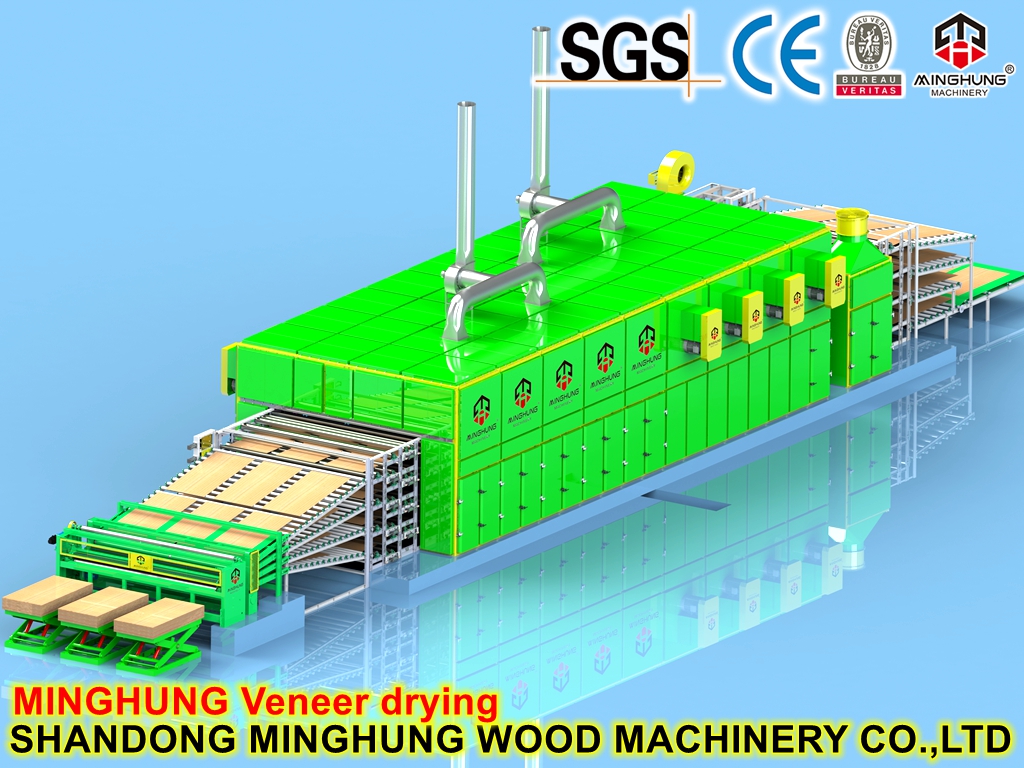

The structure of a veneer mesh belt dryer can be viewed as an integrated system where multiple subsystems collaborate with precision. Its core design philosophy is to achieve efficient, uniform, and continuous drying of veneers.

The entire machine typically consists of the following eight core systems:

1. Drying Chamber

This is the "body" of the dryer, a large insulated and sealed structure.

Material: Usually assembled from insulation panels (such as polyurethane sandwich panels or rock wool panels) and a steel structure frame. The inner panels are often made of corrosion-resistant galvanized steel or stainless steel.

Design: Generally designed as multiple parallel tunnel-like structures, internally divided into several drying zones (e.g., preheating zone, main drying zone, final drying zone, cooling zone) based on the drying curve. Partitions between each zone allow for independent control of temperature and humidity.

Doors: Equipped with large access doors for easy internal cleaning, mesh belt replacement, and equipment maintenance.

2. Mesh Belt Conveyor System

This is the "conveying bloodstream" of the dryer, responsible for carrying and transporting the veneers through the entire drying process.

