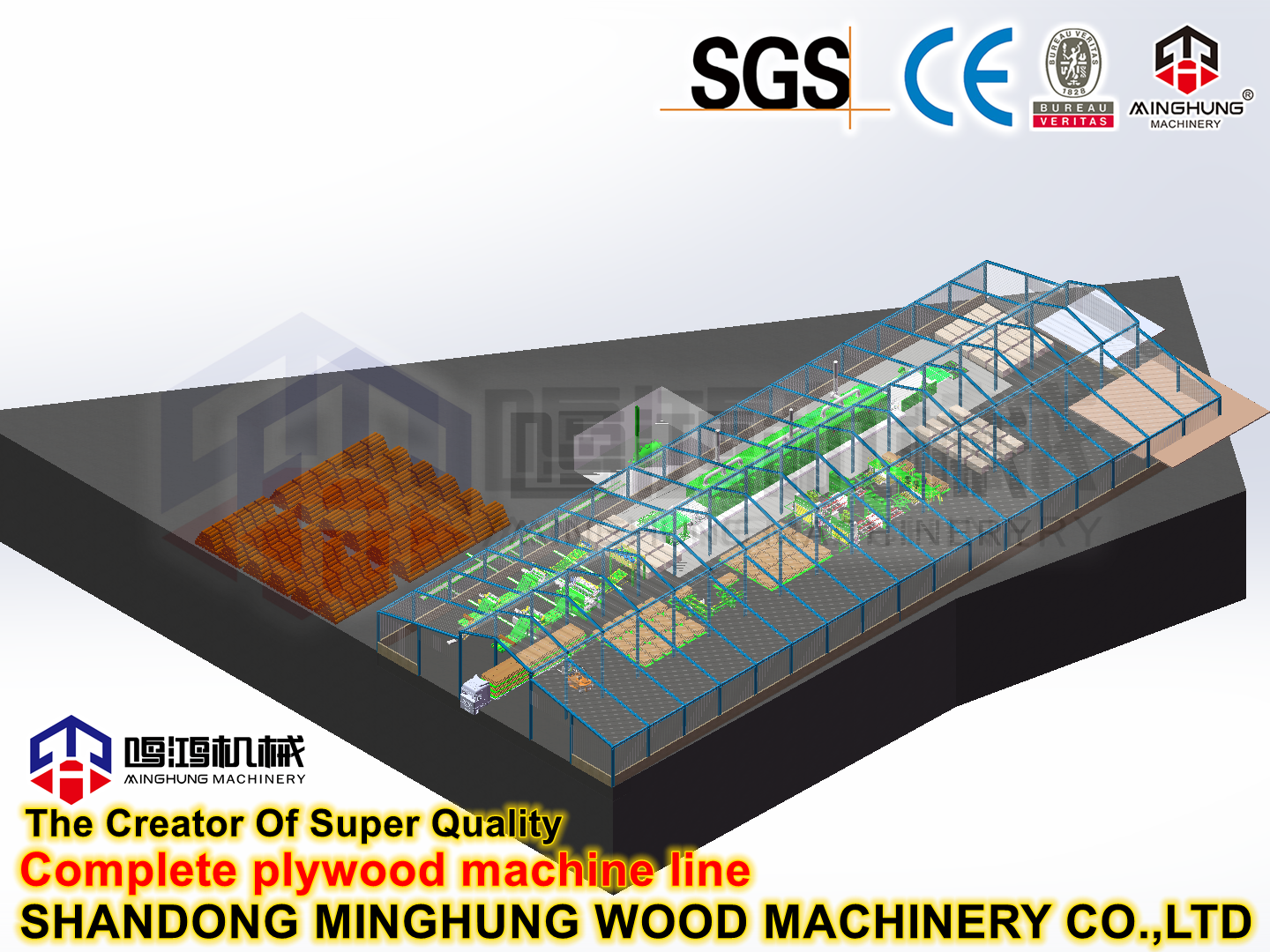

SHANDONG MINGHUNG WOOD MACHINERY CO.,LTD COMPLETE PLYWOOD MACHINE MANUFACTURER

Shandong minghung wood machine factory

produces plywood machinery in linyi city city, china, dedicated to providing high-quality and suitable machines veneer machine,plywood machine,veneer splicing machine.veneer dryer machine,veneer peeling machine,plywood veneer,for our customers.every part of machine is very important to the overall quality, and the details determine the success or failure. we know clearly about this, so we constantly improve and optimize the performance of our plywood machine,plywood hot press machine,plywood cold press machine,

produces plywood machinery in linyi city city, china, dedicated to providing high-quality and suitable machines veneer machine,plywood machine,veneer splicing machine.veneer dryer machine,veneer peeling machine,plywood veneer,for our customers.every part of machine is very important to the overall quality, and the details determine the success or failure. we know clearly about this, so we constantly improve and optimize the performance of our plywood machine,plywood hot press machine,plywood cold press machine,

