|

Product Overview

This equipment is a high-precision, high-efficiency drying solution specifically tailored to the characteristics of birch veneer. Birch, a high-grade wood, is a key raw material for producing quality plywood, decorative panels, and furniture veneers. However, with its high density and fine texture, birch veneer is highly sensitive to temperature and humidity changes during drying, being prone to defects such as cracking, warping, case-hardening, and darkening. This equipment successfully addresses these industry challenges through precise process control, ensuring rapid dehydration while perfectly preserving the veneer's excellent physical properties and natural light, bright color.

|

Core Advantages & Targeted Design

1. Birch-Specific Drying Process:

Features built-in optimized drying schedules (curves) for birch veneer of different thicknesses and initial moisture contents. It strictly controls temperature and humidity during the heating, constant-temperature, and cooling phases to ensure steady moisture migration from the inside out, avoiding stress concentration that leads to cracking.

2. Exceptional Color and Quality Preservation:

Utilizes relatively low drying temperatures and precise humidity control to effectively inhibit thermal darkening, which birch is susceptible to under high heat, thereby furthest preserving its fresh, bright natural color—crucial for high-end decorative materials.

3. Advanced Anti-Warping and Anti-Cracking Technology:

An optimized airflow design ensures hot air penetrates the veneer stack evenly and gently, allowing both sides of the veneer to dry at the same rate, significantly reducing internal stress and preventing warping and deformation.

4. High Efficiency and Energy Savings:

Equipped with high-performance insulation and a heat recovery system, drastically reducing thermal energy loss. The intelligent control system adjusts fan speed and moisture exhaust based on the real-time drying stage, avoiding energy waste.

5. Easy Operation and High Automation:

Users simply select the pre-set "Birch Mode" or input specific parameters on the touchscreen, and the equipment operates fully automatically, reducing reliance on highly experienced operators and minimizing human error.

|

Working Principle

Wet birch veneers are smoothly conveyed into the sealed drying chamber. According to the pre-set birch drying curve, the equipment activates the heating unit (steam/electric/gas, etc.) to generate hot air. High-volume, low-velocity circulation fans then evenly and gently blow this air across each layer of veneer. Moisture is carried away by the hot air, and the humid air is partially exhausted through the dehumidification system while pre-heated dry fresh air is supplied. Throughout the process, temperature and humidity sensors monitor data in real-time and feed it back to the PLC, which dynamically fine-tunes parameters to keep the drying process optimal until the veneer moisture content is uniformly reach the standard (typically 8%-12%).

|

Main Components

The High-Efficiency Birch Veneer Drying Equipment is a precision system designed with the specific characteristics of birch wood in mind. Below are its core components:

1. Insulated and Sealed Chamber

Description: This is the main structure of the equipment, typically constructed from high-quality color steel plates and internal high-strength insulation material (e.g., rock wool).

Function: Creates an enclosed drying space, effectively preventing heat loss and ensuring a stable thermal environment inside the chamber, which is crucial for achieving the low-temperature, uniform drying required for birch.

2. Targeted Hot Air Circulation System

Description: Includes circulation fans, air ducts, and air baffles.

Function: This is the core system ensuring drying quality. The fans generate powerful yet stable airflow, which, directed through scientifically designed ducts and baffles, allows hot air to penetrate the birch veneer stacks evenly and gently. This "high-volume, low-velocity" airflow pattern effectively prevents deformation and cracking of the birch veneer caused by excessive or uneven airspeed.

3. Precision Heating System

Description: Depending on the heat source, this may include steam heat exchangers, thermal oil heat exchangers, electric heating elements, or gas hot air furnaces, etc.

Function: Provides the heat necessary for drying. Tailored for birch characteristics, the system typically uses relatively low and stable heating temperatures to avoid discoloration (thermal degradation) or case-hardening of the birch surface.

4. Intelligent Humidity Control System

Description: Consists of air inlet/exhaust vents, electric actuators (dehumidification dampers), and humidity sensors.

Function: Monitors and regulates the air humidity inside the drying chamber in real-time. By precisely controlling the amount of moisture exhausted and fresh air supplied, it ensures the humidity curve during drying meets the technical requirements for birch, promoting efficient moisture evaporation while preventing defects caused by overly rapid drying.

5. Material Handling System (for continuous or batch types)

Description: This could be a multi-layer mesh belt, track carts, or stainless steel trays.

Function: Carries and transports the birch veneers through the drying zone. Its speed or dwell time is adjustable to precisely control the drying cycle, accommodating birch veneers of different thicknesses and initial moisture content.

6. Core Intelligent Control System

Description: This is the "brain" of the equipment, comprising a PLC (Programmable Logic Controller), Touchscreen HMI (Human-Machine Interface), temperature and humidity sensors, and actuators.

Function: Features built-in drying process curves optimized specifically for birch. Operators can easily select pre-set programs via the touchscreen, while the system automatically monitors and adjusts temperature, humidity, and fan operation, ensuring the entire drying process is accurate, reliable, and requires no manual intervention.

7. Safety Protection System

Description: Includes over-temperature protectors, motor overload protection, fault alarm devices, etc.

