150000m³ Annual For High-Flex 8mm MDF Production Line

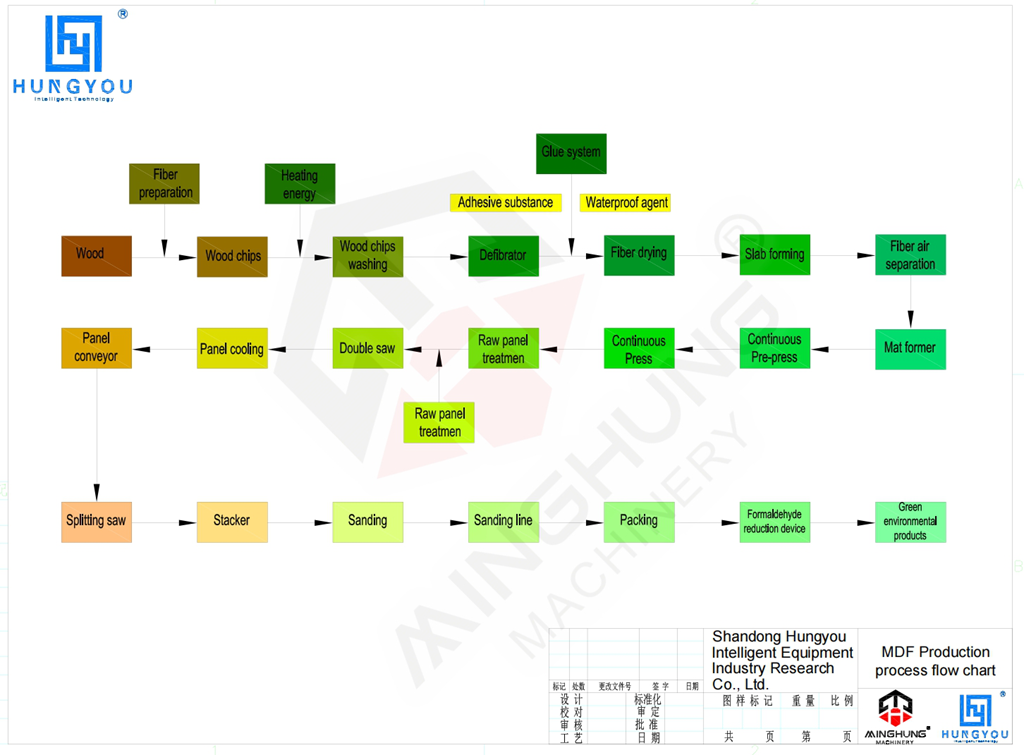

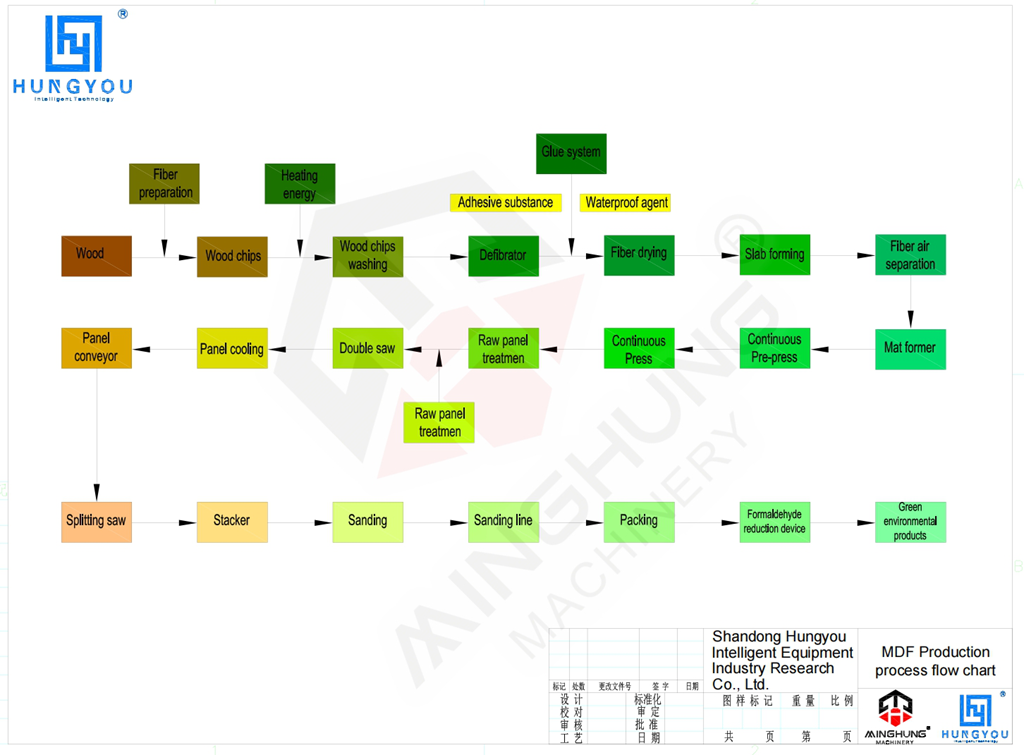

| MDF Production Process |

1. Raw Material Preparation: Wood raw materials (such as small-diameter logs, branches, and wood processing residues) are processed by a chipper to produce uniform industrial chips.

2. Fiber Preparation (Defibration/Refining): This is the core stage. The chips are softened through pre-steaming and cooking and then fed into a defibrator (refiner). Under high temperature and pressure, the defibrator separates the chips into wood fibers. Simultaneously, adhesives (such as urea-formaldehyde resin), waterproofing agents (paraffin wax), and other additives are applied, achieving uniform mixing of fibers, glue, and additives.

3. Drying: The fibers exiting the defibrator have a high moisture content and need to be rapidly dried in a drying pipeline. Typically, high-temperature airflow drying is used to reduce the fiber moisture content to a precise level suitable for forming and pressing.

4. Forming: The dried fibers are evenly distributed via an air-layering forming machine or mechanical forming machine onto a moving conveyor belt, forming a continuous and uniformly thick "fiber mat."

5. Pre-pressing and Cutting: The fluffy fiber mat is first preliminarily compressed by a pre-press to increase its density and strength for easier handling. It is then cut into specific lengths according to the press dimensions.

6. Hot Pressing: The mat is fed into a continuous flat press or multi-opening hot press. Under high temperature (typically 180-210°C) and high pressure, the adhesive in the mat rapidly cures, firmly bonding the wood fibers together to form a panel with specific density and thickness.