We are China professional manufacturer of veneer machine and plywood machine with good quality, through a constant and continuous expansion, our factory now has reached a position of leadership by supplying plywood machine in China, So far we have served more than 1.000 customers from all around the world: from Africa to Russia, and from Asia to America.plywood production line plywood machine

Our woodworking machinery include: wood debarker, veneer peeling machine, veneer dryer machine which has veneer press dryer and roller dryer, glue spreader, core composer, plywood veneer paving line, hydraulic cold press machine, hydraulic hot press machine, melamine hot press, plywood edge cutting saw/ dd saw, sanding machine, lift table, knife grinder.

We produce the whole line of wood working machine, we have special design team, our engineer continuous improve our machine, until now, our machine has advanced and mature technology; and we have professional sales team, and after-sales team, try offer you the better service to others.

This article will tell you the details of each plywood machine, which will be very helpful for you, if you want to start producing plywood or wood veneer. 1. Veneer peeling machine

Also be called wood veneer slicing machine, veneer peeling lathe, veneer cutting machine, spindleless veneer peeling machine, wood veneer making machine, veneer peeling machine for plywood, core veneer peeling lathe machine, veneer plywood making machine, wood veneer lathe, wood peeling machine for making plywood, veneer peeler, veneer plywood production line.

What’s wood veneer peeling machine’s function? Actually it is not complex, veneer machine is: process wood into thin layers or piles of wood veneer under the driving of motors. Adjust data by cnc screen, within thickness 0.5-4.0mm, you can set up as you want, and the veneer width also can adjust according to your needs.

veneer peeling machine spindle less veneer peeling lathe

Veneer peeling lathe in general has 4feet/5feet and 8feet/9feet, Max diameter can be 550mm, 600mm, max speed can be 60m/min, 80m/min, 120m/min, and if you have special size, please don’t worry, we will produce veneer machine according to  your needs.

your needs.

wood veneer making machinewood veneer press machinewood veneer slicing machinewood veneer slicer machinewood veneer peeling machinewood veneer peeling machine pricewood veneer sheet machinewood veneer clipping machineused veneer peeling machinveneer slicing machineveneer slicer machineveneer splicing machineveneer patching machineveneer pressing machine price in indiaveneer polishing machineveneer pasting machineveneer peeler machineveneer peeling machine china veneer peeling machine spindle less veneer peeling lathe veneer slicer machine

wood veneer making machinewood veneer press machinewood veneer slicing machinewood veneer slicer machinewood veneer peeling machinewood veneer peeling machine pricewood veneer sheet machinewood veneer clipping machineused veneer peeling machinveneer slicing machineveneer slicer machineveneer splicing machineveneer patching machineveneer pressing machine price in indiaveneer polishing machineveneer pasting machineveneer peeler machineveneer peeling machine china veneer peeling machine spindle less veneer peeling lathe veneer slicer machine

2. Veneer dryer

Also be called veneer dryer machine, veneer drying machine, wood veneer dryer machine, wood veneer dryer, face veneer dryer, veneer roller dryer machine, veneer roller dryer, roller veneer dryer, plywood core veneer roller dryer, plywood core veneer roller dryer, hot press dryer machine, veneer hot press dryer, core veneer dryer machine, core veneer dryer, veneer press dryer.

It’s function mainly is: remove abundant moisture/humidity of wood veneer, for making plywood, in general, wood veneer moisture is big, different wood is different, some may 50% moisture, some may 30-40% moisture, it is too wet for making plywood, therefore, people usually use veneer dryer to drying wood veneer, reduce its moisture. After drying, the end huimidity will be about ±10%, and this is suitable for making plywood.

Veneer dryer machine has three types, they are veneer press dryer, veneer roller dryer, face veneer mesh dryer, their drying effect all good, but they have their own characters and advantages. For example, veneer press dryer machine price is favorable, and cover few room, the veneer roller dryer machine and face veneer mesh dryer can be different length and floors according to your production capacity. So we usually offer the most suitable veneer dryer machine according to your own conditions.

3. Glue spreader

Glue spreader machine’s function is: coating glue on wood veneer, then making plywood. Glue spreading machine has 4feet and 8feet, has single side and double sides, usually we advise you directly buy double sides glue spreader, this will help you improve work efficiency, and its operation is very easy for your workers.

