4feet Spindleless Rotary Veneer Peeling Machine for Peeled Beech Veneer Production

Veneer peeling machine instruction: Rotary cut veneer peeling machine are used to produce pieces of wood veneer, also be called piles through process the suitable wood be cutted to the required length and diameter. And veneer is the material for making plywood, Blockboard, and other wood based panel board. Veneer peeling machine will be related with max log length and max log diameter. Especially the max log diameter, it will be divided into Spindleless veneer peeling machine and Spindle veneer peeling machine. Their big difference is that the applicable wood diameter are different. For the spindleless veneer peeling machine, it has 4feet and 8feet size, for the 4feet spindless peeling machine, its max wood diameter is 500mm, for the 8feet spindleless peeling machine, its max wood diameter is 600mm. And for the Spindle peeling machine, it can peel big diameter log, like 1000mm, 1300mm, so according to your wood diameter, you can choose the suitable veneer peeling machine. The appearance of CNC rotary peeling machine not only improves the quality and precision of the veneer, but also greatly improves the production efficiency and the degree of automation of the whole peeling machine. Rotary veneer peeling machine is one of the main equipment for producing plywood. Veneer is the material for making plywood, and veneer peeling machine for produce veneer through process the mateiral-timber wood. What is Beech veneer?

Beech, also be called alias oak king Kong, lime wood, white half tree, miscellaneous tree, dwarf chestnut tree, long stalk beech, water green hill, scientific name Fagus. Beech is a kind of plant in the family Beech of the order Beech, widely distributed in Asia, Europe and North America, and is one of the main tree species in temperate broad-leaved deciduous forests. The fruit is also food for some small mammals. Fagus, a genus of about 10 deciduous ornamentals and wood trees, is found in temperate and subtropical regions of the Northern Hemisphere. beech is a generic name for several different types of tree species, especially about 10 deciduous ornamentals and wood trees in the genus Fagaceae, which are mainly found in temperate and subtropical regions of the Northern Hemisphere. European beech (Fagus sylvatica) Beech wood is a light reddish brown wood that resists decay under water and is used for interior fittings, decorations, tool handles and containers What's the beech wood can be applied? For example, For Musical Instruments, instrument boxes, high-end furniture, veneer veneer, plywood, floor, wallboard, corridor handrails, sports equipment, ships, vehicles, stationery, industrial and agricultural tools, farm tools, barrels, toys, miscellaneous utensils, wooden posts, sleepers, pit wood, pole, papermaking, charcoal burning materials, is also a good fuelwood raw materials. The beech floor has an even white belt red, which can be turned reddish-brown by steam treatment. It has a fine and uniform structure, medium weight and a density of 0.72g/cm3. It is a loose material with fine holes, clear rings and eye-catching wood rays. Small elasticity, hardness, wear resistance, easy to split, toughness, large bearing capacity, suitable for all types of processing machines, easy to process. Beech wood is easy to dry. By steam pretreatment, it can bend well. Here, it impregnates well and is easy to finish, resulting in a variety of desired tones. Beech trees are susceptible to mildew and should not be left untreated. Parameter: | name | veneer peeling machine |

