The Completely Plywood Production Process for Plywood LVL Panel Manufacturing

1. The main equipment required for the production of plywood:

1. 2700mm, the whole line of rotary cutting machine.

2. The whole line of 1500mm rotary cutting machine.

3. A knife sharpener.

4. One veneer dryer, customized according to the output of plywood.

5. 1 glue mixer

6. Glue coating machine 1 set 2700mm

7. cold press machine 1set

8. hot press machine 1set

9. Plywood edge sawing machine 1set

2. Production process of multi-layer plywood nine-layer plywood:

Poplar→broken wood→veneer peeling→veneer drying→finishing and repairing veneer→glue mixer mixing ratio→glue spreader gluing and stringing→group embryo board→pre-pressing machine pre-pressing→hot pressing machine hot pressing→plywood saw Edge → plywood inspection → secondary coating → hot pressing → secondary inspection → storage

The specific process flow is as follows:

1. Poplar, beech, birch, eucalyptus, and other woods are classified according to their length and diameter, and then cut into segments with a chainsaw.

2. Use different rotary cutting machines to cut veneer with different thicknesses such as 2.2mm, 1.7mm, 1.5mm, etc.

3. The single veneer is neatly stacked on the tray and transported to the dryer for veneer drying. The temperature in the dryer reaches 120-150 degrees Celsius, and the moisture content of the veneer after drying is less than 10%, and it works continuously.

4. After the dried veneers are stored and stacked, they are sorted, repaired and sorted.

5. Put the different classified veneers into the gluing machine for gluing.

6. Arrange the glued veneers in a criss-cross pattern of plywood embryos (5 layers, 7 layers, 9 layers, 12 layers), and the thickness is assembled and arranged according to the thickness of the plywood. The thickness of the plywood is as follows:3mm\6mm\9mm\12mm\15mm\18mm\25mm\30mm,ect。Friends, for save your precious time, please tell me your conditions and requires, i will offer you the suitable plywood machine details for your reference.

