Model | MH-VSM | MH-VSM2600 |

Max veneer width | <2600mm | <1300mm |

Veneer thickness | 1-4mm | 1-4mm |

Speed | 30-100m/min | 30-100m/min |

Veneer sorting | 3 bin | 2 bin |

Machine size | 8000*2100*3900mm | 6500*2100*3900mm |

SHANDONG MINGHUNG WOOD MACHINERY CO.,LTD

WEBSITE: www.plywoodmachineline.com

EMAIL: minghungmachinery@gmail.com

WHATSAPP: +8618769900191

+8615589105786

Catalogue

Chapter 1、Mechanical structure...............................................................1-4

Chapter2、Cabin & screen.........................................................................5-16

Chapter3、Installation prepare .................................................................17-22

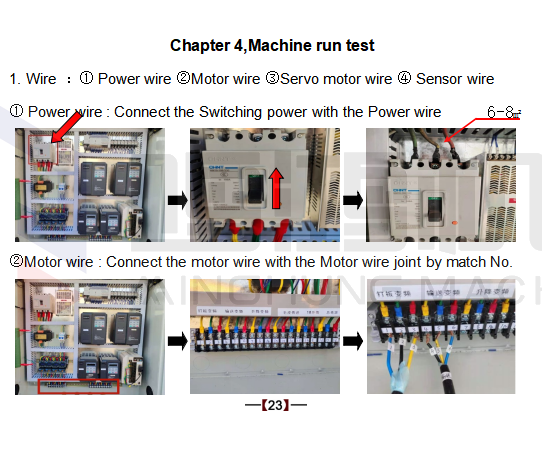

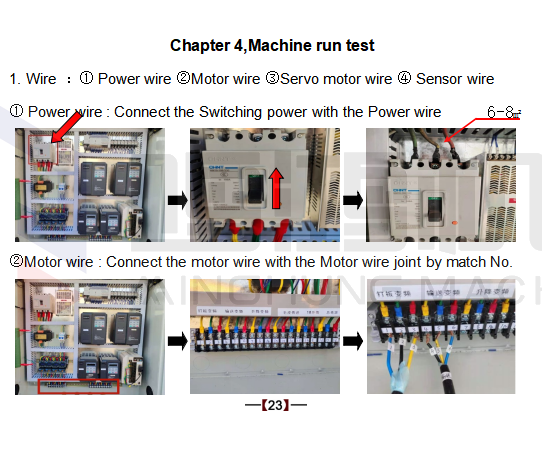

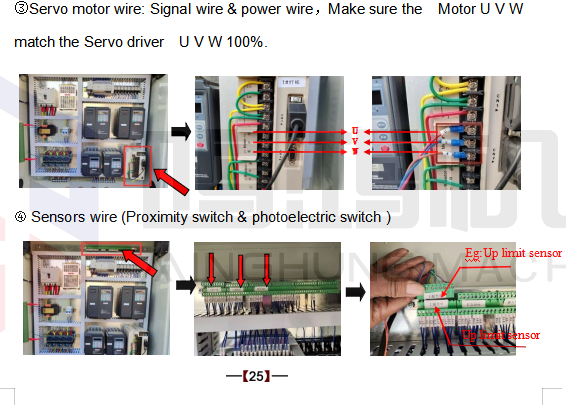

Chapter4 、Machine run test ....................................................................23-31

Chapter5、Common problems &solutions.................................................32-36

Chapter6、Machine maintenance...............................................................37-40

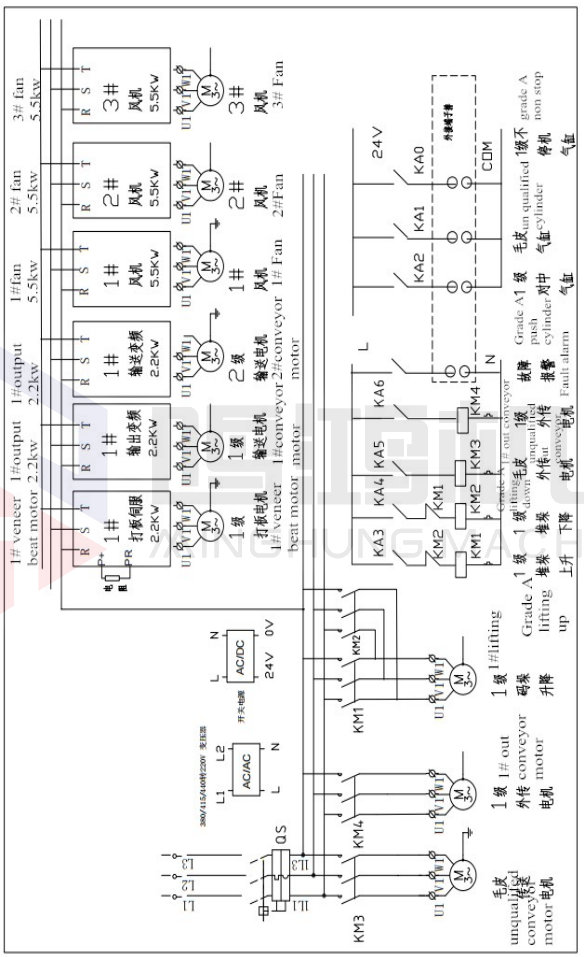

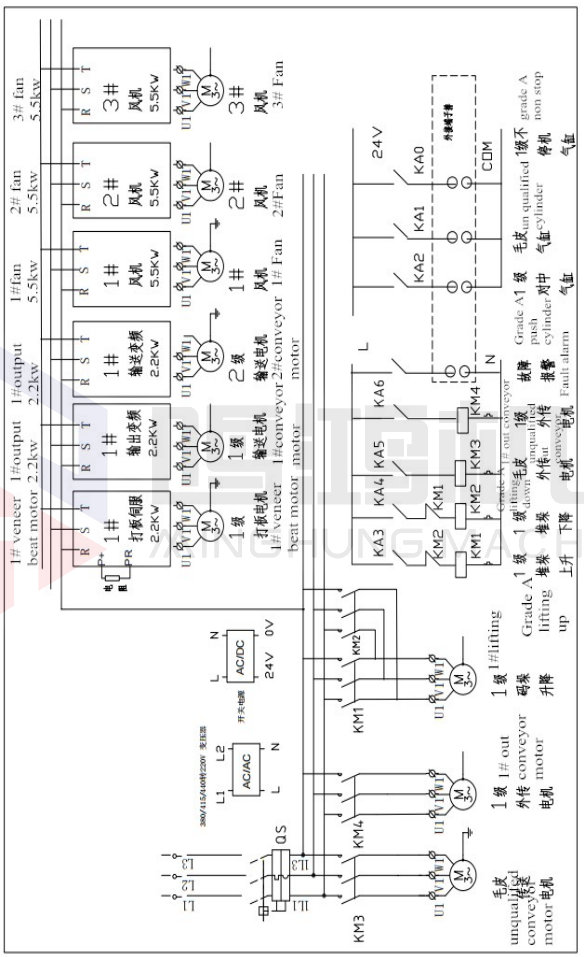

Chapter7、Circuit diagram..........................................................................41

Chapter 1、Mechanical structure

Chapter 1、Mechanical structure

1-Veneer sorting device 2-1# conveyor 3- 2# conveyor 4-Push cylinder

5-Lifting tale 6- Out conveyor 7 -Hydraulic station 8-Unqualified veneer conveyor

