I. Raw Material Processing Section Equipment

1. Bucking Saw

Function: Cross-cuts logs into predetermined lengths. Equipped with high-power motors and special alloy blades ensuring smooth cutting surfaces and high efficiency.

Type: Typically chain saws or disk saws.

2. Steaming Pond/Vat

Function: Softens log blocks using hot water or steam. Constructed from concrete or stainless steel, equipped with heating pipes and temperature control systems for precise water temperature regulation (typically 70-90°C) and steaming time control (12-48 hours).

3. Debarker

Function: Removes bark from logs. Utilizes drum or cutterhead designs to remove bark through rotational friction or cutting, equipped with water spray systems to reduce dust.

II. Veneer Production Section Equipment

1. Veneer Lathe/Peeler

Function: Peels log blocks into continuous veneer ribbons. Key components include:

Spindle stock and tailstock: Provide rotational power and support.

Precision knife carriage: Controls cutting angle and thickness.

Hydraulic system: Provides stable feed pressure.

Precision: Thickness accuracy within ±0.05mm.

2. Veneer Clipper

Function: Cuts the continuous veneer ribbon into specified dimensions. Equipped with photoelectric detection systems for automatic defect recognition and dual-cutter heads for continuous operation.

3. Roller Dryer

Structure: Conveyor system composed of dozens of rollers (1.2-1.8m diameter).

Heating Method: Steam or thermal oil heating, temperatures up to 160-180°C.

Control System: Automatically adjusts temperature and air speed to ensure uniform veneer moisture content.

III. Veneer Processing Section Equipment

1. Veneer Patcher

Function: Automatically detects and patches veneer defects. Uses CCD vision systems to identify holes and robotic arms to perform patching operations.

2. Veneer Splicer

Type:

Scarf Splicer: Uses 45° angled joints for fine glue lines.

Finger Joint Splicer: Creates finger joint profiles for higher connection strength.

Precision: Seam error less than 0.1mm.

