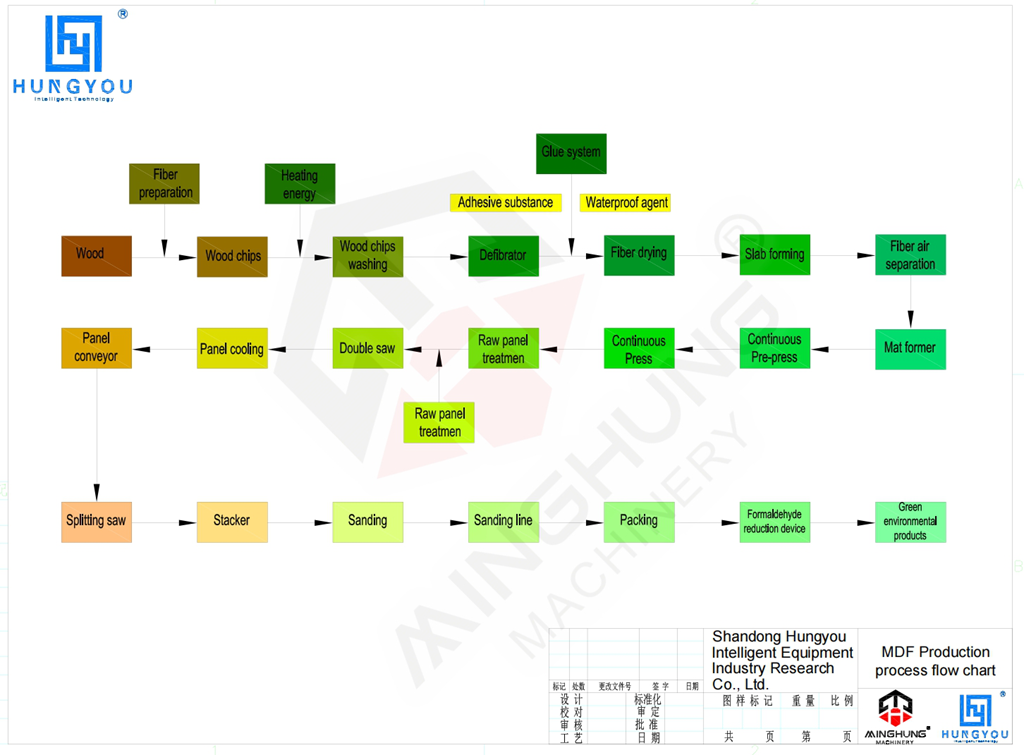

The entire line adopts a fully automated control system , enabling intelligent control throughout the entire process: from raw material chipping, fiber preparation, glue blending and drying, forming and pre-pressing, to hot pressing, sanding, and cutting. It offers high production capacity and stable operation, making it an excellent choice for your investment in the high-end wood-based panel market.

| What are the mechanical equipment on the production line? |

1. Raw Material Preparation Section

Chipping Equipment

Drum Chipper: Power 200-315kW, capacity 30-50 tons/day

Disc Chipper: Equipped with 4-6 flying knives, processing logs and branch wood

Chip Screening System: Three-stage vibrating screen, separating qualified chips from impurities

Magnetic Separator: Removing metal impurities, protecting downstream equipment

Chip Storage System

Steel Silo: Capacity 100-200m³, with discharger

Belt Conveying System: Wear-resistant rubber belt, variable frequency speed control

