| What is Hot press machine? & What is its function |

800ton Hot press machine

Hydraulic hot press machine

Plywood hot pressing machine

Hot press machine is one necessary and important machine for paper & forest products production, usually used for making plywood board, LVL.

Hot press machine's function for pressing glued veneer plywood by suitable pressure and high heating temperature, to make inside glue melt and stick together and make each pieces of plywood board be strong and solid.

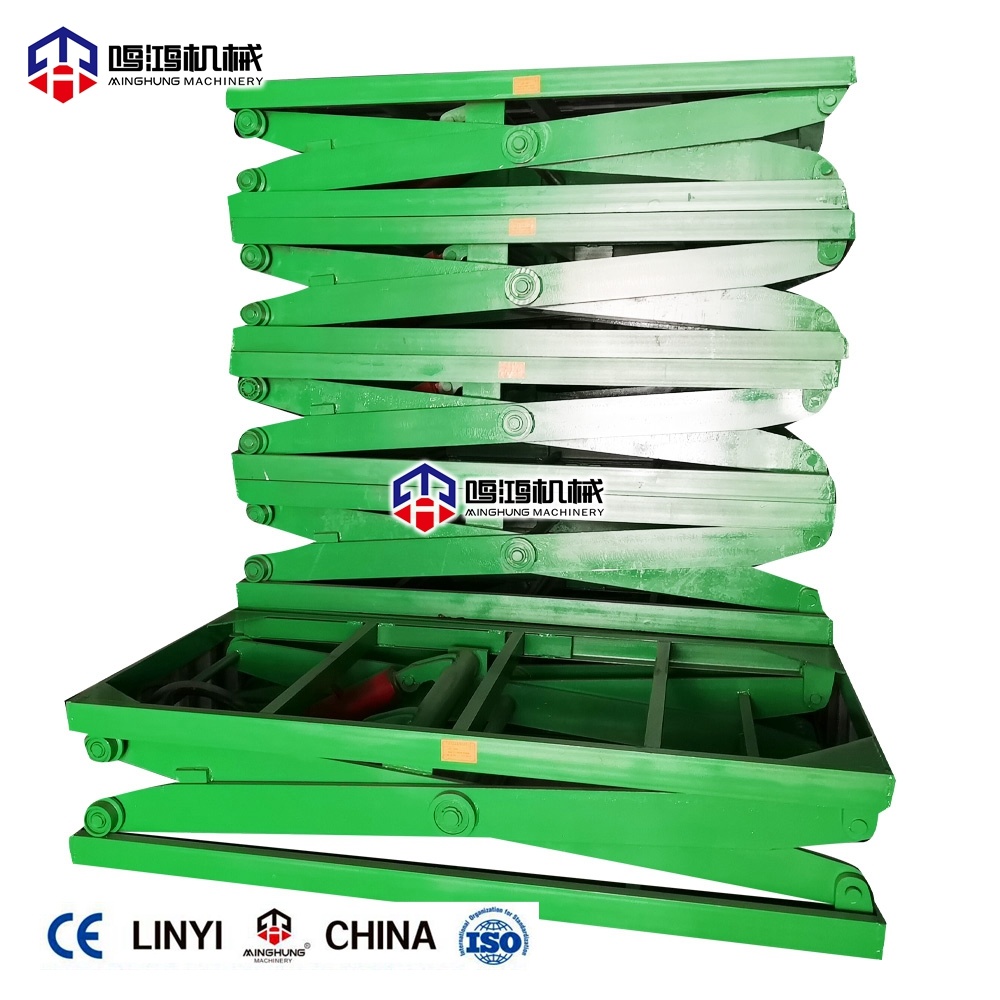

Hot press can be different layers and pressure to satisfy different requires. Each layers of hot press machine only can put one piece plywood, so the hot press mchine layers will decide plywood quantity one time. So some clients will choose less layers hot press machine like 5layers, 10 layers, some will choose multi-layers hot press macine like 30layers, 35 layers.