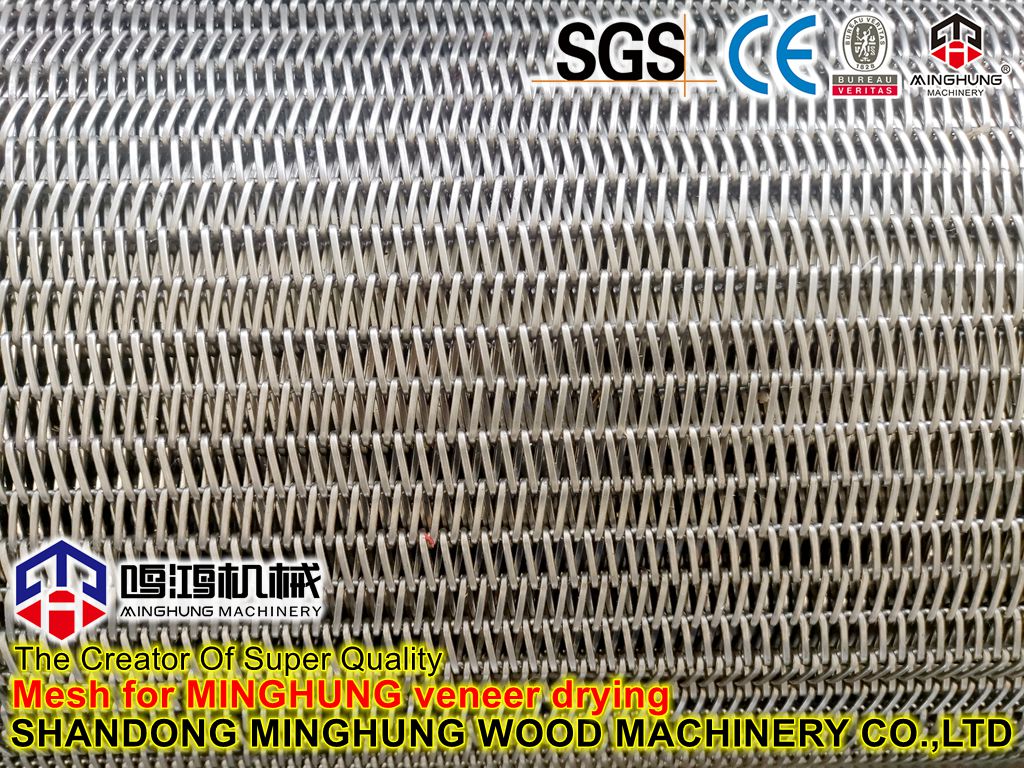

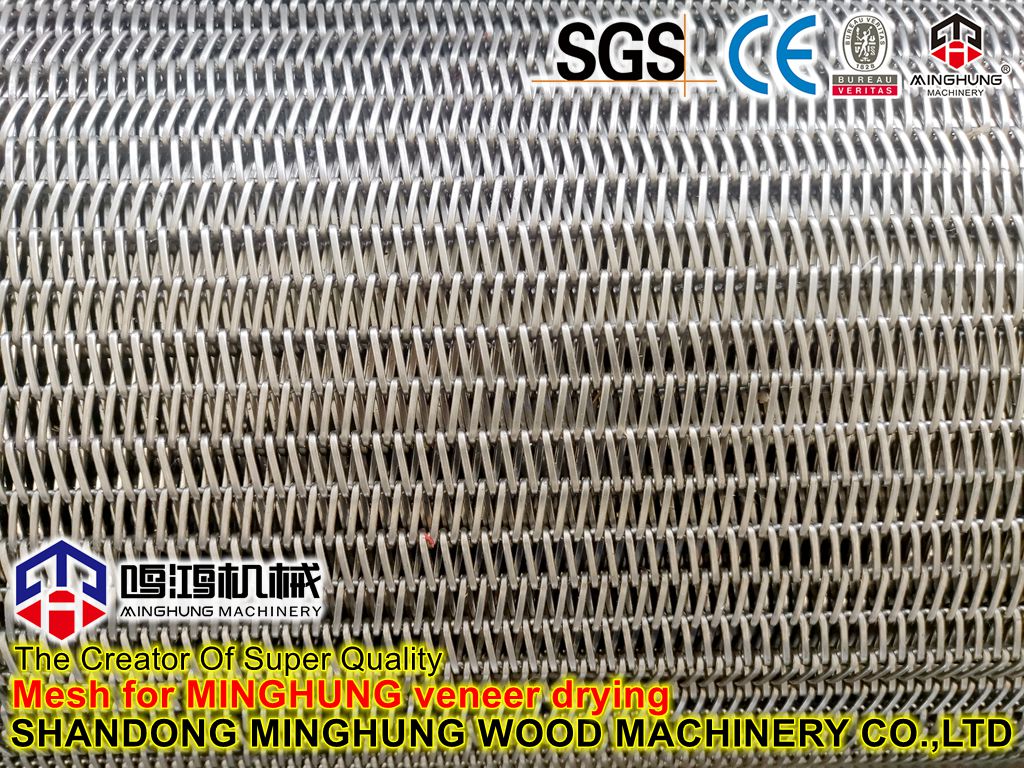

Mesh Belt:

Material: Woven from high-temperature resistant, high-strength stainless steel wire or special alloy steel wire.

Type: Typically a balanced mesh weave, ensuring hot air can penetrate the veneer layer vertically from both above and below, which is key to achieving uniform drying.

Characteristics: The mesh belt must have good air permeability, tensile strength, wear resistance, and corrosion resistance.

Driving Device:

Components: Includes the main drive motor, reducer, drive sprocket, and drive shaft.

Function: Provides smooth power to the mesh belt. Its speed must be steplessly adjustable to precisely control the residence time of the veneers in the drying chamber (i.e., the drying cycle).

Tensioning Device:

Location: Usually installed at the end of the mesh belt return path (on the driven shaft side).

Function: Automatically adjusts the tightness of the mesh belt through methods like screws or counterweights to prevent slipping or deviation, ensuring stable operation.

Deviation Correction Device (Edge Guide):

Function: Crucial. The mesh belt is prone to lateral deviation during long-distance operation. The correction device (e.g., pneumatic or roller type) detects the belt's position in real-time and automatically corrects it, preventing the belt from scraping against the chamber or getting damaged.

Support System:

Structure: Features support rollers or slides (often made of high-temperature resistant ceramic or cast iron rollers) beneath the mesh belt to bear the weight of the belt and the veneers, reducing operational resistance.

3. Heating System

This is the "heat source" of the dryer, responsible for providing the thermal energy required for drying.

Heat Source: Can be selected based on factory conditions.

Steam: Most common. Heats air via steam radiators (finned tube heat exchangers).

Thermal Oil: Heats air via thermal oil radiators, suitable for higher temperature applications.

