System Composition and Structure

A complete production line mainly consists of the following systems:

1. Feeding System: Includes automatic loaders, lift tables, and feed conveyors to ensure boards enter the drying tunnel continuously and smoothly.

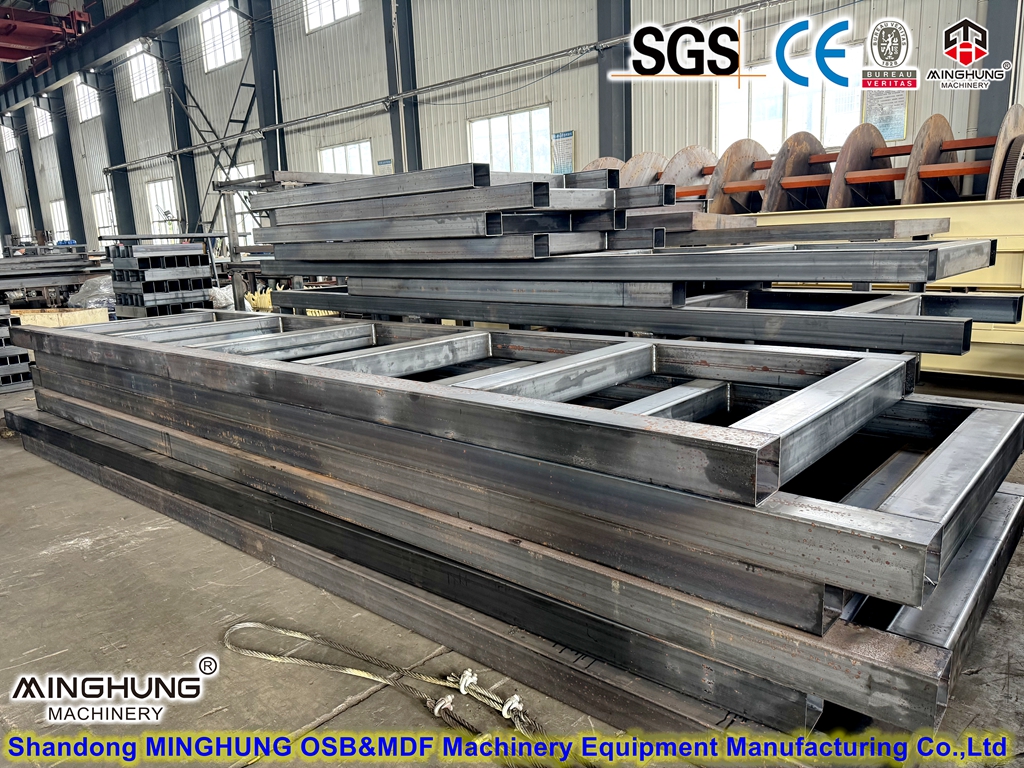

2. Drying Chamber Main Body (Tunnel): A sealed channel constructed with high-quality insulation panels (e.g., rock wool, polyurethane) to minimize heat loss and ensure a stable internal thermal environment.

3. Heating System: The core energy source of the equipment. Options based on client conditions:

Hot Air Stove: Uses wood waste (bark, sawdust) as fuel, economical and environmentally friendly, most widely used.

Steam Heat Exchanger: Suitable for factories with boiler steam, provides stable temperature.

Thermal Oil Boiler: High thermal capacity, allows for precise temperature control.

Electric or Gas Heating: Clean, but higher operating costs.

4. Hot Air Circulation System: Comprises high-power centrifugal fans, ducts, and nozzles. It distributes hot air evenly and at high velocity onto the board surfaces, breaking the boundary layer and accelerating moisture evaporation.

5. Conveying System: Roller tracks or mesh belts running through the entire tunnel, driven by variable frequency motors. The speed is adjustable to control drying time.

6. Dehumidification (Moisture Exhaust) System: Controlled automatically by exhaust fans and dampers. It expels moist air based on data from internal humidity sensors to maintain drying potential.

7. Discharge System: Receives the dried boards and automatically stacks or conveys them to the next process.

8. Intelligent Control System: The brain of the production line. Uses PLC + touch screen control, allowing pre-setting and storage of various drying curves. It monitors parameters like temperature, humidity, and speed in real-time, enabling fully automated operation with automatic fault alarms.