IV. Gluing and Layup Equipment

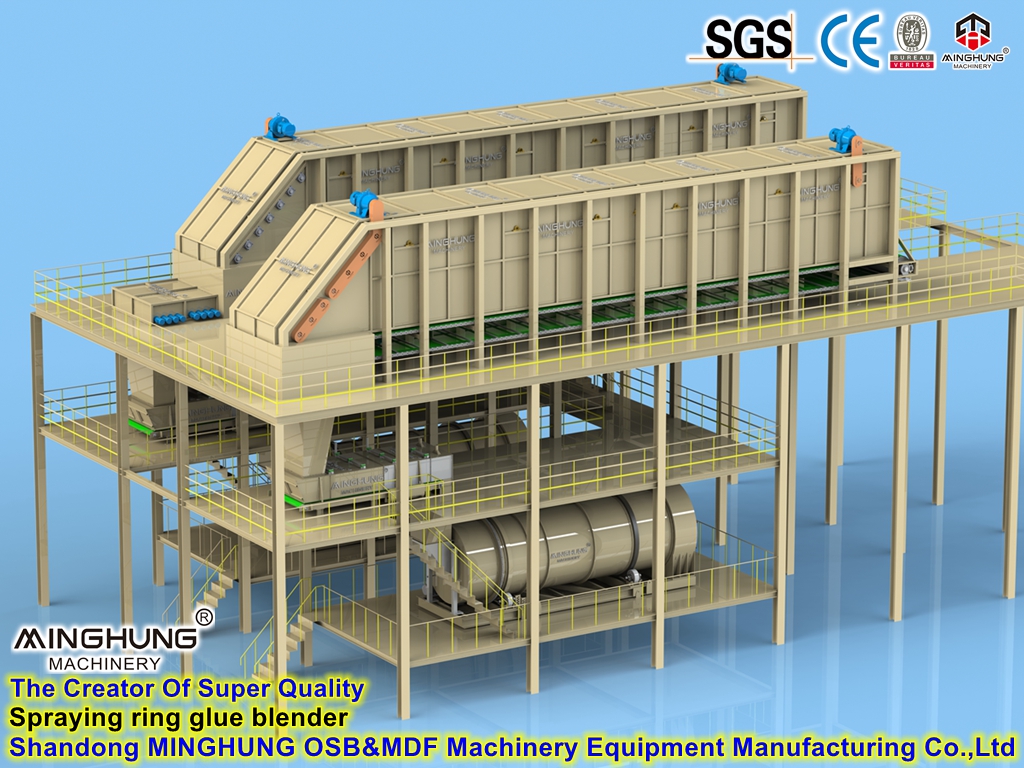

1. Glue Mixing System

Components: Includes glue storage tanks, metering pumps, mixers, and temperature control units.

Precision: Solid content control error ±0.5%, viscosity control error ±5%.

2. Four-Roll Glue Spreader

Working Principle: Precise glue application control through the coordination of metering roll, applicator roll, transfer roll, and doctor roll.

Spread Rate: Controllable within the range of 120-300g/m².

3. Layup Line

Automation Level:

Semi-automatic: Manual layup, mechanical conveyance.

Fully automatic: Robotic pickup and layup, vision system for positioning.