9- 1# Veneer beat motor10- 1#Veneer beat device11- 1# Fan/Motor12- 2# Fan/Motor

13-2#Veneer beat device14- 2#Veneer beat motorA- veneer beat sensor

3-2# conveyor 15-Air Way B-veneer arrive sensor C-Up limit sensor

C-Up limit sensor D-veneer Sorting sensors E-bottom limit sensor

F-Out conveyor sensor G-out limit sensor

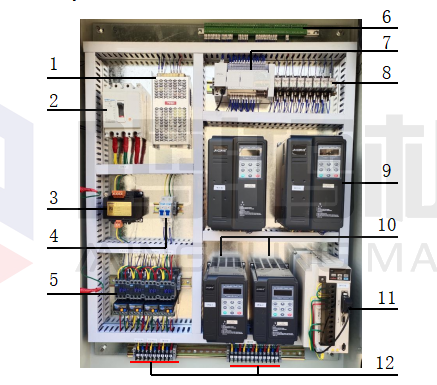

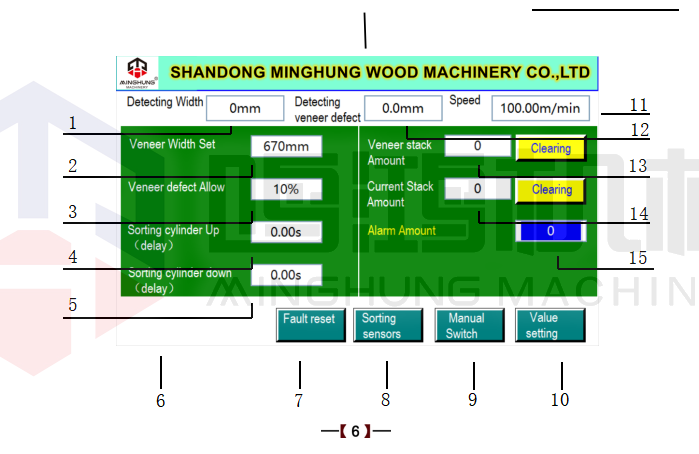

Chapter2、Cabin & screen

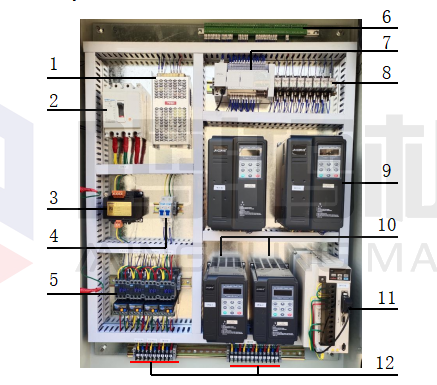

Chapter2、Cabin & screen

1-Switching power 2-Main switch 3-Isolated transformer 4-Air switch 5-Contactor 6-Terminal strip 7-PLC

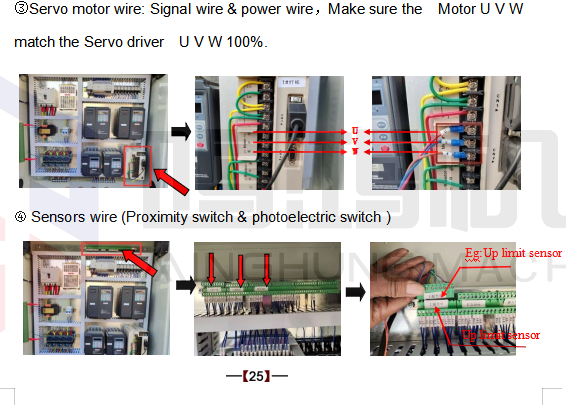

8-Relay 9-Fan inverter 10-Conveyor inverter 11-Servo driver 12-Motor wire joint

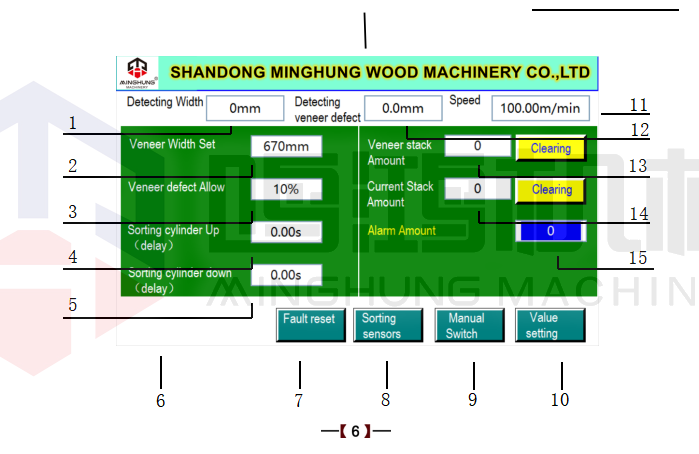

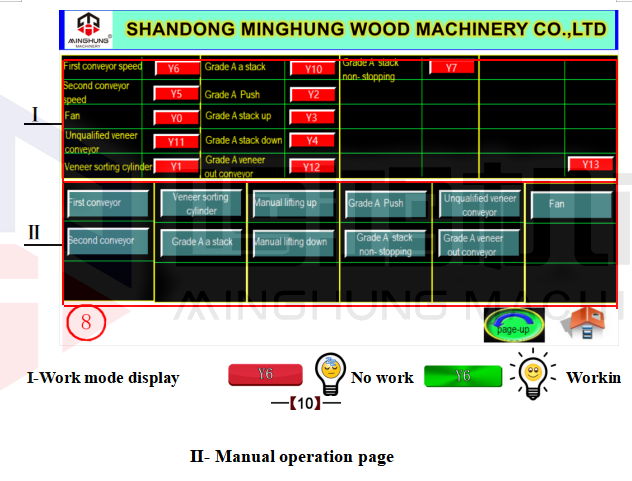

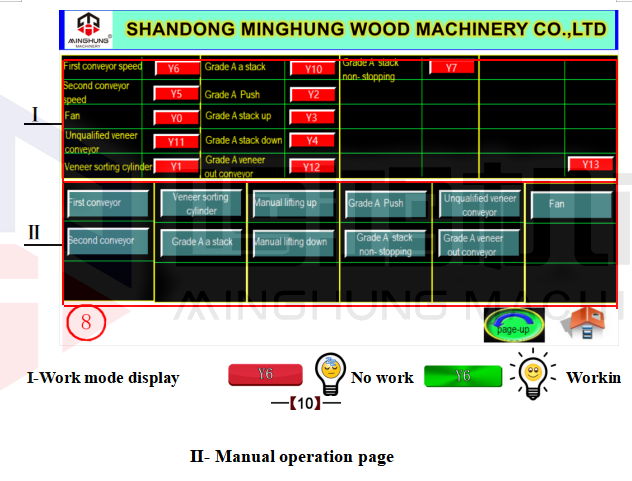

1 | Detecting width | Current veneer width from detector | 9 | Manual Switch | Go to Manual operation page |

2 | Veneer width set | The veneer width will be stacked | 10 | Value setting | Go to value setting page |

3 | Veneer defect allow | Defect area/whole piece veneer area | 11 | Speed | 1# conveyor speed from detector |

4 | Sorting cylinder Up | Sorting cylinder closed time after unqualified veneer fall down | 12 | Detecting veneer defect | The current veneer detect rate from detector |

5 | Sorting cylinder down | Sorting cylinder open time | 13 | Veneer stacker amount | All stacked veneer Amount |

6 | Working mode | Working mode display | 14 | Current veneer stack | Qty of current veneer stacker |

7 | Fault reset | Problem solve,machine return to normal | 15 | Alarm Amount | Max stacker qty set |

