Ⅲ. Core Technologies Enabling High Precision

3.1 Thickness Control Accuracy (±0.1–0.15mm)

Hydraulic Servo Closed-Loop System: High-response servo cylinders per platen zone (position resolution 0.01mm) for real-time belt deflection compensation

Online Thickness Monitoring: Gamma/X-ray thickness gauges scan full panel width every 10s, feeding data to PLC for gap adjustment

Thermal Expansion Compensation Algorithm: Dynamically corrects pressure settings based on platen temperature field models

3.2 Density Uniformity Assurance

Multi-Zone Pressure Profile Optimization: Auto-adjusts pressure gradient (e.g., 12MPa at entry → 3MPa at exit) based on mat moisture distribution

Fiber Forming-Press Synergy: Airflow speed in former synchronized with press speed, ensuring longitudinal/transverse density CV <3%

3.3 Surface Quality Enhancement

Mirror-Finished Steel Belts: Belt surface roughness Ra≤0.4μm (electrolytic polishing)

Micro-Pressure Zone Control: 0.5-1MPa micro-pressure section at press exit eliminates surface springback

3.4 Dimensional Stability Reinforcement

Gradient Cooling System: Zoned temperature control (20–60℃ adjustable) on cooling star rollers suppresses internal stress warping

Equilibrium Moisture Content Control: Post-processing humidity conditioning chamber (RH 45–55%)

3.5 Production Consistency Guarantee

Digital Twin System: Virtual press model using real-time data (temperature/pressure/speed) to predict panel performance and optimize parameters

AI Quality Alert: Machine learning analyzes historical data to identify thickness deviation trends for preemptive intervention

3.6 Thermal Field Precision

Zoned Temperature Control:

• Entry zone: 210±1℃ (accelerates resin flow)

• Calibration zone: 190±0.5℃ (precision curing)

Belt Temperature Compensation: IR thermography → Auto-adjusts thermal oil flow

Ⅳ. Industrial Value of High-Precision MDF Continuous Press

Material Utilization Increase: Reduces sanding allowance (from 0.5mm to 0.2mm)

Downstream Processing Cost Reduction: Direct suitability for digital printing, thin veneer overlaying, etc.

Energy Optimization: High-precision pressing shortens hot-pressing time by 10–15%, steam consumption ≤1.1 ton per ton of boar

Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd is a China professional factory who specilize in manufacturering and offering Wood based panel machine, including OSB making machine, MDF making machine, and Chipboard /PB making machine.

Our factory with the advanced processing lathes, Mature production technology, and Professional engineers and technicians, and independent ability of reasearch and development, and quickly service, ensure that we have the ability to offer you the suitable and good woodworking machinery as different conditions and requires.

We maintain a long-term cooperation with a well-known freight forwarding company, and adhere to the customer-first philosophy. We strictly implement the quality inspection process before shipment to ensure that each batch of products meets international quality standards, We deeply understand that high-quality service is the cornerstone of winning customer trust, and we always create value for customers with professional and efficient supply chain management.

Pre-sales service:

1) Listen to customer needs

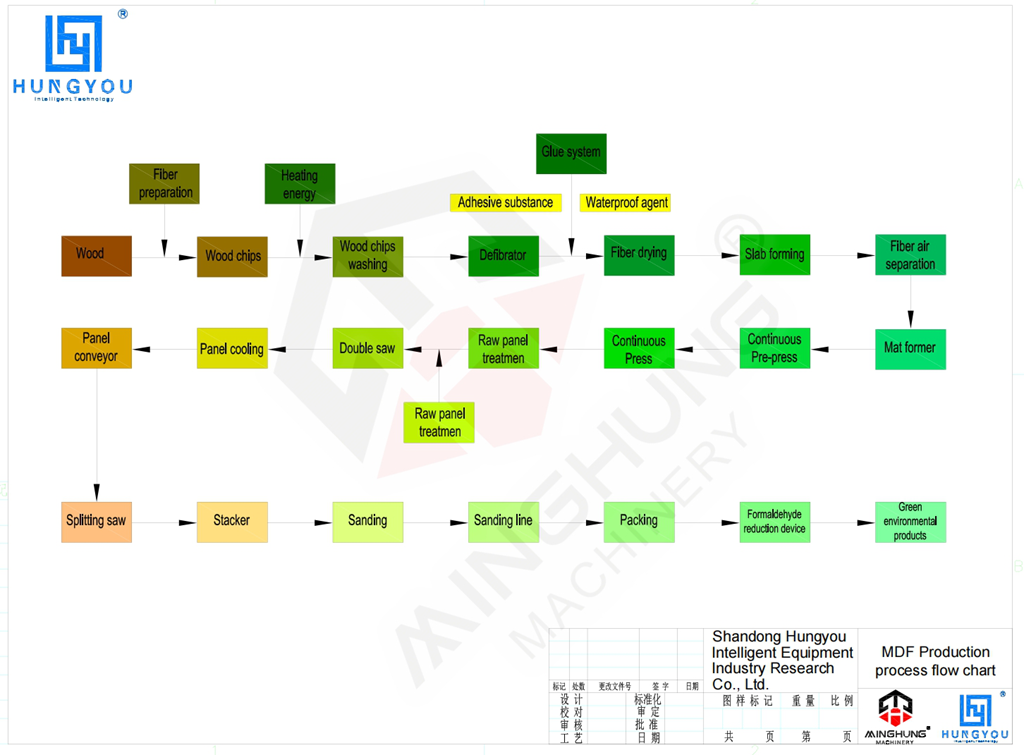

2) Provide preliminary machine design and flow chart for free, select and provide the most reasonable configuration equipment:

3) Support remote meetings and remote factory visits;

4) Provide professional advice to customers and confirm the final selection

5) Support on-site factory visits;

On-purchase service:

1) All equipment must be installed and debugged before leaving the factory, and remote video quality inspection is supported;

2) All machines must be unpacked before leaving the factory, and photos, videos, and annotations must be provided;

3) Free online or offline training for buyers' operators (domestic)

4) Assist buyers in installing and debugging equipment (overseas)

After-sales service:

1) 7*24 hours online service, remote real-time video solution;

2) During the first installation and debugging process, problems encountered during normal operation are solved in time:

3) Regular process inspection and use effect, timely machine maintenance suggestions:

4) Lifetime free technical guidance

5) Timely update the latest industry information.