7. Cooling and Trimming: The panel exiting the press is very hot and must be cooled in a cooler/stacker to stabilize internal stresses and prevent warping. The cooled panel is then trimmed to standard dimensions by cross-cutting and edge-trimming saws.

8. Sanding: The surface of the rough panel is coarse, and its thickness may have slight variations. It must be calibrated and sanded by a multi-head sander to obtain a finished panel with a smooth, flat surface and precise, consistent thickness.

9. Inspection and Packaging: Finally, the panels undergo quality inspection (e.g., measuring thickness, density, strength), are graded, and are then automatically stacked, packaged, and sent to the warehouse for storage or shipment.

| Equipment |

A highly automated MDF production line with an annual capacity of 150, 000 cubic meters typically includes the following main equipment units:

Raw Material Handling Section:

Debarker (if required)

Drum or Disc Chipper

Chip Screening and Re-crushing System

Chip Storage and Conveying System

Fiber Preparation Section:

Chip Pre-heating Bin/Silo

Defibration/Refining System (The defibrator/refiner is its core, including a preheater/digester, grinding mechanism, glue application system, etc.)

For high-elasticity MDF, the glue recipe and process here are critical.

Forming and Pre-pressing Section:

Fiber Drying Pipeline (often paired with a hot gas generator)

Fiber Screening and Metering Bin/Silo

Air-Flow Forming Machine (Crucial for thin boards and uniform mats)