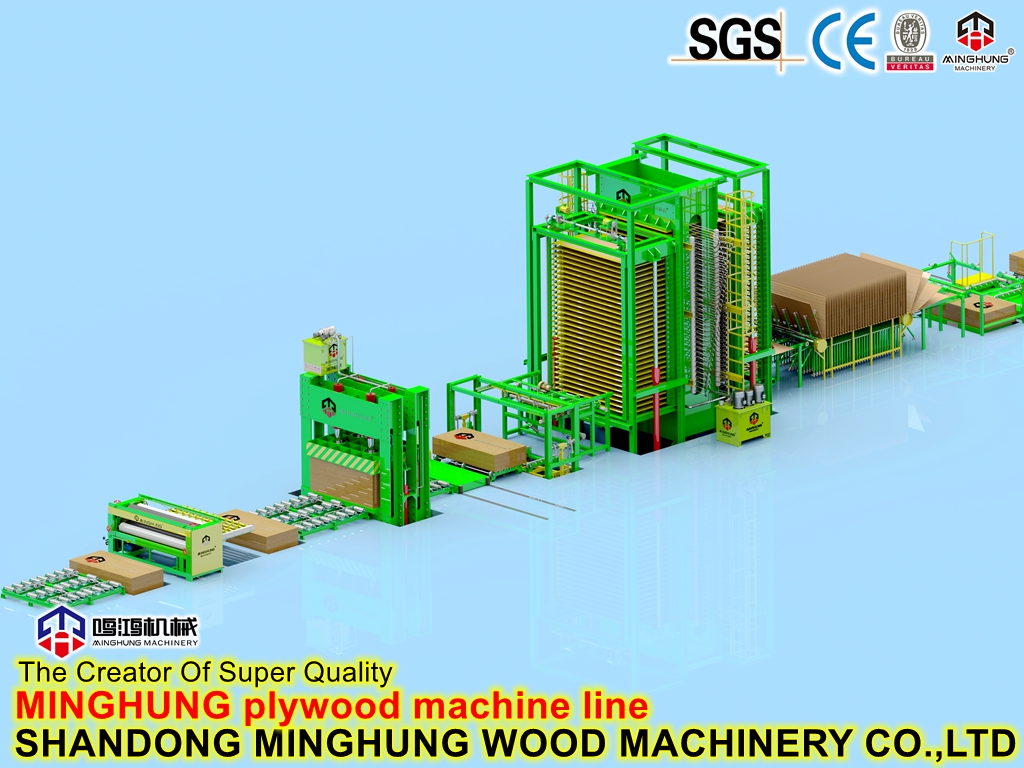

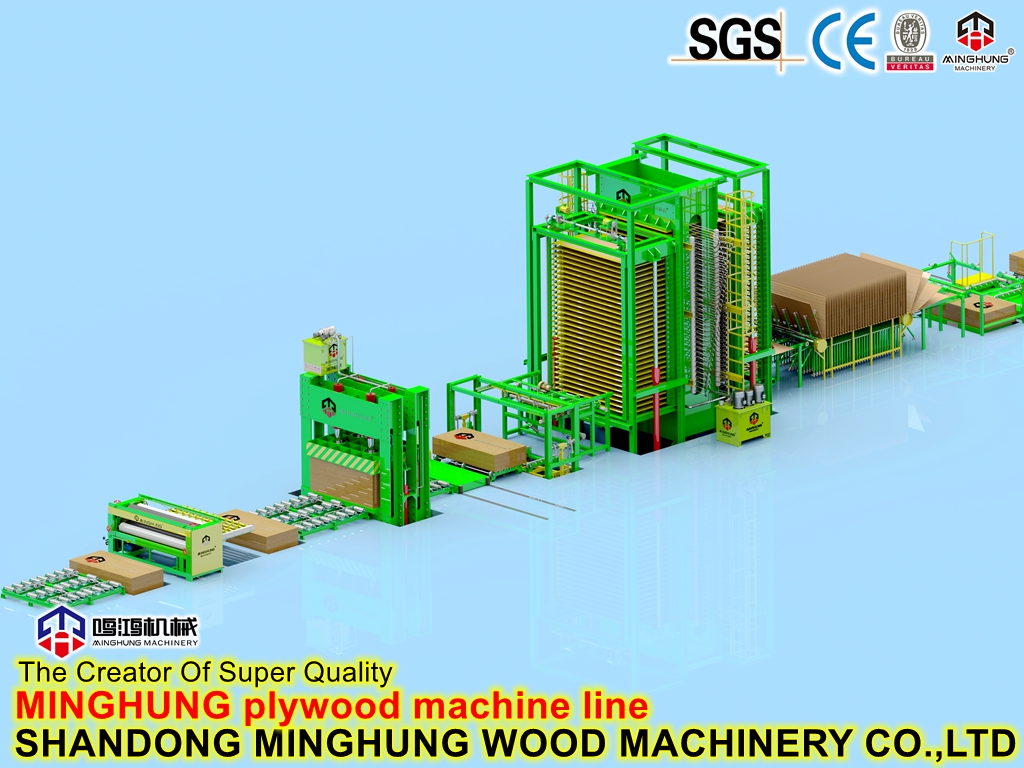

Our factory produce the whole sets Plywood Machine, include plywood hot press machine, plywood cold press machine, glue spreader, plywood veneer paving line, plywood edge cutting saw, sanding machine and others.