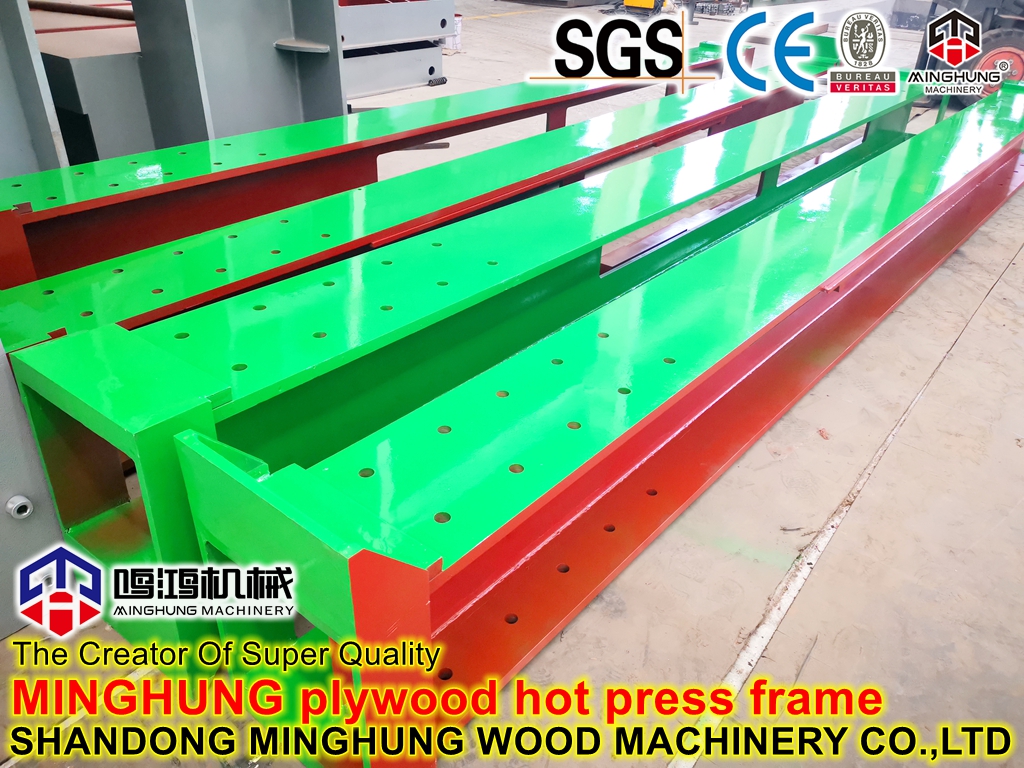

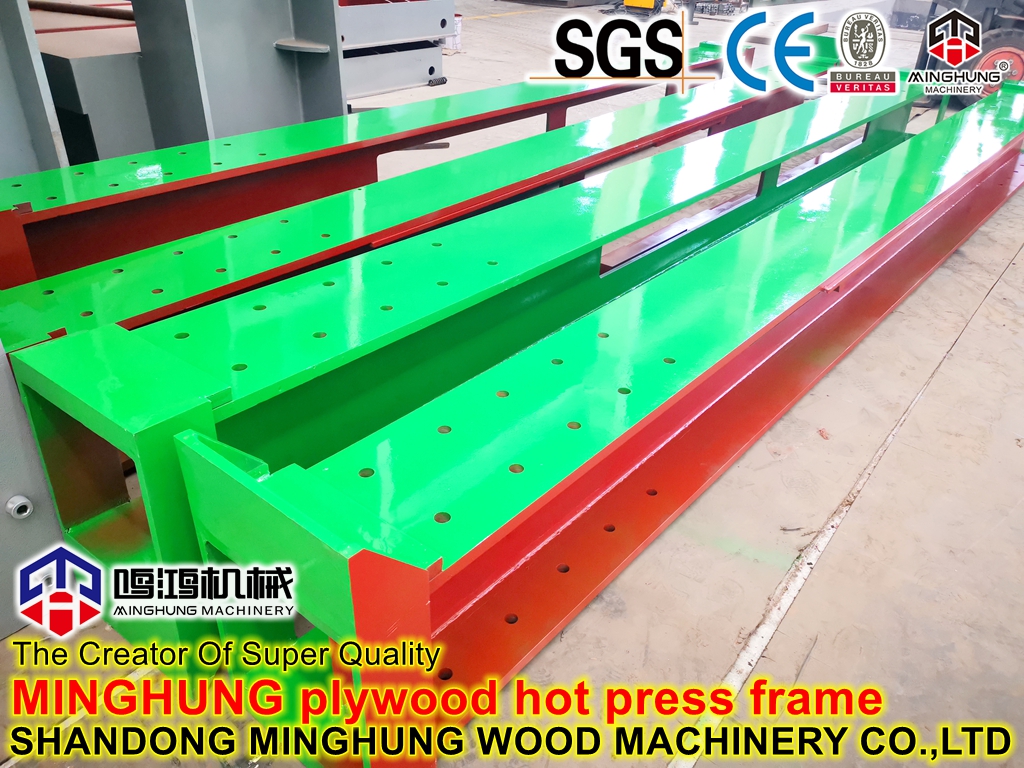

One set hot press machine's structure also not complex, mainly consist of press machine frame, hot platens, hydraulic system, electric system and others

| Hot press at our clients factory |

Hot press in Turkiye

Hot press in Vietnam

Hot press machine in Indonesia

15 layers 800ton hot press machine

Hot press with lift table

800ton Plywood hot press

Until now, we have exported many hot press machine to different countries, and got good feedback, some clients have bought five or more sets plywood hot press and introduced their friends to us.

| Mainly spare parts of Plywood hot press |

Hydraulic station

Oil cylinder

Thick material

For one set hot press machine, we can promise that we choose and use good materials and spare parts.

Hydraulic station: is also called hydraulic pump station, the motor drives the oil pump to rotate, and the pump pumps oil after absorbing oil from the tank, converting the mechanical energy into the pressure energy of the hydraulic oil.

Hydraulic oil cylinder: is a hydraulic actuator that converts hydraulic energy into mechanical energy and does linear reciprocating movement (or swinging movement). It is simple in structure and reliable in operation. When it is used to achieve reciprocating movement, the deceleration device can be eliminated, and there is no transmission gap, and the movement is smooth

Steel materials: It can be different thickness and quality choose, for our hot press machine, we choose thick steel materials to make the whole press body, make sure the whole press machine is strong and stable.

