Mixed Wood Plywood Universal Drying Equipment

| Product Overview |

The Universal Drying Equipment for Mixed Hardwood Plywood is an innovative drying system specifically engineered to tackle the core challenge of "wood species diversity." In traditional production, the vast differences in density, initial moisture content, shrinkage rate, and pore structure among mixed hardwoods (e.g., Eucalyptus, Poplar, Schima, Acacia) often lead to batch quality issues like cracking, warping, and internal stress when a single drying process is applied. This equipment successfully solves this problem through its adaptability and intelligence, enabling stable and efficient drying of plywood made from various mixed wood species. It is the ideal choice for mixed hardwood plywood manufacturers who pursue high product yield and standardized production.

| Common "Mixed Hardwood" Types Used for Plywood |

"Mixed hardwood" is a commercial and industrial term referring to a mixture of various wood species that are not single, precious, or standardized types (like pure pine or pure eucalyptus). They are characterized by wide availability and relatively low cost, but with highly variable properties. Common types used in plywood include:

1. Eucalyptus Series: Such as Eucalyptus urophylla, Eucalyptus grandis. Fast-growing, medium to high density, relatively hard. One of the primary components in mixed hardwood plywood.

2. Poplar: Fast-growing, soft texture, uniform grain, easy to cut and dry, but relatively low strength. Often mixed with harder woods to improve workability and reduce cost.

3. Schima: Hard texture, fine structure, good drying performance. A common material for high-quality mixed hardwood plywood.

4. Acacia: Such as Acacia mangium. High density, great hardness, good wear resistance, but has high drying shrinkage and is prone to cracking.

5. Oak: Very hard texture, beautiful grain, but difficult to dry and prone to warping.

6. Other Species: Also include Beech, Maple, Birch, and various tropical hardwoods.

| Working Principle |

The core of its working principle is "Flexible Control" and "Dynamic Adaptation", rather than a fixed drying program. The entire process can be summarized as follows:

1. Intelligent Parameter Setting

The operator selects or defines a "mixed drying schedule" in the control system based on the wood mix of the current batch. The system calculates an initial, relatively conservative and safe temperature/humidity curve based on built-in drying models for various woods.

2. Warming-up and Equalizing Stage

The equipment starts, warming the plywood with low temperature and high humidity. The goal is to allow heat to penetrate slowly and evenly to the core, avoiding surface hardening due to rapid heating, thus opening pathways for subsequent moisture escape.

3. Adaptive Main Drying Stage

This is the most critical phase. The equipment gradually increases temperature and decreases humidity according to the preset curve.

The core lies in "Adaptation": Sensors inside the equipment monitor multiple parameters in real-time (e.g., exhaust humidity, MC estimated by weight change).

4. Conditioning Stage (Stress Relief)

Activated when the system determines the average MC is nearing the target. The equipment injects steam or atomized water into the chamber to raise humidity.

This "steaming" process allows the board surfaces to absorb slight moisture, reducing the moisture gradient between the surface and core, thereby releasing internal stresses caused by uneven drying and effectively preventing future warping and cracking.

5. Cooling and Stabilization Stage

After drying, heating stops, and the circulation fans are used to introduce ambient air for slow cooling. This allows the boards to cool down uniformly and their structure to stabilize before being unloaded.

| Core System Components |

Main Structure: High-strength insulated chamber ensures a stable internal environment and minimal energy consumption.

Heating System: Flexible configuration for various heat sources (steam, hot water, hot air furnace) based on client conditions, offering strong compatibility.

Intelligent Control System: Equipped with a high-definition touchscreen, PLC, and high-precision sensors—the "brain" of the equipment.

Humidity Regulation Device: The built-in steam or spray humidification system is the key component enabling gentle, stress-relieving drying.

Heavy-Duty Kiln Trucks/Track System: Designed with higher load-bearing capacity than standard systems to accommodate denser mixed hardwood plywood.

| Core Technology: How "Universal" Drying is Achieved |

1. Multi-Mode Adaptive Drying System

Core: The equipment comes with an extensive built-in database of drying schedules for numerous wood species. The operator simply selects or inputs the dominant wood species for the current batch (e.g., "60% Eucalyptus, 40% Poplar") via the touchscreen, and the system automatically calls up or intelligently blends the optimal drying curve.

Execution: During drying, the system monitors the charge's condition in real-time via multi-point temperature and humidity sensors, dynamically fine-tuning temperature, humidity, and drying time against the preset curve. It functions like an experienced master, ensuring the process stays within a safe and efficient range.

