Laminated Veneer Lumber Plywood Machine

Laminated Veneer Lumber Plywood Machine Laminated Veneer Lumber (LVL for short) is a veneer made by rotary cutting. The blanks are assembled in sequence in the direction of the grain, and the ends are mitered, lapped or butted, and then pressed by processes such as gluing and hot pressing. It is a high-strength structural material with flexural strength of 18MPa, shear strength of 1.7MPa, and elastic modulus of 10000MPa. VL has the characteristics of uniform engineering performance and flexible specifications. It is superior to solid wood and is especially suitable for VL is especially favored by plywood manufacturers and veneer manufacturers on large-span wooden structures, and its consumption is expected to increase steadily in the future. It can make full use of artificial fast-growing forests and medium and small diameter logs to produce high value-added products.

LVL can be divided into two main categories: structural (ie load-bearing members) and non-structural (ie non-load-bearing members). The original structural material LVL was only used for simple beams, and now it is more and more widely used, such as structural frames, I-beams and other composite products. The main difference between non-structural LVL and structural LVL is that it cannot be used for load-bearing structures, but only for furniture components, stair components, door and window frames, etc. LVL has various specifications and a wide range of thicknesses. The thickness range of structural material LVL is mostly 2-5mm, the maximum thickness can reach 150mm; the width range is 100-1800mm; the length range is 2500-25000mm, even infinite. The size of the non-structural material LVL is usually 5 to 50 mm in thickness, 75 to 150 mm in width, and 300 to 600 mm in length. When producing a 4" X 8" LVL, a plywood plant can produce a cost-effective and dimensionally flexible LVL product with a small investment using most of the existing machinery and equipment.

The strength-to-weight ratio of structural material LVL is better than that of steel. The LVL formed by the parallel grain can reproduce the anisotropic characteristics of the wood to the greatest extent, and the longitudinal strength of the wood can be fully utilized when the structure is stressed. Because the knots and veneer cracks of the wood itself are dispersed and evenly distributed in the product, it has uniform mechanical properties, and has the characteristics of uniform quality, stable performance, accurate size and consistent straightness unmatched by other structural materials. And the processing is convenient, can be sawing, slicing, chiseling, tenoning, nailing and so on. After flame retardant treatment, the fire resistance is higher than that of steel, the weather resistance is good, and the shock resistance is strong.

Since the laminated structure of LVL greatly reduces the warpage and distortion of the product, it has good dimensional and shape stability.

The economy of LVL lies in that it can use different wood species and raw materials of different quality for lamination and gluing, so as to achieve the value-added effect of big use in small villages and good use of inferior wood. way. The LVL processing technology is mature, the equipment is simple, the production energy consumption is low, the yield is high, the pollution is small, and the production cost is not high.

LVL has a wide range of uses. It can be used not only in residential and commercial buildings, but also as vehicle materials, shipbuilding materials and sleepers. It can be widely used in various fields from load-bearing structures, non-load-bearing structures to furniture frames. When used in residential buildings, it can be widely used in houses, structural frames and floor systems. Due to its high strength-to-weight ratio, VL is especially suitable for large-span beams and some areas that cannot simply replace wood and steel. LVL not only retains the desirable natural properties of wood, but also has structural features not found in solid wood sawing villages, and its strength far exceeds that of steel roof trusses. In foreign countries, it is widely used in the roof truss structure of buildings, and can be used for paving floors, bowling lane boards, container bottom plates, railway sleepers, cement formwork, etc. In recent years, the demand for LVL in Japan and the Middle East has increased year by year. According to statistics, in 1998, the global LVL production was 2.3 million cubic meters. It is estimated that by 2002, the global consumption of LVL will reach 24 million cubic meters. At present, LVL is produced in North America, Japan, Finland, Australia, New Zealand and other countries. SHANDONG MINGHUNG WOOD MACHIERY CO.,LTD produces a complete set of equipment for the production of LVL plywood.

Hydraulic Hot Press Machine

Producing kinds of plywood, like furniture plywood, construction plywood, marine plywood, hydraulic hot press machine is the necessary and important machine.

