Woodworking Industry Plywood Panel Production Line

With many years production of veneer peeling machine, every year our peeling machine are improving.

First we have the advanced technology and equipment for process the machine. Second, we have the experienced workers to produce machine, each production step be responsible by specialized worker.

Third, for the entire production process, will be tested six times to make sure machine good characters and good quality.

Four.Our big boss are insisting use good and thick material to make our peeling machine strong and heavy enough, and choose the very good spare parts and accessories to ensure our peeling machine are long life span, and each mainly motor are big to make sure machine are powerful to processing kinds of wood includes hardwood like beech, birch and others.

Therefore, we are confident to say that our veneer peeling machine will satisfy each clients and make them happy, help them produce high quality wood veneer, help them create much value and benefits. Whatever you produce veneer for selling to other factory, or you use it by yourself to making plywood, Blockboard, Wooden furniture or others, the product quality will be very nice.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com

Hello, Our factory produce plywood production line, it includes: veneer production line, veneer dryer, glue machine, cold press machine, hot press machine, plywood trimming machine, sanding machine.

Now according to production steps, let me share each machine pictures with you

1. Veneer Production Line

This full veneer peeling line includes: wood debarker, veneer peeling machine, log conveyor. and vacuum veneer stacker.

This full veneer peeling line includes: wood debarker, veneer peeling machine, log conveyor. and vacuum veneer stacker.

It will process log into wood veneer, and automatic sorting wood veneer. High efficiency

Our peeling machines. are strong enough to peel kinds of hardwood like beech, birch and make sure its thickness accurate.

2. Veneer Dryer

Veneer dryer include different types, there are Roll dryer. Mesh dryer, and press dryer. Different dryer has its own characters and advantages.

Veneer dryer include different types, there are Roll dryer. Mesh dryer, and press dryer. Different dryer has its own characters and advantages.

If you require big drying capacity per day, then choose Roll dryer and Mesh dryer are better.

If you have factory room limits, and have budget limits, press dryer will be good choice

3. Glue Machine

Glue machine are double sides, its function is coating glue on both sides of wood veneer surface, so worker can lay them out.

Glue machine are double sides, its function is coating glue on both sides of wood veneer surface, so worker can lay them out.

The standard glue machine is 4feet and 8feet. Its structure very simple and easy operate.

4. Cold Press Machine

Cold press machine for pre-press plywood. make inside glue moulding, thus it easy to put plywood on hot press machine, and pressing time will be short

Cold press machine for pre-press plywood. make inside glue moulding, thus it easy to put plywood on hot press machine, and pressing time will be short

5. Hot Press Machine

Hot press machine are very important for plywood quality. It can be different floors and pressure, for example, it can be 500ton, 600ton, 800ton, and more, and it can be 10 floors, 12 floors, 15 floors, 20 floors.

Hot press machine are very important for plywood quality. It can be different floors and pressure, for example, it can be 500ton, 600ton, 800ton, and more, and it can be 10 floors, 12 floors, 15 floors, 20 floors.

For our hot press machine, choose thick material and good parts to make it. we can promise the hot press machine good quality.

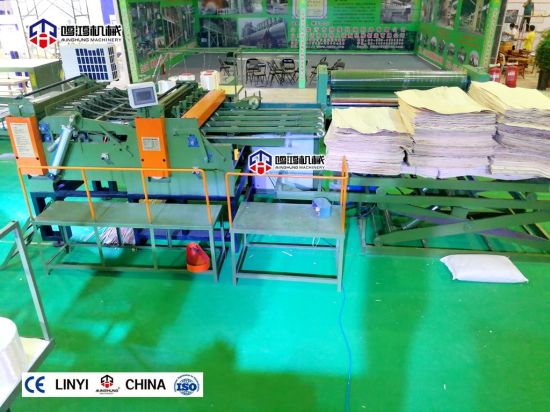

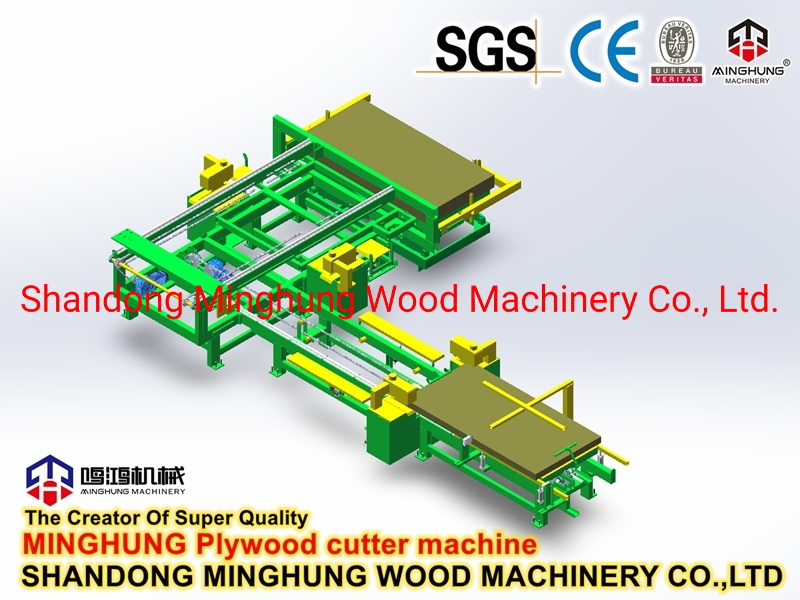

6. Plywood Trimming Machine

Plywood trimming machine for cutting four edges of plywood, make each pcs plywood size same and tidiness.

Plywood trimming machine for cutting four edges of plywood, make each pcs plywood size same and tidiness.

It is high efficiency and can automatic stacking

7. Sanding Machine

sanding machine includes different types, it can be one head, two heads. three heads, it can be single side, also can be double sides

sanding machine includes different types, it can be one head, two heads. three heads, it can be single side, also can be double sides

Some sanding machine for calibrating plywood thickness, some sanding machine for polishing plywood surface

So after you tell your requires, we will offer the suitable sanding machine for you

7. Lift Table

Lift table are auxiliary machine for other plywood machine, help workers to easy work and operate machine.

Until now, with above machines, you can start produce plywood

Whatever you wants to start produce plywood, or you want to enlarge your production capacity, Welcome contact us for more information.

Delivery:

With many years production of veneer peeling machine, every year our peeling machine are improving.

First we have the advanced technology and equipment for process the machine. Second, we have the experienced workers to produce machine, each production step be responsible by specialized worker.

Third, for the entire production process, will be tested six times to make sure machine good characters and good quality.

Four.Our big boss are insisting use good and thick material to make our peeling machine strong and heavy enough, and choose the very good spare parts and accessories to ensure our peeling machine are long life span, and each mainly motor are big to make sure machine are powerful to processing kinds of wood includes hardwood like beech, birch and others.

Therefore, we are confident to say that our veneer peeling machine will satisfy each clients and make them happy, help them produce high quality wood veneer, help them create much value and benefits. Whatever you produce veneer for selling to other factory, or you use it by yourself to making plywood, Blockboard, Wooden furniture or others, the product quality will be very nice.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com