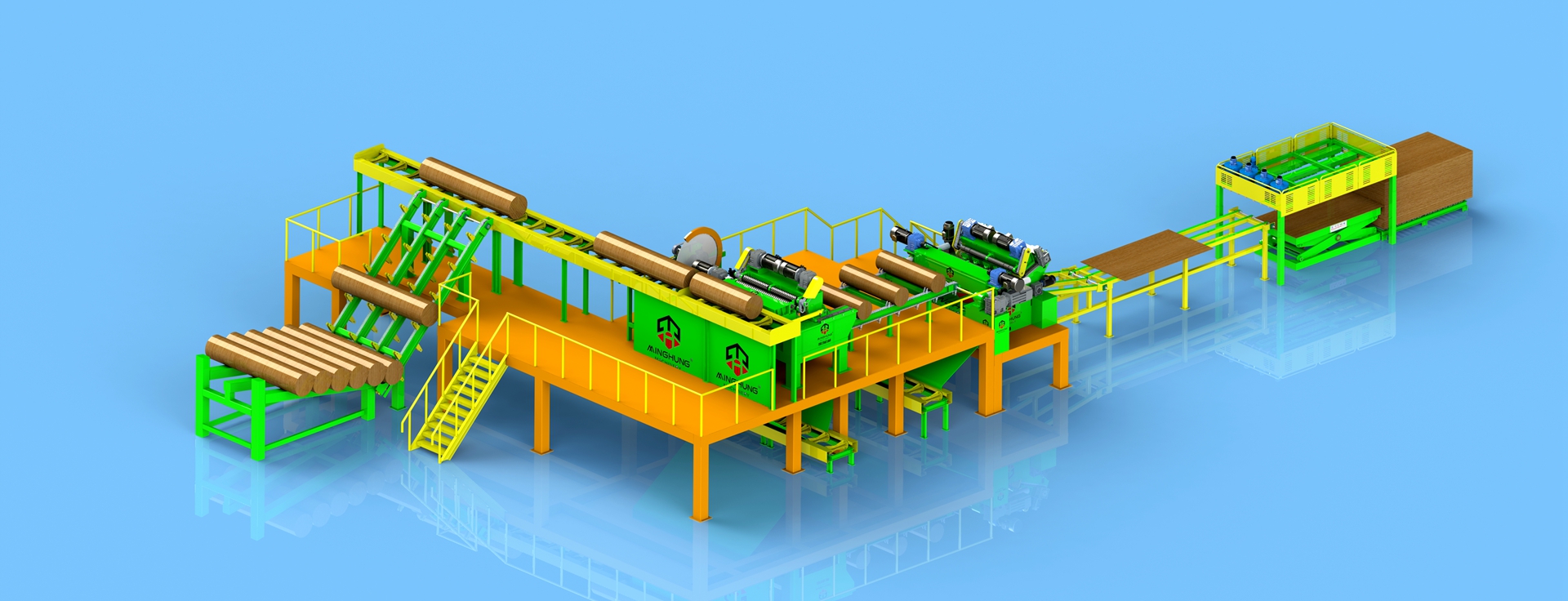

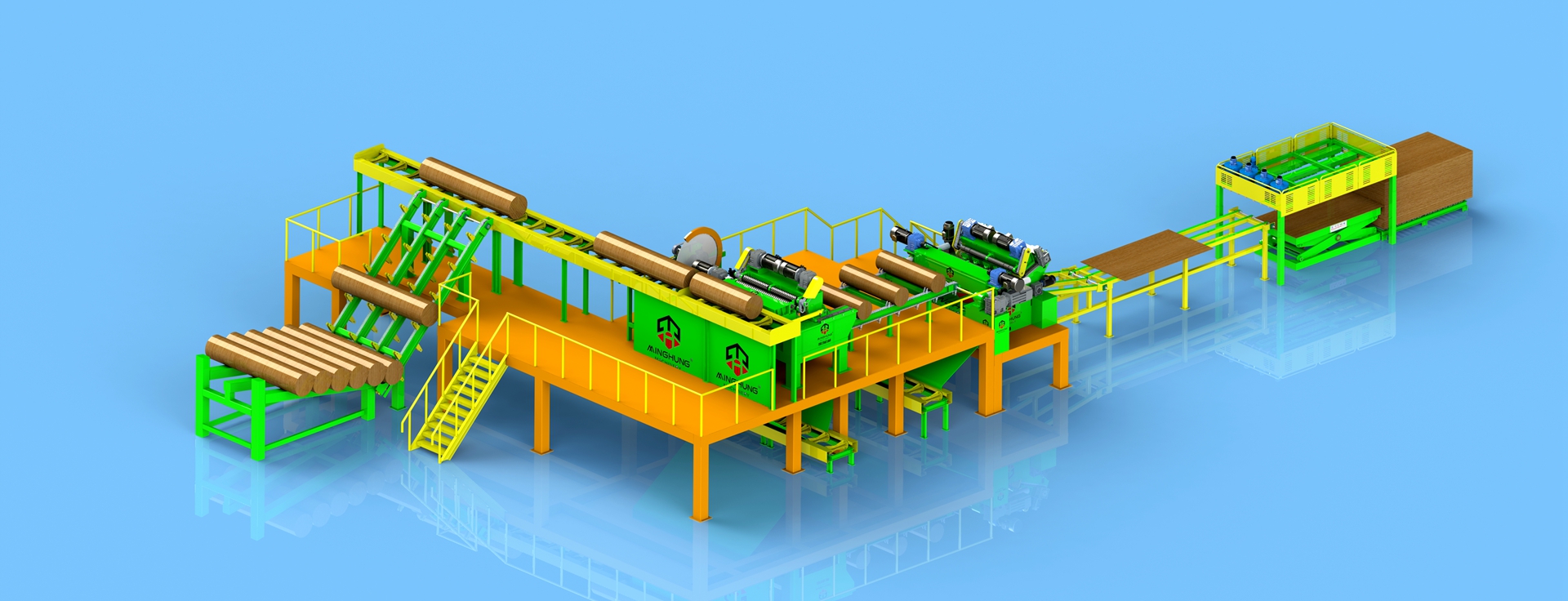

>>>>VENEER PEELING MACHINE LINE:

Veneer peeling line for producing peeled veneer sheets by processing timber wood

Through set the veneer thickness and cutting width from the cnc scree, peeling machine can produce the veneers as you want

One set good quality and strong veneer peeling lathe can process kinds of hardwood like beech wood, birch wood and others, and help you produce high quality veneer.

