Customized Large Plywood Drying Production Line

|

Product Description

The Customized Large-Scale Plywood Drying Production Line is not a single piece of equipment but a complete industrial system integrating material handling, intelligent drying, process monitoring, and energy management. It is designed for large-scale plywood manufacturers with high daily output, diverse product specifications, and stringent requirements for drying quality and cost control. Its core value lies in its deep integration with the client's current operations and future vision. Through a tailored system architecture, it automates, streamlines, and intellectualizes the entire process from "wet boards" to "dry boards," serving as a critical link in building a modern "unmanned factory" or "smart workshop."

|

Core Dimensions of "Customization"

1. Capacity & Layout Customization:

Capacity: Designs the production line's cycle time, number of drying kilns, and conveyor speed according to your annual output targets (e.g., 100m³/day, 200m³/day, or higher).

Layout: Fully adapts to your existing factory space, height, and material flow (feeding-drying-discharging), offering various layouts like "L-shaped," "U-shaped," or straight-line to seamlessly connect with upstream and downstream processes (e.g., hot pressing, sanding).

2. Process & Product Customization:

Wood Species: Pre-sets or allows creation of custom drying schedules tailored to the drying characteristics of different species (e.g., Poplar, Pine, Eucalyptus, Mixed Hardwoods).

Product Specifications: Capable of handling various sizes (e.g., 4x8 ft, 5x10 ft), thicknesses (e.g., 3mm-30mm), and special structures (e.g., large-format, ultra-thin panels).

Heat Source Compatibility: Flexibly integrates various heat source systems (steam, hot water, thermal oil, natural gas, biomass boiler, or electric heating) to maximize the use of your existing energy infrastructure and reduce retrofit costs.

3. Automation Level Customization:

Offers different levels of automation, from basic Semi-Automatic (manual stacking + automatic conveying/drying) to Fully Automatic (integrated robotic stacking/unstacking, automatic conveying, smart warehouse interface), allowing you to balance investment and return.

|

Components & Workflow

1. Automatic Loading/Unloading System:

Components: Includes roller conveyors, chain conveyors, lifting transfer stations, and (in full-auto solutions) six-axis robots or gantry manipulators.

Function: Automatically receives board batches from the cold press and precisely loads them into designated positions in the drying kilns. After drying, it unloads the stacks and conveys them to the next process.

2. Drying Kiln Cluster System:

Core: Multiple modular, high-performance drying kiln units. Each kiln is equipped with the uniform drying technology described previously (balanced air circulation, precise control, efficient insulation).

Feature: Kilns are standardized for easy expansion and maintenance, but their internal configuration (e.g., fan power, heater area) is optimized for their specific role in the line.

3. Central Control System - The Brain of the Line:

Function: This is a SCADA (Supervisory Control and Data Acquisition) system that goes beyond single-kiln control. It not only operates each kiln but also orchestrates the entire conveying system, displaying the real-time location, status (e.g., "In Kiln 3, 3 hours dried"), and process parameters of every batch.

Data Management: Generates production reports (capacity, energy consumption, yield), enables quality traceability, and allows for remote diagnostics and software updates.

4. Material Handling & Conveying System:

Acts as the "blood vessels" of the production line, connecting all workstations and ensuring boards are transported to the right place at the right time.

|

Value & Competitive Advantages

Maximum Efficiency & Capacity Leap: Continuous operation eliminates the downtime associated with traditional batch-type loading and tempering, enabling 24/7 production and potentially increasing output by over 50%.

Significant Reduction in Overall Costs:

Labor Cost: Automation drastically reduces reliance on skilled laborers, potentially saving over 70% in labor costs.

Quality Cost: Unified process standards drastically reduce rejection rates and quality variations caused by human error.

Energy Cost: Systematic thermal management and high-efficiency insulation minimize drying energy consumption per unit product.

Unmatched Quality Consistency: Machine-led processes ensure every single board undergoes an identical drying journey, pushing product qualification rates close to 100% and ensuring stable, uniform quality that enhances brand reputation.

Superior Flexibility & Scalability: When future expansion is needed, simply add more drying kiln modules and corresponding conveying units, protecting your initial investment and supporting sustainable business growth.

|

Company Profile

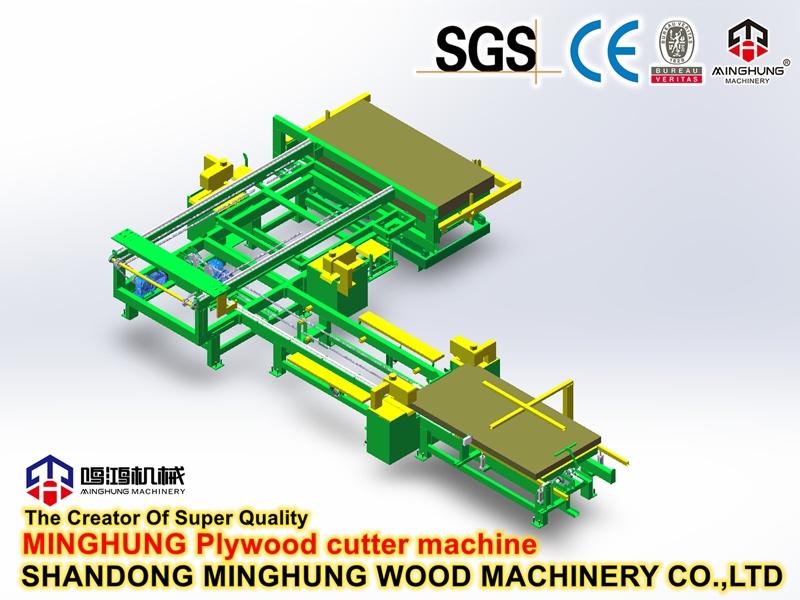

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery.

The machinery we produce includes peeling machines, chipping machines, rotary cutting machines, drying machines, gluing mixers, laying machines, pre-pressing machines, hot pressing machines, cooling machines, longitudinal and transverse sawing machines, sanding machines, as well as auxiliary machinery such as automatic feeding and discharging systems and lifting platforms.

|

Deliver

We can offer factory layout design, installation, operator training, 24-month warranty, and global spare parts delivery within 72 hours.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com