Precision control relies on the seamless collaboration of the Sensing System, Decision System (PLC), and Execution System (Actuators), forming a fully automated closed loop.

Target: Heating system (e.g., burner, steam solenoid/regulating valve).

Action: Commands proportionally regulate burner output or steam valve opening for linear heat input, not just simple On/Off.

Target: Exhaust Dampers (with electric actuators) and Circulation Fans / Fresh Air Intake Dampers.

Action: This is the quintessence of precision control.

If chamber humidity is too high, the system opens exhaust dampers and intakes slight fresh air to accelerate moisture removal.

If humidity is too low (risking case-hardening and cracking), it closes exhaust dampers to trap moisture evaporated from the veneer, maintaining the required high-humidity environment, perfectly adapting to the different humidity needs of the "warm-up, constant-rate, falling-rate" drying stages.

VFDs for Circulation Fans: Adjust air speed per stage to prevent defects from excessive airflow at critical times.

VFD for Mesh Belt Motor: Precisely controls the residence time (drying time) of veneer in the chamber.

|

Components

I. High-Precision Sensing System (The Sensory Nerves)

1. High-Temperature T&H Sensor Network: A network of sensors provides a 3D map of the chamber's conditions, far exceeding the number in standard dryers.

2. Online Moisture Detector (Optional High-End): Provides real-time final MC data for closed-loop calibration.

II. Intelligent Control System (The Brain & CNS)

1. Industrial PLC: The computational core running PID control algorithms and an expert drying database.

2. Large HMI Touchscreen: The user interface for visualizing processes and managing recipes.

3. Communication Network: High-speed industrial networks (e.g., ProfiBus) ensure real-time data exchange.

III. Precision Actuation System (The Muscles)

1. Temperature Actuators: Modulating valves (for steam/thermal oil) or proportional burners (for gas/oil/biomass) for linear heat output adjustment.

2. Humidity Actuators: Servo-driven exhaust & fresh air dampers are critical. Their precise opening (0-100%) is controlled to meticulously manage chamber humidity.

3. Airflow & Conveyance Actuators: Variable Frequency Drives (VFDs) on circulation fans and the main belt motor for precise speed control.

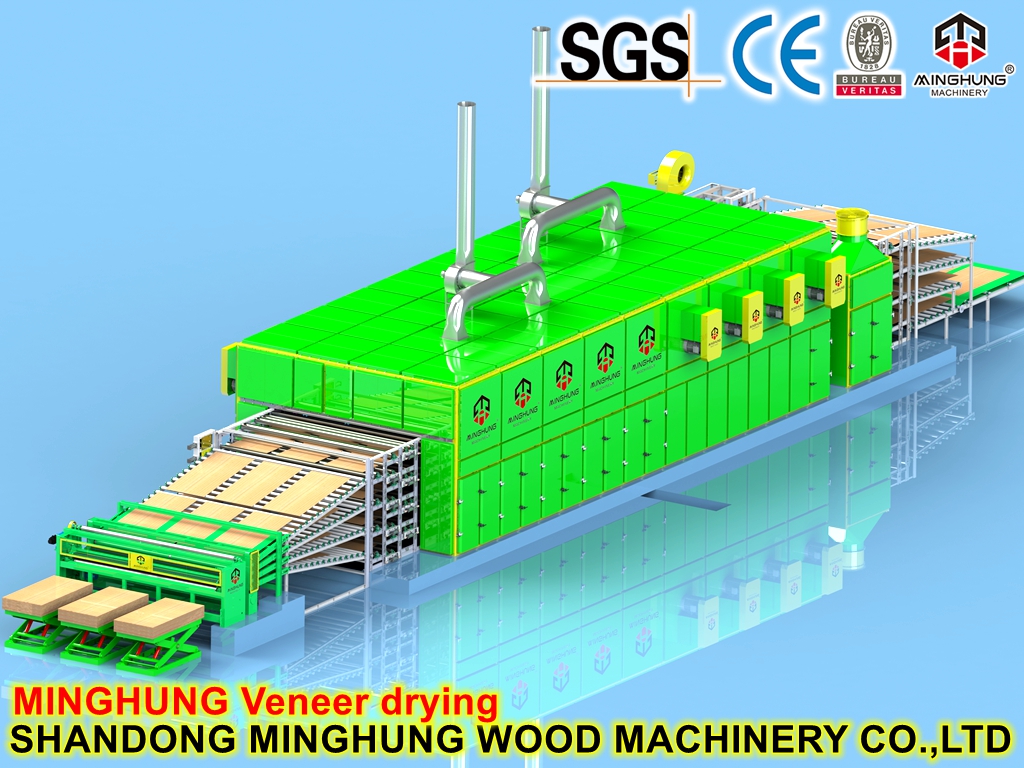

IV. Main Structure & Thermal System

1. Heavily Insulated Chamber: Thick insulation & superior sealing are fundamental to creating a stable, uncontaminated environment for precision control.

