plywood veneer sheets drying

Veneer Dryer

Veneer drying is very important for the production of plywood. After the wood is processed into a veneer by a veneer lathe, the moisture content is 50-70%. Plywood production requires a veneer moisture content of 8-%14. If the moisture content of the veneer is greater than %14, the negative effects are: 1. It will increase the hot pressing time of the plywood blank in the hot press. The heating of the hot press is heated by a steam boiler or a heat conduction oil boiler. If you increase the hot pressing time, it is equivalent to increasing the heat loss. 2. If the moisture content is higher than %14, the veneer after gluing will ooze glue during the hot pressing process, causing the plywood to crack. 3. If the moisture content of the veneer is 14%, the plywood blank needs to be dehumidified several times during the hot pressing process to remove the moisture inside the plywood blank. If the temperature is not properly controlled, air bubbles will appear in the semi-finished plywood, which will cause cracks and cause the plywood to be scrapped.

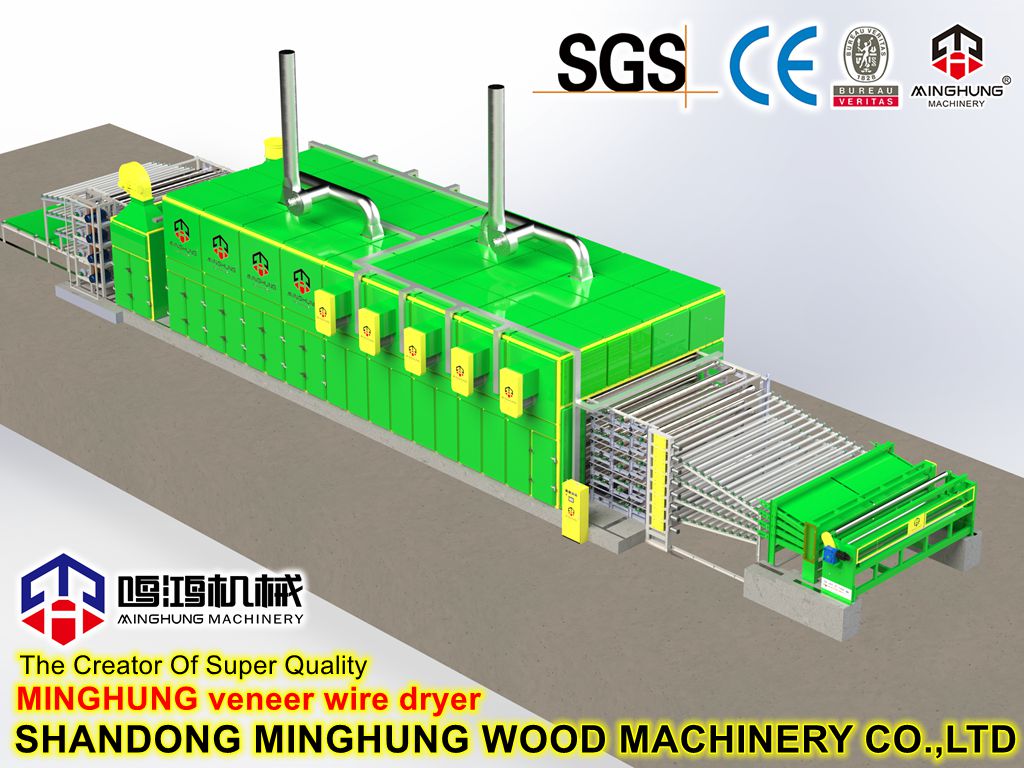

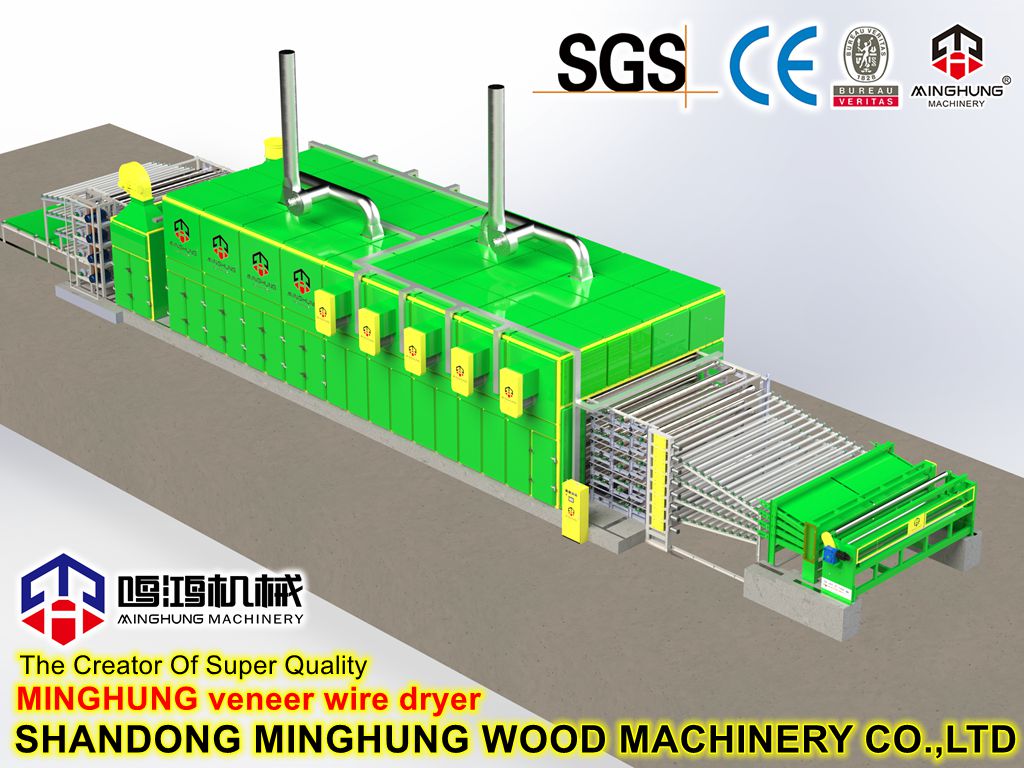

Minghong veneer drying effectively solves the problem of veneer drying, veneer drying, according to the density of different veneers, different veneer output of customers, procurement costs and other factors, MINGHUNG has developed a variety of veneer drying models MH-RD, MH-RD2830L, MH-RD304HL: drum veneer drying, wire veneer drying, mesh veneer drying, press drying, square tube veneer drying, hollow veneer drying, etc. Professional research on veneer drying and energy saving , energy saving, and improve production efficiency.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

During the veneer drying process, a large amount of steam will be generated inside the dryer. If the steam cannot be discharged in time, it will affect the veneer drying efficiency and reduce the output of veneer drying.

MINGHUNG patented automatic control veneer drying moisture removal system, the whole The machine is controlled by computer PLC. According to the water vapor generated in the drying process of different veneers, automatic detection and automatic moisture removal are carried out.