8 | Sorting sensors |  Go to sorting sensors page Go to sorting sensors page

|

|

|

|

|

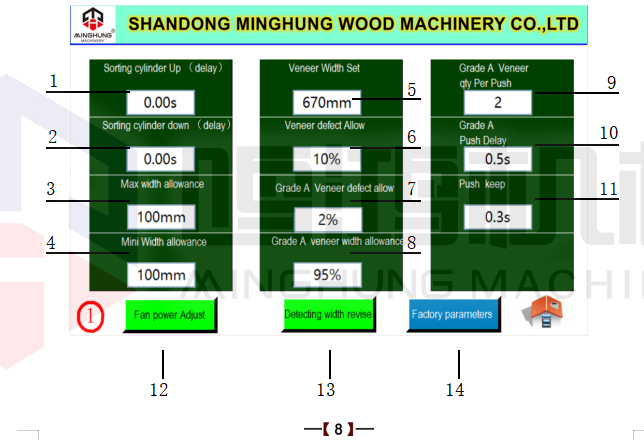

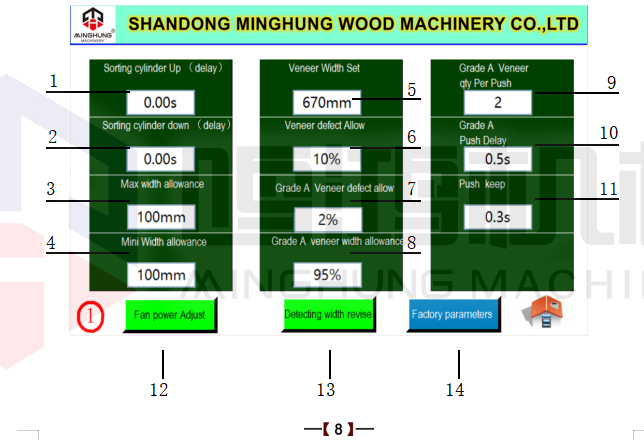

1 | Sorting cylinder Up | Sorting cylinder closed time after unqualified veneer fall down | 8 | Grade A veneer width allowance | The width range rate that Grade A |

2 | Sorting cylinder down | Sorting cylinder open time | 9 | Grade A veneer qty per Push | Qty of push cylinder one action |

3 | Max width allowance | Max width allowance of Qualified veneer | 10 | Grade A Push delay | Push cylinder open time after veneer fall down |

4 | Mini width allowance | Max width allowance of Qualified veneer | 11 | Push keep | Push cylinder keep time |

5 | Veneer width set | The veneer width will be stacked | 12 | Fan power Adjust | Go to fan power page |

6 | Veneer defect allow | Defect area/whole piece veneer area | 13 | Detecting width revise | Go to width revise page |

7 | Grade A Veneer defect allow | Defect area of Grad A veneer Allowed | 14 | Factory parameters | Parameters before machine leave |

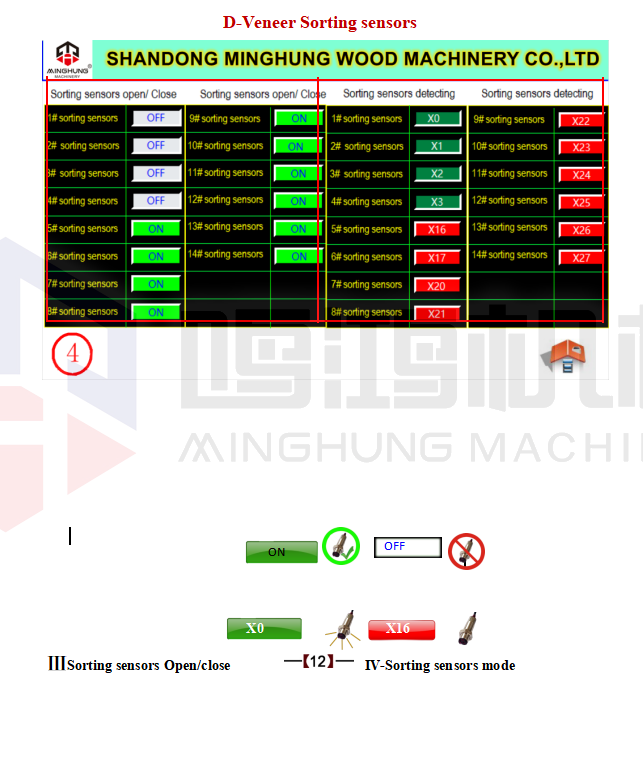

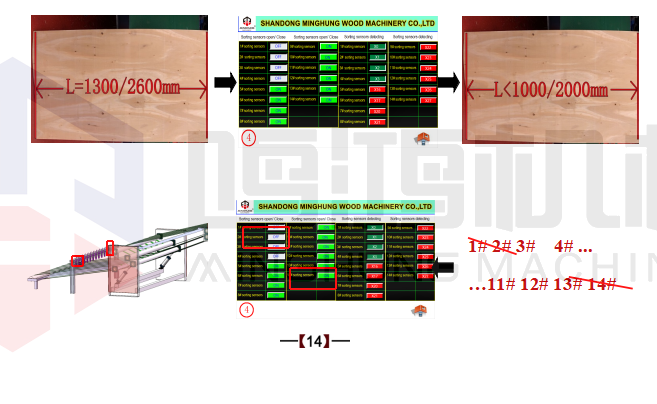

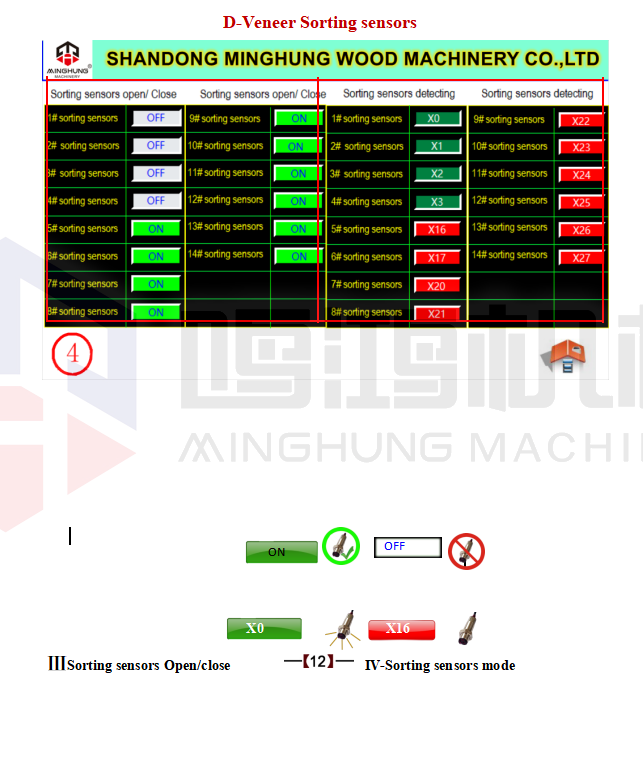

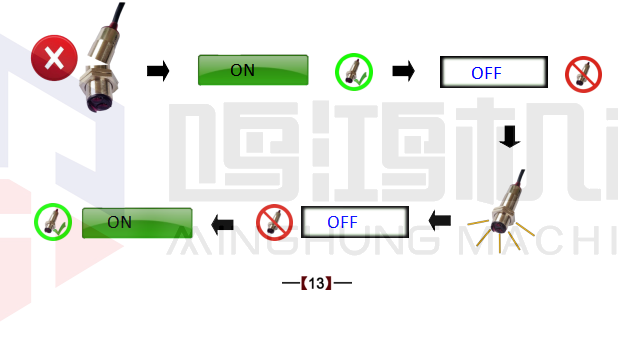

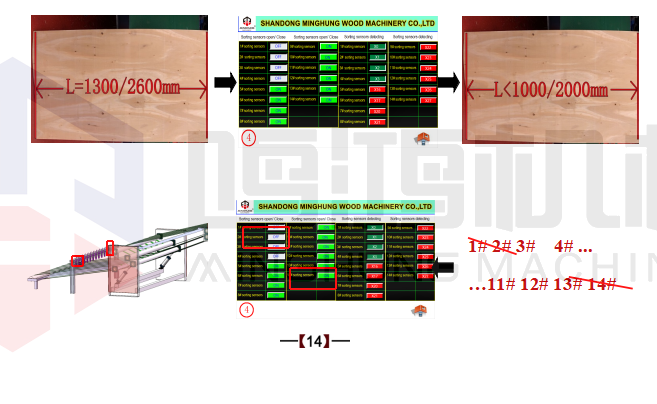

Sorting sensors Open/close

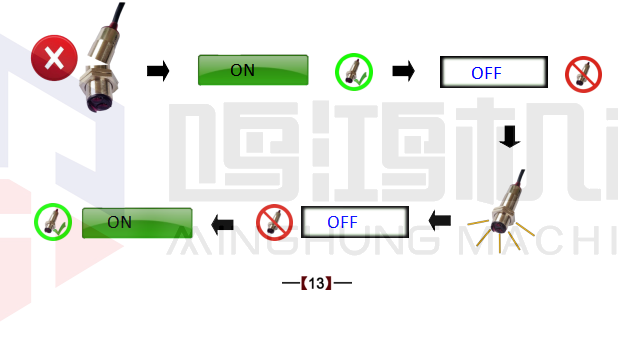

①  sorting sensors fault:Change the sorting sensors use from “ON” to “ NO”,it wont influence machine work . after change to new sensors .change “ NO” to “ ON ”

sorting sensors fault:Change the sorting sensors use from “ON” to “ NO”,it wont influence machine work . after change to new sensors .change “ NO” to “ ON ”

②Veneer width large change :Eg from 1300mm change to 970mm,or from2600 change to 2000mm ,Close the 1#,2# ,13# ,14# sensors use .