2. Efficient Air Heater & Circulation: The heater must have good modulation characteristics, and fans must be designed for even airflow distribution.

V. Material Handling System

Components must operate smoothly and consistently to ensure uniform exposure for all veneer.

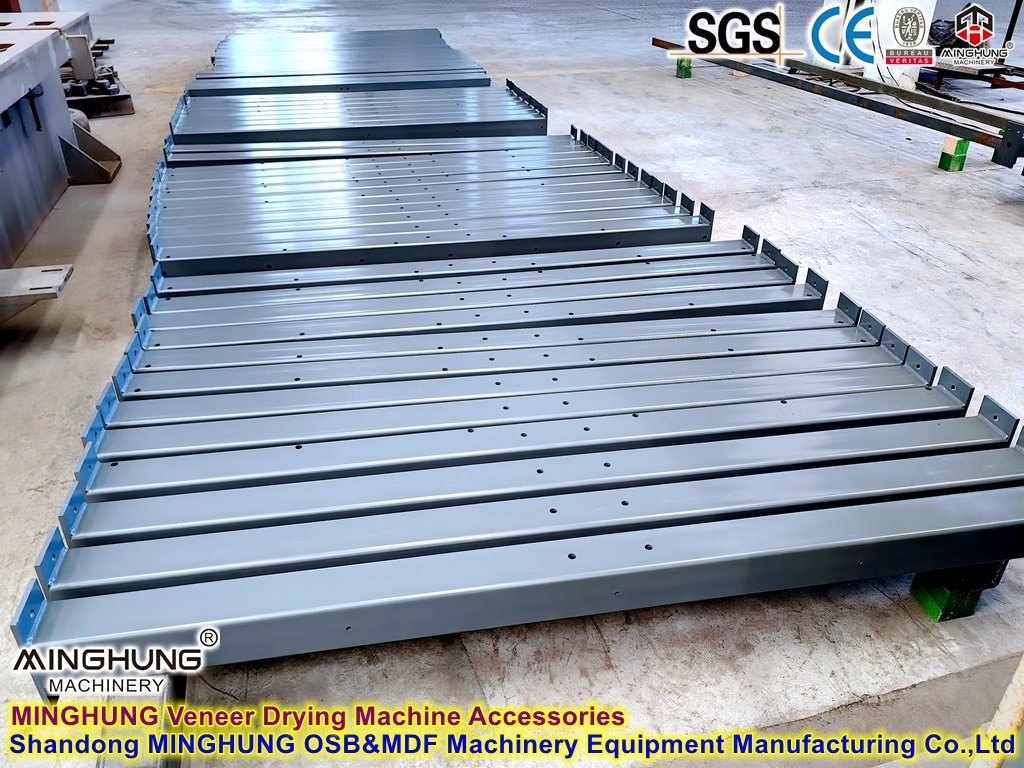

VI. Basic Component Components

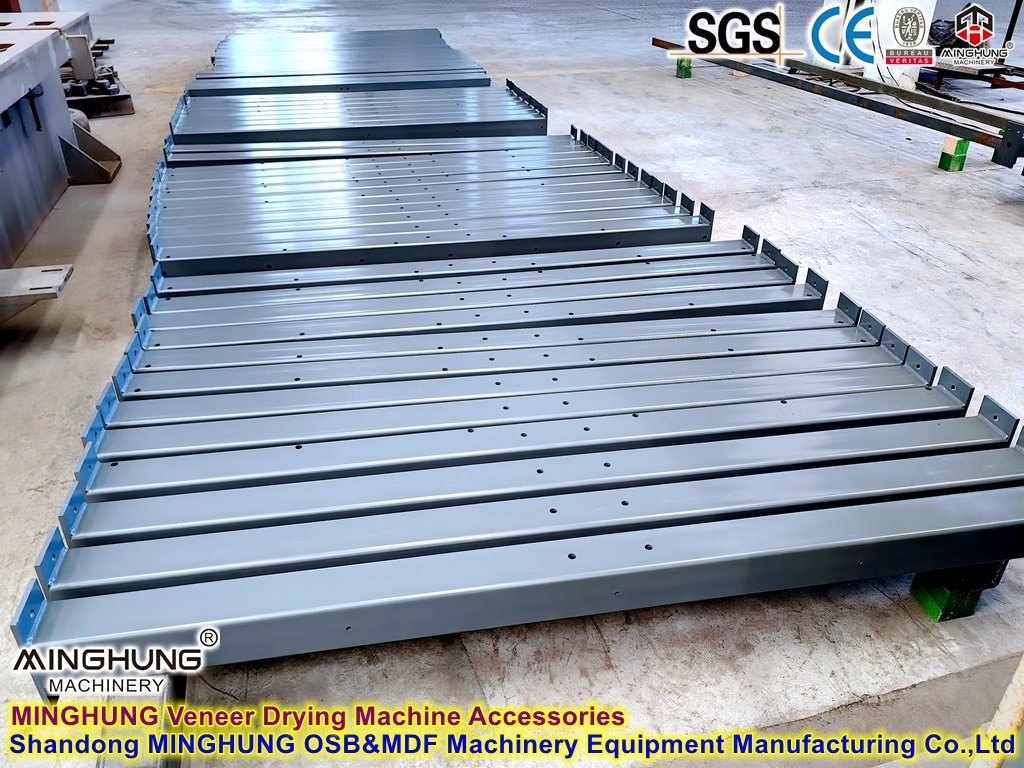

1. Drying Chamber Casing

Function: To form an enclosed, insulated space where hot air can circulate and dry the veneer.

Composition:

Structural Frame: Typically welded from section steel (e.g., channel steel, angle iron) to provide main support.

Insulation Panels: The wall panels often feature a sandwich structure filled with insulating material (e.g., rock wool, fiberglass wool) and clad with color steel plates, preventing heat loss and improving thermal efficiency.

2. Hot Air Generation & Heating System

Function: To generate and supply the heat required for drying.

Composition:

Air Heater / Heater Unit: The core heat source of the equipment.

Types vary by fuel: Coal-fired air heater,Oil/Gas burner,Biomass burner (burning sawdust, pellets),Steam heat exchanger (utilizing boiler steam), Electric heater (common in small-scale equipment).

Air Mixing Chamber: Evenly mixes the high-temperature gases from the heat source with circulating air to achieve the suitable drying temperature.

3. Hot Air Circulation System

Function: To drive the forced circulation of hot air within the drying chamber, ensuring it penetrates the veneer layers and carries moisture away.

Composition:

Circulation Fans: Typically high-pressure centrifugal fans that provide sufficient air pressure and volume for the hot air to penetrate the veneer stack.

Air Ducts & Baffles: Guide and distribute the airflow to ensure as even a distribution of hot air as possible within the drying chamber.