Continuous Belt Pre-press

Mat Edge Alignment and Cutting Device

dryer

mat forming machine

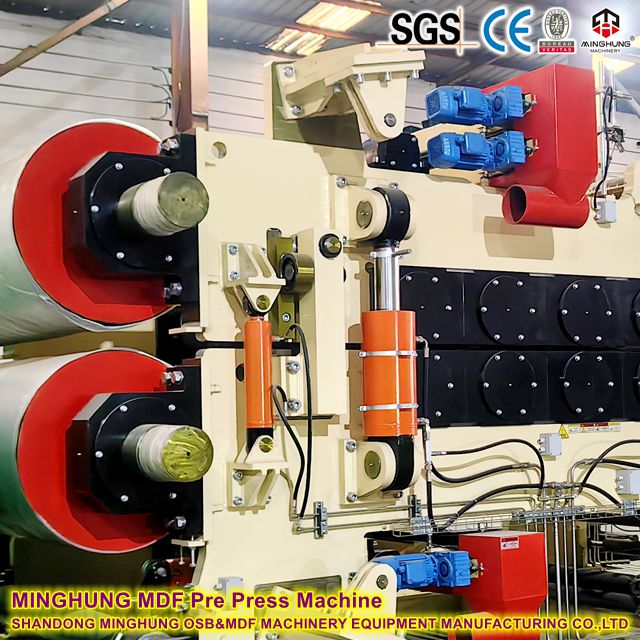

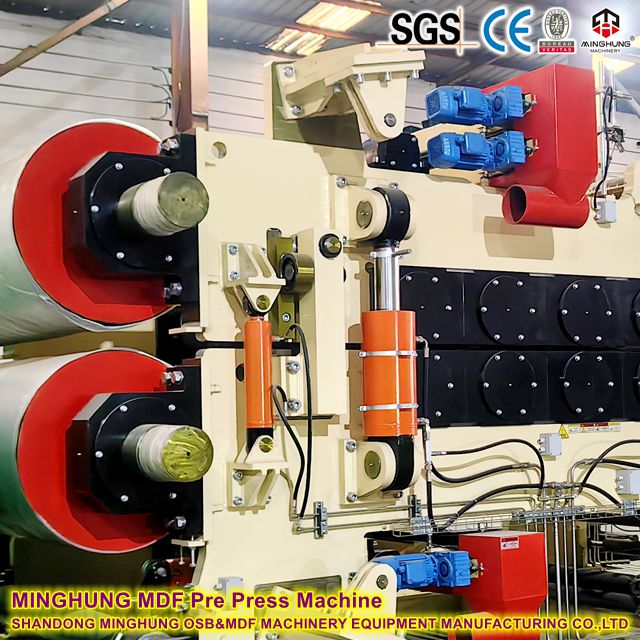

MDF pre press

Pressing and Finishing Section:

Continuous Flat Press - This is the standard configuration for modern high-capacity lines (e.g., 150, 000 m³), enabling continuous production, high efficiency, and high quality.

Mat Loading and Transport System

Discharge and Cooling System (Cooler/Stacker)

For thin boards like 8mm and below, process control in the press and cooling section is particularly critical.

Sanding and Cutting Section:

Cross-Cutting and Edge-Trimming Saws

Multi-head (usually 6-8 heads) Heavy-Duty Calibrating Sander

Panel Stacking and Packaging System

cross-cut saw

sander

Auxiliary Systems:

Central Control System (PLC/DCS): The core for full-line automated control.

Thermal Energy Plant (Provides thermal energy for drying and pressing, e.g., a Thermal Oil Heater or energy plant)

Compressed Air and Hydraulic Systems

Dust Extraction and Environmental Protection Systems

| 8mm thickness in MDF panels |

In the world of MDF, 8mm thickness is a strategically significant and highly sought-after "golden specification." Its importance can be understood from the following perspectives:

A Critical Thickness Bridging Two Categories: It perfectly fills the market gap between "thin boards" (typically referring to those under 6mm) and "standard thick boards" (12mm, 18mm, 25mm). It is stronger and more supportive than thin boards, yet lighter, easier to bend, and more cost-effective than standard thick boards.

The Optimal Balance Between Performance and Workability: The 8mm thickness provides sufficient strength and rigidity for many furniture components without extreme structural demands. Simultaneously, it maintains excellent workability: it is easy to cut, carve, mill, and is the ideal starting point for achieving curved shapes.

The Optimal Carrier for "High Elasticity" Properties: For high-elasticity MDF, 8mm is a classic thickness. At this thickness, the board can demonstrate good bending performance (achieving a relatively small bending radius) while ensuring adequate strength and surface integrity after bending, preventing easy breakage or surface cracking.

Summary: 8mm is not an ordinary thickness; it is a "star product specification" specifically designed to meet market demands for applications requiring lightweight, bendable, easy-to-process, and sufficiently strong materials.

| What are the main uses of 8mm MDF? |

8mm MDF, especially high-elasticity 8mm MDF has a wide range of applications, primarily concentrated in areas requiring bending and precision machining:

Furniture Manufacturing (Core Application Area):

Chairs and Stools: Chair backs, seat bases, the entire rear shell of bentwood chairs. This is the most classic use case for high-elasticity 8mm MDF.

