500t 600t Cold Press Woodworking Machine for Plywood Manufacture

<1> MINGHUNG Cold press machine at clients factory

Cold press machine

Double frame cold press

500ton Pre-press machine

Hydraulic cold press machine

Plywood pre press machine

Cold press

What is Cold press machine? or some people call it Pre-press machine, it belongs to one step for plywood manufacturing. So what's the cold press machine function? Actually it is very simple, it press the glued veneer plywood through suitable and high pressure in a while, the inside glue will melt and each veneers will stick together, thus each plywood first be moulding, then it will be easy to convey to the next step-hot press machine.

For cold press machine, it can be different pressure, usually 400ton, 500ton, 600ton are widely used; Also its opening also can be customized, for example, its max opening can be 1800mm, also can be 1500mm, also can be 1200mm, 1000mm or as you want.

The whole set cold press is not complex, mainly consist of the frame, oil cylinders, hydraulic station, electric box

For the cold press made from our factory, we can promise that all of them are good materials and accessories.

Electric box

Hydraulic station

Oil cylinder

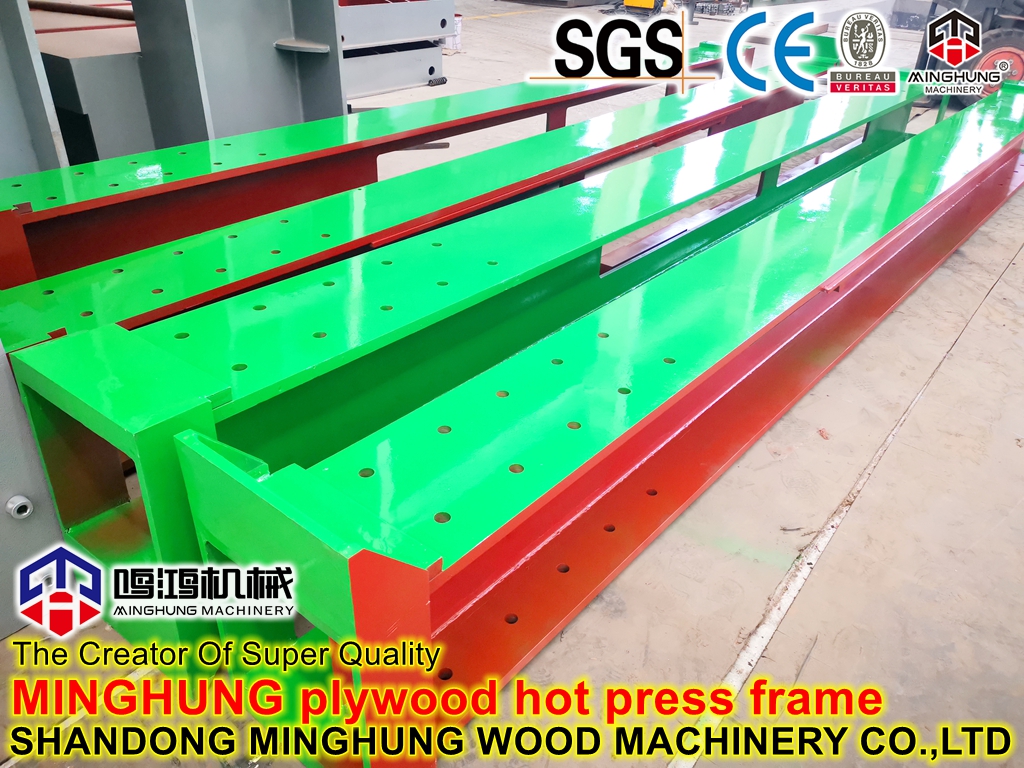

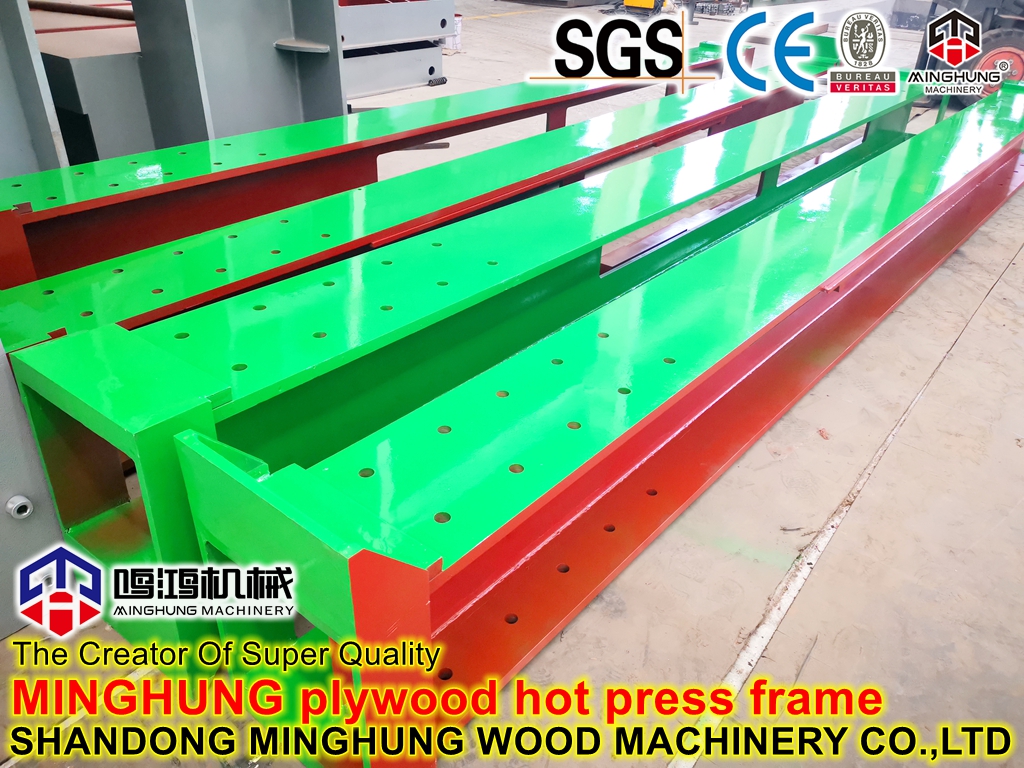

Press machine frame

For our plywood press machine whatever cold press machine or hot press machine, we use Siemens motors, and Siemens and Schneider electric parts, ensure all parts works well and long life span; And we use thick and good steel material to make press machine's body, make sure they are heavy and strong, to undertake high pressure and keep stable.

<2> Cold press machine 's specification

| Pressure | 400t /500t /600t |