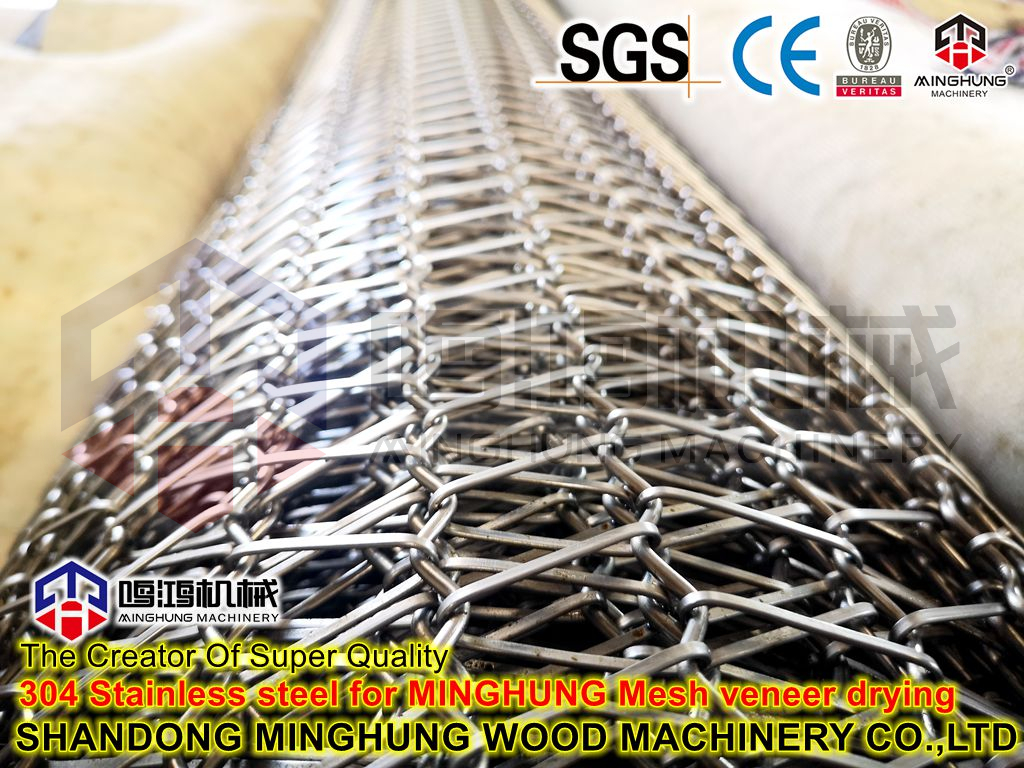

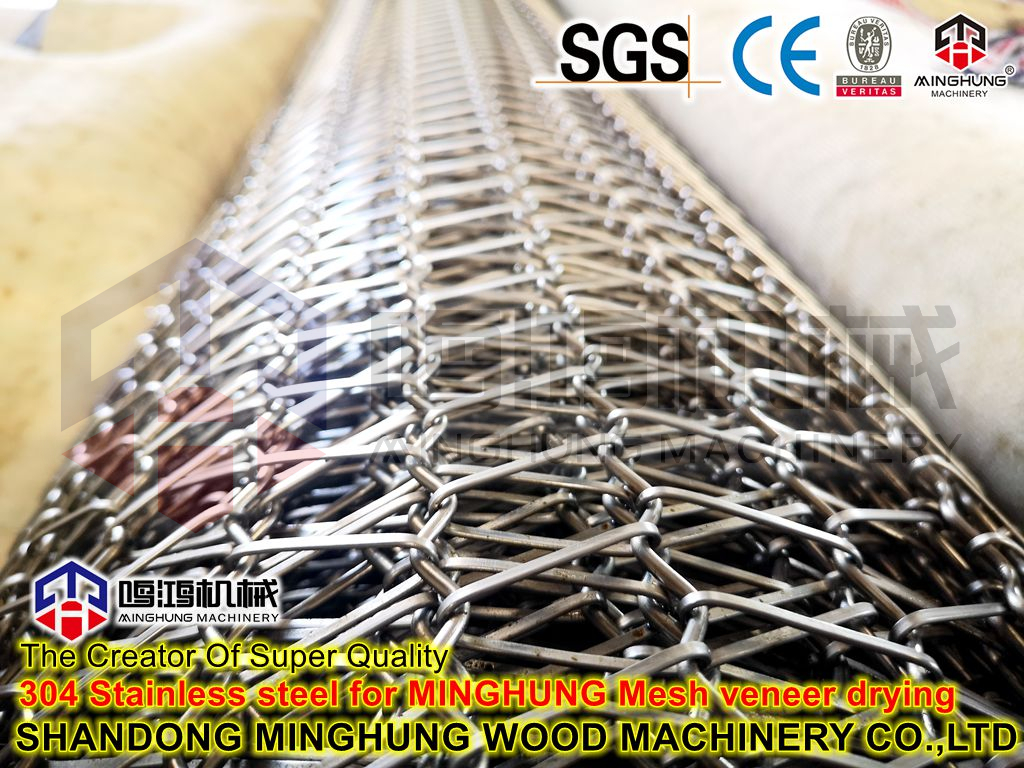

4. Material Handling (Conveying) System

Function: To carry and smoothly convey the veneer sheets through the drying chamber.

Composition:

Conveyor Mesh Belt: Usually made of metal mesh (stainless steel or galvanized wire), onto which the veneer sheets are directly laid.

