Veneer Drying Line for Mesh Wire Dryer

Pine veneer drying

The air-dry density of pine is 0.59 ~ 0.72g/cm3, that is, the specific gravity is 0.59 ~ 0.72. Usually, before the pine veneer is peeled, the moisture content reaches %50-%60, and the moisture content is high. If the pine veneer is dried after drying It takes about 10 minutes for the moisture content to reach %0-%14, so if there is a requirement for the output of pine veneer drying, special optimization of the dryer is required. MINGHUNG MH-RD2830L; MH-RD304HL These two machines Type is a pine veneer drying equipment optimized for pine veneer drying, please contact us for details

the drying line mainly have two types, one is roll dryer, inside transport material is roll.

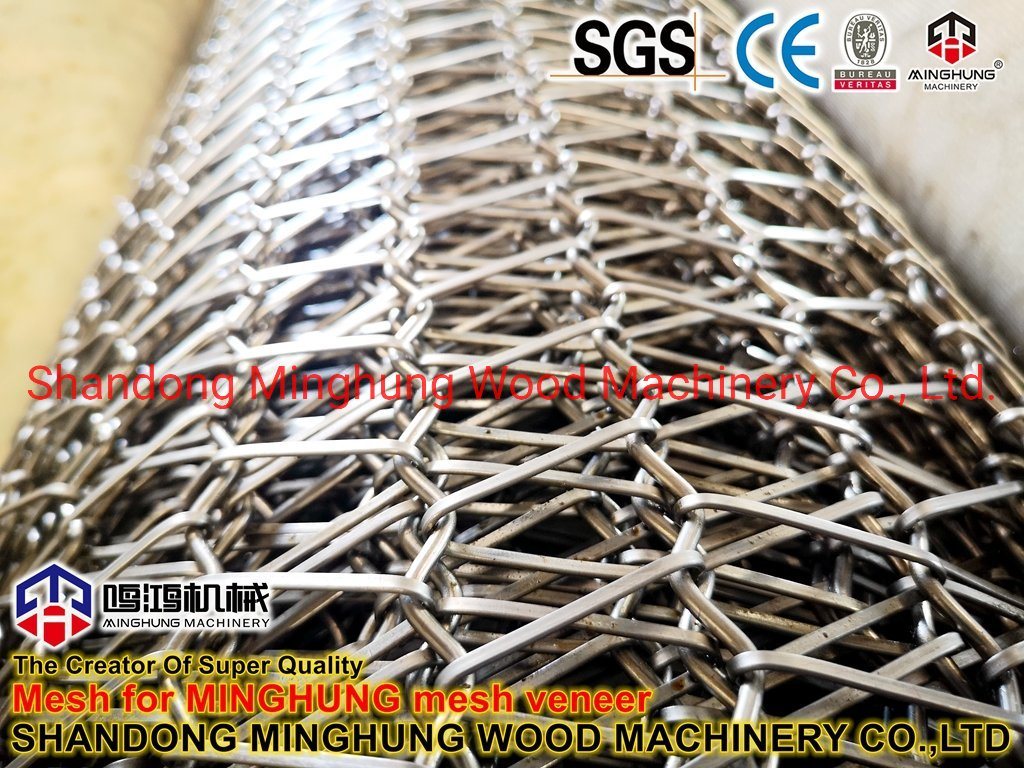

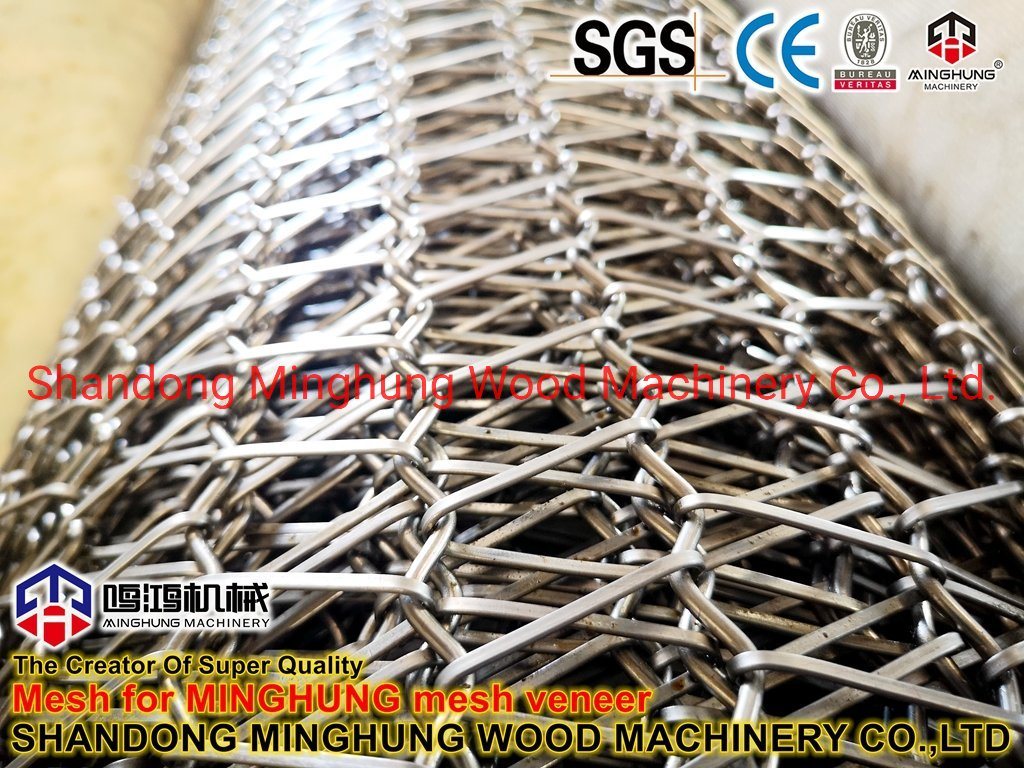

another one is Mesh dryer, also be called wire dryer, inside transport material is the mesh, it can drying the thin veneer.

today this one introduced to you is the Mesh drying line. it can be different floors, like 1, 2 3 for 4floors, on the pictures, this is one 4 floors dryer machine. and its width can be different like width 3meter, width 4meter. also dryer length can be different. usually we offer the dryer details as your required the drying capacity everyday.

and can add the semi-auto infeeding device, it will automatic convey wood veneer to different floors. save labor cost and improve high efficiency.

The veneers move through the drying machine in several layers along rollers, as the machine's name indicates. The target moisture level after drying is around 6-7% which is precisely the right moisture level for gluing veneer.