Gas/Oil: Uses direct-fired hot air furnaces. Clean hot air from combustion enters the drying chamber directly, offering high thermal efficiency.

Electric Heating: Heats air via electric heating elements. Allows precise control but has higher operating costs, often used in small equipment or for auxiliary heating.

Layout: The hot air generated by the radiators or furnace is blown towards the veneers by circulation fans. Heaters are usually arranged in zones, allowing independent temperature control for each drying zone.

4. Hot Air Circulation System

This is the "respiratory system" of the dryer, responsible for forcing hot air evenly through the veneer layer to remove moisture.

Circulation Fans:

Type: Typically high-airflow, high-static pressure axial fans or centrifugal fans.

Layout: The most critical design feature is alternating upward and downward air flow. Fans are arranged both above and below, allowing hot air to penetrate the veneers alternately from top and bottom, ensuring consistent drying on both sides and effectively preventing deformation and warping.

Material: Fan impellers and housings need to be heat and corrosion resistant, often made of aluminum alloy or stainless steel.

Air Ducts and Nozzles:

The hot air generated by the fans is directed through carefully designed air ducts and finally blown onto the veneers at a uniform speed through nozzle plates or nozzle boxes. The design of the nozzles directly affects the uniformity of the air flow.

5. Moisture Exhaust System

This is the "perspiration system" of the dryer, responsible for promptly removing the highly humid air evaporated from the veneers inside the drying chamber.

Components: Includes exhaust fans, exhaust ducts, and dampers (electric or manual).

Principle: Based on the drying process requirements, the control system automatically adjusts the opening of the exhaust dampers. In the initial drying stage, where moisture evaporation is high, the damper opening is large; in the later stages, exhaust volume decreases, and the opening is reduced to save energy.