| model | MH-VPM4A |

| max log length | 1400mm |

| max log diameter | 500mm |

| thickness | 0.5-4.0mm |

| max speed | 80m/min |

| total power | 47.2kw |

| total weight | 6800kg |

| size | 4500*2300*1500mm |

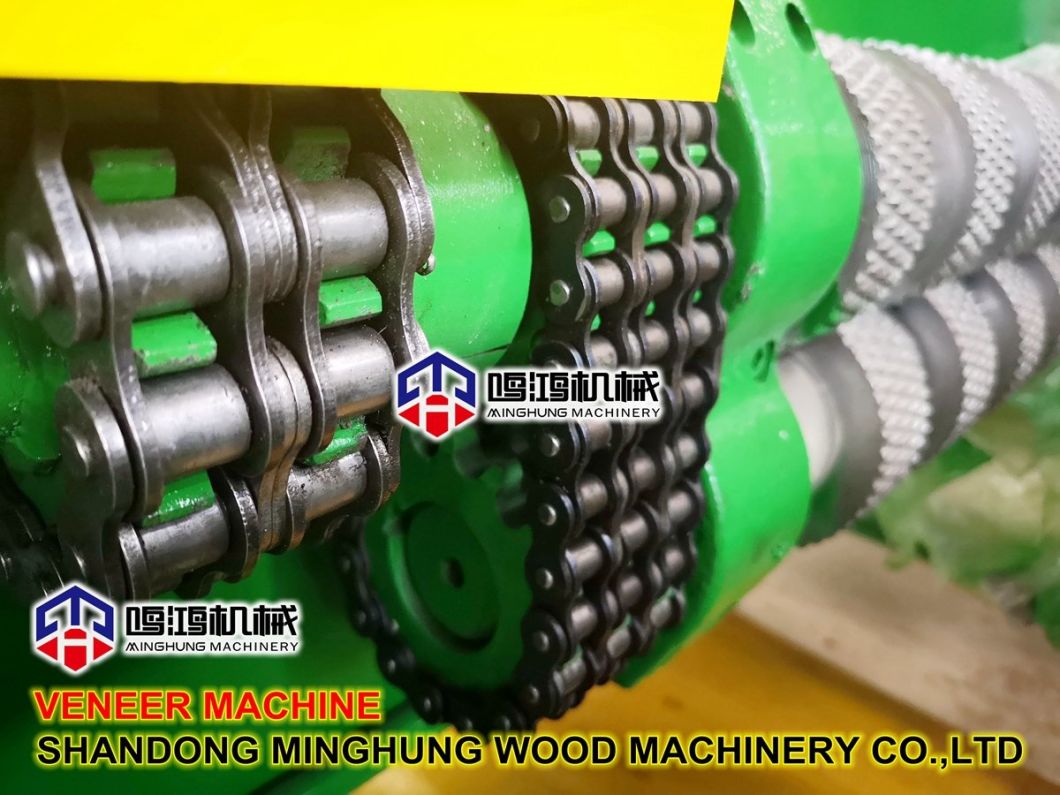

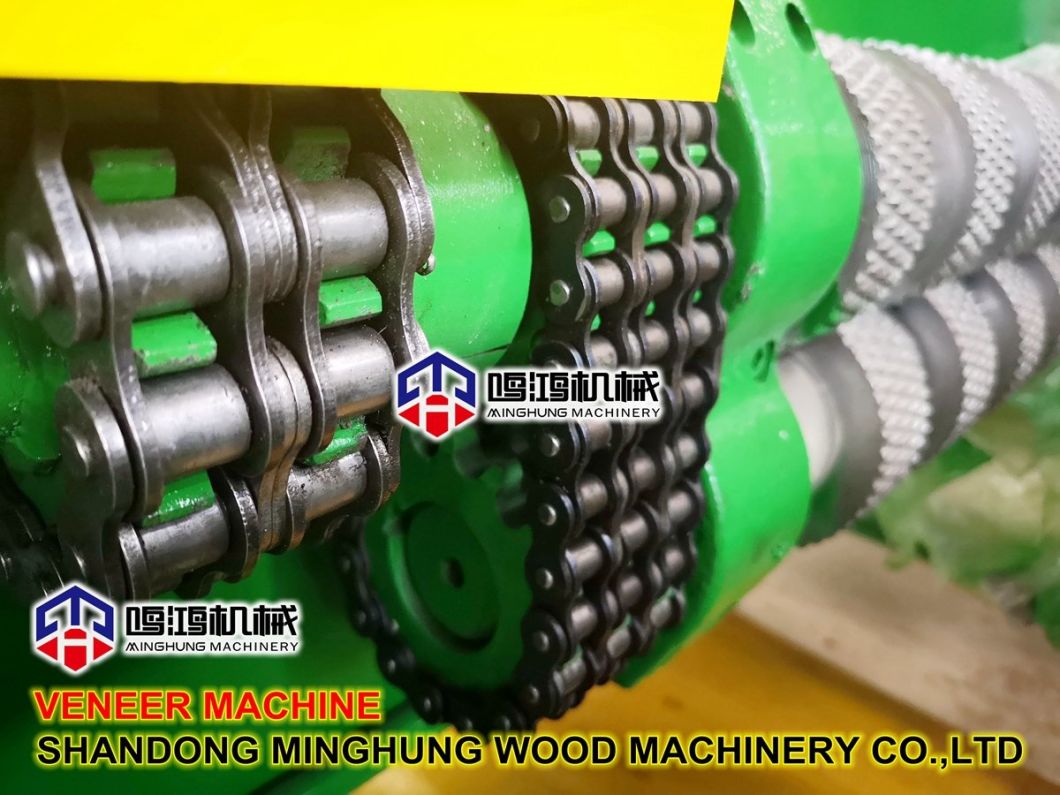

Parts of Veneer Peeling Machine:

<1> cnc screen, english language, convenient adjut veneer thickness, width.

<2> using cross-roller, the left core diameter is small, improve wood utilization.

<3> using accurate feeding screw, screw pitch is very small, make sure veneer thickness accurate.

<4> motors and frequency invertor use big power, make sure offer powerful energy to machine.

<5> all main parts of veneer peeling machine be processed by big lathe, details affect the whole machine quality.

<6> veneer machine use good material, make sure peeling machine is stable when working.