2. Fiber Preparation Section

Defibrator System

Pre-steaming Digester: Pressure 0.6-1.2MPa, temperature 160-190℃

Twin-screw Feeder: Ensuring continuous and uniform feeding

Main Defibrator: 42-48 inch diameter, power 3000-5000kW

Refiner: Secondary refining, improving fiber quality

Fiber Treatment System

Fiber Dryer: Three-pass pneumatic drying, temperature 130-180℃

Glue Blending System: High-pressure atomization, UF resin/MDI adhesive

Fiber Classification: Air classification, removing coarse fibers and impurities

fiber cooking and refining system

drying machine

glue machine

3. Forming and Pressing Section

Forming System

Mechanical Former: Creating uniform mat

Leveling Roll: Precisely controlling mat thickness

Online Density Detector: Real-time monitoring of mat uniformity

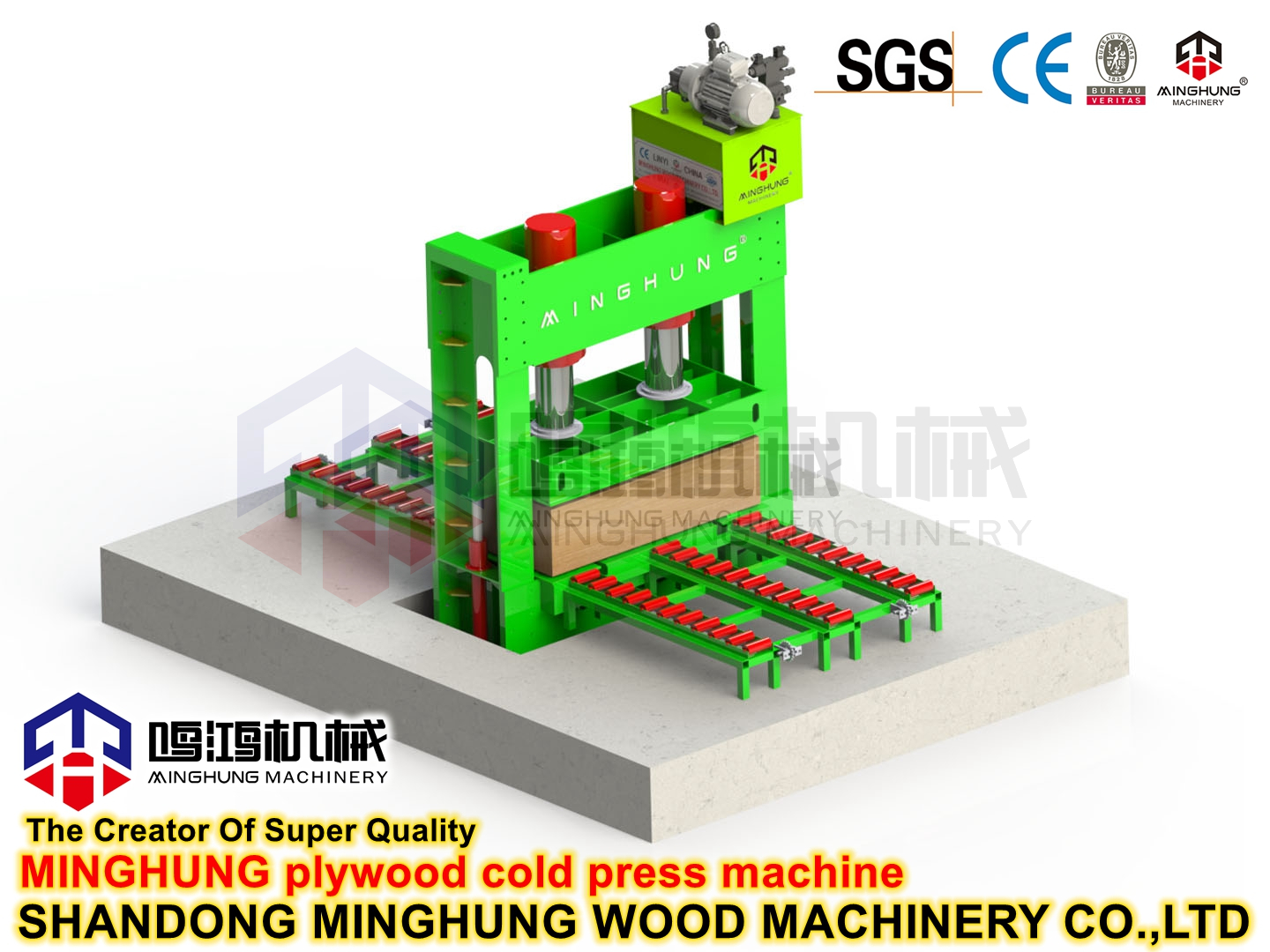

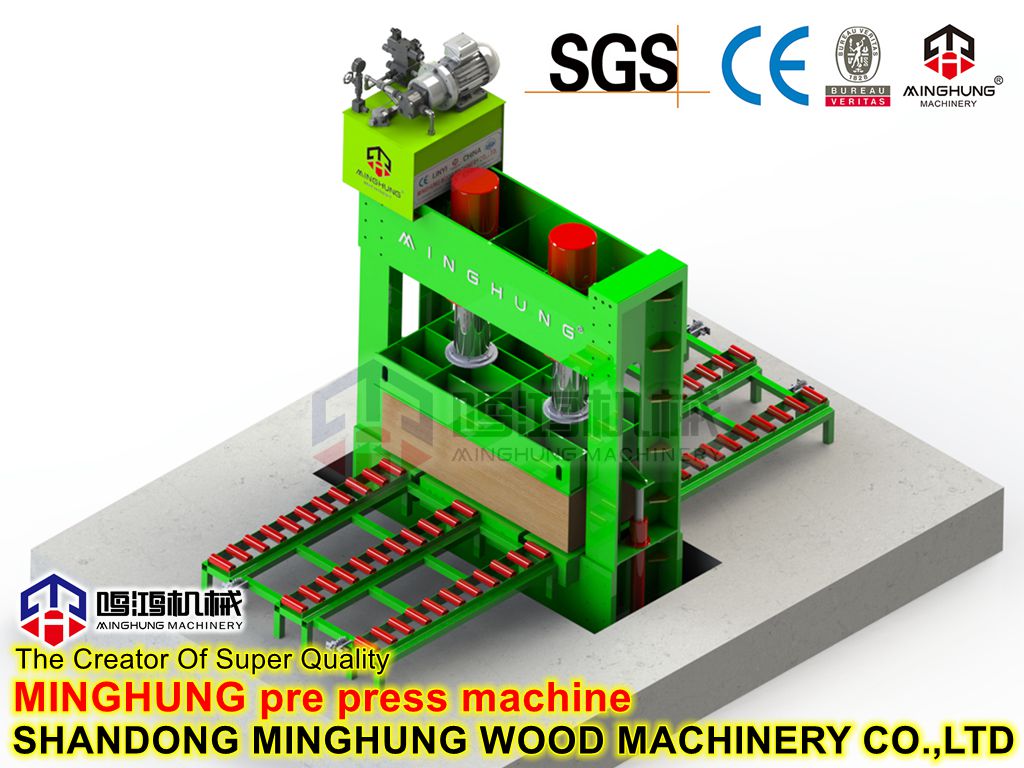

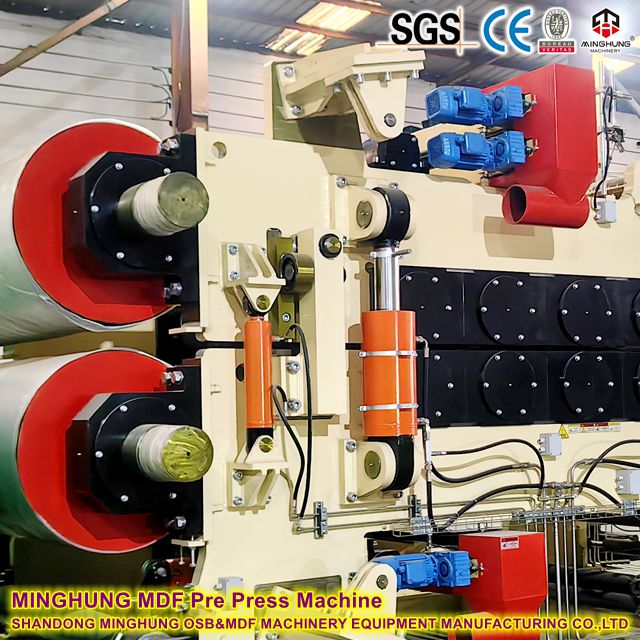

Pre-pressing System

Continuous Belt Pre-press: Initial pressure 2-5MPa

Mat Edge Trimming: Precisely controlling mat width

Metal Detector: Ensuring safe production

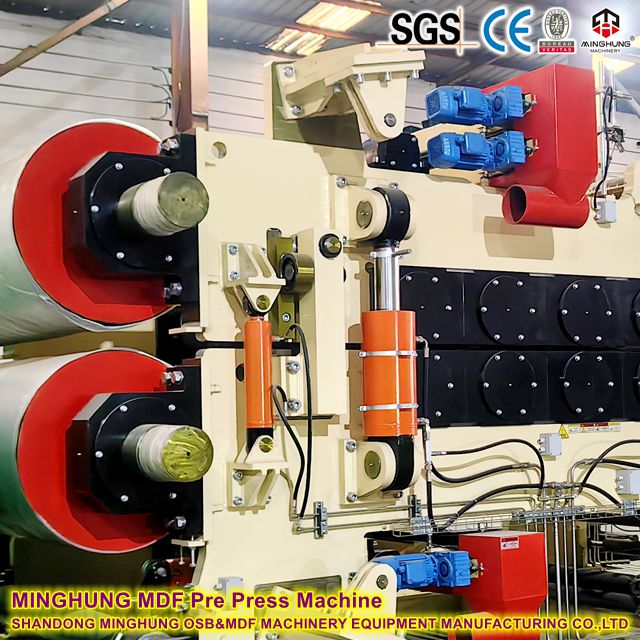

Hot Pressing System

Continuous Press: Pressure 8-12MPa, temperature 200-220℃

Heating System: Thermal oil or steam heating, temperature control ±1℃