V. Pressing and Forming Equipment

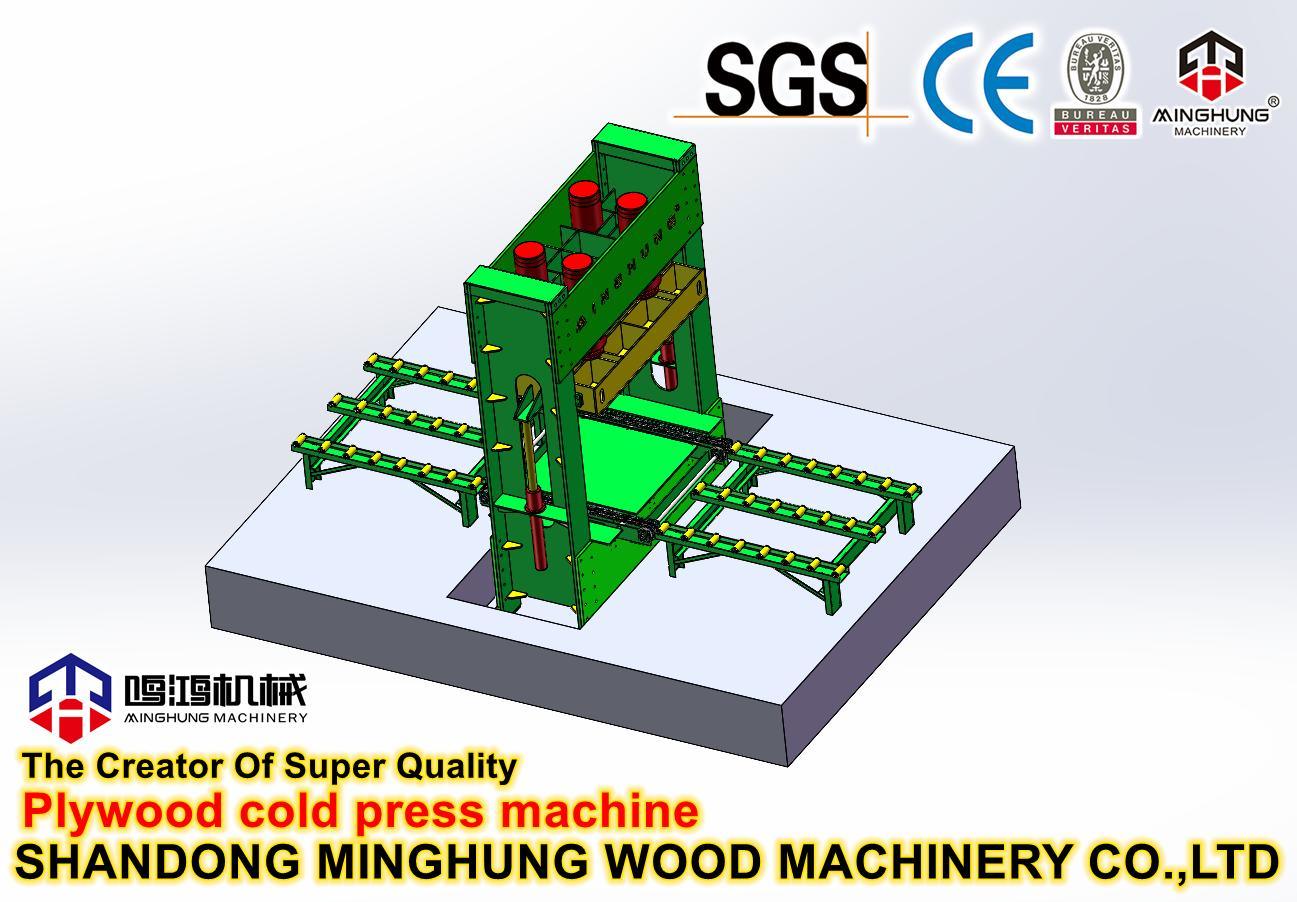

1. Pre-Press

Pressure: Typically 5-10 MPa.

Dwell Time: 3-5 minutes.

Function: Initial bonding and mat thickness reduction.

2. Multi-Opening Hot Press

Structural Parameters:

Number of Openings: 12-24.

Tonnage: 2000-10000 tons.

Platen Size: Up to 4.5m x 12m.

Heating System: Steam or thermal oil heating, temperature variation ±2°C.

Control System: PLC control of pressure and temperature profiles.

VI. Finishing and Machining Equipment

1. Cooler/Turner

Function: Cools and separates hot panels, equipped with powerful fans and turning mechanisms.

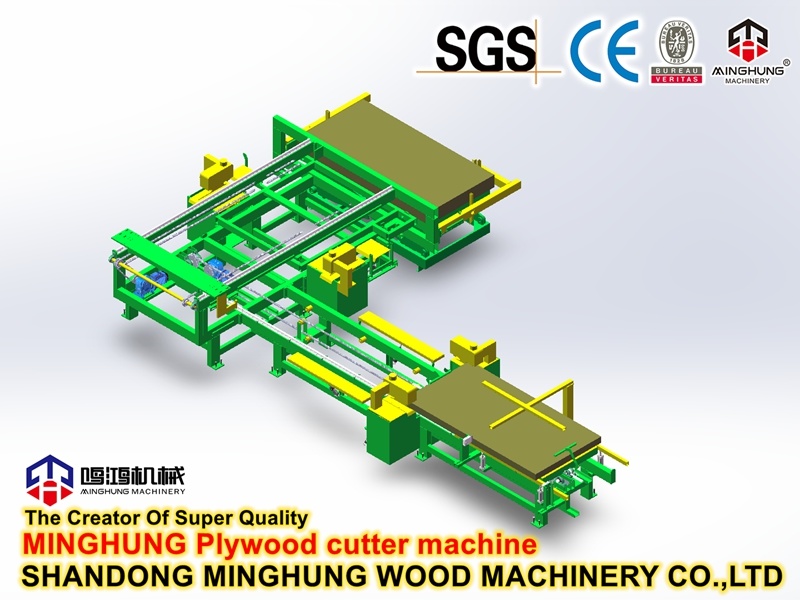

2. Double-End Trimming Saw

Precision: Dimensional error ±0.5mm.

Cutting Tools: Uses carbide-tipped saw blades with automatic sharpening systems.

3. CNC Milling Machine

Function: Machines anti-slip grooves and mortise/tenon structures.

Precision: Positioning accuracy 0.1mm, repeatability 0.05mm.

4. Wide-Belt Sander

Configuration: Typically 4-6 sanding heads.

Coarse Sanding: Removes 0.3-0.5mm stock.

Fine Sanding: Ensures thickness tolerance ±0.1mm.

Belt Specification: Grit range from 40 to 240.

