| I. Log Handling Section |

1. Debarker: Removes bark from logs to protect subsequent peeling knives and ensure smooth veneer surface. Common types are drum debarkers and ring debarkers.

2. Log Bucking Saw: Cuts long logs into standard-length sections based on production plans and peeling machine requirements.

3. Log Steaming Pond/Tank: Softens wood sections by heating with hot water or steam, reducing wood fiber hardness to enable the production of continuous, smooth, and crack-free high-quality veneer during peeling.

| II. Peeling & Veneer Processing Section |

4. Peeling Lathe: A core machine of the production line. It centers, clamps, and rotates the softened log at high speed while a sharp blade peels it into continuous sheets of veneer of varying thicknesses. Types include spindle (for large logs) and spindleless (for small logs) lathes.

5. Veneer Clipper: Cuts the continuous ribbon of veneer into rectangular sheets based on defects and size requirements.

6. Veneer Dryer: Dries the wet veneer to a suitable moisture content (typically 8-12%). The most common type is the roller dryer, which uses hot air for continuous drying. This is key for ensuring bonding quality and preventing warping.

7. Veneer Splicer: Joins small dried veneer sheets into large full-size sheets by stitching, finger-jointing, or taping, improving wood utilization. Includes dry veneer splicers and green veneer splicers (splicing before drying).

| III. Gluing & Layup Section |

8. Glue Spreader: A core machine. Spreads prepared adhesive (e.g., UF, PF resin) evenly onto the veneer surface. The common type is the four-roll spreader, which controls glue amount via upper and lower rollers.

9. Automatic Layup Machine: Automatically and accurately stacks glued core veneers with unglued face/back veneers according to preset layer count and grain direction (cross-grain) to form a mat. This is key for automation, efficiency, and ensuring structural symmetry.

| IV. Pre-pressing & Hot Pressing Section |

10. Pre-press: Applies cold (or mild heat) pressure to the assembled mat before hot pressing to achieve initial bonding, making it easier to handle and load into the hot press without collapsing.

11. Hot Press: The "heart" of the production line. It provides high temperature and high pressure to rapidly cure the adhesive in the mat within a short time, bonding the multiple veneer layers into a solid plywood panel. Usually multi-opening.

| V. Post-processing & Finishing Section |

12. Cooling & Turning Rack: Separates, turns, and cools the hot panels ,the hot plates freshly taken out from the hot press machine are then dispersed, flipped and cooled to ensure their uniform cooling, the release of internal stress and the prevention of deformation. exiting the hot press to allow uniform cooling and internal stress release, preventing warping.

13. Calibrating Sander: Sands both surfaces of the panel to eliminate thickness deviation, pre-cured layers, and surface defects, achieving precise thickness and a smooth, flat surface.

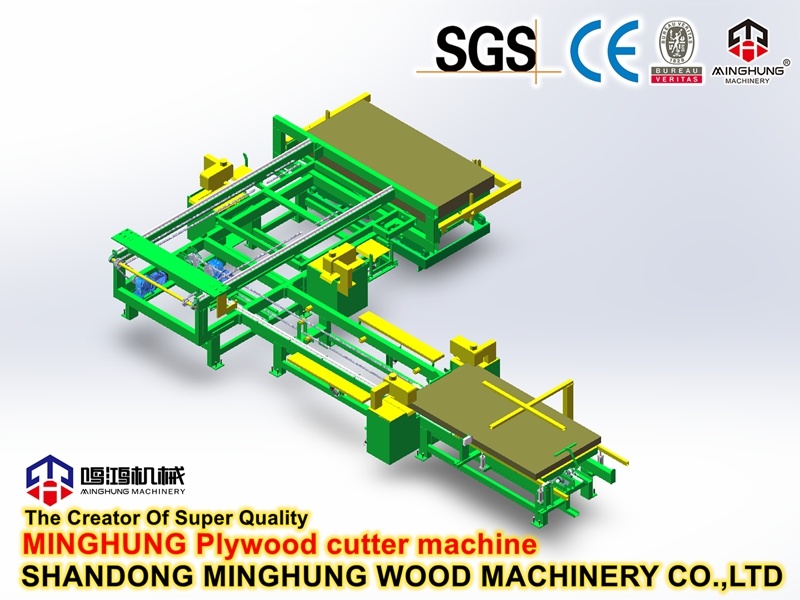

14. Cross-cutting & Rip-cutting Saw: Automatically cuts large-format rough panels into final standard-sized finished panels according to order specifications. Usually a combination of cross-cut and edge trimming saws.

turning machine

sanding machine

cross-cut saw

| VI. Auxiliary & Support Systems |

Glue Mixing System: Automatically prepares and supplies adhesive, including resin storage tanks, filler addition units, hardener metering pumps, and mixers.

Hydraulic System: Provides power for the hot press, pre-press, etc.

Thermal Energy Center: Provides heat (steam or thermal oil) for the dryer, hot press, etc. May include boilers, heat conduits, and control systems.

Dust Collection System: Collects wood chips and dust from various processes (especially sanding and cutting), ensuring a clean production environment and worker health.

Central Electrical Control System: PLC-based automation control system integrated throughout the production line for interlocking equipment control and process parameter management.

Real-time Moisture Content Monitoring System

This system is not a single piece of equipment but rather an integrated solution of intelligent sensing, actuation, and central control deployed at critical points throughout the plywood production line. It achieves precise,control of wood moisture content through real-time data acquisition, analysis, and feedback control.

1. High-Precision Online Moisture Sensors

Working Principle: Utilize high-frequency microwave or near-infrared (NIR) technology to perform non-contact, continuous measurement of the moisture content of moving veneers or panels. These technologies penetrate the wood surface, reflecting the true core moisture content, making them more efficient and comprehensive than traditional pin-type meters.

Installation Points:

Dryer Infeed: Measures the initial MC of wet veneers entering the dryer, providing baseline data for the drying process.

Dryer Outfeed: This is the most critical monitoring point. It directly measures the final MC of dried veneers to determine if they meet the preset process standards (e.g., 8%-12%).

Before the Glue Spreader: Monitors the MC of veneers about to enter the gluing stage. Ensures MC is within the optimal range (typically 6%-10%) for maximum bonding effectiveness.

After the Hot Press / Before the Curing Area: Monitors the moisture distribution of the panels after pressing, providing data for the curing process.

2. Data Acquisition and Processing Units

Function: Each sensor is connected to a data acquisition module responsible for converting sensor signals into digital MC values. These units feature signal filtering and preliminary processing capabilities to ensure data stability and accuracy.

3. Central Intelligent Control System

The System Brain: Typically a software platform running on an industrial PC or high-performance PLC.

Core Functions:

Data Integration: Receives real-time data from all sensors across the production line.

Visualization Dashboard: Dynamically displays real-time MC values, historical trends, and alarm information from all points on a touchscreen or computer via charts and graphs.

Logic Analysis & Decision Making: The system compares real-time data with preset process parameters. For example, if the MC at the dryer exit is consistently higher than the setpoint, the system determines under-drying.

4. Actuation and Interlocking Mechanisms

Function: Receive commands from the central control system and automatically adjust the operating parameters of related equipment, forming a closed-loop control system.

Typical Interlocking Controls:

Interlock with Dryer: The core application. If the system detects overdried veneers, it automatically lowers the dryer temperature or increases the conveyor speed; conversely, for wet veneers, it raises the temperature or decreases the speed, achieving precise drying and saving energy.

Interlock with Glue Spreader: Micro-adjusts the glue spread amount based on the real-time veneer MC. Slightly higher MC may trigger a small increase in glue, while lower MC may trigger a decrease, ensuring bonding quality while saving adhesive.

Interlock with Hot Press: Intelligently optimizes the hot press curve parameters (temperature, pressure, time) based on the mat's moisture condition, ensuring complete glue curing with minimal energy consumption.

Alarm & Sorting: For veneers or panels with seriously out-of-spec MC, the system triggers audio-visual alarms and can interlock with automatic sorting devices to reject them from the production line.

5. Network Communication Architecture

Composition: High-speed fieldbus technologies like Industrial Ethernet, PROFINET, or EtherCAT ensure real-time and stable data transmission between all sensors, actuators, and the control system.

This system transforms moisture content from a result parameter that required post-process lab testing into a process parameter that can be controlled in real-time through the "Sense-Analyze-Actuate" closed loop. This fundamentally enhances the intelligence level of plywood production and ensures superior product quality consistency.

Plywood is an engineered wood panel made from three or more thin layers of wood veneer. These layers are glued together with their wood grains rotated up to 90 degrees to one another. This "cross-graining" structure gives plywood several key advantages: high strength and dimensional stability across all directions, effectively overcoming the natural anisotropy and tendency to warp or split found in solid wood.

Core Structure & Production Process

1. Core Structure: Symmetry Principle

Odd Number of Layers: Typically 3-ply, 5-ply, 7-ply, etc., to ensure a symmetrical and balanced structure, preventing warping.

Cross-Graining: The grain direction of adjacent veneers is perpendicular. This structure counteracts wood's stress, making the panel's strength and shrinkage properties consistent in all directions.

2. Production Process

Log Handling: Debarking, cutting, steaming (softening).

Peeling: Rotating the log against a blade to peel it into continuous veneer sheets.

Veneer Drying: Drying veneers to a suitable moisture content (8-12%).

Veneer Patching & Splicing: Repairing defects and splicing small sheets into full-size veneers.

Gluing & Layup: Applying adhesive and assembling the veneers with grains perpendicular.

Pre-pressing & Hot Pressing: Curing the adhesive under high temperature and pressure to bond the layers.

Post-processing: Cooling, sanding, trimming, grading, inspecting, packaging.

Key Features & Advantages

High Strength & Strength-to-Weight Ratio: Stronger than solid wood of comparable thickness.

Excellent Dimensional Stability: Resists shrinking, swelling, cracking, and warping.

High Utilization & Eco-friendly: Efficiently uses small-diameter logs and short wood, reducing waste.

Good Workability: Easy to cut, nail, drill, paint, and glue.

Large Format: Available in large sheets without needing joins.

High Decorativeness: Can be overlaid with various attractive wood grains and styles.

Construction & Civil Engineering: Concrete formwork, interior & exterior wall/roof sheathing, partitions, ceilings.

Furniture Manufacturing: Substrate and panels for high-end furniture, cabinets, tables, wardrobes.

Interior Decoration: Floor underlayment, wall paneling, door cores.

Packaging & Transport: Export crates, pallets, container flooring.

Transportation: Interior paneling for cars, trains, and ships.

Others: Speakers, sports equipment, advertising boards.

We can offer factory layout design, installation, operator training, 24-month warranty, and global spare parts delivery within 72 hours.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com