|

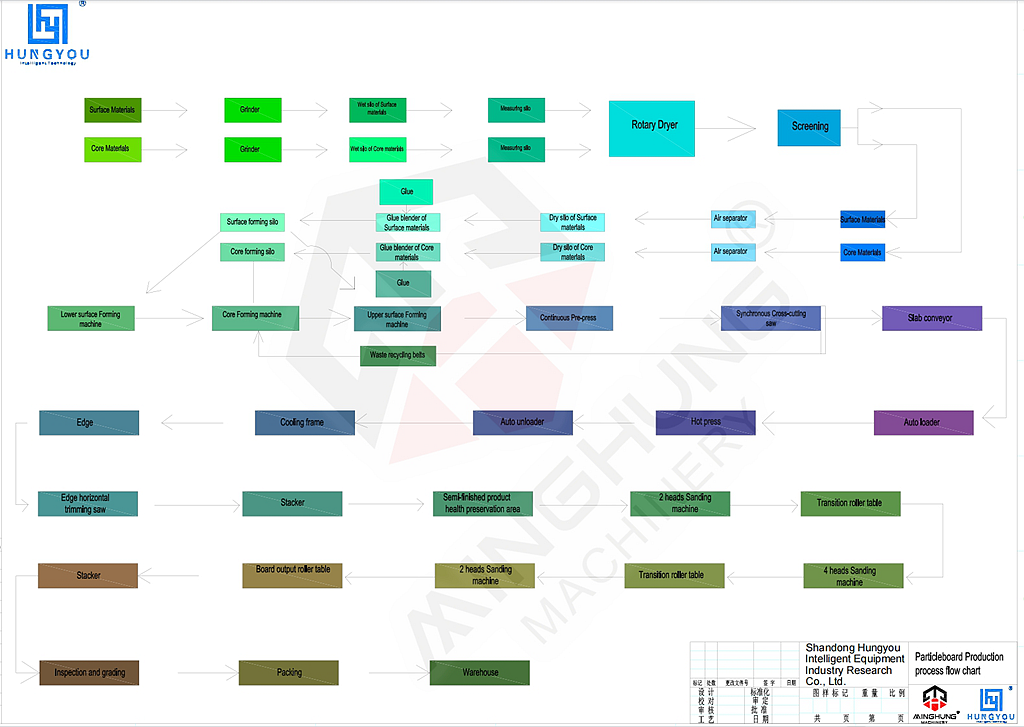

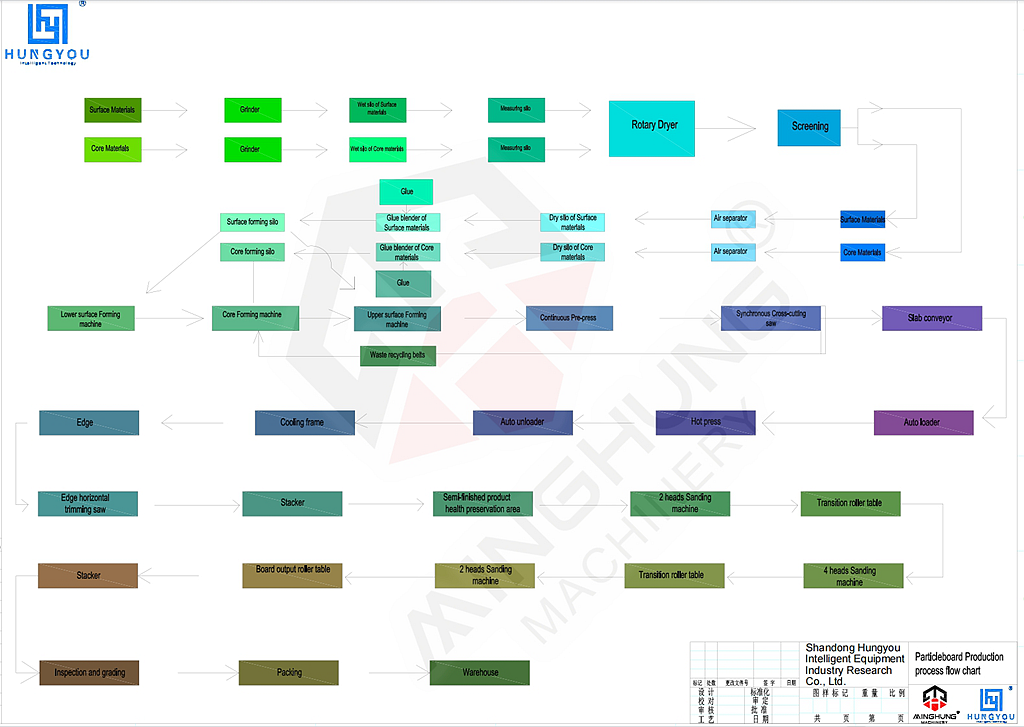

Production Line Equipment Configuration

Producing high-strength, crack-resistant particleboard with an annual capacity of 100,000 m³ requires a complete production line featuring advanced technology, a high degree of automation, and precise coordination between all sections.

The entire production line can be divided into six main systems: Raw Material Preparation, Particle Preparation, Drying & Sorting, Gluing & Blending, Forming & Pressing, and Finishing.

1. Raw Material Preparation System

Drum Chipper: Used to chip raw logs, branches, and other wood materials into wood chips that meet process requirements. Its capacity must match subsequent sections, requiring high throughput and uniform chip size.

Debarker (if using whole logs): Removes bark, which adversely affects board strength and bonding performance. This is a prerequisite for ensuring high-quality boards.

Chip Screen: Screens the produced chips, allowing accepted chips to proceed to the next stage while oversize chips are sent back for re-chipping.

2. Particle Preparation System - The Core of High Strength & Crack Resistance

Ring Flaker: Planes the cleaned wood chips into flakes of specified thickness. This is a key piece of equipment determining particle morphology quality. Excellent particle form, uniform thickness, and smooth surfaces are essential for achieving "high strength" and "crack resistance."

Particle Mill/Refiner: Used to produce finer particles for the core layer, achieving a "graduated structure" where fine surface particles ensure smoothness and coarser core particles provide strength.

Particle Screening System: An extremely important stage. Multi-deck vibrating screens precisely separate particles into surface and core layer fractions. More precise separation results in a more rational board cross-section structure, higher surface quality, and stronger crack resistance.

3. Drying and Sorting System

