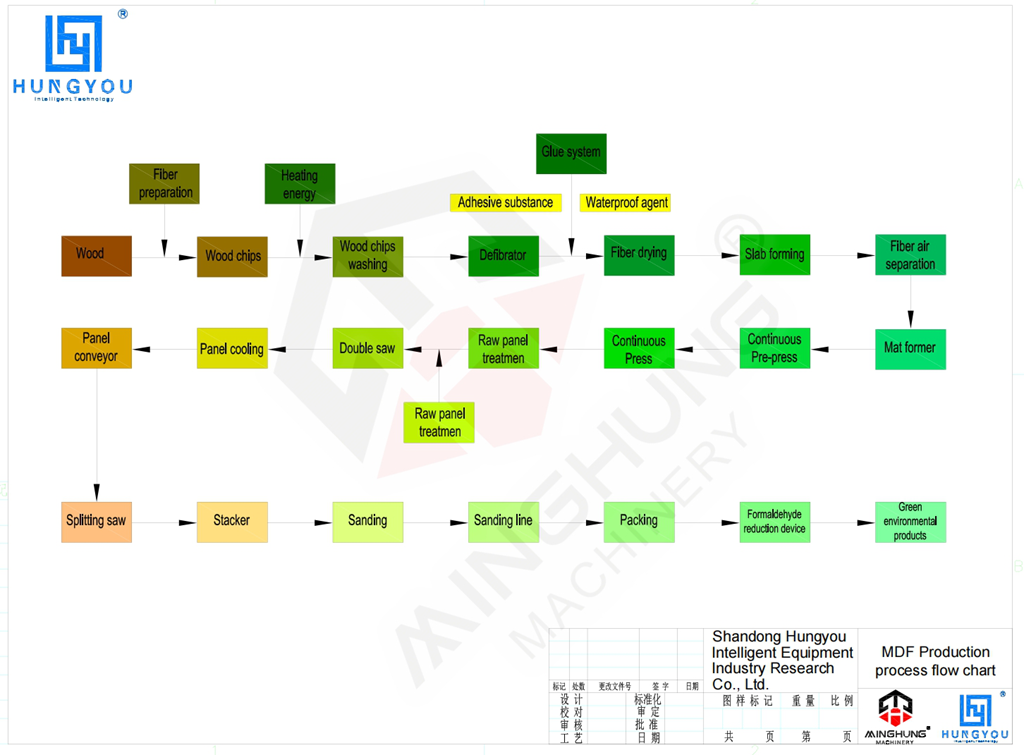

Introduction to Main Equipment

The main equipment for this production line can be divided into the following core systems:

I. Raw Material Handling and Preparation System

This system's task is to process raw wood material into qualified, uniform wood chips.

1. Debarker (Optional)

Function: If logs are used as raw material, this machine is needed to remove bark. Bark can affect board color and bonding performance and is usually removed.

Description: Uses a drum or ring-type mechanism to remove bark by friction as logs are tumbled.

2. Chipper

Function: To chip wood (logs, branches, board waste, etc.) into uniform, process-ready wood chips.

Description: Typically a disc chipper equipped with a heavy-duty disc and knives. Its production capacity is directly related to the disc diameter and motor power, making it a key front-end device determining the line's overall output.

3. Chip Screening and Re-crushing System

Function: To grade and screen chips, separating acceptable chips, oversize chips, and fines.

Main Equipment:

Screening System: A multi-deck vibrating screen that separates chips into oversize, acceptables, and fines.

Re-crusher: Crushes the oversize chips a second time to convert them into acceptable chips, improving raw material utilization.

4. Chip Storage Bin

Function: To store screened, acceptable chips, providing a buffer for continuous, stable production and ensuring uniform feeding to subsequent stages.

II. Fiber Preparation System

This is the "heart" of the production line, responsible for transforming wood chips into qualified, resin-coated dry fibers.

1. Chip Washing and Pre-heating Unit

Function: To remove impurities like sand and stones from the chips and pre-soften them with low-pressure steam, improving fiber quality and reducing refiner plate wear.

2. Defibrator System (Refiner) This is the core of the core.

Function: To soften chips under high-temperature, high-pressure steam and separate them into fibers via mechanical grinding, while simultaneously blending resin and other additives evenly with the fibers.

Main Components:

Pre-heating Digester: Treats chips with saturated steam for thorough softening.

Defibrator (Refiner): The core equipment, including precision refiner plates. Separates softened wood into fibers under high power drive. Its power and specifications directly determine fiber output and quality.

