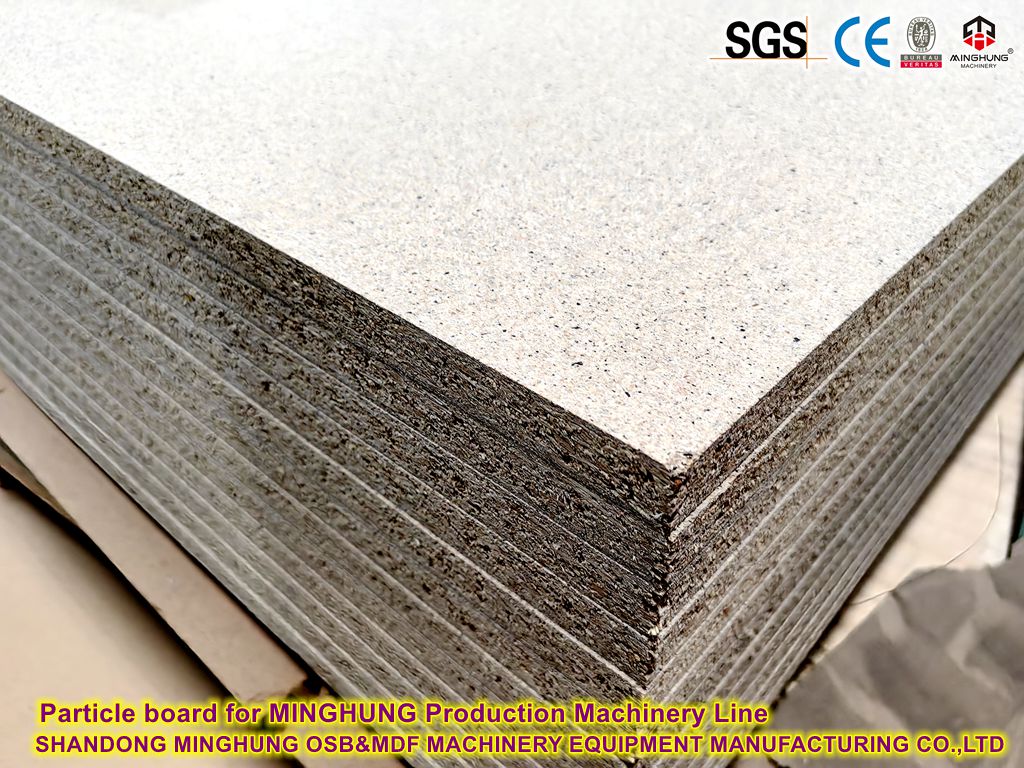

This production line is a highly automated and continuous industrial system, primarily composed of the following core machinery and equipment that work in synergy to complete the entire manufacturing process from raw wood material to finished particleboard.

1. Raw Material Preparation Section

Debarker (if required): Used to remove bark from the surface of logs. Bark can adversely affect board quality and color and is typically removed in the first step of raw material pre-processing.

Chipper: Chips logs, branches, or wood residues into uniformly sized wood chips that meet process requirements, providing consistent feedstock for subsequent flake production.

Flaker/Flaking Mill: Further processes wood chips into specialized flakes with uniform thickness and a smooth surface. This is key to ensuring the surface quality and mechanical properties of the particleboard.

Refiner/Mill: Used to break down larger or coarse flakes into finer surface flakes to meet the size requirements for different structural layers (surface and core layers).

Screening Machine/Sifter: Grades flakes by size using multi-layer vibrating screens. It separates oversize flakes (which are returned for re-crushing or chipping), qualified core flakes, qualified surface flakes, and excess fines (which are removed).

2. Drying and Blending Section

Rotary Drum Dryer: Dries the sorted wet flakes efficiently and uniformly using high-temperature hot air, reducing their moisture content to a precise range as required by the process to ensure subsequent bonding quality.

Dry Flake Sifter: Re-screens dried flakes to separate out fines and不合格 flakes deformed during drying, ensuring high-quality flakes are sent for blending.

Ring Blender (Surface/Core Layer): One of the core equipment in particleboard production. Dried surface and core flakes are fed into their dedicated blenders. High-speed rotating paddles ensure thorough and uniform mixing of flakes with resin, hardener, waterproofing agent, and other chemicals.

3. Forming and Pre-pressing Section

Mechanical/Air Forming Station: Uniformly and symmetrically spreads resinated surface and core flakes onto the caul plate according to a pre-set mat structure (typically a three-layer "surface-core-surface" structure), forming a continuous mat with consistent thickness and density. This is critical for ensuring uniform thickness and density distribution in the finished board.

Pre-press: Applies continuous cold pressure to the loose formed mat, giving it initial strength (green density) and integrity for easier handling and loading into the hot press. It also reduces the compression stroke required during hot pressing, improving production efficiency.

4. Hot Pressing and Finishing Section

Continuous Press: The heart and most critical equipment of the entire production line. The mat is conveyed on steel belts through a long heating plate zone where temperature and pressure are precisely controlled. Under high heat and pressure, the resin between flakes cures rapidly, consolidating the loose mat into a solid board with high strength, high density, and specified thickness. Continuous presses offer high production efficiency, stable board quality, and minimal thickness deviation.

Cooler: Gradually and uniformly cools the high-temperature boards exiting the hot press. This releases internal stresses, sets the resin bond, prevents board warping, and reduces moisture content. Star-coolers or roller coolers are typically used.

Longitudinal Edge Trimmer & Cross-Cut Saw: After cooling, the continuous board is first trimmed on both sides by the longitudinal saws and then cut to the required panel size by the cross-cut saw.

Sanding Machine: Typically a wide-belt sander with multiple heads (e.g., coarse and fine). Sands the top and bottom surfaces of the board to achieve precise final thickness and a smooth, flat surface by eliminating thickness deviation, the pre-cured layer, and surface defects. This prepares the board for laminating or direct use.

Stacker: Automatically stacks the finished boards into neat piles for easy packaging, storage, and transportation.

5. Auxiliary Systems

Energy Plant/Heat Generation: Provides the required heat for production, including thermal oil or steam for the dryer and hot press. It often uses process waste like sander dust, bark, and flakes as fuel, achieving energy self-sufficiency and environmental benefits.

Dust Extraction System: A central dust collection network throughout the plant collects wood dust and chips generated at various stages. It ensures a clean production environment, mitigates explosion risks, and recovers usable material.

Electrical & Automation Control System: Uses PLCs and industrial computers for centralized control and process monitoring of the entire line. It enables precise setting, adjustment, and recording of production parameters (temperature, pressure, speed, ratios, etc.), ensuring production stability and consistent product quality.