There are a variety of sensing devices inside the veneer dryer, which convert the detection data into computer signals, and convert the computer signals into PLC signals. control.

The advantage of this design is precise moisture removal, automatic processing according to the dry humidity inside the veneer dryer, and avoiding the loss of energy inside the veneer dryer. Energy is saved and thermal efficiency is improved.

Beech veneer is light yellow, with clear texture and uniform texture. The density of beech is generally about 790kg/m³, and the hardness is about 5800N. The rear beech veneer has a smoother surface. Because it is cooking, the moisture content reaches %50-%60, and the moisture content is relatively high. If the moisture content of the veneer after drying reaches %0-%14, it takes about 10 minutes, so if the output of beech veneer drying is If there are requirements, special optimization of the dryer is required. MINGHUNG MH-RD2830L; MH-RD304HL These two models are veneer drying equipment optimized for beech veneer. For details, please contact us.

Veneer drying is very important for the production of plywood. After wood is produced into veneer through veneer lathe, the moisture content is 50-70%. Plywood production requires veneer moisture content of 8-%14. The moisture content of veneer is greater than %14, which brings negative The influences are:

1. It will increase the hot pressing time of the plywood blank in the hot press. The heating of the hot press is heated by a steam boiler or a heat transfer oil boiler. If the hot pressing time is increased, it is equivalent to an increase in heat loss.

2. If the moisture content is higher than %14, the veneer after glue spreading will seep out of glue during the hot pressing process, causing the plywood to crack.

3. If the moisture content of the veneer is 14%, the plywood blank needs to be dehumidified several times during the hot pressing process to remove the moisture inside the plywood blank. If the temperature is not properly controlled, there will be air bubbles in the semi-finished plywood, which will crack and cause the plywood to be scrapped.