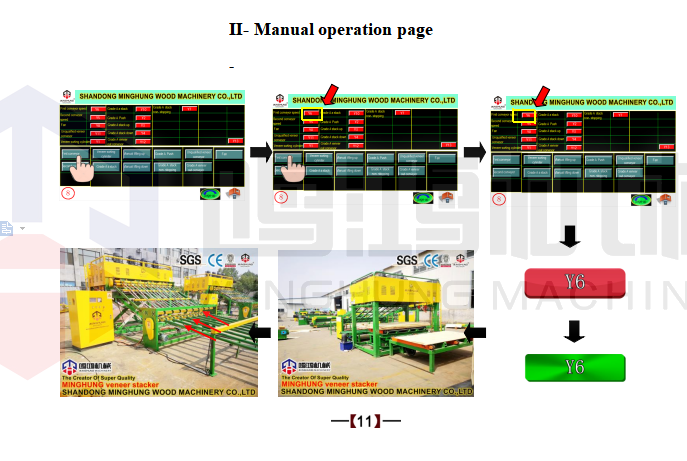

Operation area

Operation area

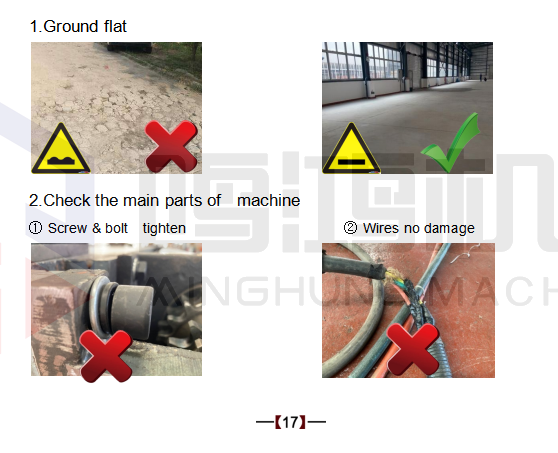

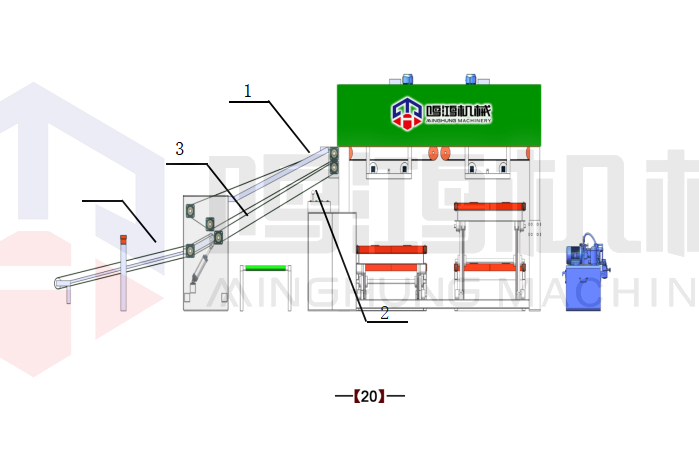

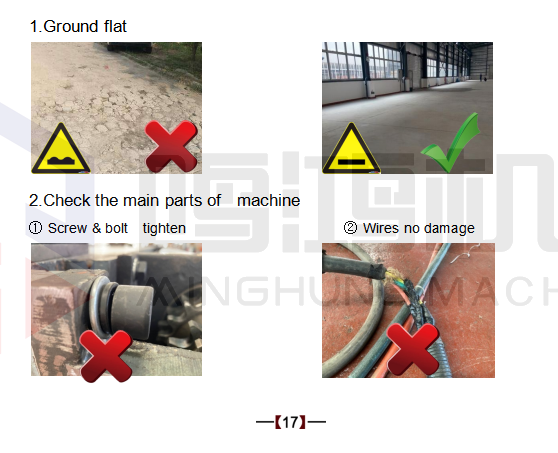

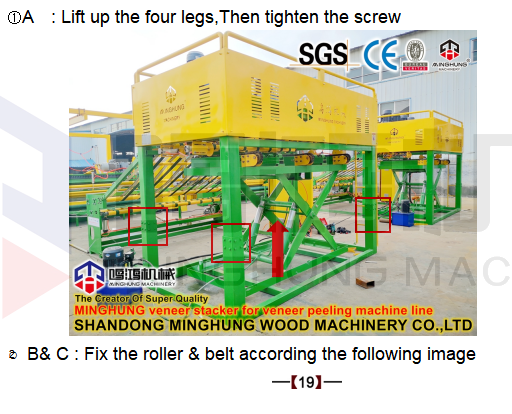

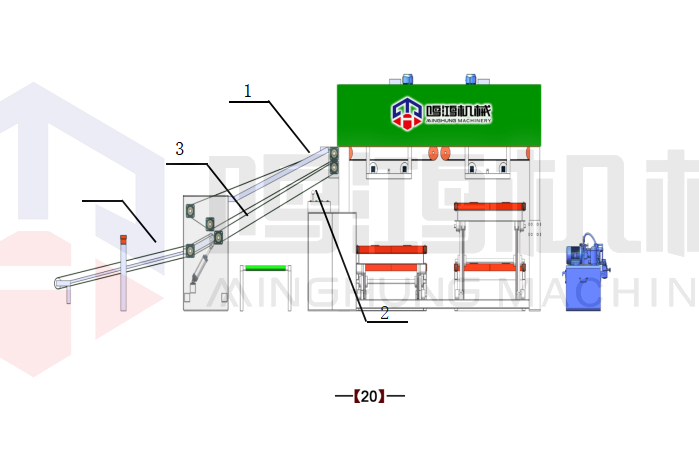

Chapter 3,Installation prepare

Machine Assemble

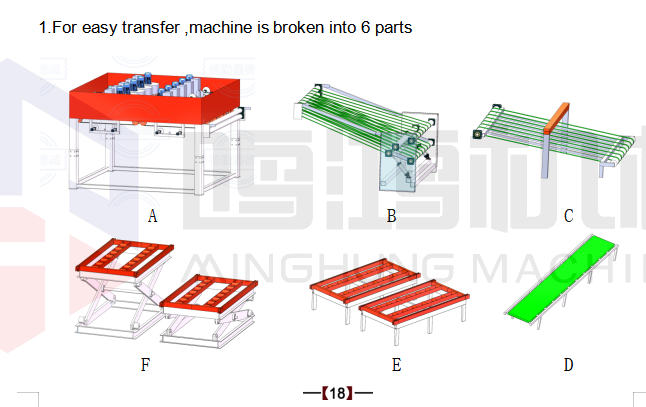

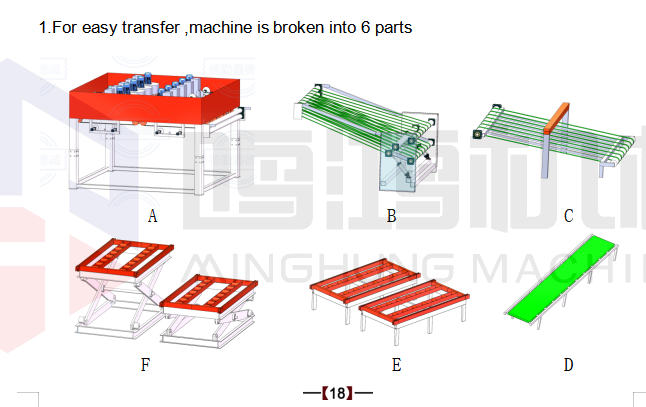

1.For easy transfer ,machine is broken into 6 parts

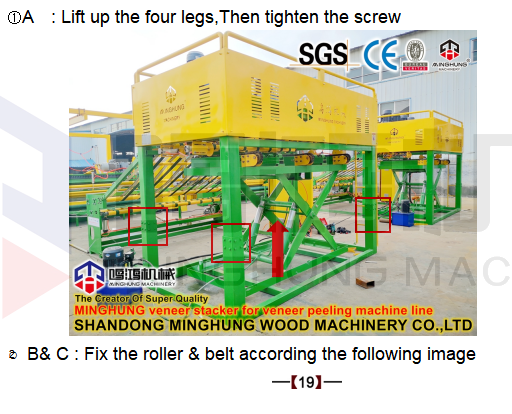

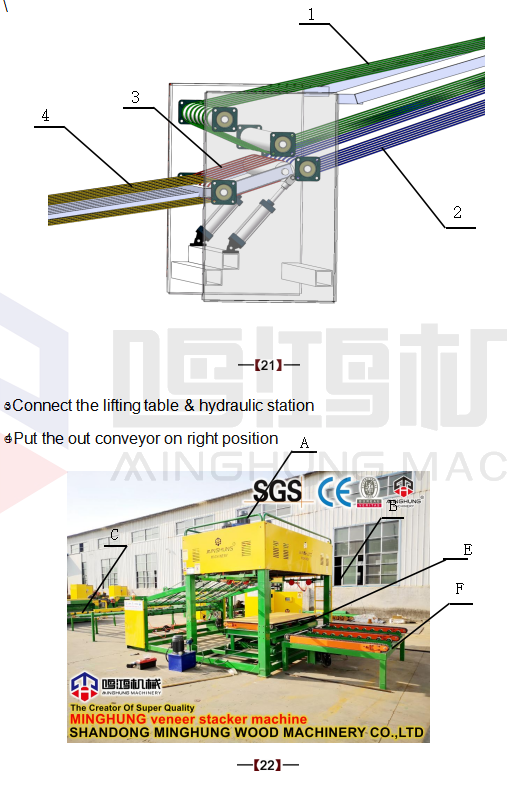

2.Assemble Steps

