1. Main Frame and Insulated Casing

Frame Structure: Modular frame welded from standard Chinese GB/Q235B rectangular steel tubes. Typical module length is 3 meters/section.

Insulated Panels: Double-layer color steel sheets filled with 150mm thick rock wool (temperature resistance ≥350°C), insulation coefficient K≤0.45 W/m²·K.

Access Doors: Each section is equipped with sealed inspection windows and quick-opening access doors, featuring high-temperature resistant silicone seals.

Connection Structure: Standard flanges and high-temperature gaskets between modules ensure airtightness.

2. Mesh Belt Conveyance System

Drive Unit: Cycloidal/helical gear speed reducer motor with variable frequency drive (VFD) for stepless speed adjustment (0.5-5 m/min).

Carrier Rollers: Φ89mm seamless steel tube, galvanized surface, spaced 300-400mm apart, with self-lubricating bearings at both ends.

Tensioning Device: Screw-type or gravity-type automatic tensioning at the tail end, adjustable tension.

Edge Alignment System: Pneumatic or electric automatic alignment device, corrects misalignment when deviation >30mm.

Guide Wheels: Nylon guide wheels installed on both sides of the belt prevent lateral displacement.

3. Hot Air Circulation System (Core Drying Unit)

Heating unit

Circulation Fans

Air Distribution System

Return Air Duct

4. Moisture Exhaust & Fresh Air System

Exhaust Fan: High-pressure centrifugal fan, exhaust air volume is 10-25% of total circulation air volume.

Exhaust Damper: Electric/pneumatic modulating damper, automatically adjusts opening based on humidity sensor signal.

Fresh Air Inlet: Equipped with filter screens (washable primary filters) and optional preheating coils.

Heat Recovery Unit (Optional): Plate/heat pipe heat exchanger can recover 15-25% of heat from exhaust air.

Structural material configuration

Component | Standard Model Material | Optional Upgraded Material |

Main Frame | Q235B Rectangular Tube | 304 Stainless Steel Frame |

Insulated Panels | Color Steel + Rock Wool | Stainless Steel Panel |

Mesh Belt | SUS304 Stainless Steel | SUS316L / Galvanized Steel Belt |

Heat Exchanger | Steel Tube + Aluminum Fins | Stainless Steel Tube + Fins |

Air Duct Inner Wall | Galvanized Steel Sheet | Stainless Steel / Aluminum Sheet |

Carrier Rollers | Galvanized Steel Tube | Stainless Steel Tube |

1.Loading: Rotary-cut veneers are laid flat (manually or automatically) onto the moving mesh belt.

2.Preheating: Gentle heating to 40-60°C prevents surface hardening of the veneer.

3.Main Drying: Gradient heating across 3-5 temperature zones (70-120°C) with forced convection hot air penetrating the veneer.

4.Humidity Conditioning: Minimal steam spray relieves drying stress and reduces deformation.

5.Cooling & Setting: Natural cooling to 40-50°C stabilizes veneer dimensions.

6.Discharge & Collection: Dried veneer with moisture content reduced to 8-12% is stacked or fed directly to the next process.

Parameter | Economy | Enhanced |

Effective Belt Width | 1600 mm | 2200 mm |

Drying Section Length | 15 meters (5 sections x 3m) | 24 meters (8 sections x 3m) |

Operating Temperature | Ambient - 120°C | Ambient - 140°C |

Heat Source Type | Steam (0.4-0.8MPa) | Steam / Thermal Oil (Optional) |

Veneer Thickness Range | 0.5 - 3.0 mm | 0.3 - 4.0 mm |

Production Capacity | 8-12 m³/shift (MC 60%→10%) | 15-22 m³/shift |

Installed Power | 45-55 kW | 75-90 kW |

Control System | PLC + HMI, Basic Temp Control | PLC + HMI, Multi-zone PID Control, Data Logging |