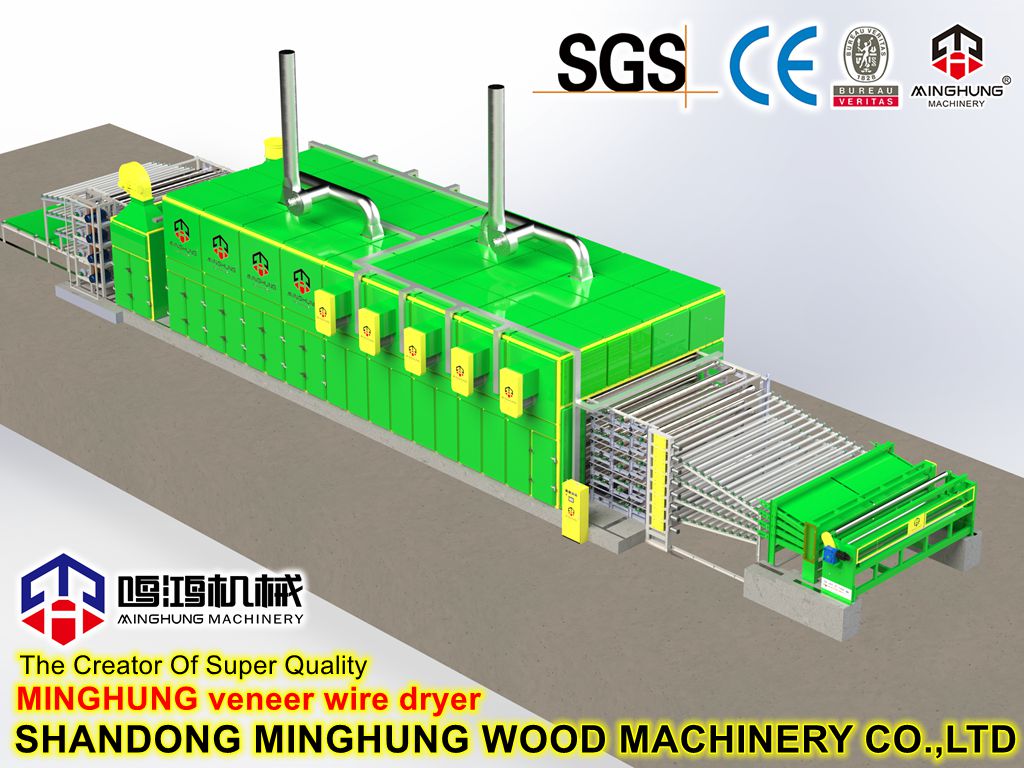

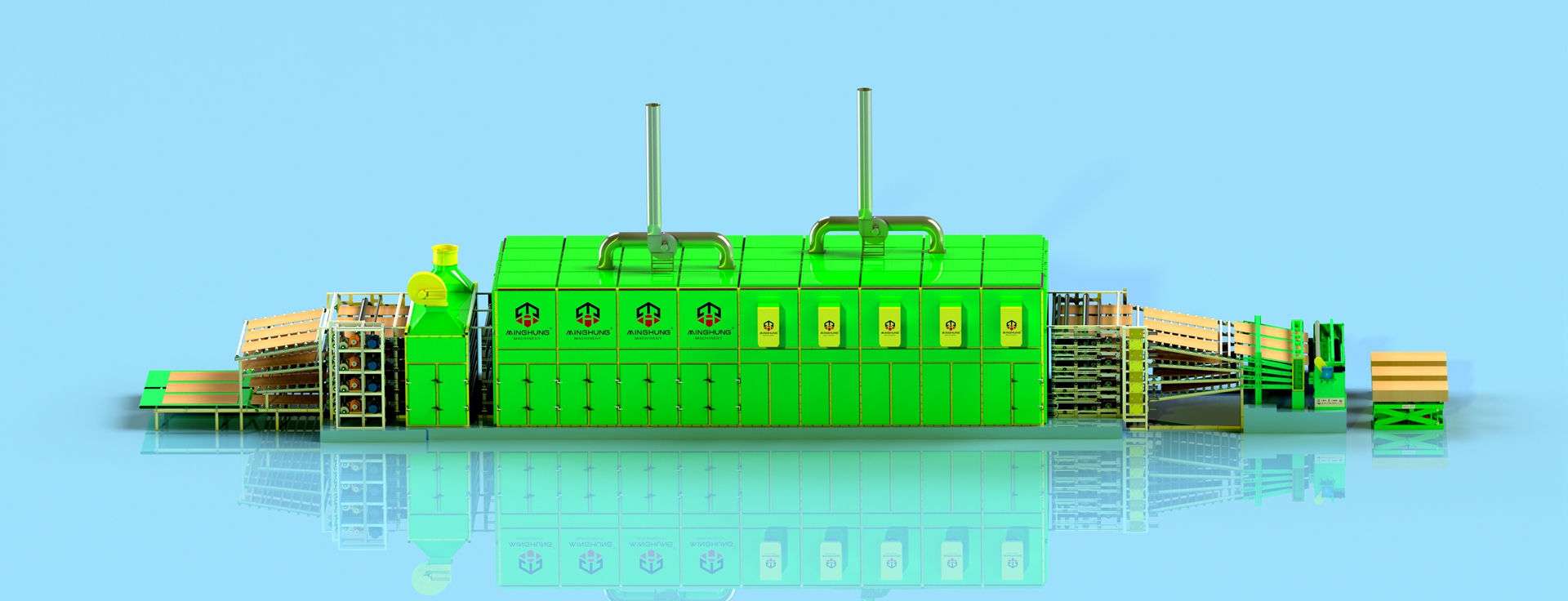

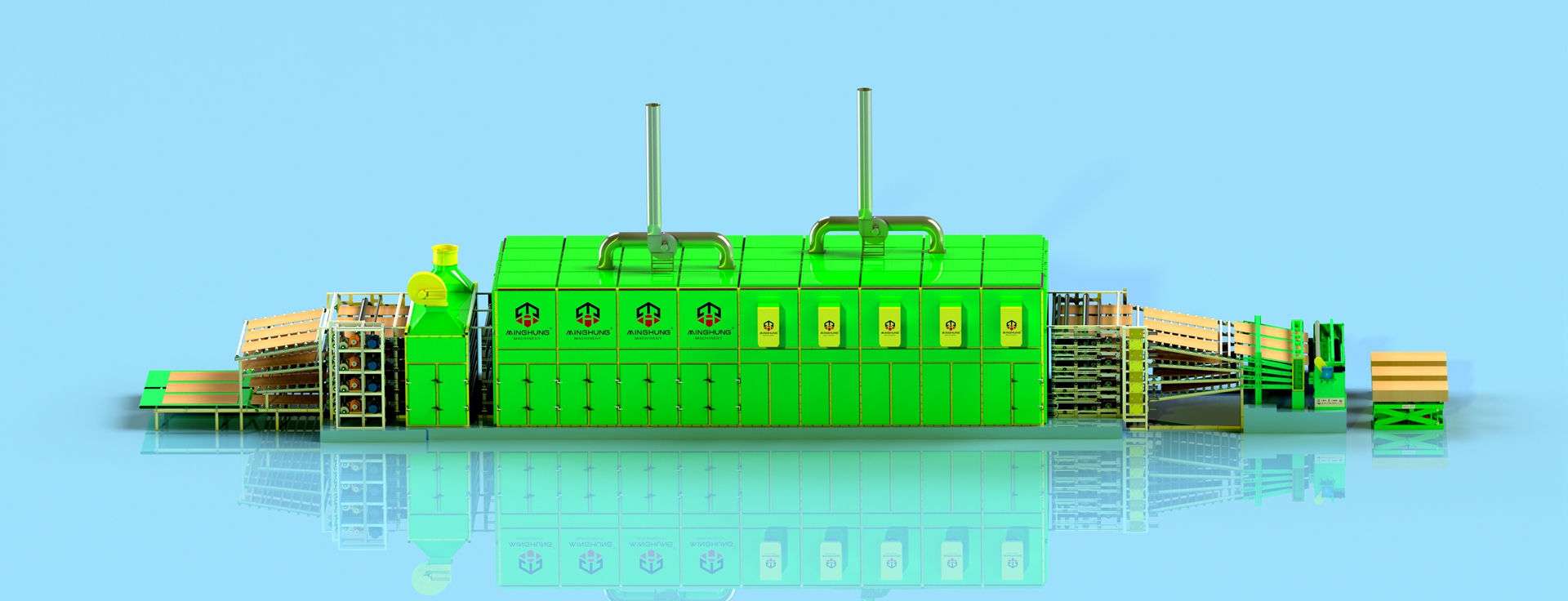

>>>>VENEER DRYING LINES:

Veneer drying lines's function for drying original veneer moisture, when the peeled veneer comes out from veneer lathe, its humidity is high, different wood species, their humidity will be different, usually between 40%-70%, and it is not suitable for making the end products like plywood board, furniture and others.

