I. Engineered Wood Panels

1. Definition

Engineered Wood Panels are composite board products manufactured from wood or non-wood plant fibers through processes including mechanical separation, drying, adhesive application, forming, and hot pressing.

Core Advantages:

Substitute solid wood, alleviating timber resource scarcity

Large dimensions, uniform structure, minimal deformation

Functional enhancements possible (flame-retardant/moisture-resistant/antibacterial)

2. Primary Types of Engineered Wood Panels

2.1 Classification by Raw Material & Process

Type | Raw Material | Structural Feature | Density (kg/m³) |

Plywood | Rotary-cut veneers | Odd-numbered cross-laminated layers | 450-650 |

Fiberboard | Wood fibers (refined to pulp) | Homogeneous, non-layered | Hardboard >800 |

MDF 600-800 |

Softboard <450 |

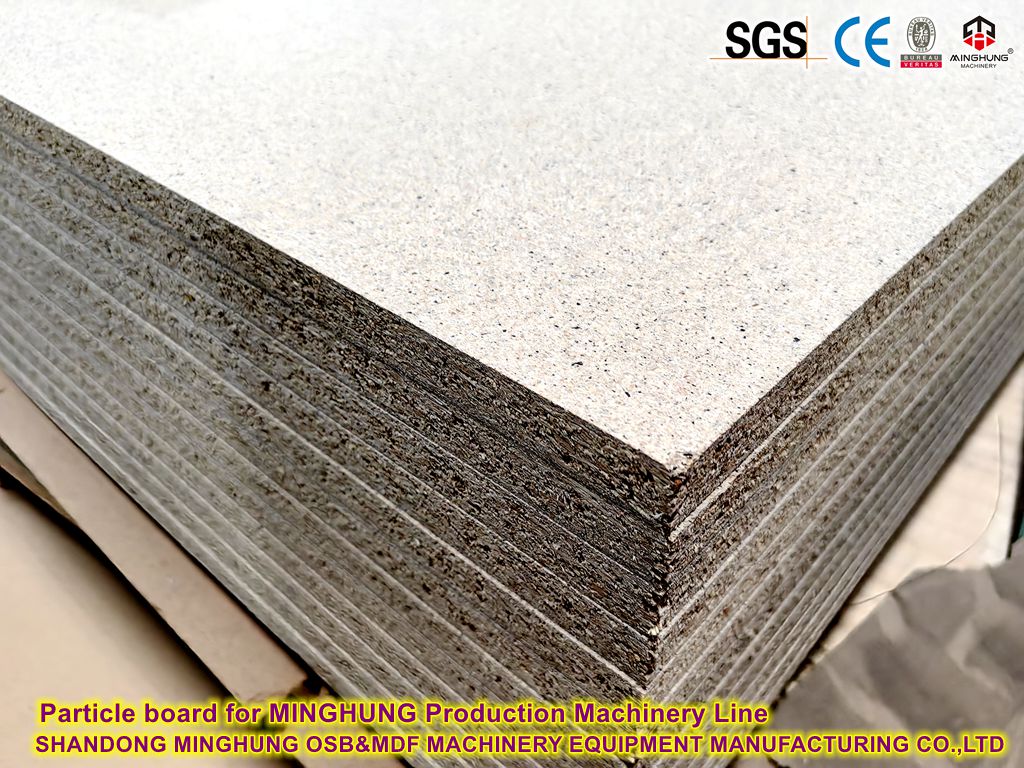

Particleboard | Wood flakes/chips | Fine surface + coarse core particles | 550-750 |

OSB | Strands (length-width ratio >3) | Surface strands longitudinally oriented + Cross-oriented core | 600-680 |

Blockboard | Solid wood strips + veneer faces | "Sandwich" core structure | 450-550 |

2.2 Functional Classification

Structural Panels (e.g., OSB compliant with ASTM D1037)

Decorative Substrates (e.g., MDF for PVC/wood veneer overlays)

