A Complete Plywood Production Line for Africa Ethiopia Addis Ababa /Ghana /Algeria

As China professional and famous manufacturer and supplier, we can offer you the complete plywood production line, for help you start to produce plywood. From materials wood to the final product plywood and laminated plywood, we can offer you all necessary plywood machinery.

According to your plywood size, production capacity, budget and other conditions, we can offer the suitable and good woodworking plywood machinery for you.

If you are new beginner for plywood production, then you may want to know what machines you need, now let me introduce one by one necessary machine for you to start plywood production business.

<1> Raw materials -Wood

Wood for Plywood

First you need have enough raw materials -wood, it is the basic and important. with it, you can consider to produce wood veneer or plywood.

Different countries will use different wood species according to their local nature resource, some our clients use Ceiba, some use Eucalyptus, some use Beech and birch, some use Pine, some use Poplar, all no problem

<2> Veneer production

Veneer is the material for making plywood. So you need a Veneer production line, Usually the Complete veneer production line includes Log debarker, Log peeler, Log loader, and Veneer stacker (for this machine, it will save two labor cost. But if your local labor cost is very low, then you can choose not to buy this machine).

Veneer production line

Includes 1 set Log debarker, 1 set Spindless Log peeler, 2 pcs Log loader, and 1 set Veneer stacker.

With this veneer production line, you can produce Veneers.

Veneer quality will directly affect the plywood quality. So one set good and strong veneer lathe is important.

Now there mainly has two types veneer peeling machine, one is Spindless peeler, another type is Spindle type peeler. What is their difference? How to choose them?

Spindless veneer peeler

it is suitable for peel wood diameter less than 600mm. Through rollers clamp and rotate wood and peel wood into pieces of veneers. As your veneer thickness, cutting size, you can directly set from the cnc screen.

Spindle veneer peeler

It is mainly for peel wood with big diameter like 1000mm, 1500mm. And it is also suitable for making face veneer,.

So, according to your wood diameter and veneer thickness, you can choose the better veneer peeler.

<3> Veneer Drying

Veneer drying machine will drying the peeled veneer humidity, make its final humidity is suitable for the next production step. Why drying? Because as we know, the wood has water content, and different wood's water content is different, this will cause the peeled veneer moisture is high. Usually betwene 40-70%. It is very high and totally not suitable for making any wooden products. That's why we need Veneer dryer.

Now in the market, The poplar veneer dryer has three types, they are: Veneer roller dryer, Veneer mesh dryer, Veneer press dryer. So how to choose one suitable veneer dryer?

Veneer Roller Dryer

Now in many big plywood factory, veneer roller dryer is very popular. One of its advantage is one set roller dryer can satisfy big drying capacity.

Roller dryer's width, decks, and length all can be designed as different drying capaicty and requires. For example, it can be 1 deck, 2 decks, 3 decks, 4 decks, 5 decks; According to your veneer size, we can make the veneer dryer width more suitable

Veneer Mesh Dryer

Veneer mesh dryer also very popular gradually. From outlooking, it is very similar with the roller dryer.

It also can be designed to be different layers, width and length according to different requires.

The biggest different compare with roller dryer, is their convey method different. For roller dryer, its convey method of veneers by many rollers, For mesh dryer, its convey method by mesh belt.

So when you drying core veneer, both dryer all be ok and good, if you drying face veneer or thin veneer, mesh dryer will be better

Veneer Press Dryer

Veneer Press Dryer

Usually in Southeast Asia like Indonesia, most plywood factory prefer the press dryer. For veneer press dryer, it has two types. One is its plate with solid hot plates, one is its plate with squre tube, both press dryer weight and price will be a little big different.

For press dryer, its drying capacity smaller, but it cover less factory space, and consume less electricity.

Therefore, we can see that each machine has its features and advantages, according to your own conditions, we can advise the better choice for you.

<4> Veneer Core Composer

For this machine, it is not the necessary machine like hot press machine, some clients choose it, some clients not choose it. you can according to your budget and plywood requires. So what is the functions of core composer?