That is why veneer drying line are required, the veneer drying line mainly includes roller dryer and mesh dryer, their sections, width and decks can be different according to different drying capacity requires.

After dryed veneers, the end humidity will be 5%-10%, and it is suitable for the next production step

>>>>GLUE SPREADER:

Glue spreader for spreading glue on veneer surface, so workers can lay them up and become the required board size.

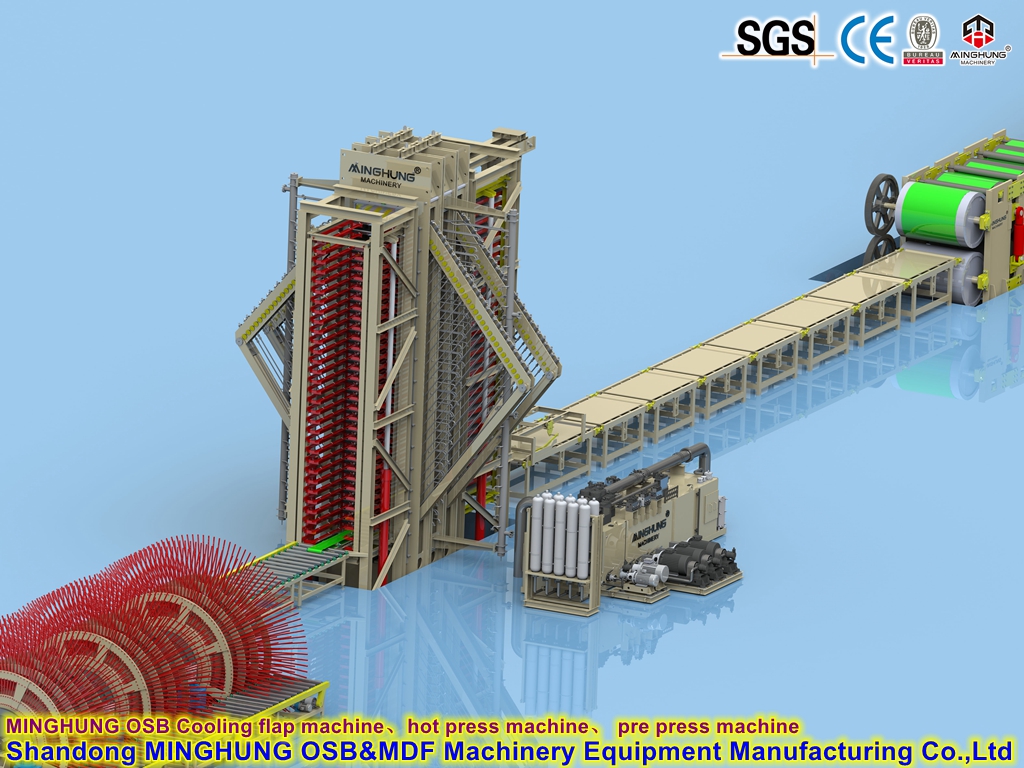

>>>> PLYWOOD PRESS MACHINE:

Plywood hot press machine and cold press machine for pressing glued veneer plywood, and make the end plywood board be one solid and strong pieces. For hot press machine, it can be different layers and pressure, and its hot plate size also can be customized according to your plywood size.

>>>>PLYWOOD EDGE SAW MACHINE :

Plywood edge trimming machine for trimming and cutting plywood edges, the trimmed plywood edge are clean and tidiness. and each pieces of plywood size be same

>>>>PLYWOOD SANING LINE:

Plywood sanding machine for calibrating plywood thickness, make plywood thickness balance, or for polishing plywood board surface, to make plywood surface smooth

According to plywood application, we can offer the suitable plywood sander for you

We are China manufacturer of Plywood machine and peeling machine, welcome contact us for more information

Welcome contact us:

WHATSAPP: +8618769900191 +8615589105786 +8615805493072

EMAIL: minghungmachinery@gmail.com