| Cylinder diameter | Φ320*2pcs /Φ360*2pcs /Φ260*6pcs |

| Power | 13.2kw |

| Application | For pressing plywood, melamine plywood, furniture plywood... |

| Max opening | 1800mm /1500mm /1200mm /1000mm |

| Size | 3600*1370*4000mm |

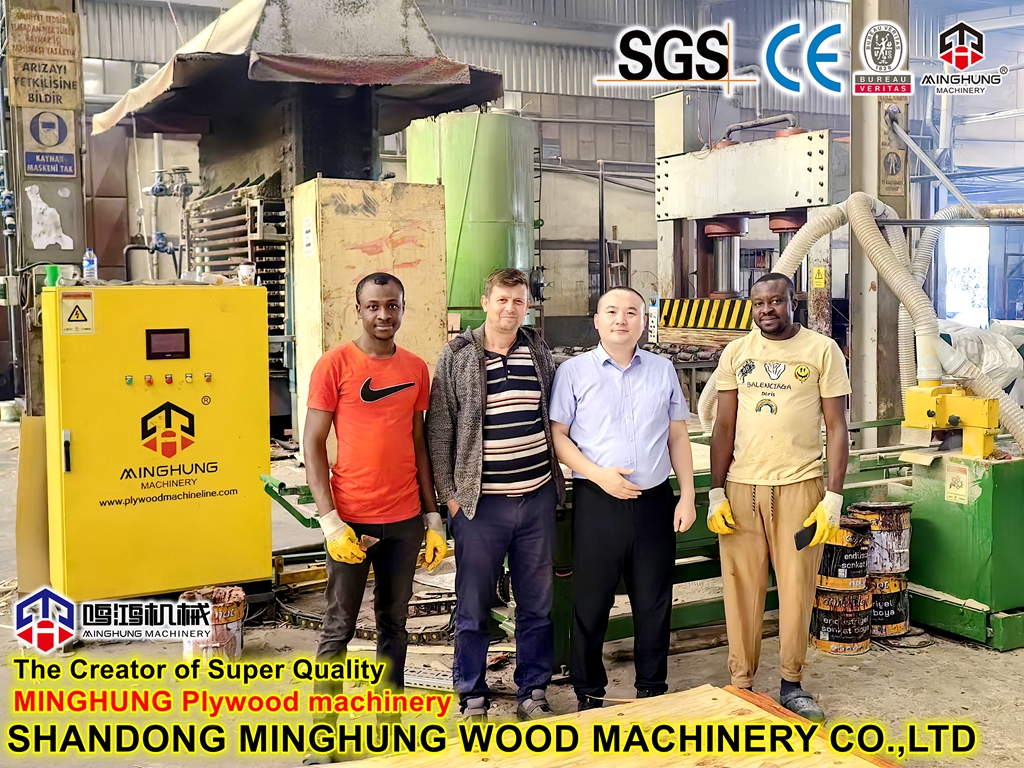

<3> MINGHUNG clients

With our clients, we not just partners, we are friends.

we will stand your position think about problem, help you choose the suitable plywood machine, help you save cost and create much value.

Before order machine, welcome come to visit our factory.

<4> About Us:

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

<5> MINGHUNG machine loading pictures:

Spindle peeling machine

Veneer dryer machine

Double sides plywood sander

Single side plywood sander

Veneer peeling machine

Log debarker

Plywood press machine

Plywood sizing machine

1> When loading, we will share the loading pictures of plywood press machine with you.

2> When ship leave, we will offer the container and ship information for you.

3> Offer all documents which for your custom clearance.

<6> Other MINGHUNG plywood machine:

Plywood hot press

Film faced plywood hot press

Plywood sizing machine

<7> Questions about machine you may want to know

| Production Time: |

| 1 month after receive your deposit. |

| Payment Terms: |

30% deposit, 70% before delivery.

100% Letter of Credit. |

| Warranty: |

| 2 years for main parts. |

| MOQ: |

| 1 set |

| Installation: |

| When machine reach your factory, our engineer can go to install |

| After-sales service: |

| Any problem that your worker can not solve, tell us, we will reply you at the first time, |

Welcome contact us for more information about plywood machinery and veneer lathe, we will reply quickly