VII. Auxiliary Systems

1. Material Handling System: Includes roller conveyors, belt conveyors, and elevators.

2. Dust Removal System: Equipped with cyclone separators and baghouse dust collectors.

3. Quality Testing Equipment: Moisture meters, mechanical property testers.

Production Process of Container Flooring

The production of container flooring is a highly precise systems engineering process. Its core lies in using phenolic resin to bond multiple layers of wood materials under high temperature and pressure, forming a structural panel with high strength, high wear resistance, and excellent weather resistance. The entire process can be divided into the following core stages:

Phase One: Raw Material Preparation and Processing

1. Log Bucking: Purchased logs (e.g., hardwoods like Keruing, Eucalyptus) are cut into required length segments using large sawing machines.

2. Block Steaming/Soating: The log segments are placed into steaming ponds or vats and softened using hot water or steam. This reduces the internal stress of the wood and increases its plasticity, facilitating subsequent peeling.

3. Debarking: Debarking machines are used to remove the bark and impurities from the log segments, obtaining clean wood surfaces.

Phase Two: Veneer Manufacturing

1. Peeling: The softened log blocks are mounted onto veneer lathes. The machine clamps both ends of the block, rotating it at high speed while a sharp blade feeds uniformly, peeling the block continuously like a pencil sharpener into a continuous ribbon of veneer of predetermined thickness (typically several millimeters).

2. Clipping: The continuous veneer ribbon is cut by automatic clippers into rectangular veneer sheets of required length and width based on preset dimensions. Preliminary sorting occurs simultaneously to reject sections with major defects.

3. Drying: The green (wet) veneer sheets are fed into dryers (typically roller or mesh belt types), where circulating hot air uniformly reduces their moisture content from over 60% down to 8-12% to meet gluing requirements.

Phase Three: Veneer Processing and Gluing

1. Patching and Splicing: Dried veneer sheets are patched for defects like holes using patching machines. Small-format veneer sheets are spliced into large-format sheets using splicers (scarf or finger jointing) to improve wood yield.

2. Gluing: This is a critical step. The processed veneer sheets pass through glue spreaders, where a large amount of Phenolic Resin is applied evenly to both surfaces. Glue application control must be very precise, as too much or too little affects product quality.

Phase Four: Layup and Pre-pressing

1. Layup: The glued veneer sheets (typically used as core layers) and unglued high-quality face/back veneers are assembled into a complete mat according to the designed number of piles, grain direction (adjacent layers perpendicular), and structure.

2. Pre-pressing: The assembled mat is sent through a cold press, applying pressure at room temperature to achieve initial bonding into a solid unit. This facilitates handling and loading into the hot press, preventing mat collapse.

Phase Five: Hot Pressing and Curing

1. Loading and Hot Pressing: The pre-pressed mat is loaded into a multi-opening hot press. The press closes under high temperature (typically 140-160°C) and high pressure (over 100 kg/cm²). The heat penetrates the mat, causing the phenolic resin to rapidly undergo a chemical reaction (curing) under this heat and pressure, permanently and firmly bonding the multiple veneer layers into a single solid panel.

2. Unloading: After the preset pressing time is reached, the press opens, and the hot, cured panels are removed.

Phase Six: Finishing and Machining

1. Cooling: The hot panels are sent through a cooler/turner for forced air cooling and stacking, dissipating residual heat and balancing internal stresses to prevent deformation.

2. Trimming: The cooled rough-edged panels are precisely cut to size on all four sides using double-end trimming saws to obtain regular rectangular panels.

3. Grooving and Milling: CNC milling machines or dedicated grooving machines are used to mill anti-slip patterns onto the panel surface and precisely machine the mortise and tenon structures (e.g., tongue and groove) on the edges for connecting to the floor bearers.

4. Sanding: Wide-belt calibrating sanders, typically multi-head (e.g., 4-6 heads) and heavy-duty, are used for fine surface finishing, removing the pre-cured layer and thickness variation to obtain smooth, flat finished panels with precise thickness.

5. Inspection and Packaging: Final inspection of the finished product (dimensions, appearance, sampling for mechanical performance testing). Qualified products are labeled, filmed, bundled, and stored.

Request Your Plywood Solution Now! 3D plant layout, on-site commissioning & global spare parts – Dominate the premium board market today!

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com