Stage 1: Recycled Wood Raw Material Pre-treatment System

1. Raw Material Reception and Sorting

Receives various types of waste wood, with preliminary sorting (manual or robotic) to remove non-wood impurities like metal and plastic.

Grades wood by species and contamination level (e.g., paint, preservatives) to match different treatment processes.

2. Crushing and Shredding

Coarse Crusher: Breaks down large timber pieces into smaller wood chips.

Fine Grinder: Further reduces wood chips into wood fibers or large flakes suitable for pulping or reconstituted veneer manufacturing.

3. Deep Cleaning and Treatment

Magnetic Separator: Removes residual metal like nails and screws.

Air Sorter / Washing System: Separates sand, gravel, and dust. Advanced systems may include chemical or thermal cleaning to degrade paint and adhesive residues.

Drying System: Dries the cleaned wood fibers/flakes to an optimal moisture content.

Stage 2: Reconstituted Veneer/Block Manufacturing

This is the core technological section of the recycled wood line, primarily involving two technical pathways:

1. Path A: Reconstituted Wood Veneer Manufacturing

Cleaned long wood strands are blended with adhesive (eco-friendly glue) and orientated during mat formation.

The mat is pressed under high temperature and pressure into large-format, continuous reconstituted wood veneer (mimicking rotary-cut veneer).

This veneer offers high strength and consistent specification, directly replacing traditional peeled veneer from logs.

2. Path B: Reconstituted Wood Block Manufacturing

Adhesive-coated wood fibers or flakes are molded into large, solid wood blocks.

These blocks are then sliced or peeled to produce decorative veneers (suitable for face/back layers).

Stage 3: Plywood Hot Pressing

This stage resembles traditional lines but uses reconstituted veneers made from recycled wood.

1. Gluing and Layup: Reconstituted veneers are combined (possibly with native wood veneers for surface layers), coated with eco-friendly adhesive (e.g., no-added-formaldehyde glue), and laid up according to the required structure.

2. Hot Press Curing: The layup is pressed in a multi-opening hot press under precisely controlled temperature, pressure, and time to cure the adhesive and form the panel. Heat systems often integrate exhaust gas combustion recovery for higher energy efficiency.

Stage 4: Post-Processing and Finishing

1. Conditioning and Cooling: Releases hot-pressing stress and balances moisture content.

2. Thickness Calibration Sanding: Utilizes high-precision double-sided thickness calibrating sanders to ensure minimal thickness tolerance and a smooth surface.

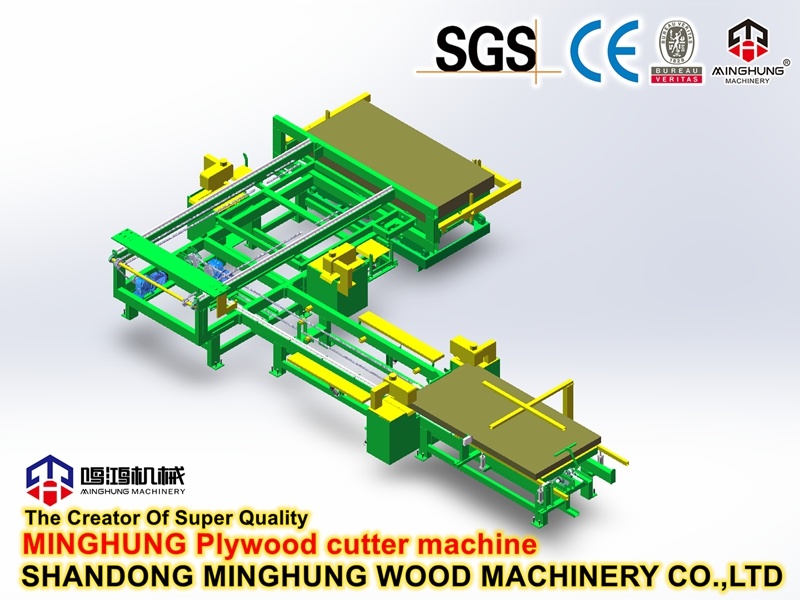

3. Trimming and Grading: Panels are cut to standard sizes and graded based on appearance and physical properties.

4. Packaging and Storage: Labeling and packaging using environmentally friendly materials.

1. Outstanding Environmental Value:

Reduces Deforestation: Consumes large amounts of waste wood, reducing reliance on virgin timber.

Reduces Landfill Waste: Effectively addresses the challenge of waste wood disposal.

Low Carbon & Energy Efficient: Significantly lower carbon footprint compared to processing virgin logs; integrated heat recovery systems.

Green End Product: Can use no-added-formaldehyde adhesives to produce eco-friendly plywood throughout its lifecycle.

2. Significant Economic Benefits:

Low Raw Material Cost: Recycled wood feedstock is much cheaper than virgin logs and offers stable supply.

High Product Value-Added: Finished products can obtain various green certifications (e.g., FSC Recycled, CARB, Green Building Labels), enhancing market price and competitiveness.

Policy Incentives: Aligns with circular economy and environmental policies in many countries, potentially qualifying for tax breaks or subsidies.

3. Technical & Performance Advantages:

Strong Raw Material Adaptability: Can process various complex sources of waste wood.

Controllable Product Performance: The reconstitution process allows for designing and producing plywood with uniform strength, stable performance, sometimes superior to some natural wood.

Efficient & Stable Production: High automation and strong line continuity ensure stable output.