Function: Provides comprehensive safety protection for both the equipment and the drying process, ensuring automatic shutdown or alarm activation under abnormal conditions to prevent damage to the equipment and the valuable birch veneer material.

|

Technical Parameters

Applicable Material: Birch Veneer (compatible with other similar species)

Final Moisture Content: 8% - 12% (Adjustable)

Operating Temperature Range: 40°C - 75°C (Low-temperature drying optimized for birch)

Heat Source Options: Steam, Thermal Oil, Natural Gas, Electric Heating

Control System: PLC + Touchscreen Intelligent Control

Capacity: Customizable according to customer production needs (Single load capacity from several cubic meters to tens of cubic meters).

|

Applications

This equipment is essential for manufacturing:

High-Grade Birch Plywood: E.g., panels for furniture, interior building linings.

Decorative Veneer (Thin Veneer): High-quality surface layers for furniture finishing, doors, wall panels, and musical instruments.

Composite Substrate: Various products requiring high-quality dried veneer as a base material.

|

The services we can offer

Pre-sales service:

1) Listen to customer needs

2) Provide preliminary machine design and flow chart for free, select and provide the most reasonable configuration equipment:

3) Support remote meetings and remote factory visits;

4) Provide professional advice to customers and confirm the final selection

5) Support on-site factory visits;

On-purchase service:

1) All equipment must be installed and debugged before leaving the factory, and remote video quality inspection is supported;

2) All machines must be unpacked before leaving the factory, and photos, videos, and annotations must be provided;

3) Free online or offline training for buyers' operators (domestic)

4) Assist buyers in installing and debugging equipment (overseas)

After-sales service:

1) 7*24 hours online service, remote real-time video solution;

2) During the first installation and debugging process, problems encountered during normal operation are solved in time:

3) Regular process inspection and use effect, timely machine maintenance suggestions:

4) Lifetime free technical guidance

5) Timely update the latest industry information.

|

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

The machinery we produce includes peeling machines, chipping machines, rotary cutting machines, drying machines, gluing mixers, laying machines, pre-pressing machines, hot pressing machines, cooling machines, longitudinal and transverse sawing machines, sanding machines, as well as auxiliary machinery such as automatic feeding and discharging systems and lifting platforms.

|

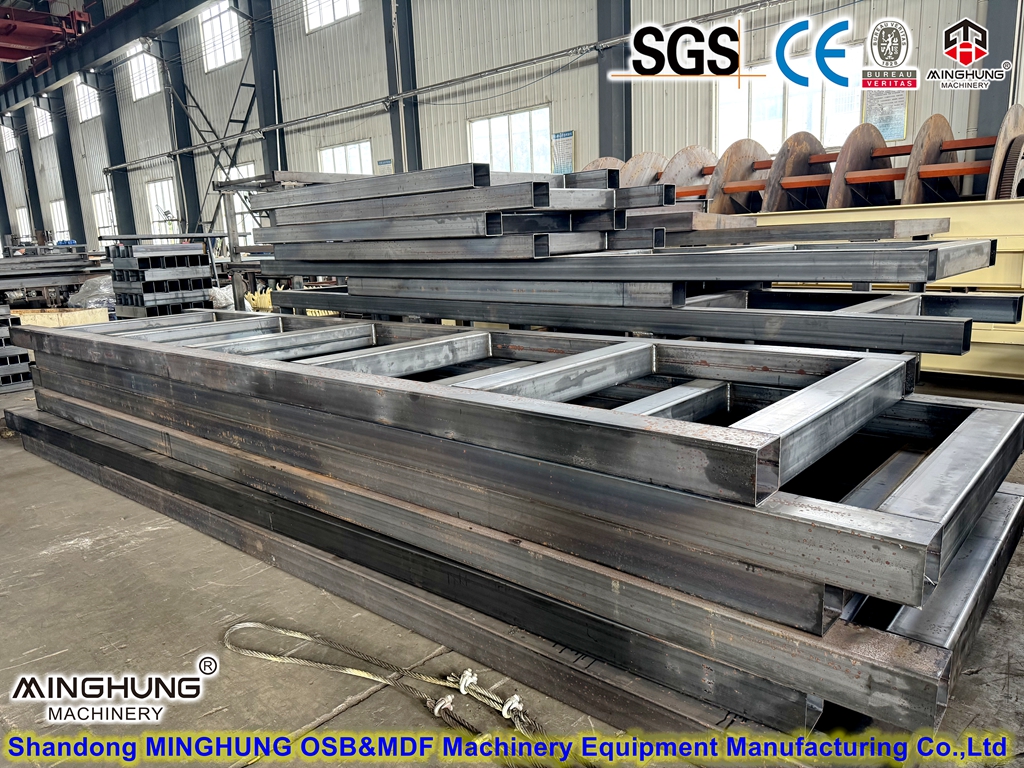

Our Workshop

|

Package and Transport

We maintain a long-term cooperation with a well-known freight forwarding company, and adhere to the customer-first philosophy. We strictly implement the quality inspection process before shipment to ensure that each batch of products meets international quality standards, We deeply understand that high-quality service is the cornerstone of winning customer trust, and we always create value for customers with professional and efficient supply chain management.

Request Your Plywood Solution Now! 3D plant layout, on-site commissioning & global spare parts – Dominate the premium board market today!