Cabinet Doors and Panels: Cabinet doors, wardrobe doors, and decorative panels with curved and relievo designs.

Tabletops and Work Surfaces: Especially for tables and coffee tables with curved edges or unique shapes.

Beds: Headboards, particularly those with modern curved designs.

Interior Decoration and Renovation:

Wall and Ceiling Decorations: Used for making decorative moldings, wall panels, arches, and suspended ceiling features.

Doors and Partitions: Core material for lightweight interior doors, or decorative screens and partitions.

Shop Display Systems: Used for creating curved display shelves, feature walls, and decorative elements in high-end malls and showrooms.

Other Professional Fields:

Loudspeaker Enclosures: Speaker boxes requiring smooth internal surfaces and specific acoustic properties.

Musical Instrument Manufacturing: Such as casings for electronic pianos and components for certain instruments.

Crafts and DIY Projects: Provides ideal material for creators and designers to realize complex curved designs.

| What is meant by High-Elasticity MDF? |

High-Elasticity MDF (or Bendable MDF) is a type of medium density fiberboard that has undergone special processing, enabling it to be cold-bent (without requiring heat or steam) without breaking or developing serious surface defects.

The fundamental difference from standard MDF lies in its "internal structure" and "performance":

Standard MDF:

Internal Structure: Shorter fibers, adhesive system primarily focused on high hardness and rigidity. Although internal bond strength is high, brittleness is also high.

Performance: Hard, very rigid, but brittle. Attempting to bend it will cause it to snap due to internal fiber breakage, much like trying to bend a biscuit.

High-Elasticity MDF:

Internal Structure:

1. Specialized Fibers: Often uses longer, more flexible fiber raw materials.

2. Special Adhesives: Employs special, flexible synthetic resins as binders. These adhesives, once cured, form a flexible network that allows fibers to move and slide slightly under stress rather than break immediately.

3. Modified Process: The pressure and temperature profiles during hot pressing are optimized to create a structure with a more uniform density gradient and lower internal stress, thereby enhancing its flexibility.

Core Performance:

Bendable: Can be cold-bent across the grain to achieve a small bending radius.

Crack-Resistant: Exhibits high resistance to cracking and breaking during bending and machining.

Strength Retention: Maintains its structural integrity and strength after being bent into shape.

Simply put, standard MDF is like a "piece of ceramic," while high-elasticity MDF is more like a "piece of leather." The "high elasticity" property that your production line adds is achieved through the synergy of raw material formulation, adhesive systems, and production processes, which significantly enhances the added value and market competitiveness of the 8mm MDF product.

| The core advantage of this production line |

Outstanding elasticity and bending performance: The core process of this production line can produce 8mm MDF boards with extremely high internal bonding strength and excellent elasticity. The finished products are highly suitable for applications that require bending, engraving, and complex shaping, significantly expanding your product design and market potential.

High production capacity and automation: The highly automated system ensures smooth and efficient production processes, with an annual production capacity of up to 150,000 cubic meters. This maximizes output while significantly reducing labor costs and operational errors.

First-class uniformity and surface quality: By employing advanced forming and press machine technologies, the density distribution of the sheet material is made extremely uniform, and the surface is smooth and flat, providing an ideal substrate for subsequent veneering, coating or printing.

Energy Efficiency and Sustainability: Integrated optimization of drying, heat pressing and energy recovery systems significantly reduce energy consumption and production costs, meeting modern environmental protection standards.

Sturdy and Durable with Intelligent Control: The equipment is made of high-quality materials to ensure long-term stable operation. Equipped with an advanced PLC control system, it enables full-line monitoring, data analysis and fault diagnosis, ensuring easy operation and production stability.

| Main Application Scenarios |

The main application scenarios for high-elasticity 8mm MDF panels are extensive. Their core value lies in enabling elegant curves, complex shapes, and lightweight structures while maintaining sufficient strength and stability.

1. Furniture Manufacturing - Core Application Area

This is the largest and most classic market for high-elasticity 8mm MDF. It has revolutionized furniture design language.

Seating:

Chairs: It is the preferred material for modern chair backs (especially dining chairs, conference chairs, bar stools). It allows for the monolithic manufacturing of ergonomic, flowing curves that provide comfortable support and are highly aesthetically pleasing.

Stools: Used for creating curved stool seats or decorative bases.