Thickness Control System: Laser thickness measurement, accuracy ±0.05mm

Cooling System: Forced air cooling, reducing internal stress

forming machine

pre press machine

continuous belt hot press

4. Finishing Section

Green Board Processing

Cross Cutting: Double-end trimming, dimensional accuracy ±0.5mm

Stacking System: Automatic stacking, height 1.2-1.5m

Intermediate Storage: 48-hour conditioning, releasing internal stress

Sanding Treatment

Six-head Sander: Sanding belt width 1350-1650mm

Rough Sanding Unit: Removing 0.3-0.5mm surface material

Fine Sanding Unit: Surface roughness Ra≤3.2μm

Dust Extraction: Air volume 20,000-30,000m³/h

Cutting and Packaging

Panel Saw: Maximum processing size 1300×5000mm

Automatic Stacker: Stacking accuracy ±1mm

Film Wrapping Machine: Moisture and dust proof packaging

Automatic Labeling: Product information identification

sanding machine

cross-cut saw

5. Auxiliary Systems

Resin System

Resin Storage Tanks: Stainless steel, capacity 20-50m³

Automatic Resin Blending: Precise ratio control

Hardener Dosing Unit: Proportioning accuracy ±0.5%

Energy Center

Thermal Energy Plant: Output 15-30MW

Flue Gas Treatment: Baghouse dust collector + wet desulfurization

Heat Recovery System: Efficiency ≥85%