Specialty Panels: Flame-retardant (oxygen index >30%), Moisture-resistant (thickness swelling <10%)

3. Engineered Wood Panel Production Process

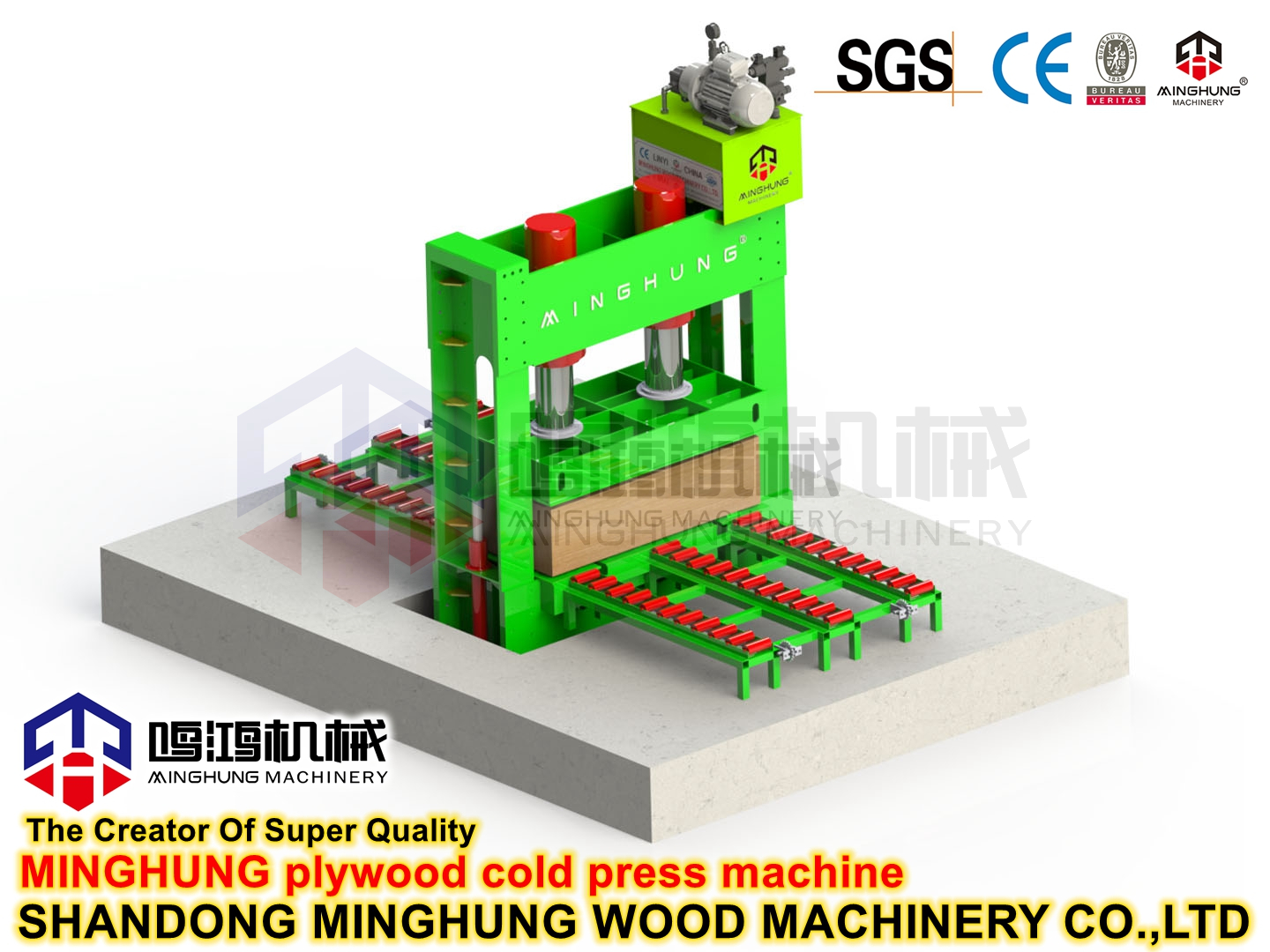

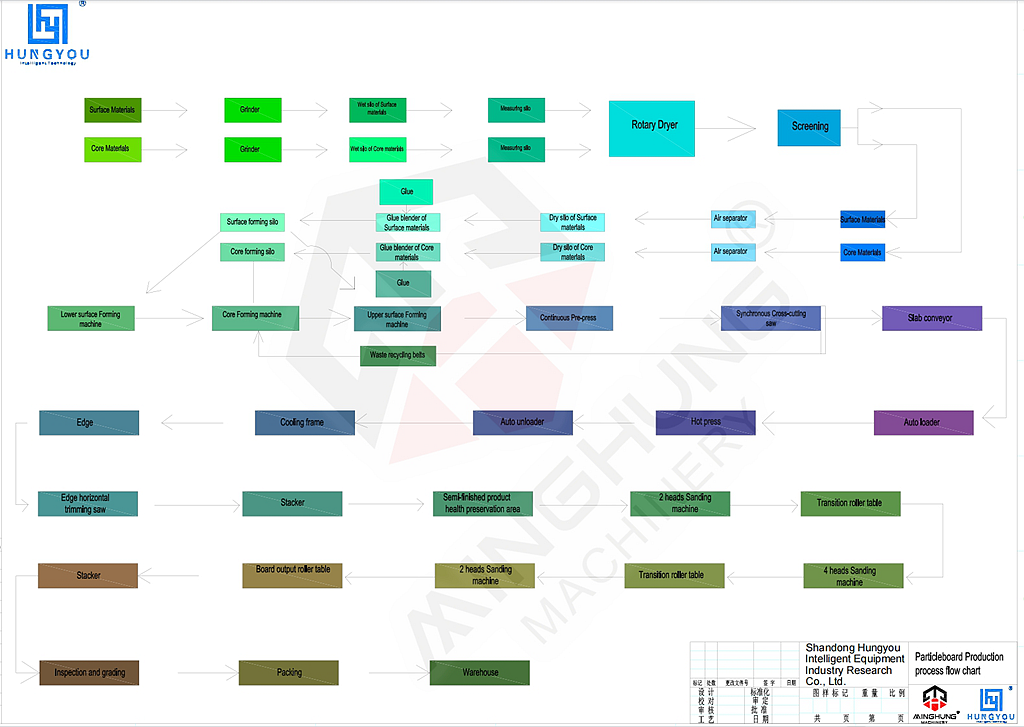

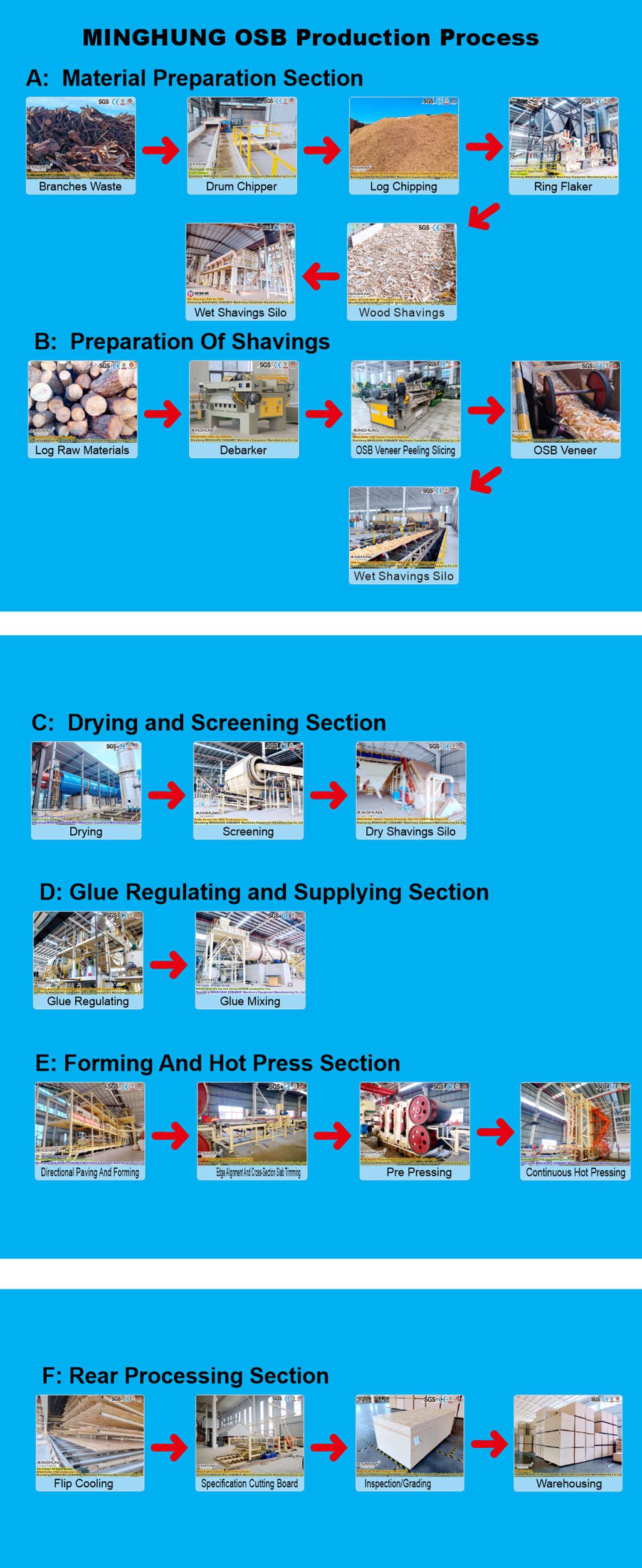