2. Gradient Humidity Control & Stress Balancing Technology

To address the prone-to-crack nature of mixed hardwoods, the equipment features a multi-stage conditioning function. At critical phases of drying (e.g., near the fiber saturation point), the system automatically injects slight steam or atomized moisture into the chamber.

This effectively moderates the surface moisture evaporation rate, synchronizing it with the internal moisture migration, thereby significantly reducing drying stress and fundamentally preventing cracking and deformation.

3. Omnidirectional Balanced Airflow System

Utilizes high-airflow, evenly pressurized circulation fans and CFD-optimized air ducts. This ensures that hot air is forcibly and uniformly distributed across every board's surface, even when loading plywood of different specifications and densities, eliminating dry spots and guaranteeing consistent results throughout the kiln charge.

| Core Advantages & Customer Value |

Exceptional Wood Adaptability: Versatile and multi-purpose, it effortlessly handles production with different wood species and mixed batches. Eliminates the need for separate dedicated dryers for each wood type, greatly improving equipment utilization and production flexibility.

High Product Yield & Quality: Intelligent process control and gradient conditioning drastically reduce the defect rate (cracking, warping) in mixed hardwood plywood, directly enhancing product quality and economic return.

Simple Operation, Reduces Reliance on Skilled Labor: Translates complex wood drying expertise into standardized, intelligent programs. Regular workers can operate it after basic training, effectively solving the "skilled operator shortage" problem.

Energy Efficient & High Performing: Precise control prevents energy waste, and optimized drying curves shorten the cycle time without compromising quality, increasing overall throughput.

| Application Scenarios |

This equipment is an excellent solution for:

Specialized Mixed Hardwood Plywood Producers: whose primary raw material is purchased mixed hardwoods.

Factories with Diverse Product Lines: that need to frequently switch between producing plywood from different wood species.

Enterprises Pursuing Stable Quality & Brand Upgrading: aiming to eliminate quality fluctuations caused by wood variability.