4. Plywood cold press machine

Also be called plywood cold press machine, cold press machine, plywood hydraulic cold press machine, hydraulic cold press machine, automatic cold press machine, wood cold press machine, laminate machine cold press, hydraulic cold press, cold hydraulic press, cold press machines wood working, cold press plywood, laminate press machine cold press, cold press for plywood, cold press woodworking.

Also be called plywood cold press machine, cold press machine, plywood hydraulic cold press machine, hydraulic cold press machine, automatic cold press machine, wood cold press machine, laminate machine cold press, hydraulic cold press, cold hydraulic press, cold press machines wood working, cold press plywood, laminate press machine cold press, cold press for plywood, cold press woodworking.

Cold press has up-cold press which cylinder press from up to bottom, and down-cold press which cylinder press from bottom to up, pressure 500t is popular, also can produce according to your conditions.

The structure of cold press is very simple, it mainly consist by press machine frame, cylinder, hydraulic station, its max opening is 1800mm.

The operation of cold press machine also very easy, put plywood into cold press, pressing the start button, cold press will automatic closing and pressing plywood.

5. Plywood hot press machine

Plywood hot press’s function is: press plywood to make it into one complete one. Hot press’s structure consists of press machine frame, it uses international standard steel, very thick and good; hot plates, which be processing by big lathe, high hardness and surface smooth, make sure pressing plywood good quality; with anti-rust cylinders, make sure our hot press machine is strong and good quality.

Hot press machine can be different pressure and floors/daylights, for example, the pressure can be 400t, 500t, 600t, 800t, 1000t, 1200t, 1500t, 2000t, usually pressing common plywood, 500t or 600t hot press is good and enough, if you need laminating melamine or face veneer on plywood, then pressure 800t is a better choice, if you wants press your melamine has texture and emboss, then the pressure need bigger. The layers can be 8layers 10layers 12layers 15layers 20layers 25layers.

#veneerhotpress #hotpressmachine, #heatpressmachine, pressing machine, #hydraulichotpress, #hydraulichotpressmachine, hot plate hydraulic press, hydraulic hot press price, hot hydraulic press machine, hot hydraulic press, hydraulic hot press machine for composites, hydraulic hot press machine plywood, hydraulic laminating hot press, hydraulic hot press for veneer, hot press machine for plywood, plywood hot press machine, selling plywood hot press machine, hot press plywood machine, hydraulic hot press machine plywood, plywood production line making machine, thermal oil heating for hot press machine, laminate hot press machine, melamine laminating hot press machine, hydraulic press, hydraulic press machine price

All plywood machine not one type, we will offer you the most suitable machine according to your own needs and requires, which will be better for you, and we insist offer the good quality plywood machine to every our customers, help their business going better and create much value.

When our plywood machine or veneer machine reach your factory, our engineers will go to install and teach your workers how to operate them. And before plywood machine reach your factory, we will offer you machine foundations. And in the future, if any problem your worker can not solve in the future, just contact us, we will reply you first time and help you solve it.

Until now, our machine has been exported to many countries, and get good feedback.

All dear friends, for us, we are not just partners, we are friends, so we will always think about probelm standing your position, try help you save cost and create much benefits.

Welcome contact me for more details of plywood machine.

plywood dd saw machine, strictly control every production step, operated by experienced workers, processed by advanced minghung wood machinery eplywood quipment, through multiple inspection procedures, to ensure that the machine is accurate and durable.

hydraulic station is one important part for press machine, our hydraulic station be designed by our engineer.reasonable design of hydraulic system, save energy, all hydraulic components are arranged reasonably,

neatly and beautifully placed, and the components like electromagnetic valve, hydraulic pump all use good one.

the plywood hot press machine and cold press oil cylinder is treated with anti-rust, alloy casting, high hardness, scratch resistance, suitable for high-strength operations. and uses a good oil seal to prevent leakage, ensure the pressure in the oil cylinder, and good performance

the hot platen be processed by large lathe, make the surface is smooth, with sufficient strength and stiffness. it does not deform at high temperatures. and the temperature and heat are uniform. this makes the plywood heated evenly, the surface is flat, and the thermal efficiency is high, which improves the production efficiency.

the rollers of the rotary cutting machine are chrome plated, wood debarker machine.log debarker,veneer machine with hard quality, no deformation, corrosion resistance and long service life.

the heavy duty of the machine makes the machine very stable during operation.plywood manufacturing process, plywood working machinery,wood log debarking machine,wood debarker.