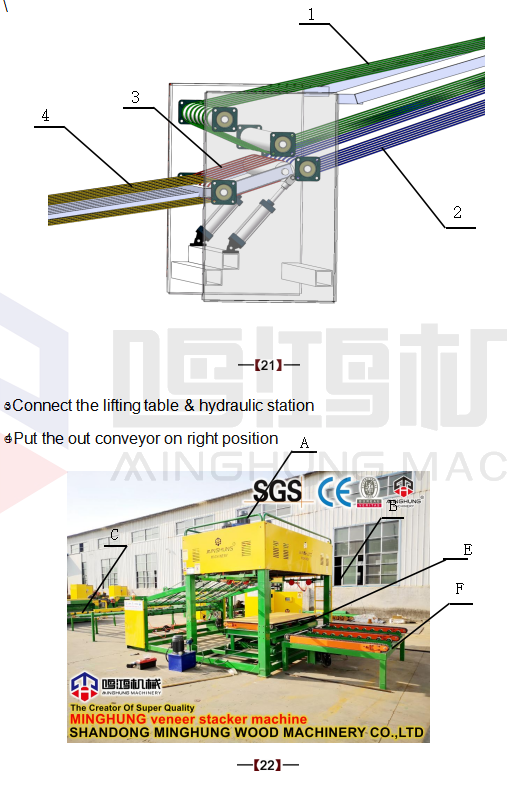

3Connect the lifting table & hydraulic station

3Connect the lifting table & hydraulic station

4Put the out conveyor on right position

4Put the out conveyor on right position

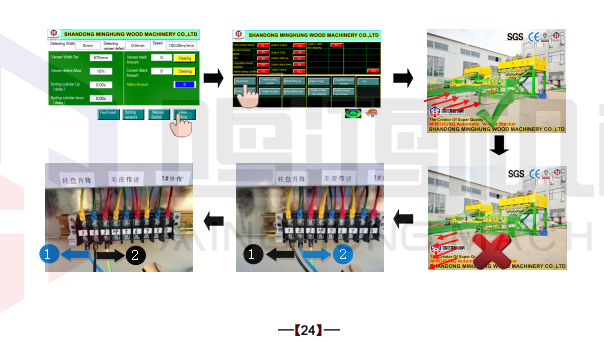

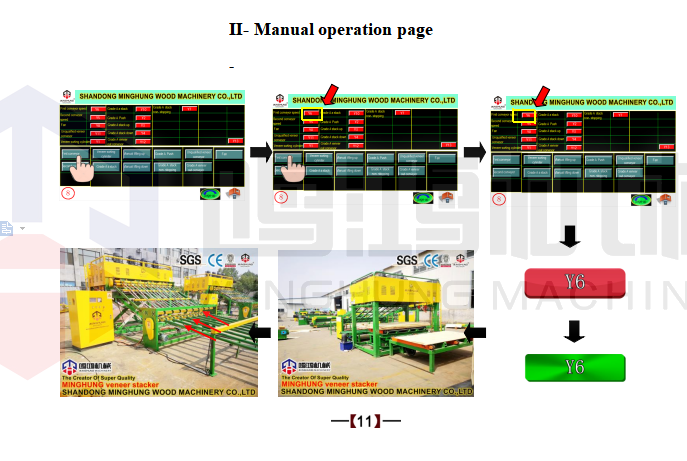

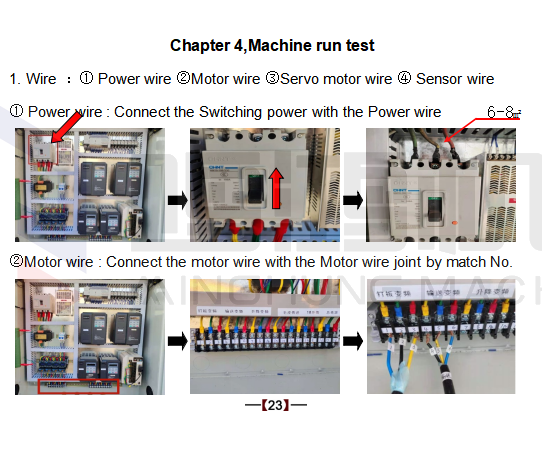

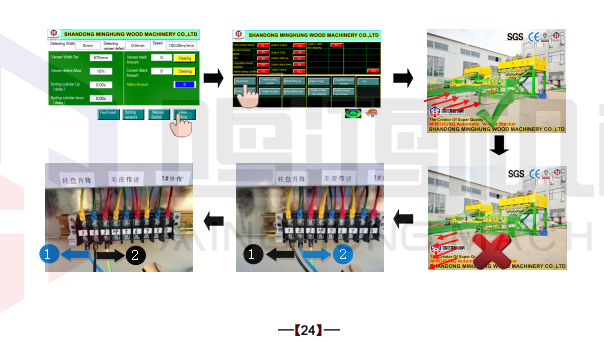

After motor wire connect,Open screen , Go to Manual operation page,Click the Manual operation area ,check the motor run in right direction ,if wrong ,Exchange the 2 wire.