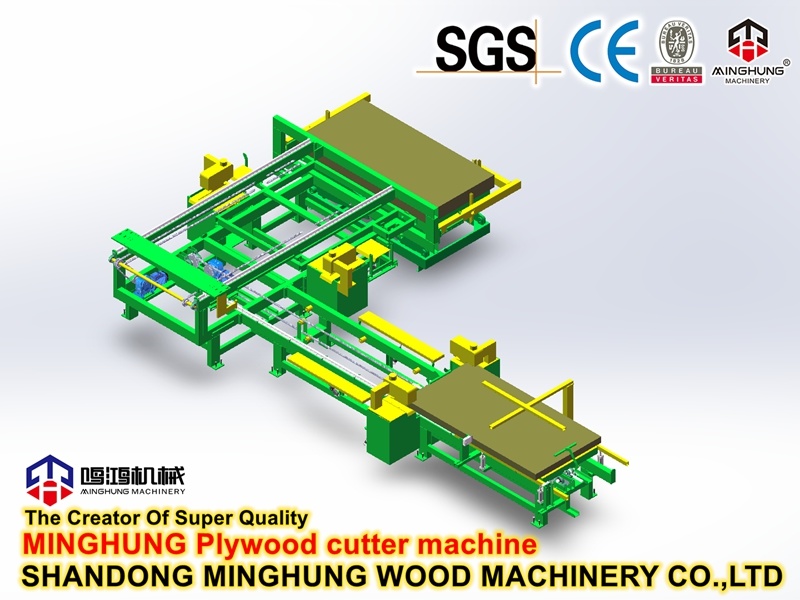

MINGHUNG veneer drying effectively solves the problem of veneer drier, veneer drying, according to the density of different veneers, the customer's different veneer output, the factors of purchasing cost, MINGHUNG has developed a variety of veneer drying types MH-RD40L,MH-RD304HL / MH-2830L / MH-MD3618 : roller veneer dryer, wire veneer dryer, mesh veneer drier, press drying, square tube veneer drying, Hollow veneer drier, ect specialized in research on saving energy, energy consumption and improving production efficiency of veneer drying.

Veneer drying is a very important link in the production process of plywood. The moisture content of veneer is too high, or the moisture content of veneer is uneven, which directly affects the production quality of plywood. Usually, the moisture content of veneer is required to be %8-%14 , the moisture content of the veneer in this interval is the most reasonable for the quality of the plywood veneer, so a veneer dryer is required to complete the veneer drying. The selection of the veneer dryer needs to provide us with several data to ensure that we provide the best solution:

1. What is the thickness of the veneer?

2. What is the throughput for 10 hours?

3. What is the moisture content of the veneer?

4. The name of the tree for the veneer?

5. Is the heating boiler heat transfer oil or steam? Etc.,

MINGHUNG MH-304HL model dryer, providing energy-saving and efficient veneer drying solutions.

Veneer drying parts:

FAN:

We have professionally designed according to different types of dryers, positive pressure fans and negative pressure fans, different fans for different veneer drying equipment, energy-saving, high-efficiency design concepts provide an effective guarantee for improving the quality of veneer drying products .