Rotary Drum Dryers: Typically, three are equipped (one for surface particles, one for core particles, one standby). They precisely reduce particle moisture content from ~40%-60% to 2%-4%. Drying stability directly affects subsequent gluing and board quality.

Wind Sifter: Further removes impurities and excess fines after drying, ensuring efficient adhesive use and board strength.

dryer system

vibrating screen

4. Gluing and Blending System

Weighing System: Precisely measures the weight of dried surface and core particles for continuous and stable output.

Glue Kitchen: Used for preparing and storing adhesives (typically modified urea-formaldehyde resin or MDI). Using MDI adhesive can significantly improve moisture resistance and strength but at a higher cost.

High-Speed Blenders: Used for applying adhesive to surface and core particles separately. Atomized spraying technology ensures adhesive evenly coats each particle. This is core to ensuring internal bond strength and preventing delamination.

5. Forming and Pressing System - The "Heart" of the Production Line

Mechanical Former: Uses a multi-head forming system to achieve graduated structure formation (fine-coarse-fine). This forms the foundation for the high-strength, crack-resistant board structure.

Continuous Pre-press: Initially compresses the fluffy mat to remove air, facilitating transportation and preventing mat collapse entering the press.

Continuous Press: This is the absolute core equipment for achieving the 100,000 m³ annual capacity and high quality. Compared to multi-opening presses, continuous presses offer higher efficiency, uniform density, consistent longitudinal and transverse strength, extremely smooth surfaces, and low residual stress, thereby greatly reducing the risk of deformation and cracking. Their length and opening must be precisely designed based on capacity and product thickness.

mat forming machine

pre press

continuous press machine

6. Finishing System

Cooling and Star Cooler: Cools the hot-pressed boards to room temperature, curing the adhesive and releasing internal stress to prevent deformation.