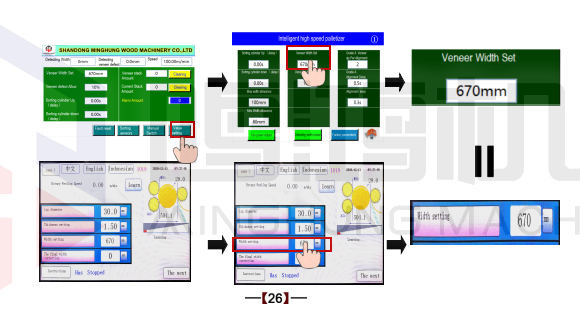

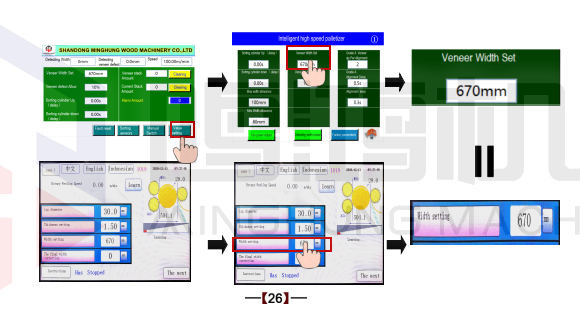

2.Input right veneer width in the screen

2.Input right veneer width in the screen

Please note : the “veneer width set”should be same as the veneer peeling machine

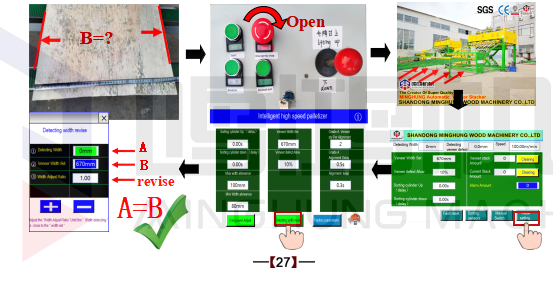

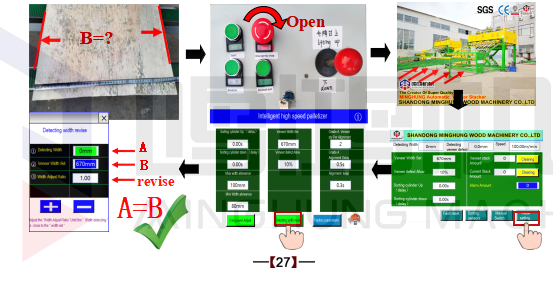

3.Detect width revise

①

①

Get a veneer and remember its width B=? ②Put it on the conveyor before sensors

Get a veneer and remember its width B=? ②Put it on the conveyor before sensors

③open Emergency button ,veneer go though sensors ④ Click “Detect width revise ”

③open Emergency button ,veneer go though sensors ④ Click “Detect width revise ”

O

O

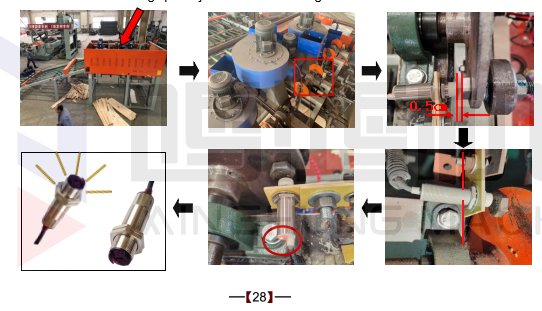

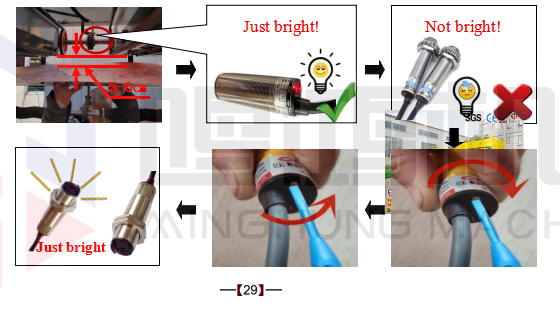

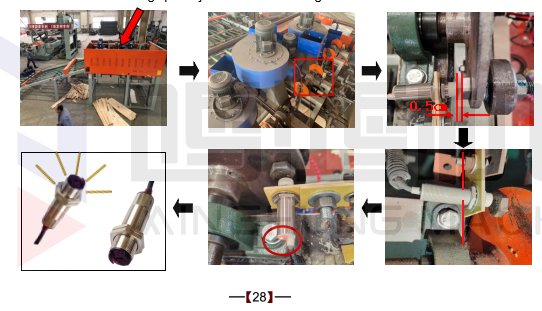

4.Veneer beat sensor (proximity switch)

①Adjust the distance of veneer beat sensor and veneer beat device,0.5cm, the sensor light just bright!

②The sensor‘s insulating spacer just touch the bearing house

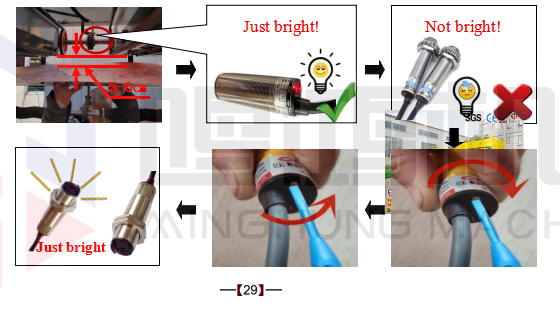

5.Adjust veneer arrive Sensor’s effective range

① Put a veneer 5-6cm from the above sensor ,check its light bright or not

② If sensor light not bright , adjust the sensor’s reach range as following .

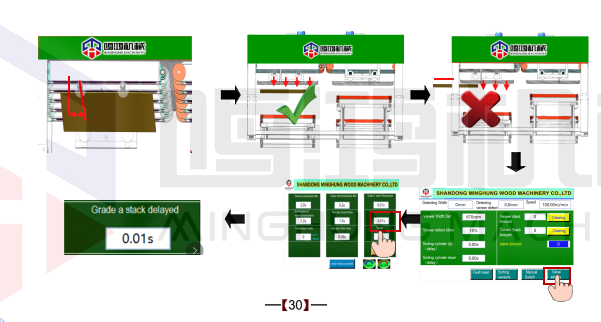

6. Veneer Arrive sensor adjust

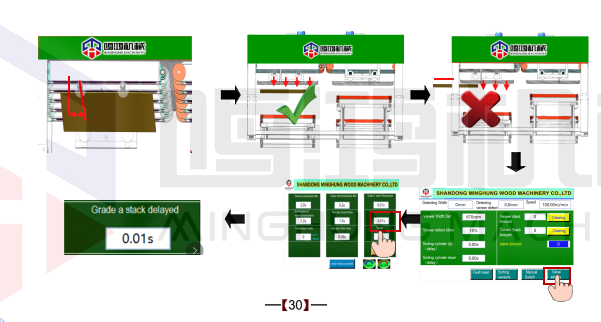

①Power on ,put a veneer on front of 1# conveyor ,check the time difference between veneer pass the Air way and the veneer beating strip push .②if the veneer beating strip push after whole veneer enter air way ,its okay. if not enter completely but push out ,please adjust “Grade A stack delayed"

①Power on ,put a veneer on front of 1# conveyor ,check the time difference between veneer pass the Air way and the veneer beating strip push .②if the veneer beating strip push after whole veneer enter air way ,its okay. if not enter completely but push out ,please adjust “Grade A stack delayed"