Automation Control

Central Control System: Siemens S7-1500 PLC

Field Bus: PROFIBUS-DP network

HMI: 21-inch touch screen, multi-language display

Production Management System: Real-time OEE monitoring

| The technical features of the production equipment |

1. Thick Board Production Technology

Special Forming Technology: Adapted for 25mm thick mat forming

Layered Pressing Technology: Ensuring complete core curing

Gradient Temperature Control: Surface-core temperature difference <10℃

Slow Pressure Release System: Preventing delamination and blistering

2. High-Density Assurance Technology

High-Pressure System: Maximum pressure up to 15MPa

Precision Thickness Control: Digital thickness monitoring

Fiber Quality Optimization: Long fiber proportion >60%

Glue Uniformity: Glue application accuracy ±1%

3. Energy Saving and Environmental Protection

Heat Recovery: Waste heat reuse

Water Circulation System: Zero wastewater discharge

Dust Control: Emission concentration <20mg/m³

Noise Control: Boundary noise <65dB(A)

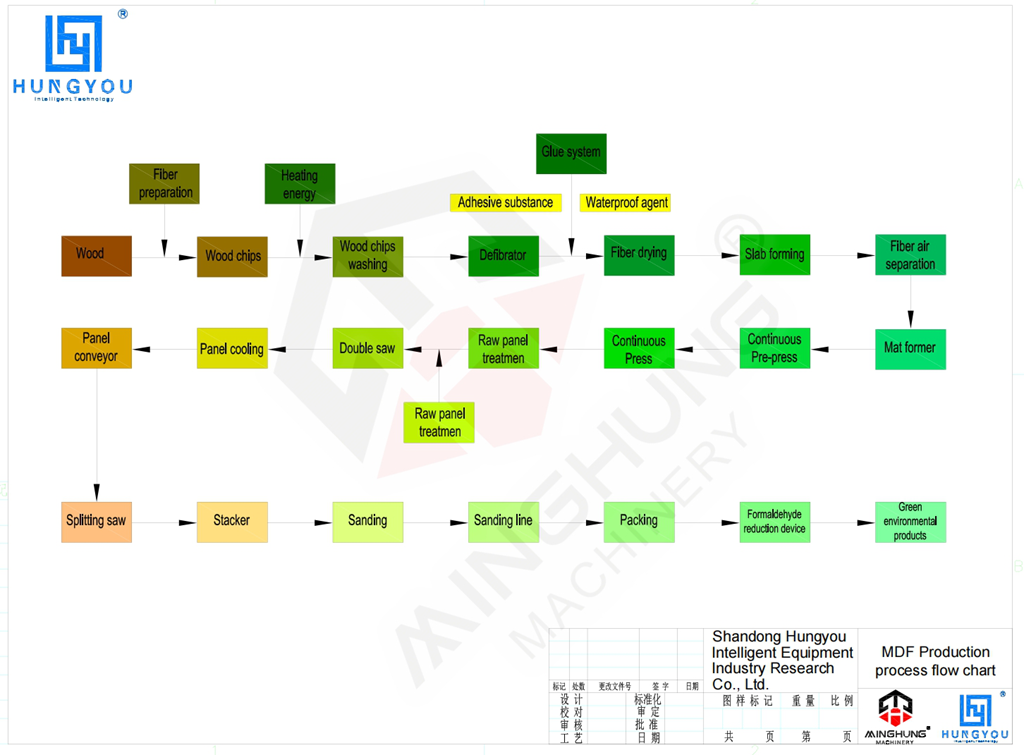

| Production Process |

1. Raw Material Preparation Stage

Wood Chipping: Processing mixed wood and branch materials into 20-30mm specification chips using drum chippers

