1. Raw Material Processing Equipment

Drum Chipper: Capacity 20-25 t/h

Particle Crusher: Processes oversized particles

Vibrating Screening System: Three-deck screen design

Washing Equipment: Removes sand and impurities

drum chipper

particleboard vibrating screen

2. Drying Equipment

Triple-pass Rotary Dryer: Evaporation capacity 8-10 t/h

Thermal Energy Center: Biomass fuel heating

Dust Removal System: Cyclone + baghouse filter

dryer

energy center

3. Blending Equipment

Ring Blender: Volume 8-10 m³

MDI Adhesive Supply System: Constant temperature storage

Wax Emulsification System: Improves moisture resistance

4. Forming Equipment

Mechanical Former: Forming width 1300-2600mm

Mat Weighing System: Accuracy ±0.5%

Pre-press: Preliminary mat compaction

mat forming machine

pre pressing machine

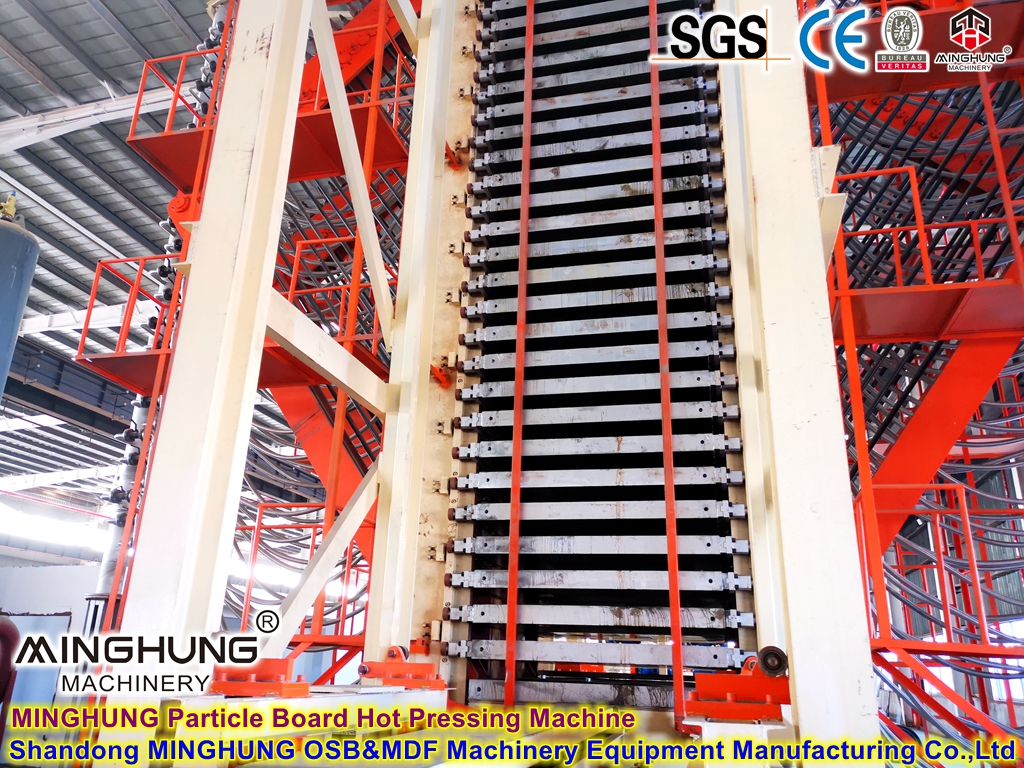

5. Pressing Equipment

Multi-opening Hot Press: 15 openings, 4'×16' platen size

Heating System: Thermal oil heating

Hydraulic System: Precise pressure control

6. Finishing Equipment

Board Cooler: Cooling time 40-60 minutes

Cross-cut & Edge Trim Saws: CNC dimensional cutting

Wide Belt Sander: 4-head, sanding amount 0.5-1.0mm

Board Cooler

Cross-cut & Edge Trim Saws

Sander

7. Auxiliary Equipment

Central Dust Collection: Air volume 200,000 m³/h

Electrical Control System: Siemens PLC control

Quality Testing Equipment: Internal bond strength tester

Technical Features

1. Uses MDI formaldehyde-free adhesive, formaldehyde emission ≤0.03 mg/m³

2. High automation level, only requires 15-20 operators

3. Low energy consumption, steam consumption ≤1.2 ton/product ton

4. High product precision, thickness deviation ±0.15mm

5. Meets environmental standards, dust emission ≤20 mg/m³