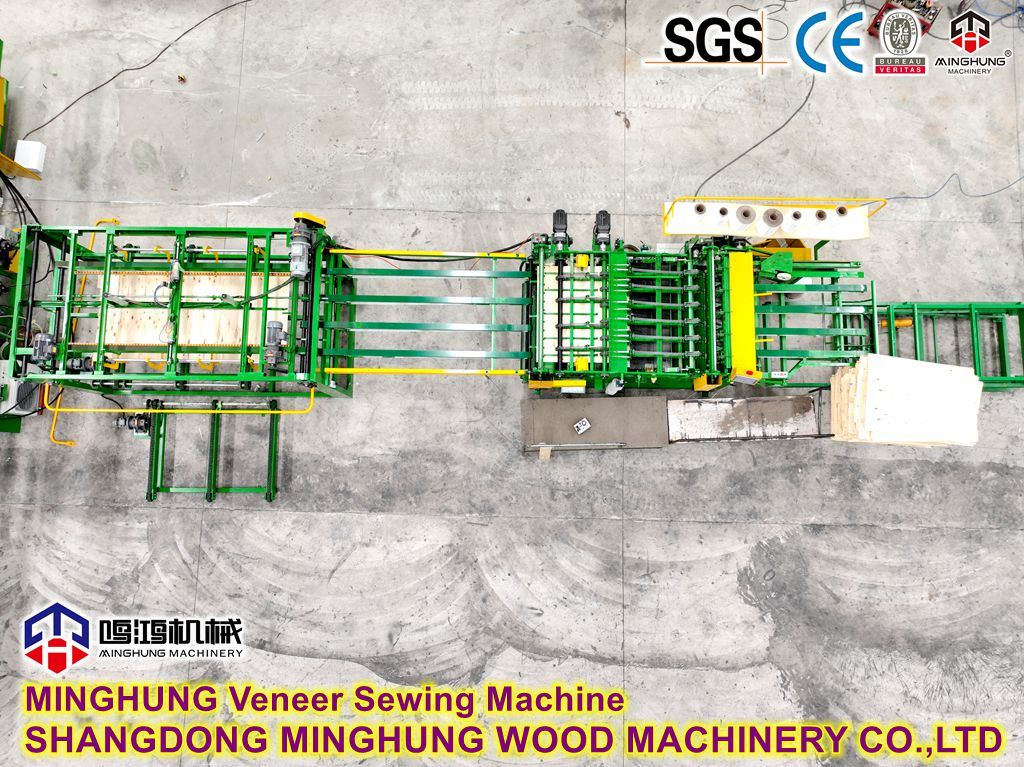

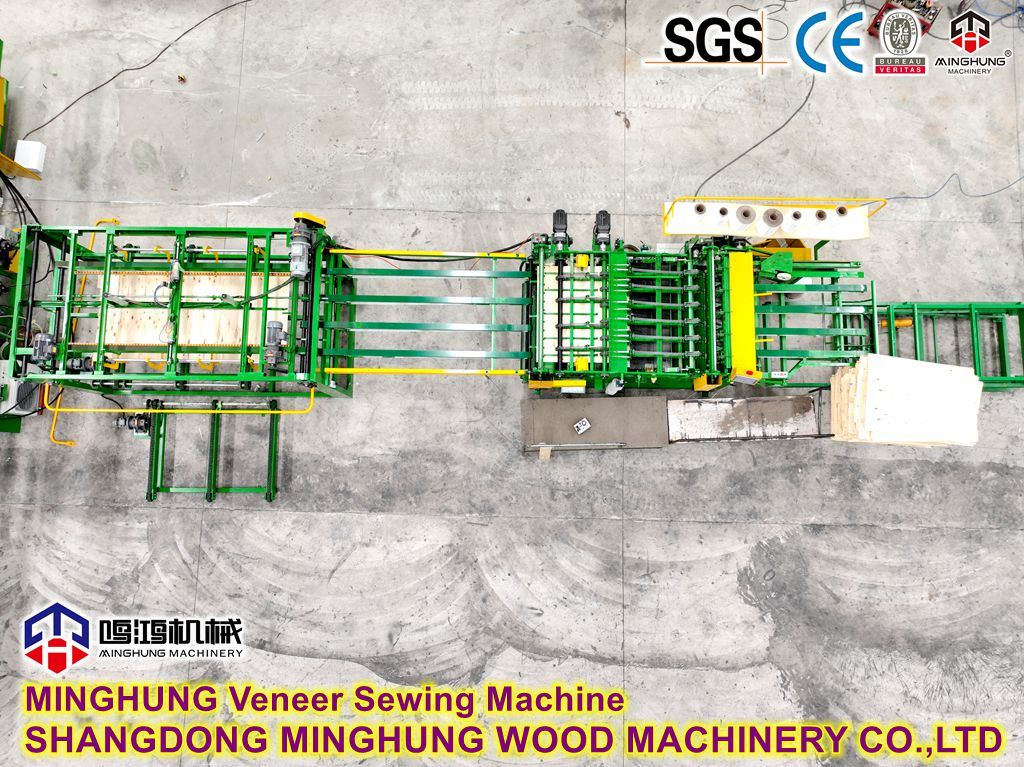

Core composer /Veneer sewing machine /Veneer joint machine

Its function for joint two or three or more pieces veneers to be one big size as your plywood size. Usually when workers lay veneers out, the jointed veneer will be put on the surface. Thus it will make your plywood more balance, improve your plywood quality.

Usually it is for 4*8feet plywood, but as some clients requires, we also can design the core composer as your special plywood size.

L Core composer with Teeth joint

This is another core composer type. Compare the first type, this core composer will vertical joint veneers and with teeth joint, thus the veneer joint will be more stronger.

<5> Hydraulic Glue Mixer

Glue mixer

It is mainly mix kinds of materials for make glue. This machine is very simple, but also necessary.

<6> 4 rollers Glue Spreader Machine

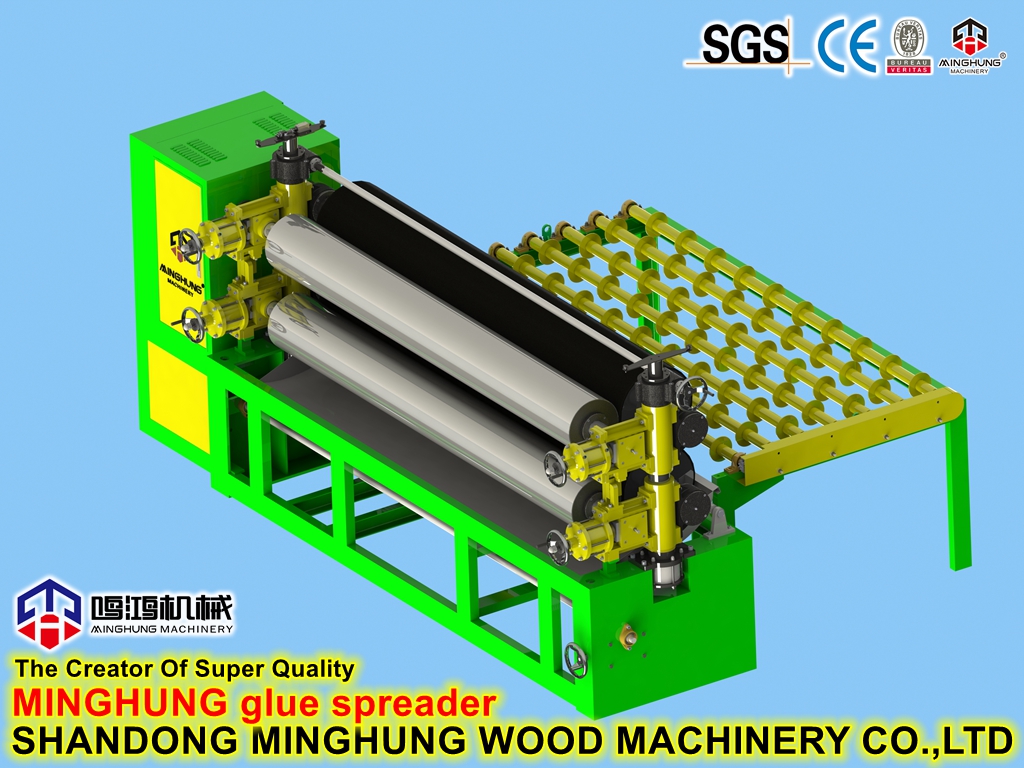

Glue spreader's function is coating glue evenly on wood veneer surface, and workers will lay the glued veneer out, as plywood size.

Glue spreader

Glue spreader can be single side and double sides, now most people choose double sides, because it can coating both sides of veneers at the same time, improve production capacity.

The standard glue spreader has 4feet and 8feet, or we can customize the glue spreader as your veneer size.

<7> Cold press machine

Cold press machine for pre-press the glued veneers and make inside glue melt, let the plywood be forming.

Hydraulic cold press machine

It can be different pressure, usually the frequently-used is 400Ton, 500Ton, 600Ton, some require 800Ton

Except for 1220*2440mm plywood, as your requires, we can design the press table size for you

<8> Multi-layers Hot press machine

Hot press machine is one very important step for plywood production.

Hot press

Hot press machine can be different layers like 5, 8, 10, 12, 15, 20, 25, 30, 32, 35, as you want. And it also can be different pressure like 400Ton, 500Ton, 600Ton, 800Ton, 1000Ton or as you want.

When the Layers of hot press more than 20 layers, we advise equipped with the Semi auto loader or Auto loader, thus it will be more faster and improve production capacity.