Screening and Washing: Selecting qualified chips through vibrating screens, removing sediment through washing

Magnetic Separation: Removing metal foreign objects using magnetic separators to protect downstream equipment

2. Fiber Preparation Stage

Thermomechanical Pulping:

Pre-steaming: Cooking wood chips under 0.8-1.0MPa pressure to soften

Defibration: Separating wood chips into fibers under high temperature and pressure

Fiber Refining: Further refining fibers to improve quality

Glue Blending and Drying:

Precision Glue Application: Applying urea-formaldehyde resin using high-pressure atomization systems

Pneumatic Drying: Reducing fiber moisture content to 8-10% in pipeline dryers

3. Forming and Pressing Stage

Forming:

Mechanical Forming: Creating uniform mat

Pre-pressing: Initial compression to improve mat strength

Edge Trimming: Precisely controlling mat width

Hot Pressing and Curing:

High-temperature Pressing: Hot pressing at 200-220℃

Pressure Control: Using 8-12MPa pressure with three-stage pressure control

Thickness Control: Precisely controlling 25mm thickness through laser measurement system

Slow Pressure Release: Special pressure release curve to prevent delamination and blistering

4. Finishing Stage

Cooling and Conditioning:

Forced Cooling: Reducing internal temperature, stabilizing internal structure

Natural Conditioning: Stacking for 48 hours to release internal stress

Sanding and Cutting:

Thickness Sanding: Precise sanding with six-head sanders

Cross Cutting: Precise cutting to required dimensions

Inspection and Packaging:

Quality Inspection: Testing density, strength and other indicators

Film Packaging: Moisture and dust proof packaging

| What is the main purpose? |

1. Furniture Manufacturing

Tabletop Substrates: Heavy-duty tabletops for dining tables, office desks, workbenches

Load-bearing Components: Load-bearing shelves for bookcases, wardrobes, cabinets

F furniture Frames: Structural components for sofa frames, bed frames

2. Building Decoration

Flooring Substrate: Base material for laminate flooring, sports flooring

Interior Partitions: Partition walls for offices, shopping malls

Door Core Material: Core material for solid wood composite doors, fire doors

3. Industrial Applications

Packaging Materials: Heavy equipment packaging cases, pallets

Exhibition Equipment: Structural materials for exhibition stands, display cabinets

Vehicle Interiors: Interior panels for buses, trucks

Audio Equipment: Speaker enclosures, acoustic partitions

4. Special Applications

Machine Tool Base Plates: Installation base plates for industrial machinery

Test Platforms: Precision instrument test platforms

Sports Equipment: Structural components for fitness equipment

| Product Advantages |

1. High Strength: 830kg/m³ density provides excellent mechanical properties

2. Thickness Stability: 25mm thickness suitable for high load-bearing applications

3. Good Workability: Easy secondary processing such as cutting, drilling, milling

4. Eco-friendly: Uses renewable wood resources, environmentally friendly production process

5. Cost-effective: Replaces solid wood, reduces production costs

| Technical Parameter Table |

Indicator | Parameter Value |

Thickness | 25±0.2mm |

Density | 830±30kg/m³ |

MOR | ≥40MPa |

IB | ≥1.0MPa |

Thickness Swelling | ≤8% |

Formaldehyde Emission | E0 grade(≤0.5mg/L) |

Our company

Shandong MINGHUNG OSB&MDF Machinery Equipment Manufacturing Co.,Ltd. was founded in 1983, specializes in continuous press solutions for over 40 years.

MINGHUNG is a leading company in the industry of OSB&MDF making machine. With a strongfocus on producing high-quality machinery, we specialize in manufacturing thecomplete production line of Medium density fiberboard (MDF), High densityfiberboard (HDF),Particle board (PB), Oriented strand board (OSB) , Veneerable super strong particle board (LSB),Laminated board and veneer.

Our workshop

Upgrade your production line now!

We provide global installation support and technical training, 2-year machine warranty, and 24-hour online response - let your fiberboard production enter a new era of intelligence and low carbonization.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com