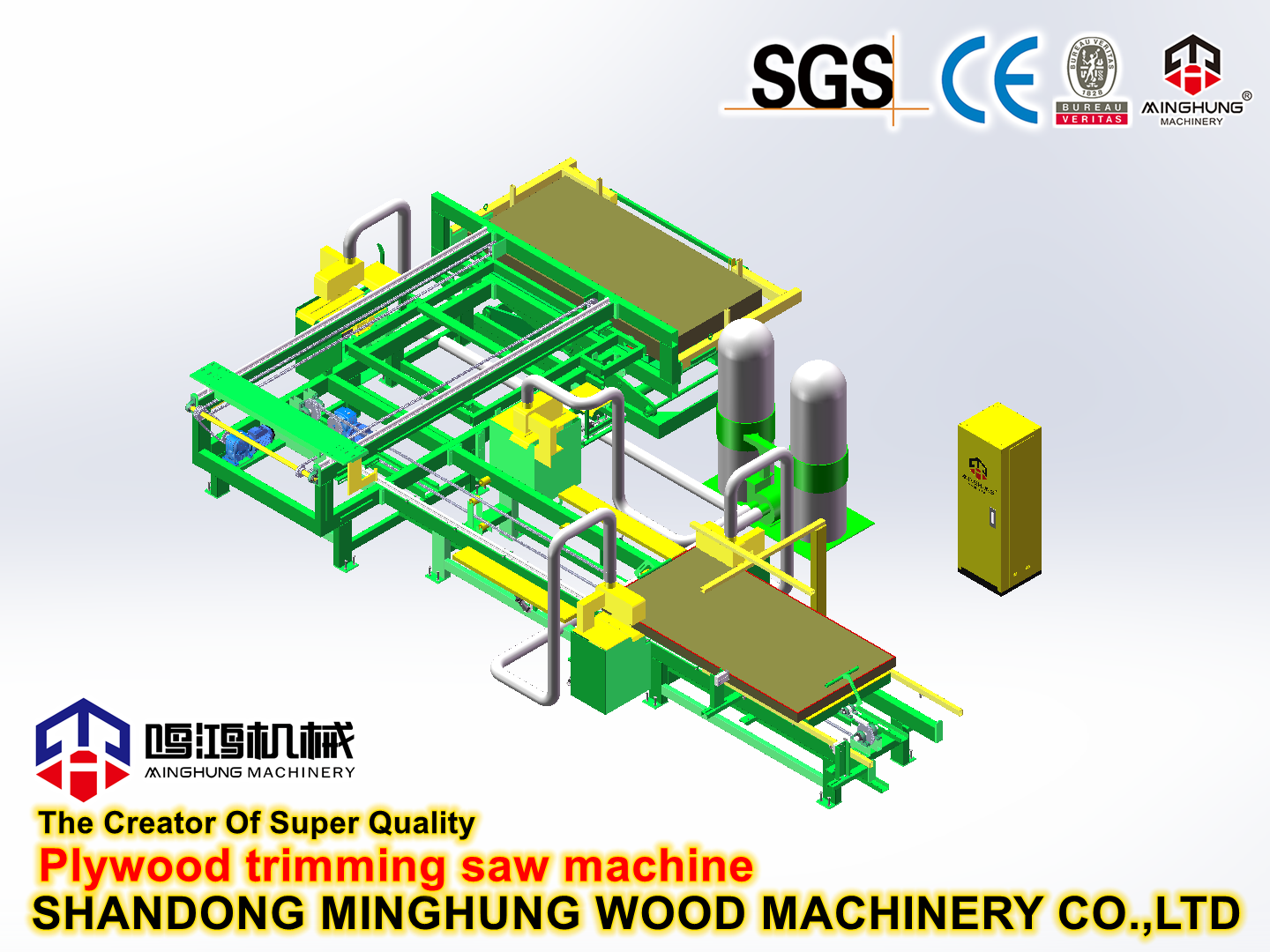

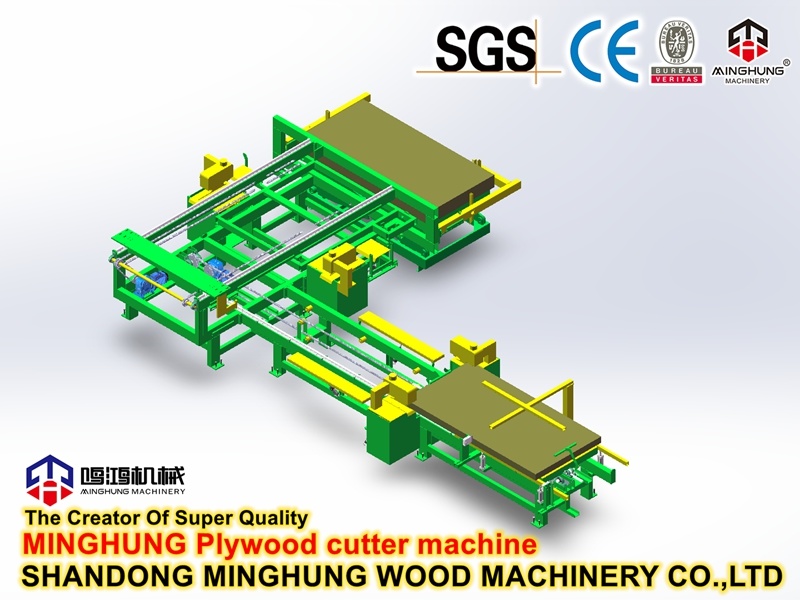

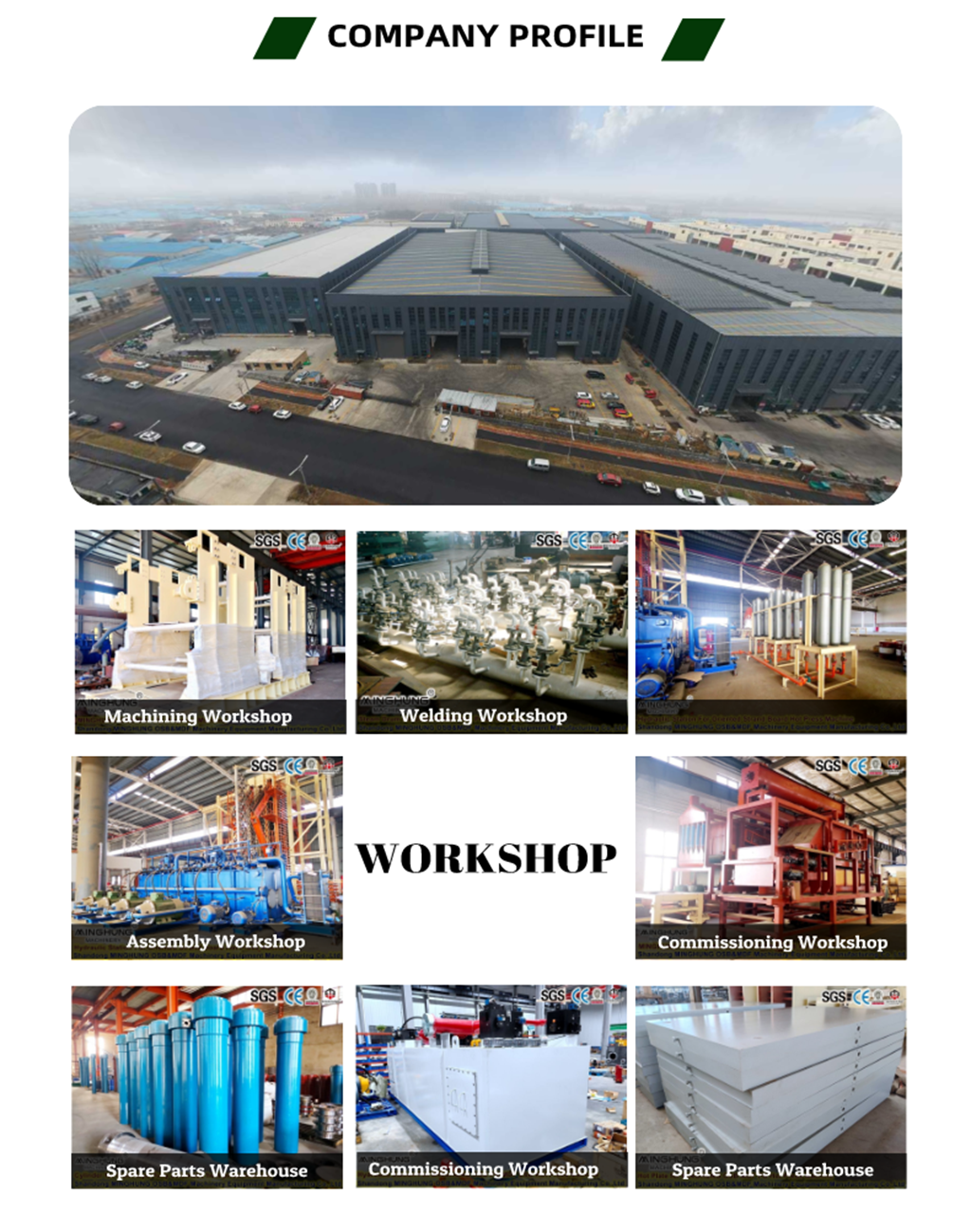

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

Choosing our Quick-Delivery Standard Model means gaining a comprehensive advantage in time, efficiency, and cost—not just acquiring a piece of equipment.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com