Resin Blending System: Uses high-precision metering pumps and nozzles in the blowline to evenly spray resin, wax, and other additives onto the fibers.

Discharge Valve/Blow Valve: Controls the discharge of fibers from the high-pressure refining chamber to the atmospheric-pressure drying tube.

3. Fiber Drying System

Function: To rapidly dry the resin-coated, high-moisture fibers to a suitable moisture content (8-12%).

Main Equipment:

Pipeline Dryer: Fibers are conveyed and dried in a suspended state within a high-temperature air duct. Equipped with a hot air furnace, fans, cyclones, etc.

Dry Fiber Storage Bin: Stores dried fibers, acting as a buffer and balancing capacity between preceding and subsequent stages.

III. Forming and Pre-pressing System

This system forms the dry fibers into a "blank" with the initial shape of a mat.

1. Forming Machine

Function: To spread dry fibers evenly and steadily onto a moving caul plate, forming a continuous mat with consistent thickness, uniform density, and no edge drop.

Description: Uses advanced mechanical or air-mechanical composite forming heads, consisting of scanning devices, metering belts, and the forming head itself. It is the first key piece of equipment for achieving high flatness.

2. Mat Pre-press

Function: To perform an initial cold pressing of the fluffy mat, removing most of the air, increasing the blank's strength for transport, and establishing the initial thickness.

Description: Usually a continuous belt pre-press or a single-opening pre-press.

3. Mat Scale and Metal Detector

Function: The mat scale checks forming density online and provides feedback to adjust the former. The metal detector identifies and rejects any metal contaminants in the mat to protect the expensive press belts in subsequent stages.

4. Caul Plate Return System

Function: After carrying the formed and pre-pressed mat into the press, the empty caul plates are cycled back to the front of the former via an underlying conveyor line.

IV. Hot Pressing and Curing System

This is the most technologically advanced and capital-intensive part of the line, and is the decisive stage for high flatness.

1. Continuous Press

Function: To subject the mat to precisely controlled temperature, pressure, and time while it moves continuously, curing the resin and bonding the fibers firmly into a dense board.

Description: This is the ultimate equipment for achieving high output, high quality, and especially high flatness.

It consists of the following key components:

Steel Belts: Precision components with extremely high flatness, surface finish, and heat resistance, acting as the "mold" for the board.

Heating Platen System: Provides uniform heat, often divided into multiple temperature zones for precise control.

Hydraulic Pressure System: Comprises dozens or even hundreds of hydraulic cylinders forming a vast pressure array, allowing for precise pressure profile control along the board's length and width.

Main Frame and Roller System: Supports the enormous pressing force and drives the smooth operation of the steel belts.

V. Finishing and Sanding System

Processes the pressed rough board into a sellable product.

1. Cooling Star / Turner

To rapidly and uniformly cool the high-temperature boards exiting the press, setting their shape, releasing thermal stress, and preventing deformation.

2. Longitudinal and Cross-Cut Saws

To cut the continuous board strip into preset widths and lengths (e.g., 1220x2440mm).

3. Stacker

To automatically stack the sawn boards into neat piles.

4. Intermediate Storage System (Conditioning Warehouse)

Allows stacked boards to rest for 24-48 hours, enabling further equilibration of internal stress and moisture content. This is a crucial step for ensuring the board's long-term dimensional stability and preventing subsequent warping.

5. Sanding Line

To perform thickness calibration sanding and surface finishing on the boards.

Main Equipment:

Multi-Head Calibrating Sander: Typically with 4, 6, or more heads. The first few heads are for calibration and coarse sanding to eliminate thickness deviation; the latter heads are for fine sanding to achieve a high-quality surface finish. This is the final process for achieving the ultimate macro-flatness and perfect surface.

6. Final Cutting and Packaging System

To perform final cutting of the sanded boards according to customer requirements, and to carry out automatic film wrapping, strapping, and packaging.

VI. Central Control System

Function: This is not a standalone machine but the "brain" distributed throughout the entire line.

Description: Uses a Distributed Control System or large PLC to monitor, record, and automatically adjust the operating parameters (speed, temperature, pressure, metering, etc.) of all equipment in real-time, ensuring the entire production line operates stably and efficiently on the optimal process curve.

Summary: This production line is a complex system where all the above precision equipment work in coordination. From uniform chipping to precise forming, to the ultimate control of the continuous press, and finally through stress relief and precision sanding, every single piece of equipment contributes to achieving the two core objectives: "Daily Production of 900 cubic meters" and "High Flatness".