| Hot press machine loading pictures |

| Who we are? |

Veneer production machine

Veneer glue machine

Plywood cold press machine

With more than 20 years production experience, our factory can offer you the mature and good woodworking plywood machinery, from the raw materials wood to the end product plywood pane, we can offer you the full plywood production line.

The specific machines as below: Veneer production line (Debarking machine, Peeling machine, Log loader, Automatic stacker, Blade sharpener); Veneer dryer (Mesh dryer, Roller dryer, Veneer press dryer); Glue spreading machine; Veneer sewing machine; Plywood lay-up machine; Pre-press machine; Hot press machine; Plywood edge trimming machine; Sanding and calibrating machine; Plywood overturn machine; Lift table; Putty machine; Veneer patching machine and others

What we pursue is continuous to improve our machine characters and quality, insist use good levels spare parts and components, help our clients create much value.

| Questions you may want to ask |

<1> How long of your machine warranty?

2 years for main parts.

<2> The production time?

1 month.

<3> Payment terms:

T/T. 30% deposit, 70% before delivery.

<4> Will you help me solve when i meet problem about machine?

We will at the fist time reply you and help you solve.

<5> Will you engineer come to install machine?

Yes, when machine soon reach your factory, our engineer will go to your factory.

Welcome contact us for more information

Mark: +8618769900191

Ali: +8615805496117

Lucinda: +8615805493072