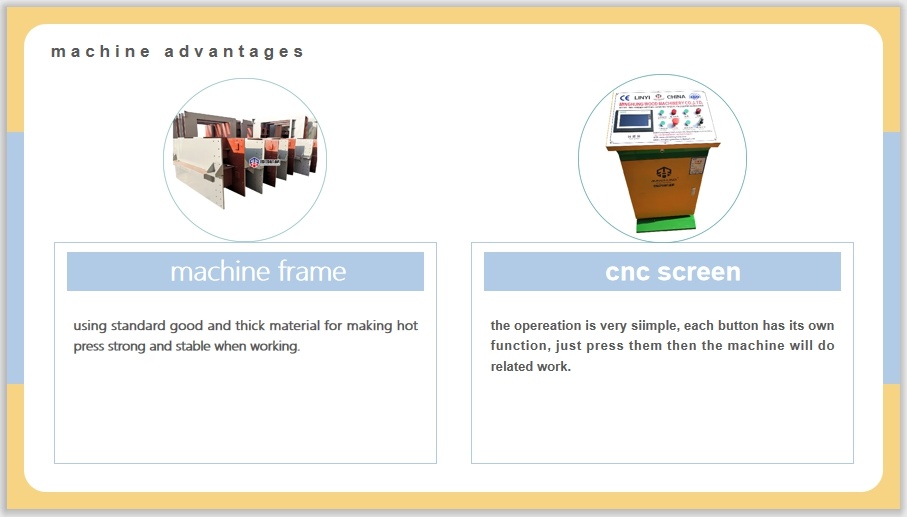

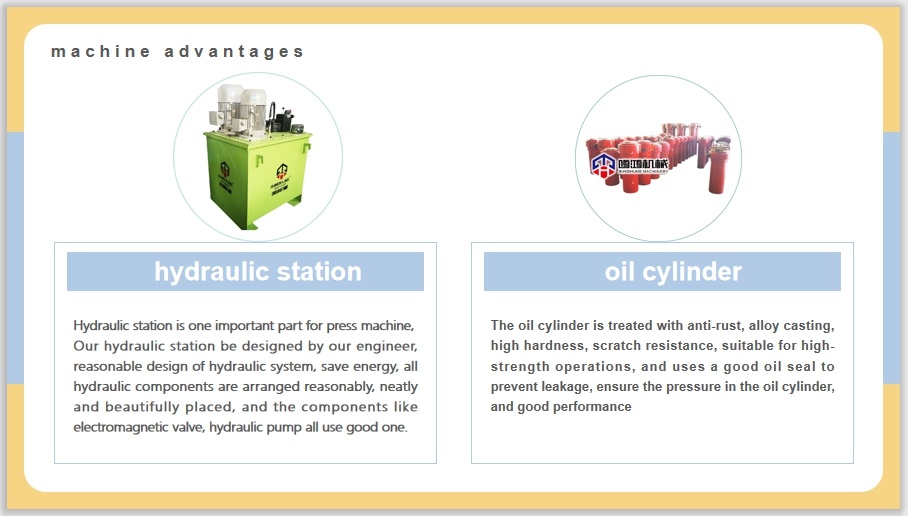

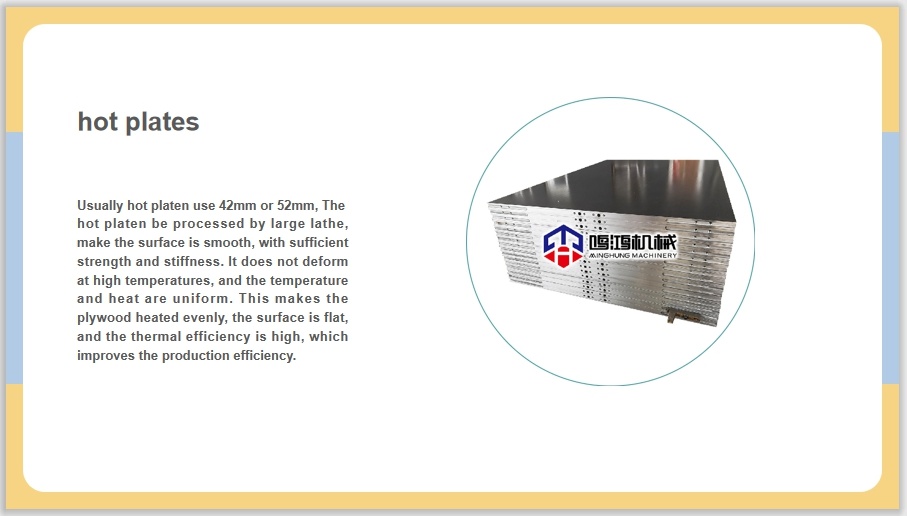

Hot Press's structure not complex, mainly consist of: the machine frame, hot plates, hydraulic station, cylinder.