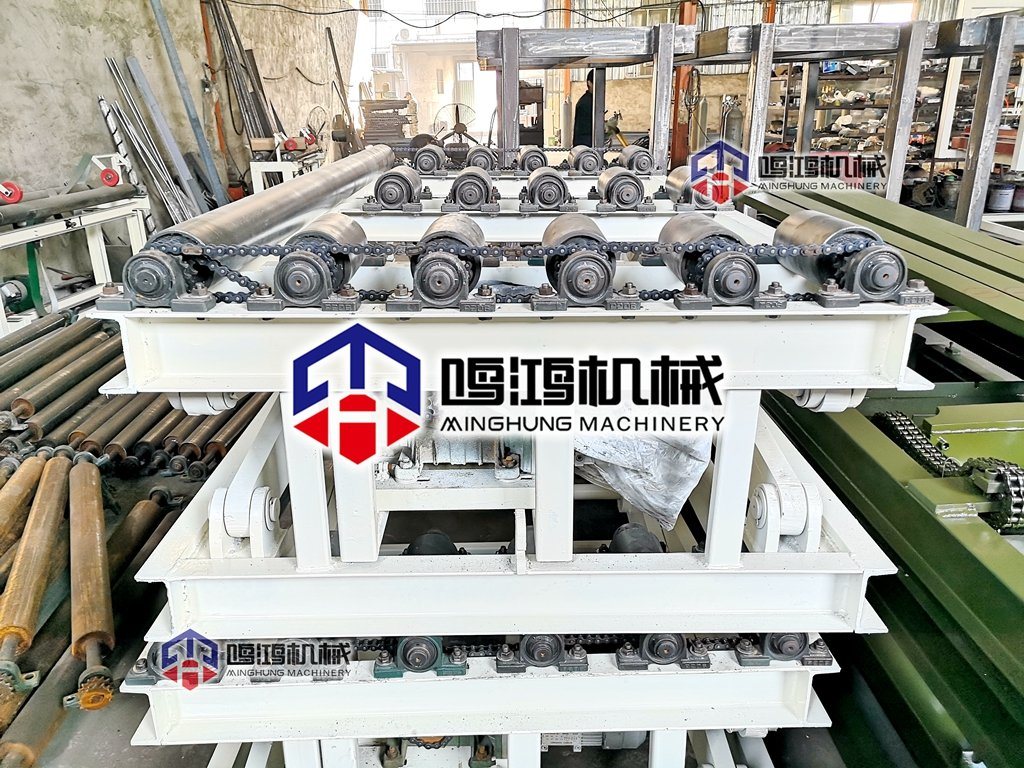

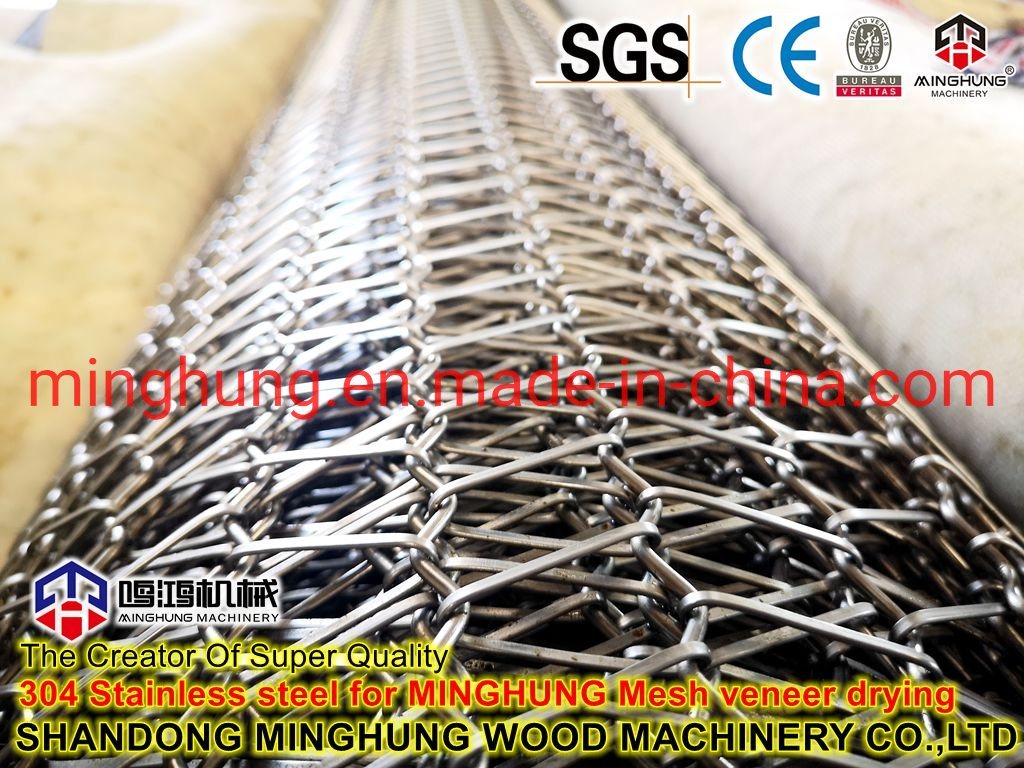

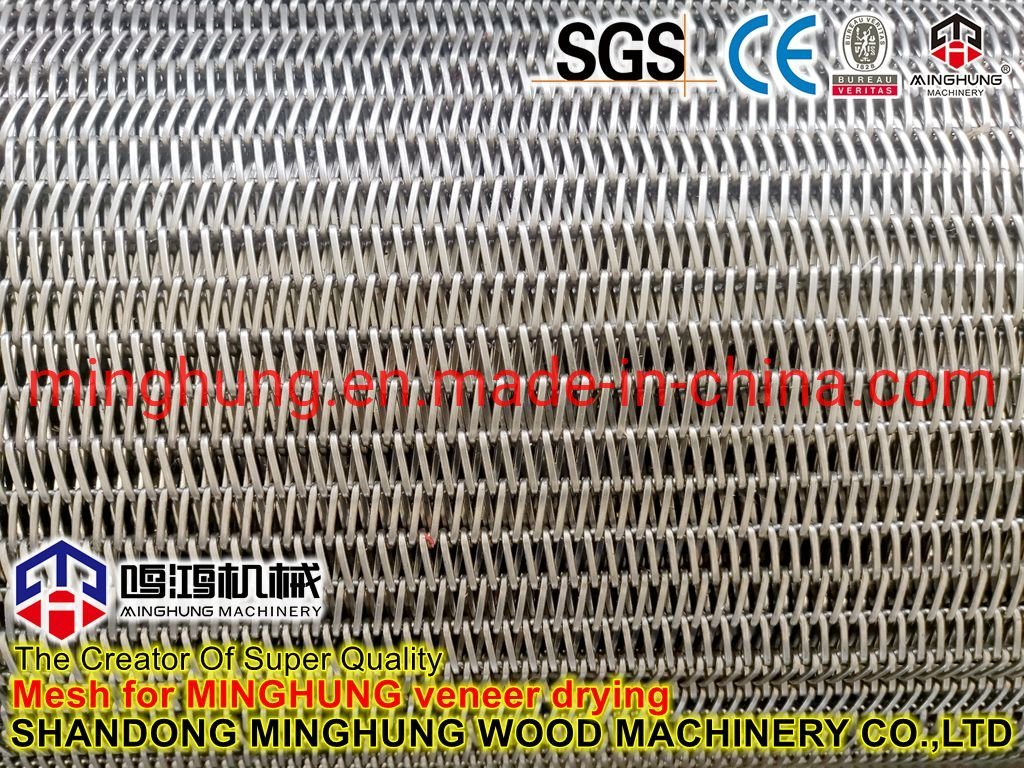

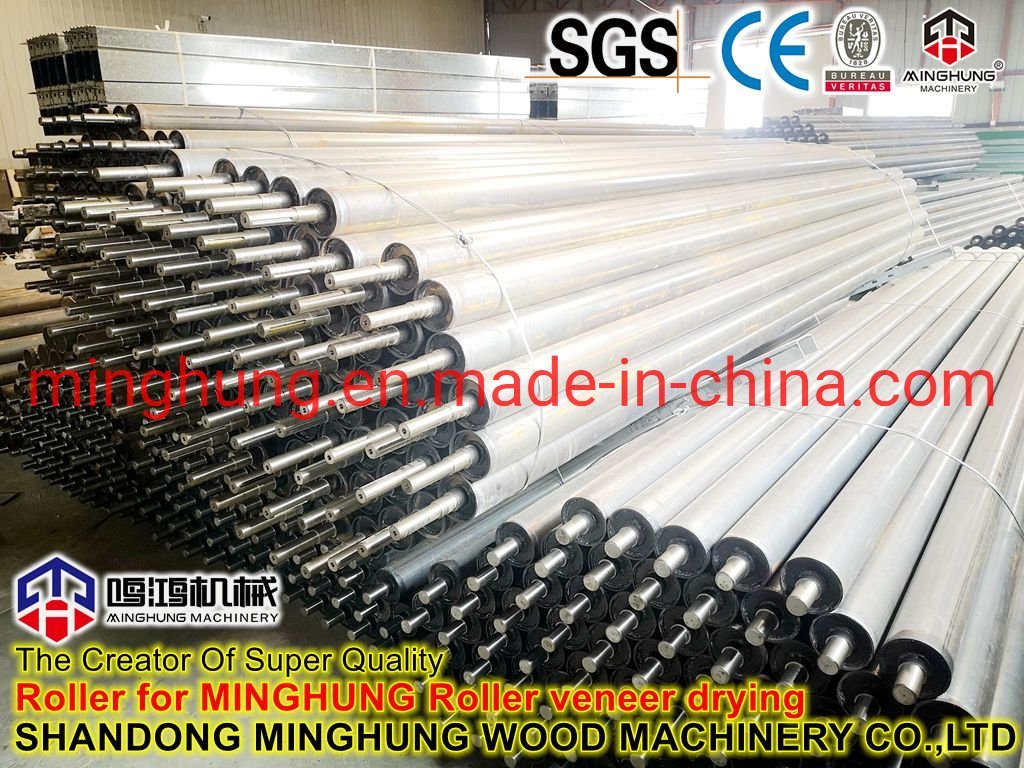