Energy Saving Design: Advanced systems are equipped with heat recovery devices (such as heat pipes or plate heat exchangers) that use the exhausted humid air to preheat incoming fresh air, significantly reducing energy consumption.

6. Cooling System

Function: A cooling zone is set up at the end of the dryer. Ambient air (unheated) is introduced to cool down the dried hot veneers and set their shape.

Benefit: Prevents the veneers from absorbing moisture, deforming, or cracking due to sudden exposure to cold outside air after drying. It also facilitates subsequent handling and stacking by workers.

7. Control System

This is the "brain and nerve center" of the dryer, representing the level of automation in modern dryers.

Core: Typically centered around a PLC (Programmable Logic Controller) and an Industrial Touch Screen (HMI).

Controlled Parameters:

Temperature Control: Temperature sensors (thermocouples or PT100) monitor the temperature in each zone, and PID algorithms adjust the opening of the heating system's steam valves (or gas supply).

Humidity Control: Humidity sensors, or humidity values calculated based on dry and wet bulb temperatures, automatically control the opening of the exhaust dampers.

Mesh Belt Speed Control: Precisely controls the speed of the mesh belt drive motor based on the target moisture content and drying process curve.

Monitoring and Recording:

Online Moisture Content Monitoring: Advanced equipment is equipped with microwave or resistance-type moisture sensors at the outlet to monitor the final drying effect in real time.

Data Logging: The system can record and store historical curves of temperature, humidity, speed, etc., throughout the drying process, facilitating quality tracing and process optimization.

Fault Diagnosis: Includes functions for alarms and interlocked shutdown in case of motor overload, overtemperature, mesh belt deviation, etc.

8. Feeding and Discharging Device

Feeding End: Usually equipped with a spreading mechanism to ensure wet veneers are laid evenly and flatly on the mesh belt with consistent thickness. This is a prerequisite for ensuring uniform drying.

Discharging End: The dried and cooled veneers are smoothly discharged from the mesh belt via discharge rollers or stripper rollers at the outlet, entering a stacker or the next process step.

High Efficiency and Energy Savings: Recycled hot air utilization reduces energy consumption by over 30% compared to batch drying.

Uniform Drying: Penetrating airflow prevents veneer deformation and cracking, with a qualification rate exceeding 95%.

High Automation: Supports online moisture content monitoring and adaptive adjustment.

Strong Adaptability: Suitable for veneers of different wood species (e.g., eucalyptus, poplar) with thickness ranges of 0.5-3mm.

Primarily used in the veneer drying stage of plywood production lines, also applicable for continuous drying of sheet materials such as bamboo strips and textiles. Typical capacity ranges from 10 to 30 tons of water evaporation per day.

Parameter Name | Unit | Small Equipment Example | Large Equipment Example | Note |

Evaporation Capacity | kg water/h | 500 - 800 | 1200 - 2000+ | Core capacity indicator |

Effective Belt Width | mm | 1300 (4ft) | 2600 (8ft), 4800 | Determines veneer width |

Effective Drying Length | m | 15 - 25 | 30 - 50 | Affects drying time |

Drying Temperature | °C | 120 - 160 | 140 - 180 | Adjustable by wood species |

Belt Speed | m/min | 0.8 - 4.0 | 0.5 - 5.0 | Stepless speed regulation |

Total Installed Power | kW | 80 - 120 | 200 - 350 | Sum of all motors |

Steam Consumption | kg steam/kg water | ≤ 1.8 | ≤ 1.7 | Lower is more energy efficient |

Drying Time | min | 5-15 | 8-20 | Adjustable |

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

Machines include:Veneer production line(Log debaker,Veneer peeling machine, Log loader,Automatic stacker),Blade sharpener,Veneer patching machine,Veneer dryer machine(Veneer roller dryer, Veneer mesh dryer, Veneer press dryer), Veneer gluing machine,Plywood lay-up machine, Veneer jointing machine, Plywood cold press, Hot press machine,Plywood edge trimming cutting machine, Sanding and calibrating machine, Plywood overturn machine, Lift table, and so on.

Request a Quote Today! OEM/ODM solutions available – Start your plywood business with competitive edge!

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com