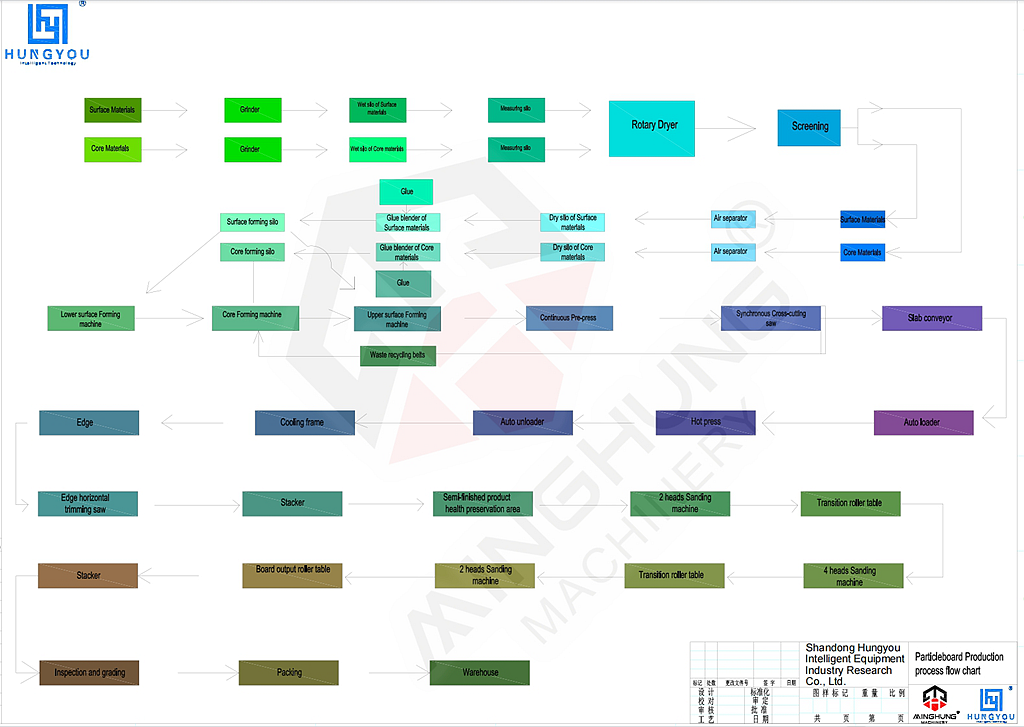

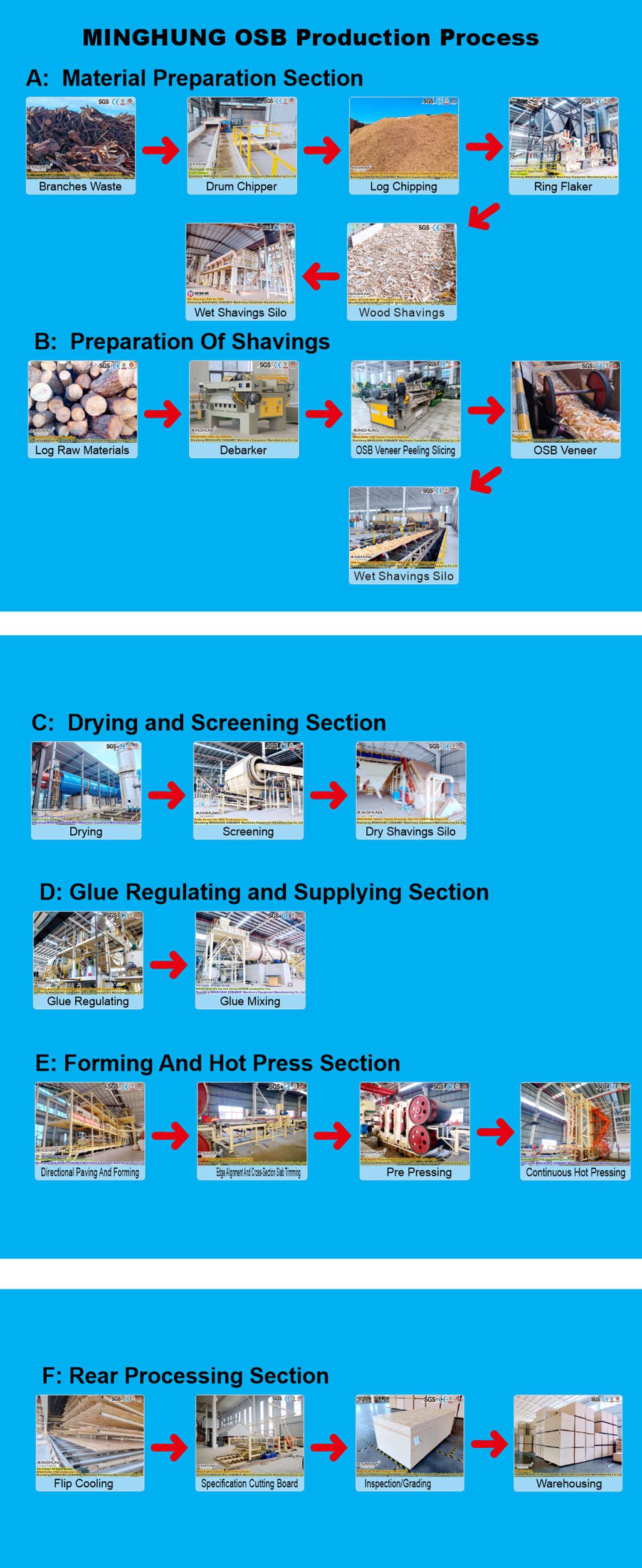

Logs --> Debarking & Chipping --> Fiber/Particle Preparation --> Drying --> Adhesive Blending --> Forming --> Pre-pressing --> Hot Pressing --> Cooling --> Trimming & Sanding --> Grading & Packaging

