|

Product Description

The Spindleless Veneer Peeling Machine is a revolutionary piece of equipment in the modern veneer production industry. It completely abandons the traditional design of spindle-type lathes, which require spindles to clamp the log through its center for rotation. Its core principle involves using multiple (typically two or three) motorized driving rollers to frictionally grip the log's outer circumference, directly driving the log itself to rotate, thereby enabling peeling. This design fundamentally eliminates the limitation imposed by "spindles" on the log diameter, allowing the log to be peeled almost completely to its end. This significantly reduces the core remnant and dramatically increases the veneer yield and raw material utilization rate.

|

Working Principle

The operation of a spindleless peeler can be summarized as "peripheral driving, pressure roller centering, coreless peeling."

1. Driving and Clamping: The main driving rollers (usually two) located beneath the log rotate in opposite directions, driven by motors. When a log is placed on them, friction causes the log to rotate. Simultaneously, the upper pressure roller, controlled by hydraulics or a servo motor, applies downward force, pressing the log firmly against the driving rollers. This forms a secure "roller-log" frictional driving pair and automatically determines the log's instantaneous center of rotation.

2. Peeling and Feeding: Similar to spindle-type machines, the knife carriage equipped with the peeling knife moves in a steady linear feed towards the rotating log. Because driving relies on the log's outer circumference, as peeling progresses and the log diameter decreases, the driving rollers and pressure roller automatically and continuously adjust their positions based on detected diameter changes or a preset program. They constantly maintain tight pressure and stable driving on the log.

3. Peeling to the Core: This process continues until the log diameter becomes very small (often as small as 40-60mm) and can no longer be effectively gripped and driven, or until a preset minimum diameter is reached. Ultimately, only a very small core remains, achieving maximum wood utilization.

|

Main components

1. Base and Bed: A high-rigidity, integrally welded structure ensures stability and precision under asymmetric cutting forces.

2. Twin Driving Roller System: The core driving component, typically consisting of two rollers with special surface patterns or rubber coating to provide powerful frictional drive.

3. Upper Pressure Roller Assembly: A hydraulically or servo-controlled roller used to press down on the log, providing clamping force and centering function.

4. Knife Carriage Assembly: Includes the peeling knife, pressure bar, and their adjustment mechanisms. Its feed motion is typically controlled by a servo motor and a precision ball screw for high-accuracy thickness control.

5. CNC Control System: The "brain" of the spindleless peeler. It is usually equipped with an advanced PLC and a touch-screen HMI for setting veneer thickness, controlling the movement logic of the rollers, storing process parameters, and enabling fault diagnosis.

6. Hydraulic System (if applicable): Provides stable and adjustable pressure for the pressure roller.

|

Prominent advantages

Extremely High Yield: No need to reserve a core for spindles, allowing logs to be peeled to a much smaller diameter. Yield is generally 15%-30% higher than spindle-type machines.

Wide Raw Material Adaptability: Exceptionally good at processing small-diameter logs, short logs, crooked logs, and irregularly shaped wood blocks, which are difficult to process efficiently with traditional spindle-type machines.

High Veneer Quality: Peripheral driving minimizes impact and damage to the log, helping to reduce checks (splits) on the back of the veneer and improving veneer integrity and quality.

High Automation Level: The entire process from loading to the end of peeling can be automated or semi-automated, reducing labor intensity and skill requirements for operators.

High Production Efficiency: Reduces downtime associated with retracting spindles and removing cores when changing logs, leading to better production continuity.

|

Application scenarios

The spindleless veneer peeler is an ideal choice for:

Factories focusing on processing small-diameter fast-growing timber (e.g., poplar, eucalyptus).

Enterprises with extreme demands for yield, seeking to maximize raw material value.

Factories recycling wood processing residues (e.g., branches, off-cuts).

Modern production lines producing high-quality decorative thin veneers.

|

Product Packaging

|

Comment & FAQ

1.How long the production time?

A:If one set machine,3-4 months;If the full production line 6-8 months.

2.What are your advantages?

A:We have rich experience in the market, with the same cost, we do better because we have strict control of the production process. We have an independent inspection department to check the quality.

3.Can you customize products for customers?

A:Yes, we can customize products according to customer requirements or drawings. At the same time, we protect customers' business privacy with the strongest awareness.

4.What payment methods do you offer?

A:Usually T/T and LC. If you have other payment methods, we can also consider it.

|

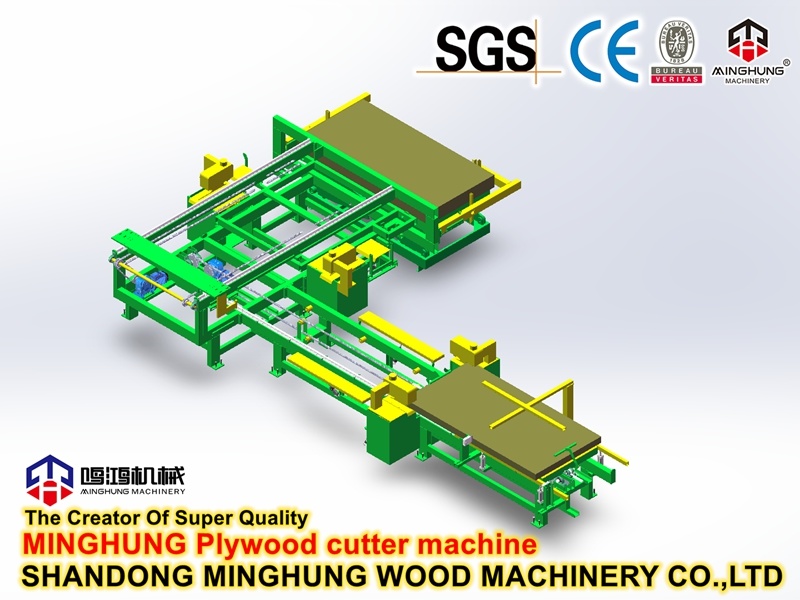

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

Machines include:Veneer production line(Log debaker,Veneer peeling machine, Log loader,Automatic stacker),Blade sharpener,Veneer patching machine,Veneer dryer machine(Veneer roller dryer, Veneer mesh dryer, Veneer press dryer), Veneer gluing machine,Plywood lay-up machine, Veneer jointing machine, Plywood cold press, Hot press machine,Plywood edge trimming cutting machine, Sanding and calibrating machine, Plywood overturn machine, Lift table, and so on.

|

Certifications

Customize Your Plywood Solution Now! Plant layout design, on-site training & global logistics support – Build your competitive plywood brand today!

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com