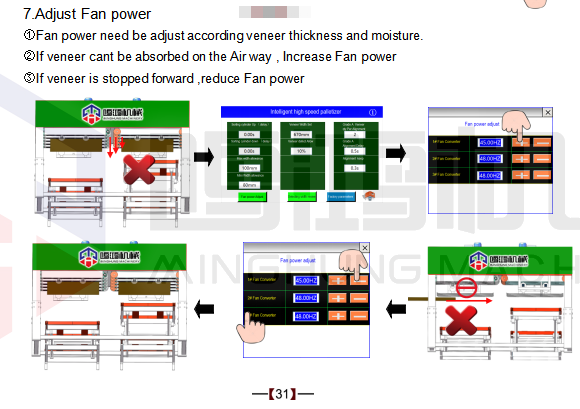

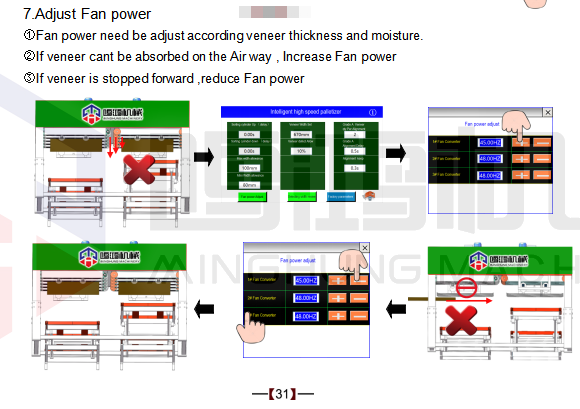

7.Adjust Fan power

①Fan power need be adjust according veneer thickness and moisture.