It can be different pressure and layers according to the real conditions, like 500t, 600t, 800t, 1000t, 1200t. 8layers, 10layers, 12layers, 15layers, 20layers, 25layers

>>>Specification:

>>>Advantages:

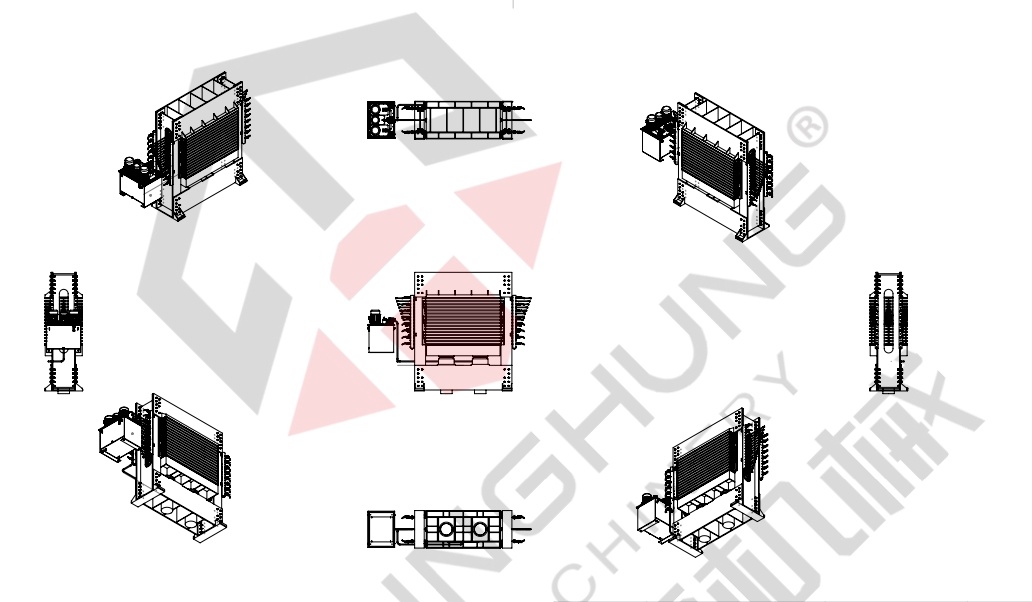

>>>Machine show

>>>Machine show

when machine reach your factory, our engineer will go to install machine, and teach your worker how to operate and maintain.

>>>Us >>>Our friends:

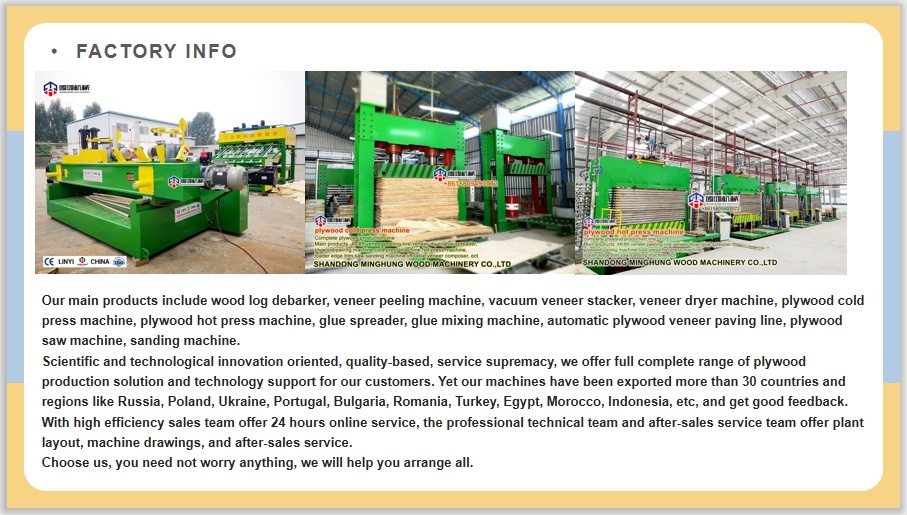

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

>>>Delivery:

1> When loading, we will share the loading pictures of plywood press machine with you.

2> When ship leave, we will offer the container and ship information for you.

3> Offer all documents which for your custom clearance.

>>>Related Plywood Machine:

we produce the full line of plywood machine.

wood debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine include veneer press dryer and roller dryer, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

>>>Contact us:

Laminated Veneer Lumber Plywood Machine

Laminated Veneer Lumber Plywood Machine