China MINGHUNG PLYWOOD VENEER MACHINE: No 1. Matrial

Our experienced purchase manager choose the good machine material and spare parts after compare different suppliers,

No 2. Engineer

Our engineer service domestic and abroad clients more than ten years, from clients start build factory, plant layout, machine maintain, etc, offer all-sided support, this is a real engineer. The most important thing is: their serious and responsibility attitude is the main source for improving and optimizing our machine.

No 3. Processing Lathe

Our processing lathe make sure machine accurate, we have invested $3000000 for cnc lathe, precise cutter, welding machine, PLC test system, Machine test system and other machines, It reduces the intensity of workers' work, improve machine parts accuracy. this is the big weapon for us to competitive with other suppliers.

No 4. Multiple inspection procedures

The whole production step, will through more than 5 times detection to make sure machine production is good. And after finish production, our engineer will test machine to ensure it is in good conditions.

No 5. Factory Management

Our company and workshop use 5S (Seiri and Seiton, Clean-up and Removal, Attainment), the application of 5S make us become one international company, keep up with the world's top 500 companies.

No 6. Our Company Value

Continuous create much more value for clients.

Delivery:

Before loading, we will test veneer machine until make sure it is in good conditions, and we will show you test video.

<2> When loading, we will share loading pictures with you

<3> After ship leave, we will offer you container and ship information, and send all documents to you

Peeling machine in Client factory:

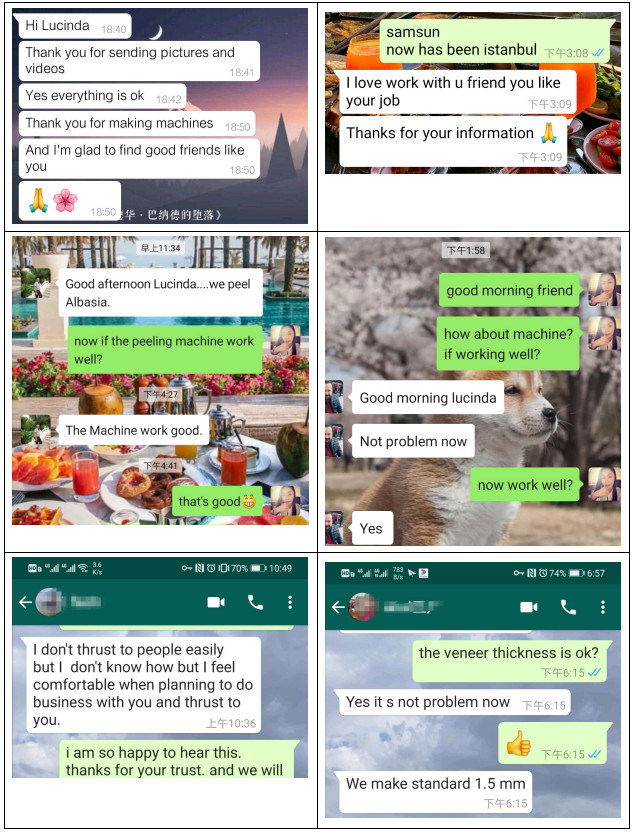

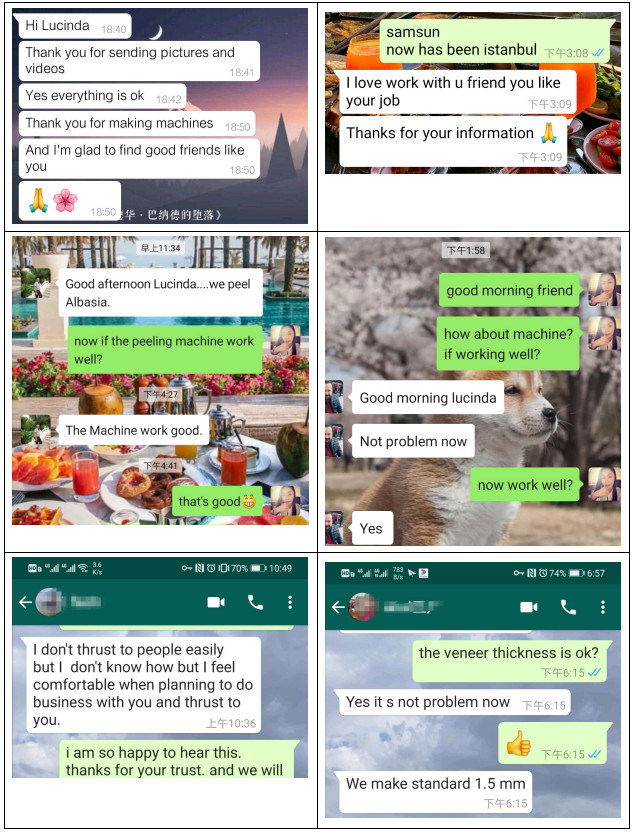

Clients Comment: