Woodworking Machine Plywood Machine Hot Press Machine

Hot press machine processing for plywood making

The first stage is closed. In the boosting stage, the heat press starts slowly at first, and then closes quickly to shorten the heat pressing cycle. When it is close to the heat platen closing, the heat press turns to slow speed closure to ensure the heat press runs smoothly. . After the press is closed, the slab is compressed and the pressure is gradually increased until the highest pressure is reached

The second stage is the high-pressure dehydration stage. The hot press is maintained under high pressure for a period of time to squeeze out the free moisture in the slab. The holding time is set according to the process requirements

The third stage is the depressurization and low-temperature drying stage. After the high-pressure dehydration is completed, the hot press is depressurized. And keep it under low pressure for a period of time to make the slab form a plywood with a certain strength. The holding time is set according to the process requirements

The fourth stage is boosting. After the low-pressure drying is completed, the press is boosted to the highest pressure again, and the pressure is maintained for a period of time, so that the slab can form a plywood with a certain strength.

The fifth stage is the step-down and opening stage. The compressor depressurizes slowly at first. The high-pressure steam in the slab is gradually released to prevent defects such as delamination and bulging of the plywood. Then the heat press is turned on quickly. When the hot press descends to the end point, reduce it to a slow descent to avoid impacting the machine.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com

Hydraulic Hot Press Machine

Producing kinds of plywood, like furniture plywood, construction plywood, marine plywood, hydraulic hot press machine is the necessary and important machine.

Hot Press's structure not complex, mainly consist of: the machine frame, hot plates, hydraulic station, cylinder.

It can be different pressure and layers according to the real conditions, like 500t, 600t, 800t, 1000t, 1200t. 8layers, 10layers, 12layers, 15layers, 20layers, 25layers

>>>Specification:

>>>Advantages:

HYDRAULIC STATION

HYDRAULIC STATION Hydraulic station is one important part for plywood hot press machine, it will offer the oil to cylinder, driving it lift hot press machine.

The hydraulic station is also called the hydraulic pump station. The motor drives the oil pump to rotate. The pump sucks oil from the oil tank and pumps the oil. The mechanical energy is converted into the pressure energy of the hydraulic oil. The hydraulic oil is realized by the hydraulic valve through the integrated block (or valve combination). After the flow adjustment, it is transmitted to the oil cylinder or oil motor of the hydraulic machinery through the external pipeline, thereby controlling the direction change of the hydraulic motor, the size and speed of the power, and promoting various hydraulic machinery to do work.

MACHINE FRAME

MACHINE FRAME machine frame using good and thick steel material, by our experienced purchasing manager choose after company with different suppliers. make sure machine itself strong, stable and long life span.

Cylinder

The oil cylinder is treated with anti-rust, alloy casting, high hardness, scratch resistance, suitable for high-strength operations, and uses a good oil seal to prevent leakage, ensure the pressure in the oil cylinder, and good performance

Hot platen

Hot platen

Usually hot platen use 42mm or 52mm, The hot platen be processed by large lathe, make the surface is smooth, with sufficient strength and stiffness. It does not deform at high temperatures, and the temperature and heat are uniform. This makes the plywood heated evenly, the surface is flat, and the thermal efficiency is high, which improves the production efficiency.

>>>Hot press in client factory:

> For convenient loading, hot press machine's frame is combined, and use international standard steel plate, make sure hot press weight is very heavy, stable and good quality.

> When plywood press machine and other plywood machine reach your factory, our engineer will go to install and teach your worker how to operate and maintain machine.

> And in the future, when your worker meet any problem, or your factory need purchase some spare parts of plywood machine, we will help you solve and help you buy.

>>>Us

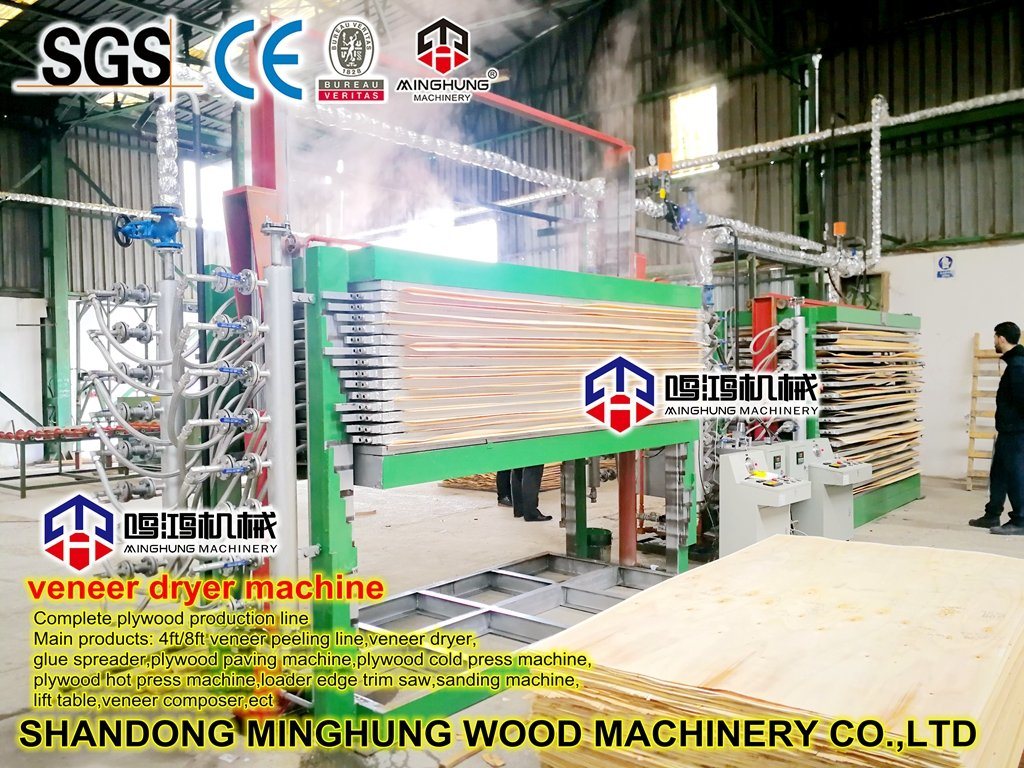

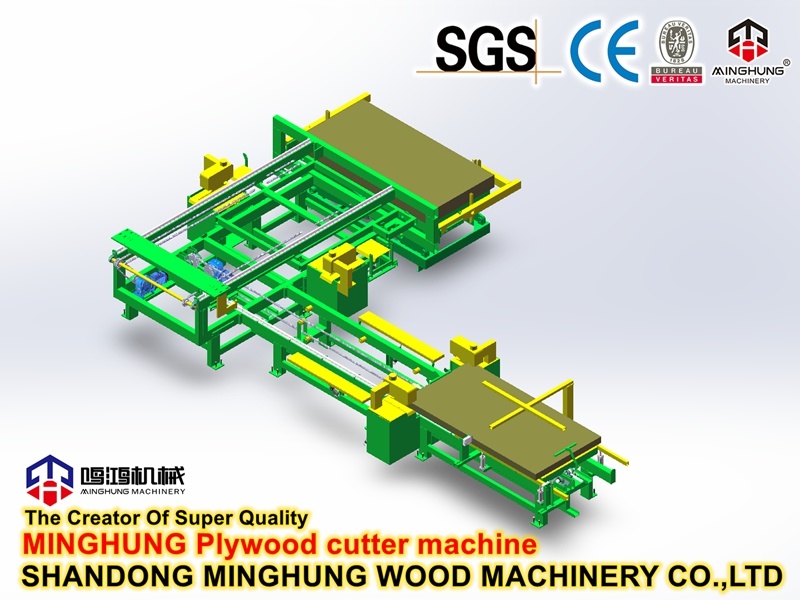

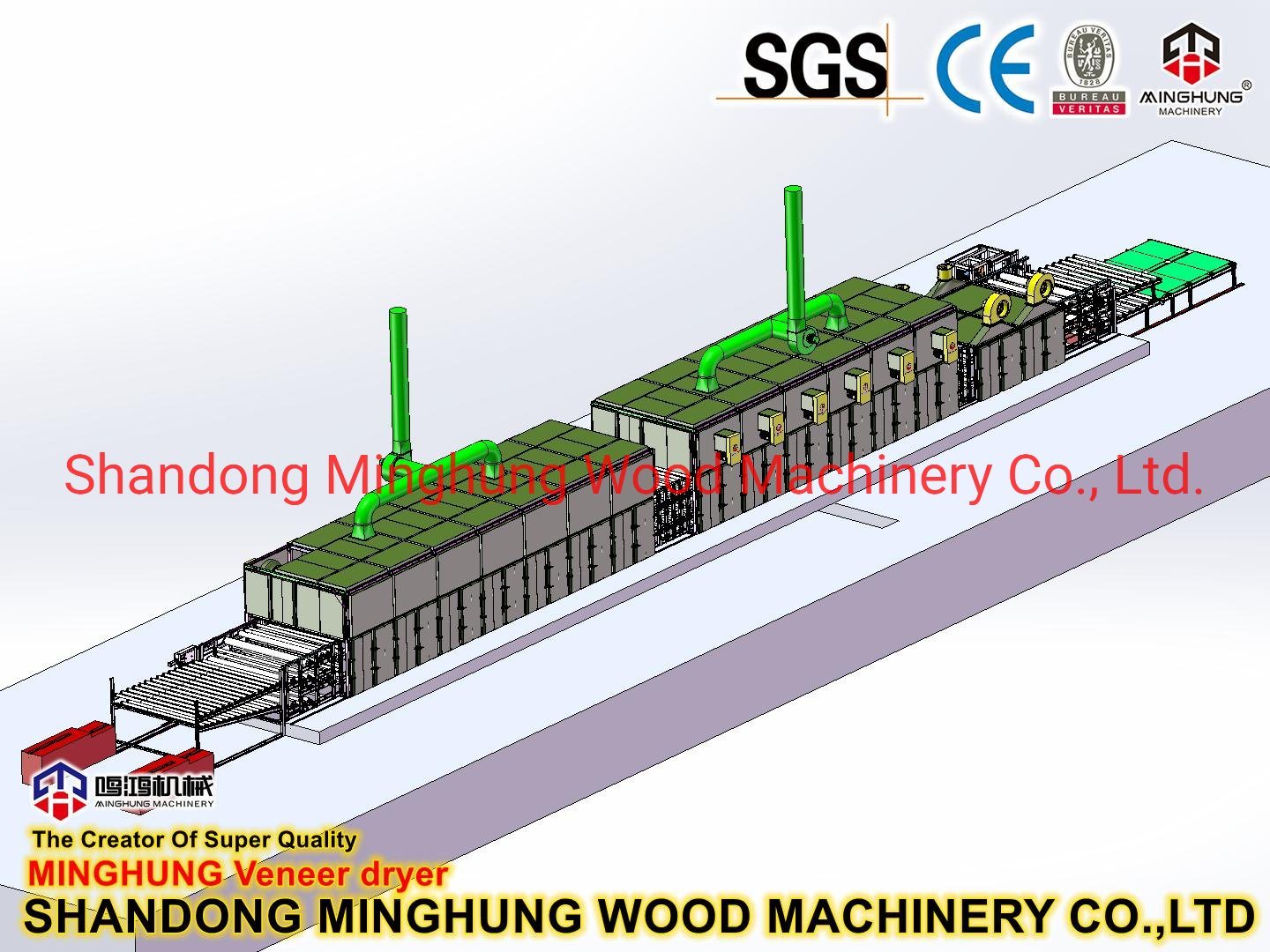

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

>>>Delivery:

1> When loading, we will share the loading pictures of plywood press machine with you.

2> When ship leave, we will offer the container and ship information for you.

3> Offer all documents which for your custom clearance.

>>>Related Plywood Machine:

we produce the full line of plywood machine.

wood debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine include veneer press dryer and roller dryer, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

>>>Contact us:

Hot press machine processing for plywood making

The first stage is closed. In the boosting stage, the heat press starts slowly at first, and then closes quickly to shorten the heat pressing cycle. When it is close to the heat platen closing, the heat press turns to slow speed closure to ensure the heat press runs smoothly. . After the press is closed, the slab is compressed and the pressure is gradually increased until the highest pressure is reached

The second stage is the high-pressure dehydration stage. The hot press is maintained under high pressure for a period of time to squeeze out the free moisture in the slab. The holding time is set according to the process requirements

The third stage is the depressurization and low-temperature drying stage. After the high-pressure dehydration is completed, the hot press is depressurized. And keep it under low pressure for a period of time to make the slab form a plywood with a certain strength. The holding time is set according to the process requirements

The fourth stage is boosting. After the low-pressure drying is completed, the press is boosted to the highest pressure again, and the pressure is maintained for a period of time, so that the slab can form a plywood with a certain strength.

The fifth stage is the step-down and opening stage. The compressor depressurizes slowly at first. The high-pressure steam in the slab is gradually released to prevent defects such as delamination and bulging of the plywood. Then the heat press is turned on quickly. When the hot press descends to the end point, reduce it to a slow descent to avoid impacting the machine.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com