Stacker: Automatically stacks the cooled boards.

Sanding Line: Usually employs a wide-belt sander with multiple heads (e.g., 6-8 heads) to precisely control the final board thickness and smoothness, providing a perfect substrate for further processing.

Cross-Cut Saw: Saws the continuously produced board strip into required sizes.

Quality Control System: Online detection equipment (e.g., continuous density profiler) monitors the board's density distribution in real-time, ensuring consistent quality for every board.

dryer rack

sander

cross-cut saw

Summary: Key Equipment & Processes for Achieving "High-Strength & Crack-Resistant" Properties

1. High-Quality Particle Production (Ring Flaker + Screening): Uniform particles are the foundation.

2. Precise Classification and Forming (Screening + Mechanical Former): Creates the ideal graduated structure—fine surface material ensures smoothness, coarse core material provides strength.

3. High-Performance Adhesives (Gluing System with MDI capability): Using modified resins or MDI improves mechanical properties and moisture resistance.

4. Continuous Pressing (Continuous Press): Ensures extreme density uniformity and minimal residual stress, fundamentally solving cracking and deformation issues.

5. Precise Cooling and Conditioning (Cooling Star): Releases internal stress and stabilizes board performance.

|

Product Process

This production process is highly automated and continuous, designed to ensure the particleboard possesses high strength and excellent crack resistance. The core principles involve precise raw material handling, ideal particle morphology, graduated structure forming, and uniform and stable hot pressing.

1. Raw Material Preparation

Raw logs or wood residuals (e.g., chips, shavings) are processed through debarking and chipping to produce clean wood chips that meet technical specifications.

2. Particle Preparation and Screening

The washed wood chips are fed into a ring flaker to be planed into particles of specific sizes.

This is a critical step. The particles are precisely separated into fine surface particles and coarser core particles by a multi-deck screening system. This lays the foundation for the "graduated structure," which is central to high strength and crack resistance.

3. Drying

Surface and core particles are sent into rotary drum dryers separately to have their moisture content precisely and evenly reduced from 40%-60% to 2-4% oven-dry status. Consistent drying is crucial for subsequent gluing.

4. Gluing and Blending

The dried particles are precisely weighed and then fed into high-speed blenders.

Adhesive (typically modified urea-formaldehyde resin or MDI) is evenly sprayed onto the particles via atomizing nozzles. Different adhesive recipes or amounts can be used for surface and core layers to achieve optimal performance.

5. Forming and Pre-pressing

The glued surface and core particles are formed by a mechanical former into a loose mat with an ideal "fine-coarse-fine" graduated structure on a moving caul plate.

The mat then enters a continuous pre-press for initial compaction, which removes air, increases density, provides initial strength for transport, and prevents mat collapse entering the main press.

6. Hot Pressing

The pre-pressed mat enters the continuous press. This is the core section of the production line.

The mat is continuously compressed into a dense board under set temperature, pressure, and time parameters. The continuous press ensures extreme uniformity in density distribution, consistent strength in length and width directions, and minimal residual stress, thereby significantly enhancing resistance to deformation and cracking.

7. Cooling, Trimming and Stacking

The hot pressed board must be immediately cooled in a star cooler or similar to cure the adhesive, release internal stress, stabilize dimensions, and prevent warping.

The cooled continuous board is trimmed to required sizes by cross-cut and edge saws and then automatically stacked by a stacker.

8. Sanding and Inspection

The stacked and conditioned boards are precisely sanded by a multi-head wide-belt sander to ensure high standards of thickness tolerance and surface smoothness, providing a perfect substrate for decoration.

Finally, the boards are inspected by quality control systems (e.g., online density profiler), packaged, and warehoused after passing.