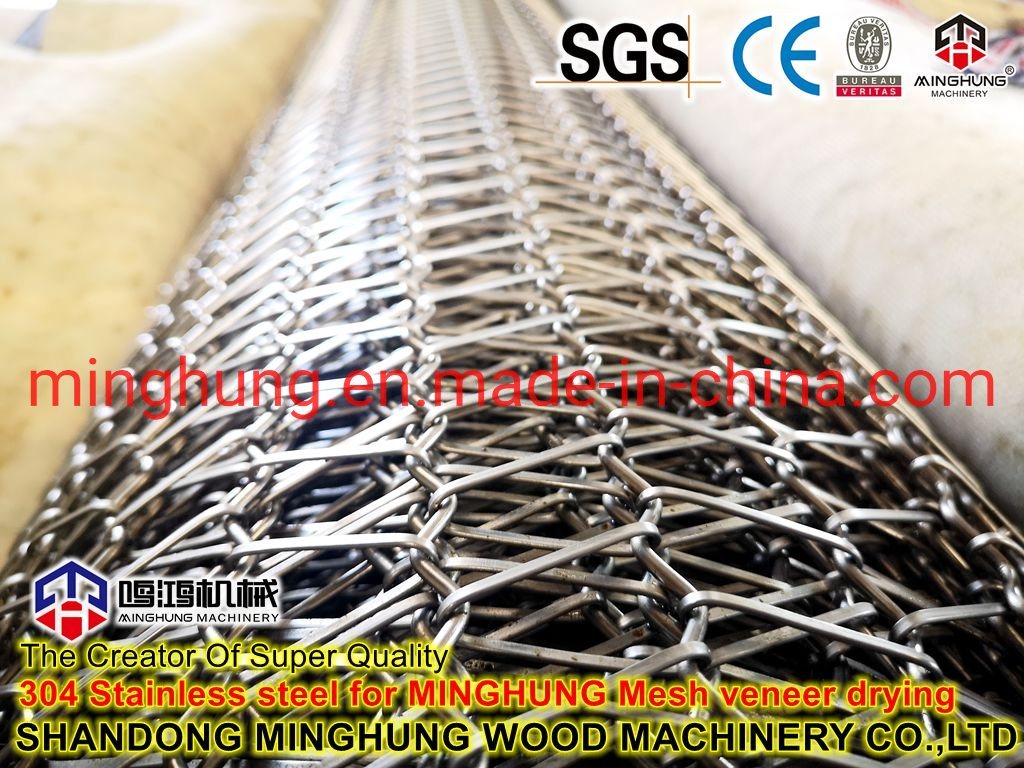

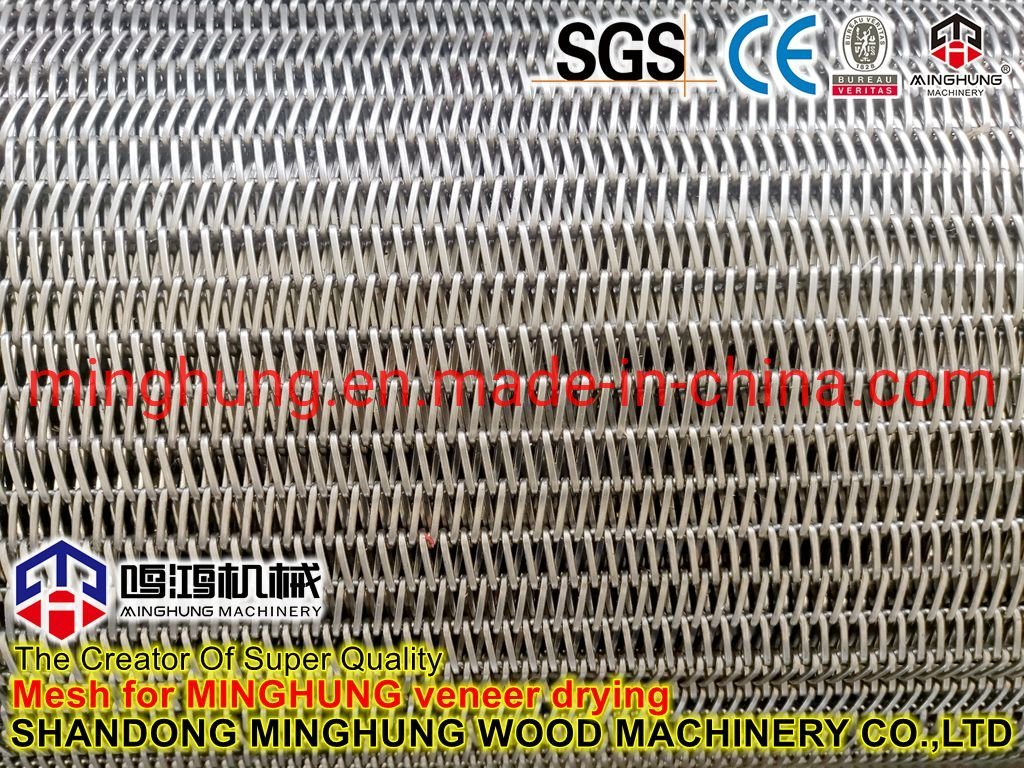

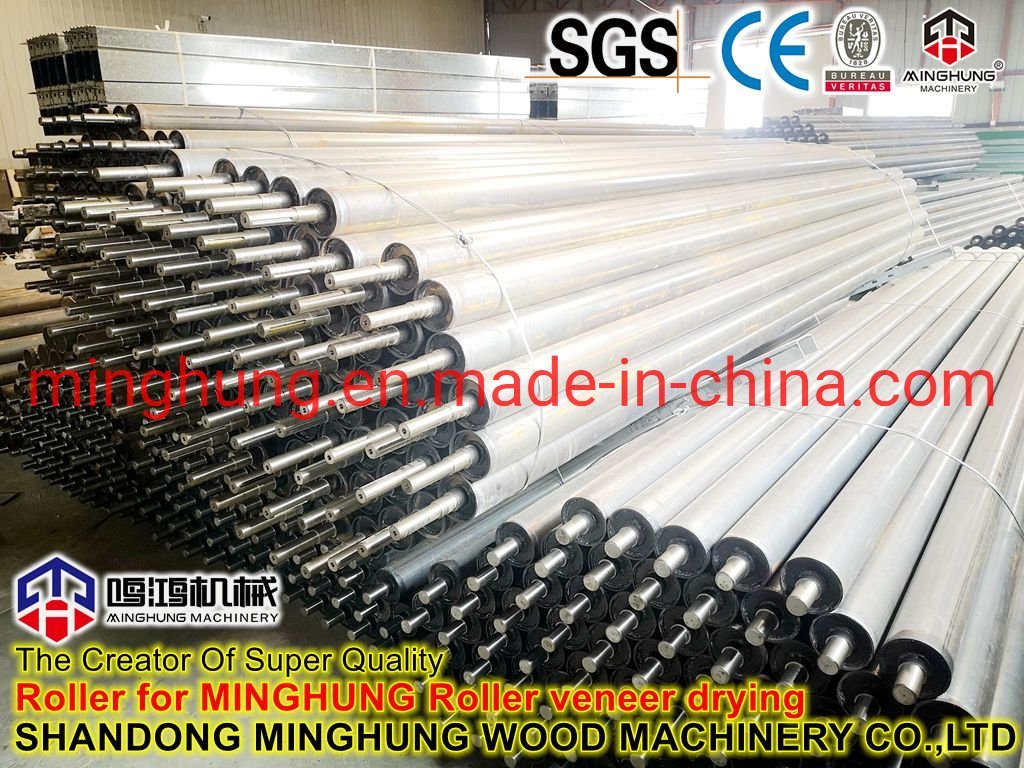

MESH AND ROLLER:

HEAT CONDUCTION HEAT SINK:

Heat conduction heat sink, used for MINGHUNG veneer drying, the warp is made of aluminum, the characteristics of aluminum material is good heat conduction effect, low heat loss, can better improve heat conduction efficiency, internal design forced circulation, heat conduction effect is better than traditional heat dissipation Warp increased by %70. Greatly improved energy utilization.

Delivery: