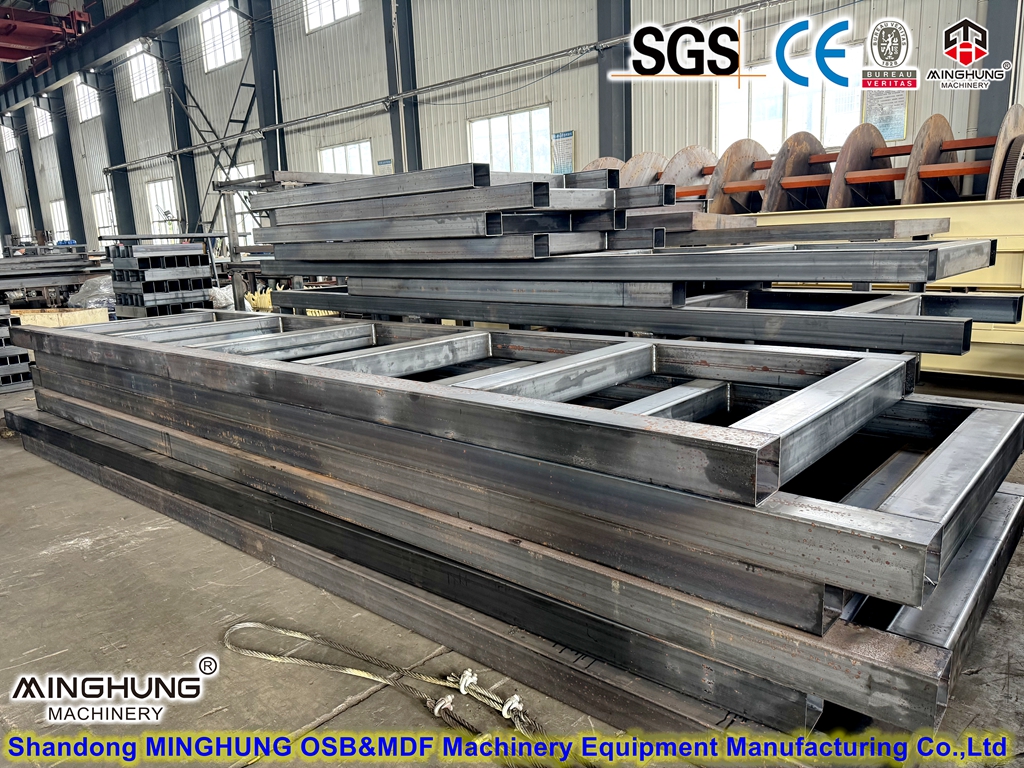

1. Main Structure

Drying Chamber: A large, well-sealed chamber or tunnel with internal insulation (e.g., rock wool) to prevent heat loss and improve energy efficiency.

Main Door: A sturdy, sealed door for loading and unloading the plywood.

2. Heating System:

Steam Pipeline: Includes main steam pipes, control valves, steam traps, etc.

Radiators (Finned Tube Heat Exchangers): The core heating components, typically installed at the top, bottom, or side walls of the drying chamber.

3. Ventilation System:

Circulation Fans: Usually axial or centrifugal fans that provide strong airflow to ensure even distribution of heat and humidity.

Air Ducts / Baffles: Scientifically designed ducts and baffles guide the hot air to flow optimally through the plywood stacks.

4. Moisture Exhaust System:

Exhaust Vents / Dampers: Their opening can be adjusted automatically or manually.

Exhaust Fans: Used to force the expulsion of humid hot air.

5. Control System:

PLC (Programmable Logic Controller) and Touch Screen: The brain and operation interface.

Temperature & Humidity Sensors: Monitor environmental parameters inside the chamber in real-time.

Actuators: Such as electric steam valves, exhaust damper actuators, etc., which act on commands from the PLC.

6. Loading System:

Drying Carts / Drying Racks: Used to stack the veneers/plywood into piles, which are then pushed into the drying chamber on carts.

7. machine parts

1. Loading: Wet, pressed plywood (typically with an initial moisture content of 60%-100% or more) is stacked onto drying carts, with stickers placed between each sheet to create air passages.

2. Charging: The loaded carts are pushed into the drying chamber, and the main door is closed.

3. Drying: The operator selects or sets an appropriate drying schedule on the control panel (based on wood species, thickness, etc.) and starts the program.

The program runs automatically through stages like Pre-heating → Constant Drying Rate Stage → Falling Drying Rate Stage → Conditioning & Balancing.

During this process, the PLC precisely controls the opening of steam valves (controlling temperature) and exhaust dampers (controlling humidity) based on real-time sensor data.

4. Discharging: Once drying is complete (final moisture content usually 8%-12%), the system stops. The door is opened, and the carts are pulled out. The plywood is now ready for subsequent processing and storage.