the high-power motor provides powerful power for the machine to cut hard wood and precision wire. the bar ensures that the thickness of the veneer is accurate and even.

the unique dual-drive structure makes the surface of the veneer smoother and can produce high-quality veneer for you.

the rollers of the peeling machine are made of spikes. the numerous knives on the surface enable the machine to peel off the bark easily. and make the wood rounder machine,wood debarker. the machine is fast and easy to operate.

we have a professional sales team to serve you online 24 hours, technical team and maintenance team to provide you with factory layout, machine drawings, and after-sales service. choosing us is tantamount to choosing rest assured

friends, our machines include peeling machines. rotary cutting machines, tumble dryers, 4 * 8 feet glue spreaders.plywood cold press machine, hot presses, sawing machines, sanding machines, boilers. please contact us, we will provide you with the most suitable machine to help your business create revenue.

MINGHUNG Strong product design capabilities:

Our company advantages and difference compare with other suppliers:

No 1. Sales Person

Our sales person participate in this whole process, from offer clients information, follow up the order, to the end product. And they ever worked in different post in workshop, familiar and master every production step of machine, make sure offer the most suitable machine to you.

No 2. Matrial

Our experienced purchase manager choose the good machine material and spare parts after compare different suppliers,

No 3. Engineer

Our engineer service domestic and abroad clients more than ten years, from clients start build factory, plant layout, machine maintain, etc, offer all-sided support, this is a real engineer. The most important thing is: their serious and responsibility attitude is the main source for improving and optimizing our machine.

No 4. Processing Lathe

Our processing lathe make sure machine accurate, we have invested $3000000 for cnc lathe, precise cutter, welding machine, PLC test system, Machine test system and other machines, It reduces the intensity of workers' work, improve machine parts accuracy. this is the big weapon for us to competitive with other suppliers.

No 5. Multiple inspection procedures

The whole production step, will through more than 5 times detection to make sure machine production is good. And after finish production, our engineer will test machine to ensure it is in good conditions.

No 6. Factory Management

Our company and workshop use 5S (Seiri and Seiton, Clean-up and Removal, Attainment), the application of 5S make us become one international company, keep up with the world’s top 500 companies.

No 7. Warranty

Offer two years warranty for our clients, because we have 100% confidence for our machine quality. One time cooperation, lifetime friends.

We spare no effort to make every our client’s factory be our exhibition hall, do excellent project.

No 8. Our Company Value

Continuous create much more value for clients.

Our team has dreams, and everyone is sincere and virtuous, so what we want is do our best satisfy every our customers, do our best offer them good plywood machine, help their business become better and better.

If you have any demands of plywood machine, please tell us, we will offer the most suitable plywood machine according to your conditions and needs. We believe our machine will help you create much benefits.

Contacts us:

Whatsapp:

Mark: +8618769900191

Ali: +8615589105786

Lucinda: +8615805493072

Email:

minghungmachinery@gmail.com

linyiminghungmachinery@gmail.com

garysinghco@gmail.com

produces plywood machinery in linyi city city, china, dedicated to providing high-quality and suitable machines veneer machine,plywood machine,veneer splicing machine.veneer dryer machine,veneer peeling machine,plywood veneer,for our customers.every part of machine is very important to the overall quality, and the details determine the success or failure. we know clearly about this, so we constantly improve and optimize the performance of our plywood machine,plywood hot press machine,plywood cold press machine,

produces plywood machinery in linyi city city, china, dedicated to providing high-quality and suitable machines veneer machine,plywood machine,veneer splicing machine.veneer dryer machine,veneer peeling machine,plywood veneer,for our customers.every part of machine is very important to the overall quality, and the details determine the success or failure. we know clearly about this, so we constantly improve and optimize the performance of our plywood machine,plywood hot press machine,plywood cold press machine,

wood veneer making machine

wood veneer making machine

Also be called plywood cold press machine, cold press machine, plywood hydraulic cold press machine, hydraulic cold press machine, automatic cold press machine, wood cold press machine, laminate machine cold press, hydraulic cold press, cold hydraulic press, cold press machines wood working, cold press plywood, laminate press machine cold press, cold press for plywood, cold press woodworking.

Also be called plywood cold press machine, cold press machine, plywood hydraulic cold press machine, hydraulic cold press machine, automatic cold press machine, wood cold press machine, laminate machine cold press, hydraulic cold press, cold hydraulic press, cold press machines wood working, cold press plywood, laminate press machine cold press, cold press for plywood, cold press woodworking.