A sufficient drying temperature is 145-160ºC and the veneers pass through the machine in about six minutes. Drying conditions and the moisture of the veneers are monitored continuously to make sure that the drying quality remains even.

Usually, the original moisture is 70-80%, after drying, the moisture is about 10%

>>>Parameters:

>>>Parameters:

The dryer machine-mesh dryer, can be different layers, length and width, so we usually offer and produce according to your production capacity required.

| Name | Mesh dryer |

| Model | MH-MD3618 |

| Heating mode | Steam/Oil |

| Veneer thickness | 0.3-3mm |

| Transport mode | mesh belt drying mode |

| Speed | Speed adjustable |

| Number of layers | 1layer/2 layers/3layers/4layers |

| Length of hot wind area | 20m/26m/30m |

| Peoduction capacity | 10-20m³/day, 20-30m³/day, more |

| Final Moisture of veneer | 10%±2 |

>>>Main Parts:

>>>Machine In Client Factory:

The installation of veneer roller dryer is more complex and spend longer time than others, so our engineer will go to install with your workers.

>>>Clients:

With our clients, we not just partners, we are friends.

We will stand your position think about problem, consider how to save cost for you, and offer the better and suitable plywood machine to you.

>>>RFQ:

| Production Time: |

| 1 month after receive your deposit. |

| Payment Terms: |

30% deposit, 70% before delivery.

100% Letter of Credit. |

| Warranty: |

| 2 years for main parts. |

| MOQ: |

| 1 set |

| Installation: |

| When machine reach your factory, our engineer can go to install |

| After-sales service: |

| Any problem that your worker can not solve, tell us, we will reply you at the first time, |

>>> Contacts:

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com