| Who We Are |

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

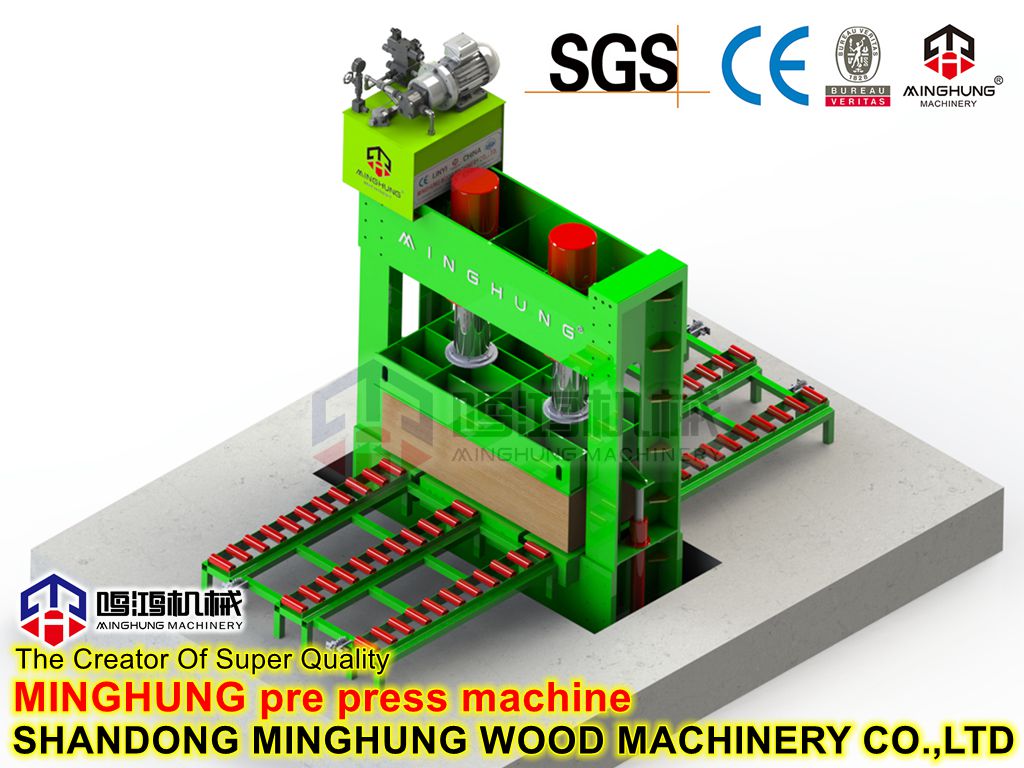

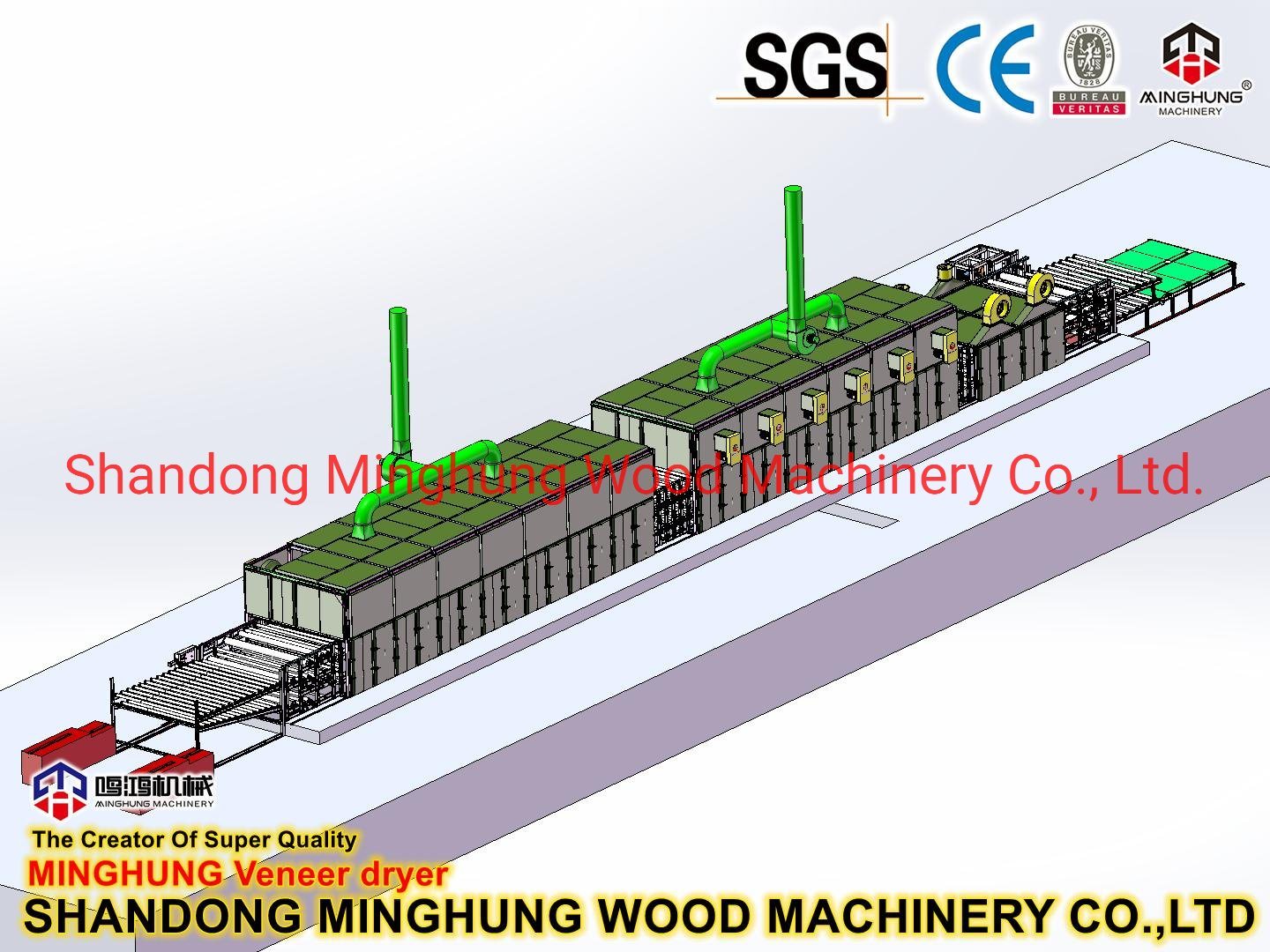

Machines include:Veneer production line(Log debaker,Veneer peeling machine, Log loader,Automatic stacker),Blade sharpener,Veneer patching machine,Veneer dryer machine(Veneer roller dryer, Veneer mesh dryer, Veneer press dryer), Veneer gluing machine,Plywood lay-up machine, Veneer jointing machine, Plywood cold press, Hot press machine,Plywood edge trimming cutting machine, Sanding and calibrating machine, Plywood overturn machine, Lift table, and so on.

Delivery Photos

Why choose us?

We are not only equipment suppliers, but also your reliable business partners. We offer a turnkey solution covering factory planning, equipment installation, commissioning, personnel training and after-sales support. Choosing us means choosing quality, innovation and continuous support.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com