Automatic Vacuum Veneer Stacker

Dear Friends,

The world is so big, suppliers so many, if we meet, that's our destiny.

Such special chance, we cherish, so we must will offer you good and suitable machine, be your good partner and friend in China.

For save your precious time, please do not be hesitate send message to me, i will offer you information according to your needs.

The Purpose Buying Vacuum Veneer Stacker Machine:

Save two labors, connecting with veneer peeling machine, automatic sorting wood veneer, high efficiency.

In general, vacuum veet/5feet and 8feet/9feet, their configuration will be very different according to different requires. One type is not suitable for all people, so we always produce machinie according to our clients own conditions, make sure offer the most suitable machine to them.

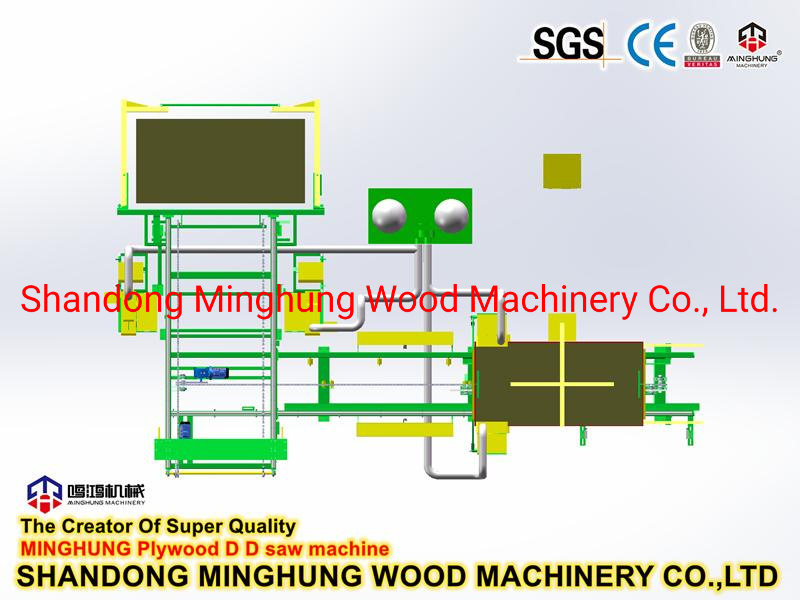

4feet & 8feet Vacuum Veneer Stacker

Parameter:

Parameter:

4feet veneer stacker

4feet veneer stacker

| name | vacuum veneer stacker machine |

| model | MH-VS127A |

| lifting mode | hydraulic lift |

| veneer size | 1400*500-1300mm |

| thickness | <3.6mm |

| installed power | 18.55kw |

| total weight | 2.2t |

| size | 4500*3200*2750mm |

8feet veneer stacker

| name | vacuum veneer stacker machine |

| model | MH-VS2600A |

| lifting mode | hydraulic lift *3kw*1set |

| veneer size | 2600*500-1300mm |

| thickness | <3.6mm |

| installed power | 23.25kw |

| total weight | 4.5t |

| size | 6500*3200*2750mm |

Workshop:

No 1. Matrial

Our experienced purchase manager choose the good machine material and spare parts after compare different suppliers,

No 2. Engineer

Our engineer service domestic and abroad clients more than ten years, from clients start build factory, plant layout, machine maintain, etc, offer all-sided support, this is a real engineer. The most important thing is: their serious and responsibility attitude is the main source for improving and optimizing our machine.

No 3. Processing Lathe

Our processing lathe make sure machine accurate, we have invested $3000000 for cnc lathe, precise cutter, welding machine, PLC test system, Machine test system and other machines, It reduces the intensity of workers' work, improve machine parts accuracy. this is the big weapon for us to competitive with other suppliers.

No 4. Multiple inspection procedures

The whole production step, will through more than 5 times detection to make sure machine production is good. And after finish production, our engineer will test machine to ensure it is in good conditions.

No 5. Factory Management

Our company and workshop use 5S (Seiri and Seiton, Clean-up and Removal, Attainment), the application of 5S make us become one international company, keep up with the world's top 500 companies.

No 6. Our Company Value

Continuous create much more value for clients.

Delivery:

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Website: www.plywoodmachineline.com

Email: minghungmachinery@gmail.com

4feet veneer stacker

4feet veneer stacker