②If veneer cant be absorbed on the Air way , Increase Fan power

③If veneer is stopped forward ,reduce Fan power

③If veneer is stopped forward ,reduce Fan power

Chapter 5、Common problems &solutions

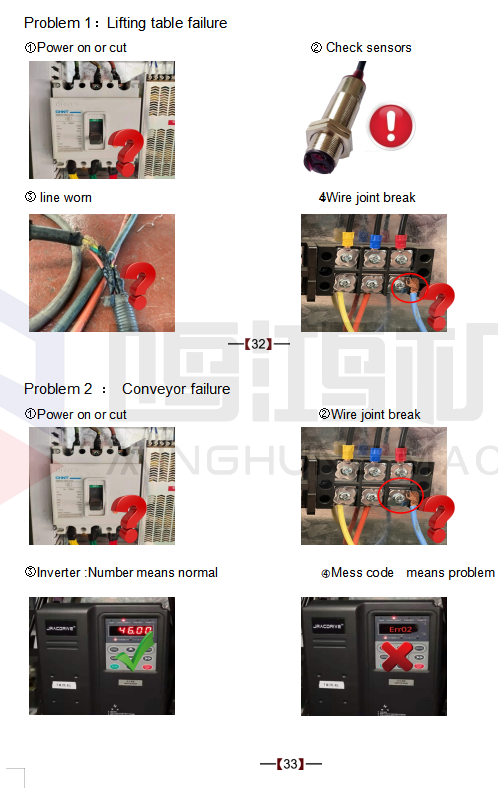

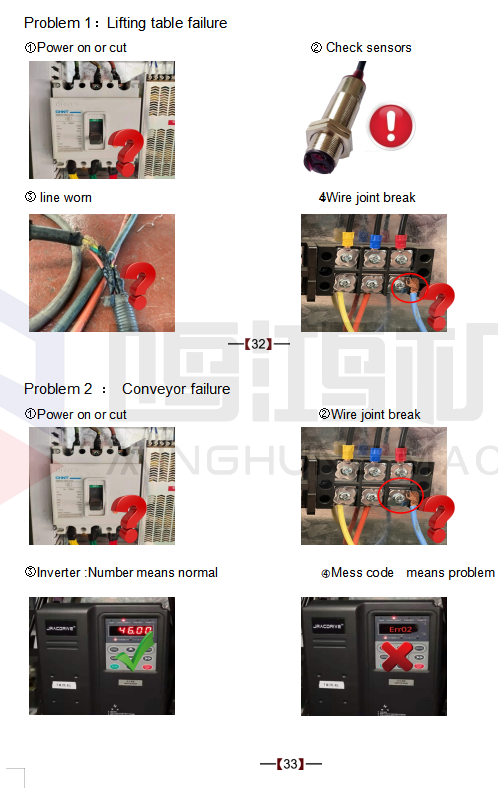

Problem 1:Lifting table failure

①Power on or cut ② Check sensors

③ line worn 4Wire joint break

Problem 2 : Conveyor failure

①Power on or cut ②Wire joint break

③Inverter :Number means normal 4Mess code means problem

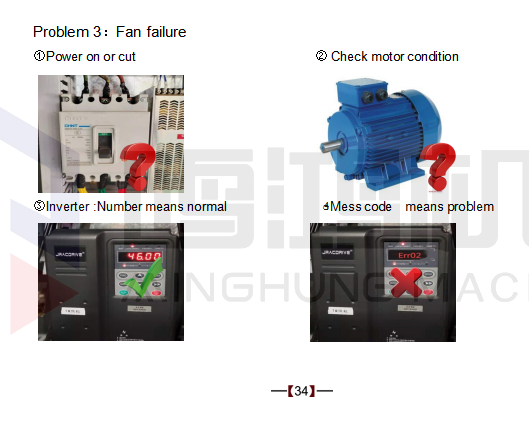

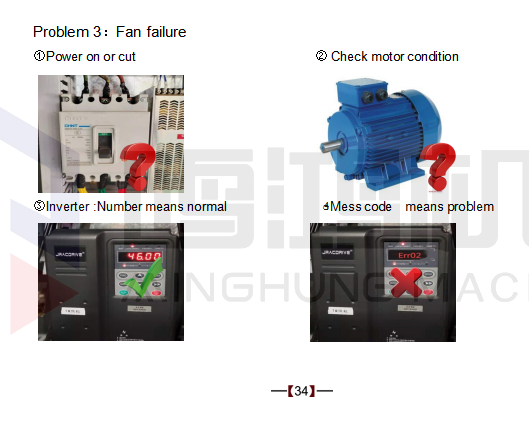

Problem 3:Fan failure

①Power on or cut ② Check motor condition

③Inverter :Number means normal 4Mess code means problem

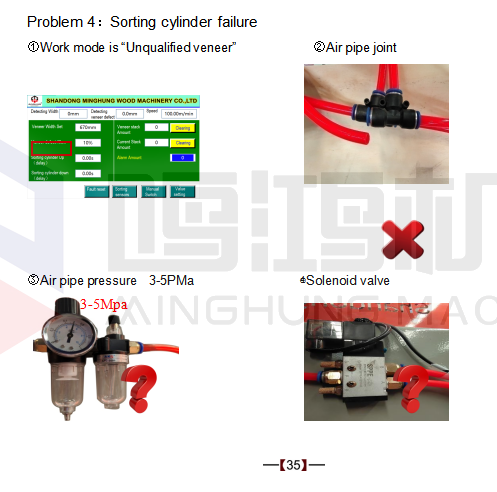

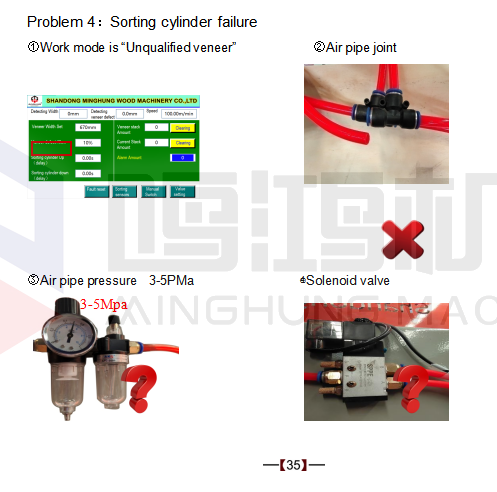

Problem 4:Sorting cylinder failure

①Work mode is “Unqualified veneer” ②Air pipe joint

③Air pipe pressure 3-5PMa 4Solenoid valve

③Air pipe pressure 3-5PMa 4Solenoid valve

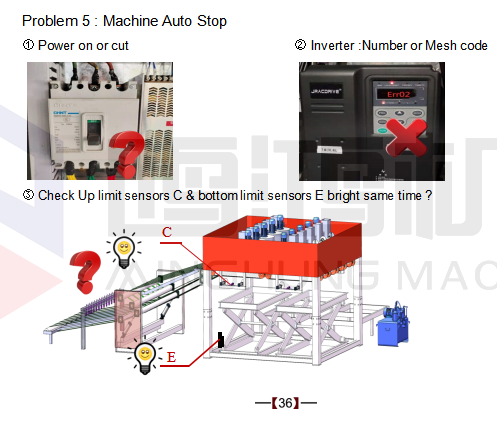

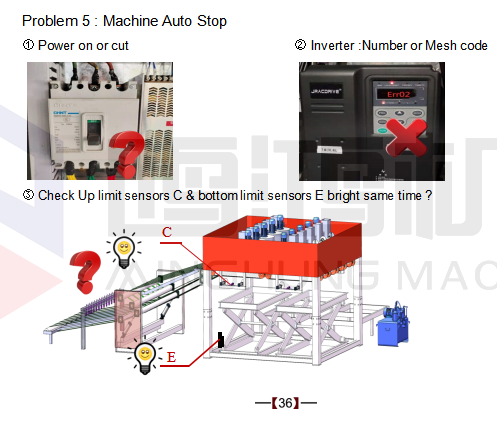

Problem 5 : Machine Auto Stop

① Power on or cut ② Inverter :Number or Mesh code

③ Check Up limit sensors C & bottom limit sensors E bright same time ?

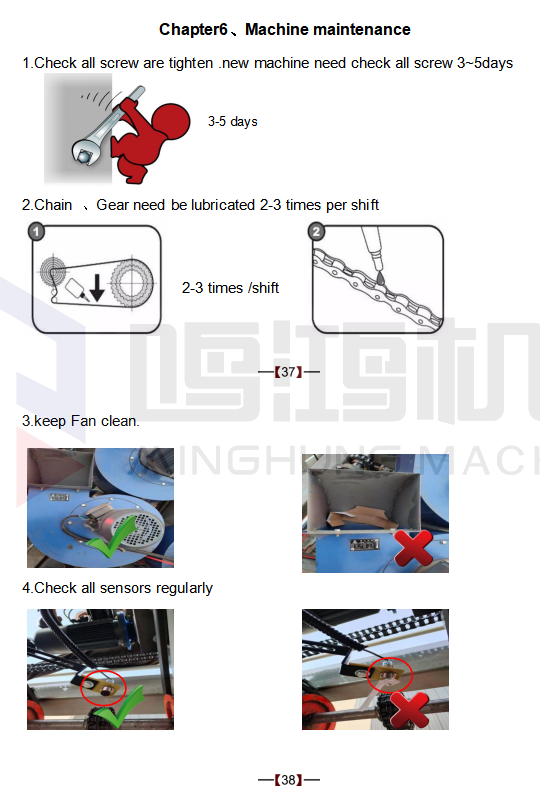

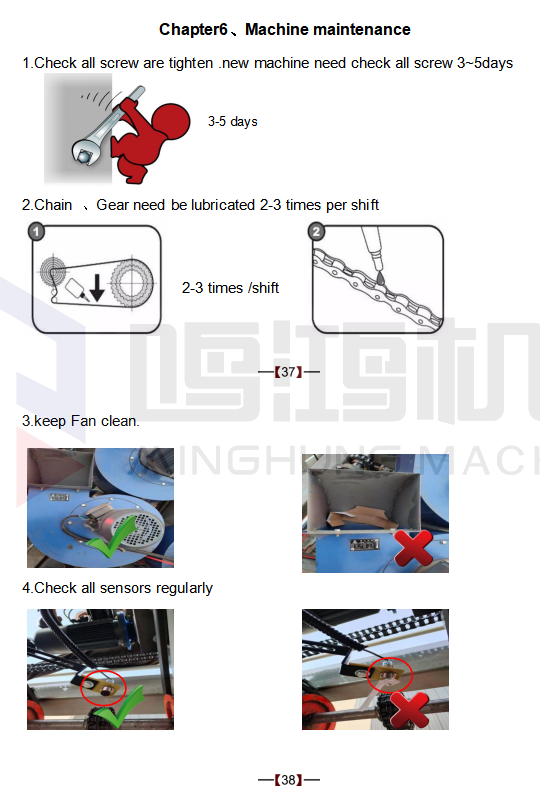

1.Check all screw are tighten .new machine need check all screw 3~5days

1.Check all screw are tighten .new machine need check all screw 3~5days

3-5 days

2.Chain 、Gear need be lubricated 2-3 times per shift

2.Chain 、Gear need be lubricated 2-3 times per shift

2-3 times /shift3.keep Fan clean.

4.Check all sensors regularly

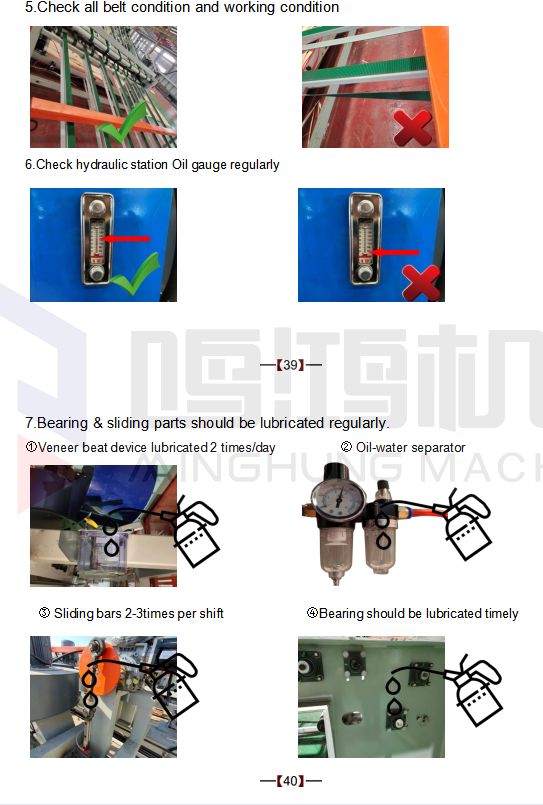

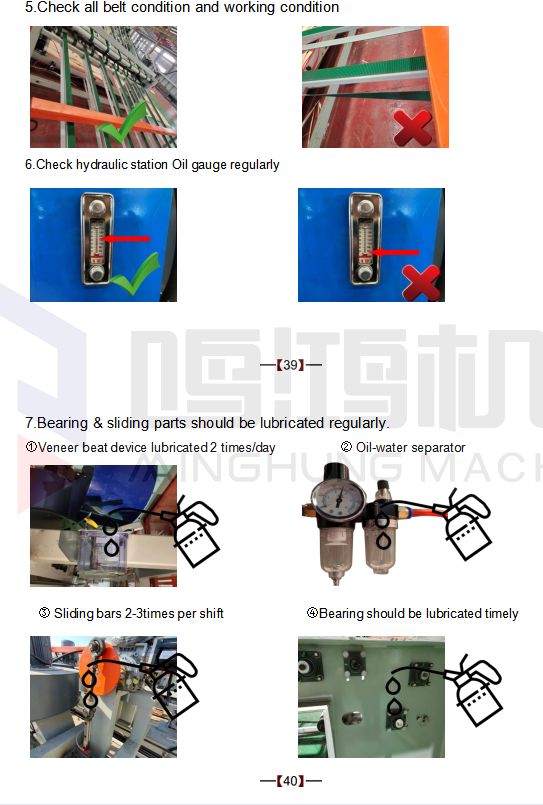

5.Check all belt condition and working condition

5.Check all belt condition and working condition

6.Check hydraulic station Oil gauge regularly

7.Bearing & sliding parts should be lubricated regularly.

①Veneer beat device lubricated 2 times/day ② Oil-water separator

③ Sliding bars 2-3times per shift ④Bearing should be lubricated timely