Key Process Details

Process | Technical Requirements | Equipment Examples | Quality Control Points |

Raw Material Prep | Wood moisture <8% | Drum chipper / Refiner | Qualified particle size rate >95% |

Adhesive Blending | Adhesive coverage >90% | Ring blender | Solid resin content: 8-12% |

Forming | Density deviation <±3% | Mechanical/Air forming station | Longitudinal density gradient |

Hot Pressing | Temp: 180-220℃, Pressure: 2-5MPa | Continuous flat-press / Multi-opening press | Curing time = thickness × 1.2 min/mm |

Post-Processing | Sanding removal: 0.2-0.5mm/face | Wide-belt sander | Thickness tolerance: ±0.1mm |

Ⅱ. Core Technology of Continuous Flat Press

1. Basic Definition

The continuous flat press is the core equipment in wood-based panel (MDF, Particleboard, OSB) production lines. It enables 24/7 continuous pressing via steel belt conveyance, with line speeds reaching 30-100 m/min – tripling efficiency compared to batch presses.

2. Core Structure

Steel Belt System: Two heat-resistant (250°C) alloy belts with non-stick coatings

Modular Heating Platens: Segmented design (typically 12-30 modules), each independently controlled:

Hydraulic pressure: 0-10MPa adjustable (entry zone >8MPa, exit zone <2MPa)

Temperature: Thermal oil/steam heating (180-230°C ±1°C)

Thickness Control:

Laser scanners monitor thickness in real-time (accuracy ±0.05mm)

Servo hydraulic cylinders dynamically adjust platen gaps

3. Workflow

Dried raw material → Forming → Pre-pressing → Continuous hot pressing (gradient pressure/temperature) → Cutting → Cooling & Stacking

Process Features:

Gradient Pressing: High temp/pressure at entry (rapid resin activation), low at exit (prevent springback)

Density Optimization: Longitudinal density variation <3% (vs. >8% in conventional presses)

dryer

mat forming machine

continuous pre-press

continuous hot press

Cross-cut saw

Dryer rack

Ⅲ. Intelligent Technology Integration

1. Smart Sensing Layer

Multi-sensor Network:

Infrared thermal cameras: Real-time temperature field monitoring (0.5°C resolution)

Microwave moisture detectors: Online measurement (±0.3% accuracy)

Acoustic emission sensors: Anomaly vibration detection

2. Intelligent Decision Layer

Self-optimizing Process Parameters:

Resin curing models based on deep learning dynamically adjust temperature profiles

Case study: 12% shorter press time and 15% energy reduction for 18mm OSB

Digital Twin System:

Virtual press mirrors physical equipment status

Predictive maintenance: 72-hour early warning for hydraulic failures

3. Smart Execution Layer

Adaptive Control:

Intelligent belt steering: Laser positioning + pneumatic servo (accuracy ±0.1mm)

Pressure compensation: Auto-adjusts module pressure based on material fluctuations (response <50ms)

4. Cloud-Edge Architecture

Edge Computing: Real-time command execution (<10ms latency)

Cloud Big Data: Historical data trains optimization models, enabling multi-factory knowledge sharing

Ⅳ. Technological Advantages & Industry Impact

1. Breakthrough Performance

Parameter | Conventional Press | Intelligent Press |

Thickness tolerance | ±0.3mm | ±0.1mm |

Energy consumption | 180-220 kWh/ton | 130-150 kWh/ton |

Product changeover | 30-60 minutes | <5 minutes |

2. Typical Applications

Customized Production: One line handles both HDF (2.5g/cm³) and lightweight particleboard (0.6g/cm³)

Zero-Defect Manufacturing: AI vision detects surface flaws (>99.2% accuracy)

Carbon Footprint Management: Real-time energy/carbon tracking for green production

For more information, welcome contact us, we will reply you quickly and offer working videos with you.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com