Woodworking Lathe Log Peeling Lathe for Wood Veneer

Rotary veneer peeling lathe

Machine principle description

The stick is driven by the transmission system to rotate at a uniform speed, and the speed of the double stick is the same as that of the single stick.

Due to the feed pressure of the knife table, there is a great friction between the log and the stick. The rotation of the stick drives the wood to rotate. During the rotation, the wood is gradually cut into thin slices. The linear velocity of the wood is equal to the linear velocity of the stick.

Since the linear velocity of the stick is constant, the linear velocity of the wood is also fixed. During the cutting process, the diameter of the wood gradually becomes smaller, so the rotational speed of the wood becomes faster and faster. Every time the wood rotates, the radius decreases by a value of the thickness of the veneer. At the beginning, the rotation speed is slow and the radius change rate is small. When the wood is very thin, the rotation speed is very fast, and the radius change rate is very large. The knife table should be fed according to the change of the diameter of the wood. In the early stage of cutting, the speed of the wood diameter change is slow, and the feed speed of the knife table is slow. In the later stage of cutting, the diameter of the wood changes rapidly, and the knife table must also be fed quickly. This requires the feed system of the knife table to adjust the feed speed according to the change process of the wood diameter, resulting in a gradually changing nonlinear feed speed.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

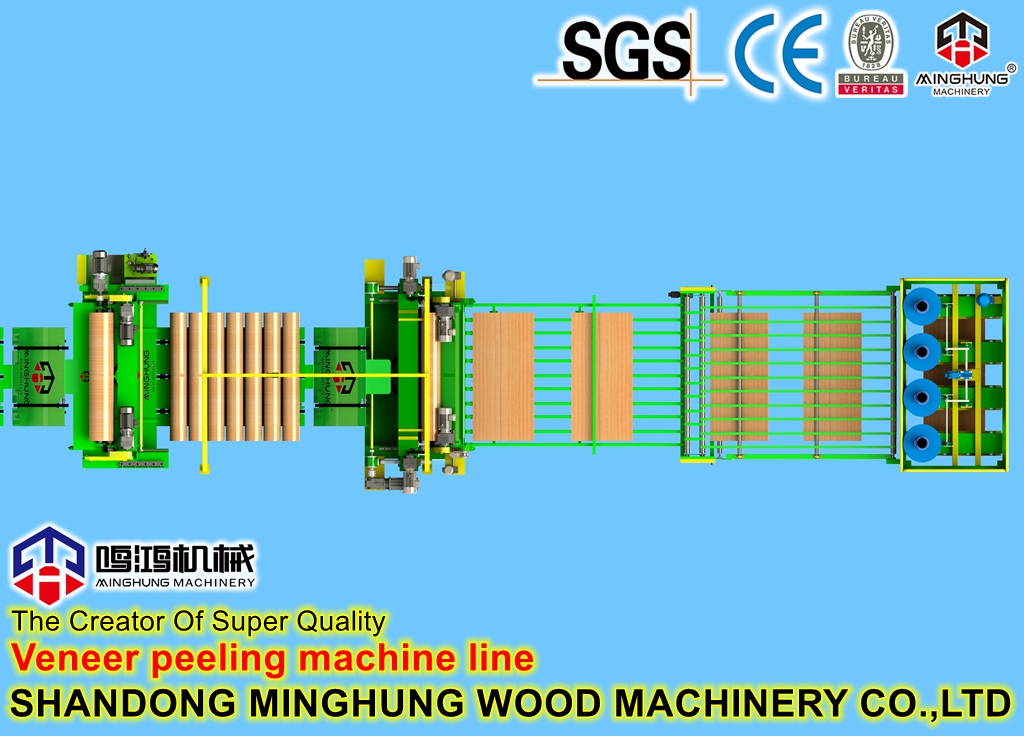

Veneer Peeling Lathe:

Rotary cut veneer peeling machine are used to produce pieces of wood veneer, also be called piles through process the suitable wood be cutted to the required length and diameter. And veneer is the material for making plywood, Blockboard, and other wood based panel board.

Veneer peeling machine will be related with max log length and max log diameter. Especially the max log diameter, it will be divided into Spindleless veneer peeling machine and Spindle veneer peeling machine.

The appearance of CNC rotary peeling machine not only improves the quality and precision of the veneer, but also greatly improves the production efficiency and the degree of automation of the whole peeling machine.