<9> Film laminating Hot press machine

If you want produce laminated plywood, then this machine also required

Film hot press

It will laminating Film paper or Melamine on plywood surface. Usually Hot press machine at most 10 layers, equipped with Semi auto loader, so you can easy to laminate both sides at the same time, improve production capacity.

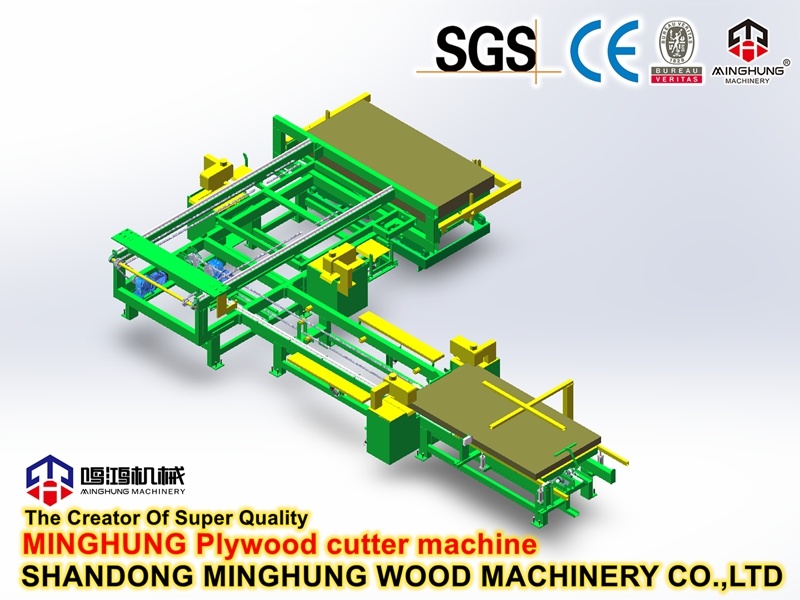

<10> Plywood cutting machine

Standard plywood cutting machine

It will semi automatic trimming and cutting plywood four edges, make plywood edge be clean, and each plywood size be same.

This machine is not complex, works and operation is easy

Automatic Roller type plywood cutting machine

This is another type, it is fully automatic, and working speed faster, so production capacity higher, and save labor cost.

<11> Sanding Machine

Sanding machine /Calibrating machine for calibrating plywood thickness and make it balance and accurate, and it also can polishing plywood surface and make it smooth. Plywood sander can be different specification, it can be single side, it also can be Double sides; It can be One sanding head, Two sanding heads, Three sanding heads or as your requires; And as different production capacity and panel types, we also can offer the suitable sanding machine for you

Single side sanding machine with 2 sanding heads

This sanding machine is our heavy duty type, it will sand one side of plywood one time, and keep good sanding effect. In China plywood factory, many of them choose buy 2 sets single side sanding machine and equipped with 3 Ton Plywood turnover machine, and with Auto loader and Unloader, this whole sanding machine line no need workers, and keep the sanded plywood very good.

Double sides sanding machine

This sanding machine can sanding plywood both sides at the same time, so the working efficiency higher, and keep good sanding effect.

Auto loader+unloader for Sanding machine

If you want to save labor cost, less workers, and be automatic. Then your sanding machine can equipped with auto loader and stacker, so the whole sanding process no need workers, fully automatic.

3T Plywood Turnover Machine

It is usually assit the single side sanding machine works. Because the single side sanding machine only can sand one side one time, so after sanding all plywood, the Turnover machine can overturn plywood, and sanding machine can sanding another side, save time.

<12> Lift table

There are mainly two types lift table, one for Hot press machine, one for other plywood machinery

Lift table for Hot press

Usually for Hot press machine, we advise this type lift table. Because its structure, is more suitable and safety for workers stand on it

Lift table

Usually this type lift table for on the front of Veneer dryer, on the front of plywood cutting machine, sanding machine and glue machine

<13> Boiler

For plywood production, boiler is necessary and important too. Now usually Steam boiler or Oil boiler you can choose

Steam Boiler

It can be different capaicty as your machine information and quantity.

Oil boiler

With these machines, you can start to produce plywood.

Choose good quality plywood machine, will make your plywood quality better, will help your business going better.

According to the real machine specification and quantity, we will tell you how many containers required, and when machine loading, we can help you check freight cost, we also can arrange ship for you

#plywoodproductionline #plywoodmachinery #plywoodmachineryforethiopia

Welcome contact us for more information about plywood machinery. we will share machine working videos with you

Contacts:

Mark:+86 18769900191

Ali: +86 15805496117

Lucinda: +86 15805493072

Email: minghungmachinery@gmail.com

Veneer Press Dryer

Veneer Press Dryer