Key Process Points: High-quality chips, precise particle morphology control, graduated structure forming, uniform glue application, continuous press hot pressing, and sufficient stress release collectively guarantee the high strength and crack-resistant properties of the final product.

|

Application

Due to its exceptional mechanical properties, stable structure, excellent moisture resistance, and anti-deformation capabilities, high-strength crack-resistant particleboard has a far wider range of applications than standard particleboard, penetrating deeply into fields with stringent material performance requirements.

1. Furniture Manufacturing

High-End Custom Furniture & Cabinetry: Used for cabinet bodies, side panels, shelves, and door cores. Its high strength and crack resistance ensure long-term stability and durability under load (e.g., books, dishes) and frequent use, preventing sagging, warping, or joint loosening.

Office & Commercial Furniture: Used for office partitions, workstations, reception desks, and retail display units. Its stable dimensions and excellent surface flatness facilitate various finishing treatments (e.g., PVC laminating, HPL, natural veneers), meeting the aesthetic and durability demands of commercial environments.

2. Construction and Interior Decoration

Interior Doors & Door Cores: Serves as the core material for solid core or composite doors, providing good sound insulation and thermal properties. It resists cracking and warping due to temperature/humidity changes, maintaining the door's flatness.

Wall & Ceiling Systems: Used as a substrate for feature walls and ceiling panelling. Its crack resistance ensures that finish materials (e.g., drywall, wallpaper, paint) will not crack due to substrate movement.

Floor Underlayment: Used as an underlayment for laminate or engineered wood flooring, providing a level, solid, and stable base that enhances the overall feel underfoot and impact resistance of the floor.

Stair Treads & Handrail Substrates: Offers good load-bearing capacity and wear resistance, providing stable support for subsequent wrapping or finishing.

3. Commercial and Industrial Applications

Retail & Showroom Fit-outs: Used for shelving, display racks, checkout counters, and fitting rooms. It can bear the weight of heavy merchandise and maintain its appearance over long-term use.

Industrial Workbenches & Storage Systems: Used for manufacturing workbench tops, shelving boards, and warehouse racking dividers. Its high load-bearing capacity and impact resistance fully meet the demanding requirements of industrial settings.

Vehicle Interiors: Used for wall panels, ceiling panels, and partitions in RVs, freight liners, and buses, requiring materials that are lightweight, strong, and resistant to vibration during transport.

4. Other Specialized Fields

Furniture & Appliance Housings: Serves as the back panel or substrate for housings of home appliances like washing machines and refrigerators.

DIY & Creative Projects: Its good machinability (easy to cut, drill, and edge-band) and stable quality make it popular among DIY enthusiasts and woodworking studios for creating various creative furniture and items.

Summary of Core Advantages:

The core value of high-strength crack-resistant particleboard lies in its reliability and versatility. It provides customers with an economical solution that achieves a perfect balance between load-bearing capacity, durability, dimensional stability, and workability, making it an ideal choice for mid-to-high-end furniture manufacturing, commercial renovation, and industrial applications.

|

Company Profile

We are China professional factory and supplier of OSB board making machine, MDF/HDF making machine and Flakeboard/Particleboard making machine. Whatever which size, thickness, capacity you want to make, and whatever what kinds of raw materials do you use, our professional team can offer a suitable and good solution for you.

From A to Z, from Raw materials to the final wood based panel, we can offer you all necessary machinery. including: Wood chipper, Strander, Disc chipper, Ring flaker, Rotary drum dryer, Vibrating screener, Glue dosing and applying system, Refiner, Mat frorming line, Continuous pre-press, synchronous Cross-cut saw, Multi-layers Hot press /Continuous single layer hot press, Auto edge trimming machine line,Sanding line,etc.

|

Package and transport

|

Exhibition

We regularly participate in international industry exhibitions based on the company's business development and customer needs. On one hand, this helps us showcase our company's strength and expand new customers. On the other hand, we visit existing customers for follow-up visits, thereby enhancing the bond between them.

Claim Your Free PB Line Layout! Get end-to-end plant design from strand preparation to sanding. Receive 3D factory plan within 30 days.