Rotary veneer peeling machine is one of the main equipment for producing plywood. Veneer is the material for making plywood, and veneer peeling machine for produce veneer through process the mateiral-timber wood.

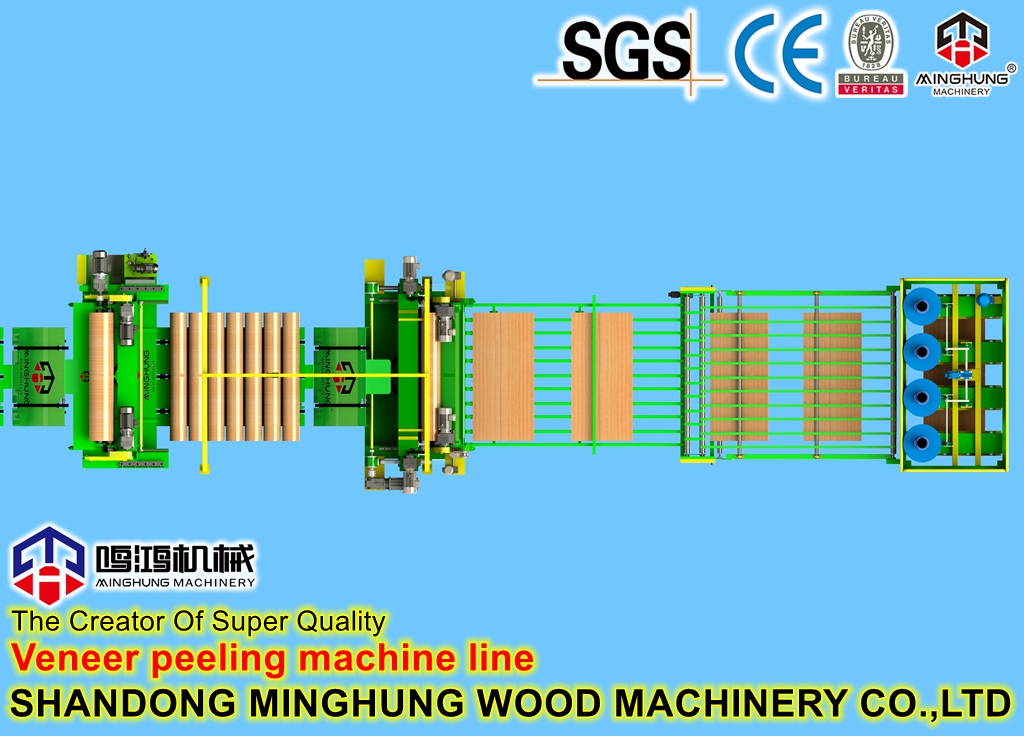

For our strong 8feet veneer peeling lathe, we can ensure that you will use very well. Because With many years production of veneer peeling machine, every year our peeling machine are improving.

First we have the advanced technology and equipment for process the machine. Second, we have the experienced workers to produce machine, each production step be responsible by specialized worker.

Third, for the entire production process, will be tested six times to make sure machine good characters and good quality.

Four.Our big boss are insisting use good and thick material to make our peeling machine strong and heavy enough, and choose the very good spare parts and accessories to ensure our peeling machine are long life span, and each mainly motor are big to make sure machine are powerful to processing kinds of wood includes hardwood like beech, birch and others.

Therefore, we are confident to say that our veneer peeling machine will satisfy each clients and make them happy, help them produce high quality wood veneer, help them create much value and benefits. Whatever you produce veneer for selling to other factory, or you use it by yourself to making plywood, Blockboard, Wooden furniture or others, the product quality will be very nice.

MINGHUNG veneer machine at clients factory:

Parameter of 8feet Veneer peeling lathe:

| name | veneer peeling lathe |

| model | MH-VPM8A |

| max log length | 2700mm |

| max log diameter | 600mm |

| thickness | 0.5-4.0mm |

| max speed | 80m/min |

| total power | 61.2kw |

| total weight | 10t |

| size | 6500*2300*1500mm |

MINGHUNG veneer machine Delivery:

NEW Upgraded type strong veneer peeling machine

Powerful veneer peeling machine

Powerful veneer peeling machine

Strong wood peeling machine

Welcome contact us for more information about wood veneer machine

Whatsapp: +8618769900191 +8615805493072 +8615589105786

Email: minghungmachinery@gmail.com

Powerful veneer peeling machine

Powerful veneer peeling machine