Case Goods:

Cabinet and Wardrobe Doors: Used for producing high-end doors with curved edges,patterns, and wavy surfaces, significantly enhancing the furniture's aesthetic value and grade.

Drawer Fronts: Especially those with curved designs.

Tabletops and Work Surfaces:

Coffee Tables, Side Tables, Desks: Used for creating non-rectangular tabletops, such as round, oval, or other organic shapes, with edges that can be easily sanded into soft radii.

Beds:

Headboards: An ideal substrate for creating modern upholstered or non-upholstered headboards, easily facilitating complex shapes like curves and wings.

2. Interior Decoration & Architecture

In commercial and high-end residential decoration, high-elasticity 8mm MDF is a key material for realizing personalized designs.

Wall and Ceiling Decor:

Decorative Wall Panels: Creating feature walls with 3D effects, curves, and geometric patterns.

Arches and Vaults: Easily wrapping and creating arched doorways and ceiling features.

Suspended Ceilings and Ceiling Features: Fabricating complex multi-level drop ceilings, wave-shaped ceilings, etc.

Doors and Partitions:

Lightweight Interior Doors: Serves as the core material for doors, which can be laminated with various finishes and designed with profiles featuring radii and small-radius rounded corners.

Decorative Screens and Partitions: Creating artistic curved screens that divide space while becoming a visual focal point.

Molding and Edging:

Decorative Moldings: Can be bent into curved corner moldings, picture frame moldings, and baseboards (for walls requiring curves).

3. Retail & Display Systems

Brand stores and showrooms require unique designs to attract customers, and high-elasticity MDF is the ideal material to achieve this.

Display Shelves and Racks: Creating curved backdrop walls, curved display stands, and unique product display units.

Brand Zones and Exhibition Booths: Used at trade shows or in malls to build brand experience spaces with a sense of flow and innovative design.

Counters and Checkout Desks: Fabricating service desks with soft curves and unique shapes.

4. Creative & Professional Applications

Its easy workability and bendability attract designers and creators.

Loudspeaker Enclosures: An excellent material for high-end speaker boxes. It bends easily into required acoustic chambers, provides a smooth surface for painting, and its uniform density contributes to sound performance.

Prop and Model Making: Used in film, theater, and theme parks for creating sets, props, and models because it is easy to cut and bend into various shapes.

Crafts and Artwork: Used by artists and DIY enthusiasts to create sculptures, three-dimensional artworks, and home decorations.

Musical Instrument Components: Used for the casings or components of certain instruments, such as electronic keyboards, drum shells, etc.

Application Scenario | How it Leverages the Advantages of High-Elasticity 8mm MDF |

Furniture (Chair backs, Doors) | Cold Bending: Achieves small-radius bends without an autoclave, enabling ergonomic curves and aesthetic shapes. |

Interior Decoration (Arches, Ceilings) | Excellent Workability: Easy to cut, mill, and carve, enabling complex, customized architectural elements. |

Display Systems (Display Units) | Lightweight & Strength: Lighter than solid wood or thick boards, facilitating transportation and installation, yet sturdy enough for commercial environments. |

Creative Applications (Speakers, Art) | Surface Quality: Provides an extremely smooth and uniform surface, ideal for painting, laminating, or direct printing, achieving a high-end finish. |

In summary, the main application scenarios for high-elasticity 8mm MDF are concentrated in fields that require a combination of aesthetic design and functionality. It gives designers greater creative freedom, allowing them to break away from traditional straight lines and create more fluid, organic, and attractive products and spaces.

We are providing not just a production line, but a solution for manufacturing a high-value-added flagship product. This line efficiently produces 8mm thickness MDF, for which there is huge market demand, and because of its high elasticity, can be used to produce higher-margin curved furniture and decorations, bringing significant profits to both you and your end clients.

Other mechanical equipment we can offer

Wood chipper, Ring flaker, Strander, Wet silo, Drum dryer, Dry silo, Glue dosing and applying system /Glue blender, Mat forming, Continuous Multi-rolls pre-press, Multi opening hot press and Continuous press, Auto edge cutting machine line, Sanding machine line, kinds of related belt conveyor and so on.

Why choose us?

We are not only equipment suppliers, but also your reliable business partners. We offer a turnkey solution covering factory planning, equipment installation, commissioning, personnel training and after-sales support. Choosing us means choosing quality, innovation and continuous support.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com