Drive Unit: Includes a drive motor, reducer, sprockets, chains, etc., providing power for the mesh belt movement.

Tensioning & Tracking Devices: Ensure the mesh belt remains taut and runs on the correct path, preventing misalignment.

5. Moisture Exhaust (Ventilation) System

Function: To remove the large amount of water vapor evaporated from the veneer from the drying chamber in a timely manner, maintaining the drying driving force.

Composition:

Exhaust Vents: Usually located on the top or upper part of the drying chamber.

Exhaust Fans / Dampers: Remove the moist air either by natural pressure or through forced extraction.

6. Basic Control System

Function: To control the basic start/stop and operation of the equipment.

Composition:

Control Cabinet: Houses electrical components like circuit breakers, contactors, and thermal relays.

Temperature Controller/Indicator: Displays and provides basic control over the drying temperature (might use simple on/off control rather than precise PID regulation).

Operation Buttons: Used to start/stop fans, the mesh belt, etc.

Conclusion: The value of this equipment lies not in individual components but in the highly synchronized and precise ganged achieved through the intelligent control system, transforming drying from an "art" into an exact science.

|

Core Advantages

Ultimate Precision Control: An integrated network of high-precision temperature and humidity sensors continuously monitors the micro-environment in every zone of the chamber. The intelligent central processor dynamically adjusts heat temperature, fan speed, and moisture exhaust volume, ensuring every veneer sheet dries evenly under the optimal process curve.

Exceptional Drying Quality: The closed-loop control of temperature and humidity guarantees highly uniform moisture content across all veneers. This significantly enhances the glue-bond strength, surface smoothness, and stability of the final plywood product, dramatically reducing the rejection rate.

Fully Automated Intelligent Operation: Operators simply select the pre-set parameters for wood species and thickness on the touch screen. The system automatically executes the most suitable drying program, eliminating reliance on operator experience and human error.

Efficiency with Energy Savings: The precise "on-demand" energy control prevents over-drying and energy waste, achieving high efficiency while guaranteeing top-tier quality.

|

Key Differences & Advantages VS.Traditional Dryers

Feature | Traditional Dryer | Precise T&H Controlled Dryer |

Control Method | Open-loop, manual experience-based setting | Fully Automated Closed-Loop Dynamic Control |

T&H Monitoring | Point-based,sketchy | Networked, High-Precision, Real-Time 3D Monitoring |

Exhaust Control | Timed or manual setting | Automatically Adjusted via Real-Time Humidity Sensor Data |

Drying Quality | Uneven MC, prone to warping, cracking | Highly Uniform MC, drastically fewer defects |

Operator Skill | High, relies on expert experience | Low, system auto-executes expert schedules |

Consistency | High batch-to-batch variation | Highly Stable, Traceable Quality Every Batch |

|

Applications

Production of High-End Furniture Plywood

Production of Aviation Panels, Marine Templates, and other specialty boards

Wood for Instruments (e.g., piano, guitar soundboards)

Any veneer drying application demanding extreme dimensional stability and quality.

In summary, the Precise Temperature & Humidity Controlled Plywood Drying Machine transforms drying from an "artisanal craft" into a "controlled industrial science" through intelligent, data-driven means. It is the ultimate solution for high-quality plywood production.

|

Product Packaging

|

Comment & FAQ

Q:What can you purchase from us?

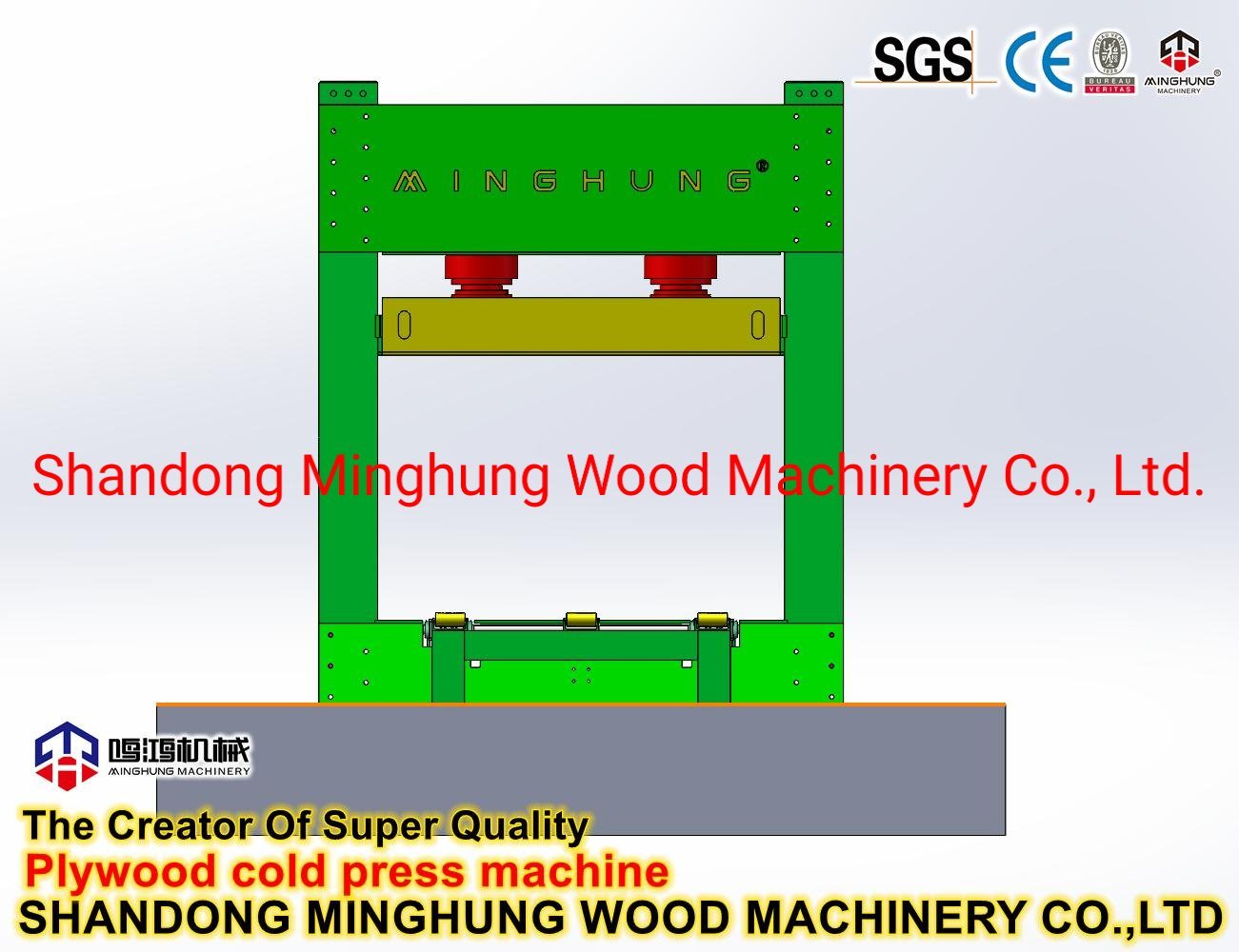

A:Particle board production line, directional particle board production line, medium/high fiber board production line, hot press, preforming press machine, plywood production line, automatic production line for hot press, veneer dryer, hot press, cold press machine and other woodworking machinery.

Q:How long the production time?

A:If one set machine,3-4 months;If the full production line 6-8 months.

Q:What are your advantages?

A:We have rich experience in the market, with the same cost, we do better because we have strict control of the production process. We have an independent inspection department to check the quality.

Q:How is your quality?

A:As an experienced manufacturer, the quality of our machines can be guaranteed and we have supplied our products to thousands of customers all over the world.

Q:Can you provide on-site engineer services?

A:Yes, usually our engineers are experienced and provide visa, air tickets and flight services.

|

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

Machines include:Veneer production line(Log debaker,Veneer peeling machine, Log loader,Automatic stacker),Blade sharpener,Veneer patching machine,Veneer dryer machine(Veneer roller dryer, Veneer mesh dryer, Veneer press dryer), Veneer gluing machine,Plywood lay-up machine, Veneer jointing machine, Plywood cold press, Hot press machine,Plywood edge trimming cutting machine, Sanding and calibrating machine, Plywood overturn machine, Lift table, and so on.

|

Exhibition

We regularly participate in international industry exhibitions based on the company's business development and customer needs. On one hand, this helps us showcase our company's strength and expand new customers. On the other hand, we visit existing customers for follow-up visits, thereby enhancing the bond between them.